Sound absorption wall

A technology of sound-absorbing cotton and sound-absorbing panels, applied in walls, sound insulation, construction, etc., can solve problems such as cumbersome installation process, poor sound-absorbing effect, and lack of safety, and achieve the effects of ensuring sound-absorbing efficiency, improving sound-absorbing effect, and high economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

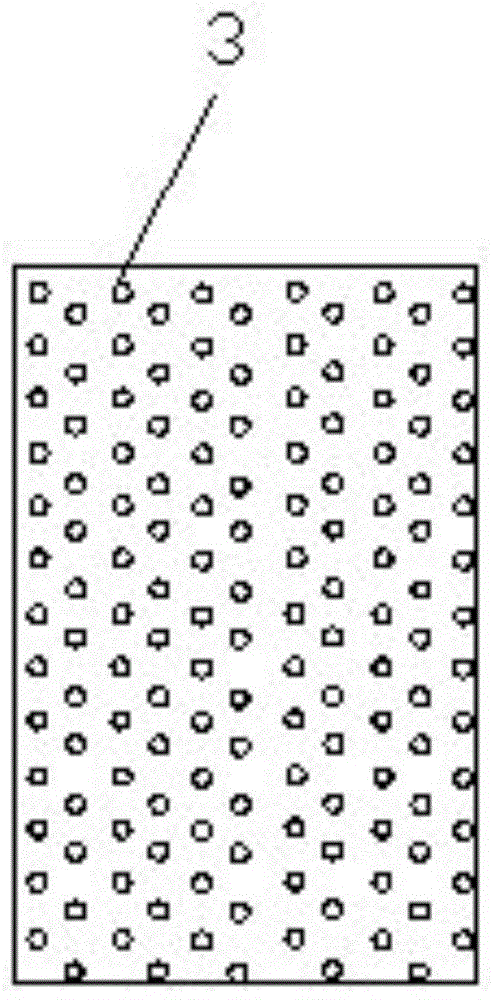

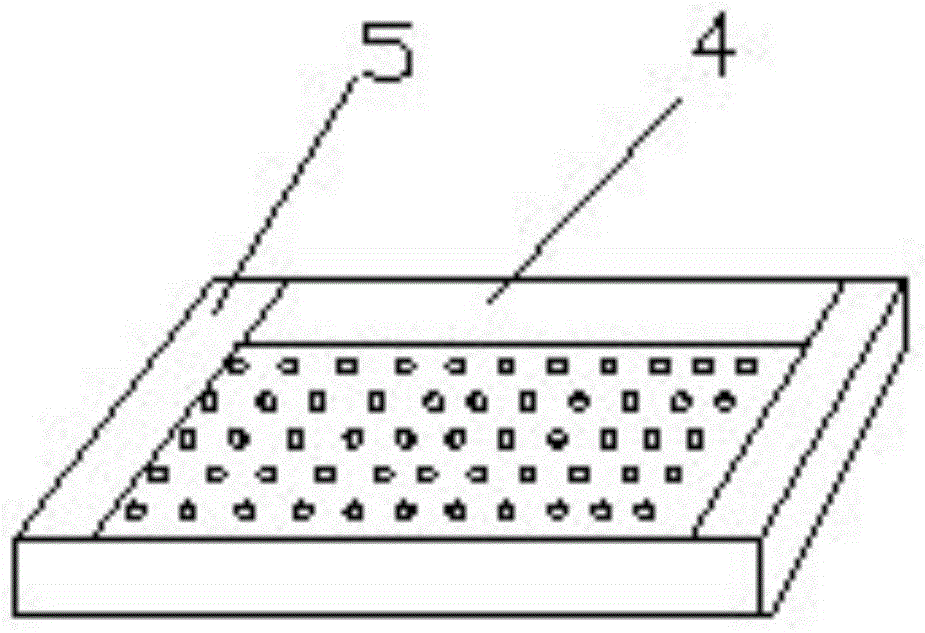

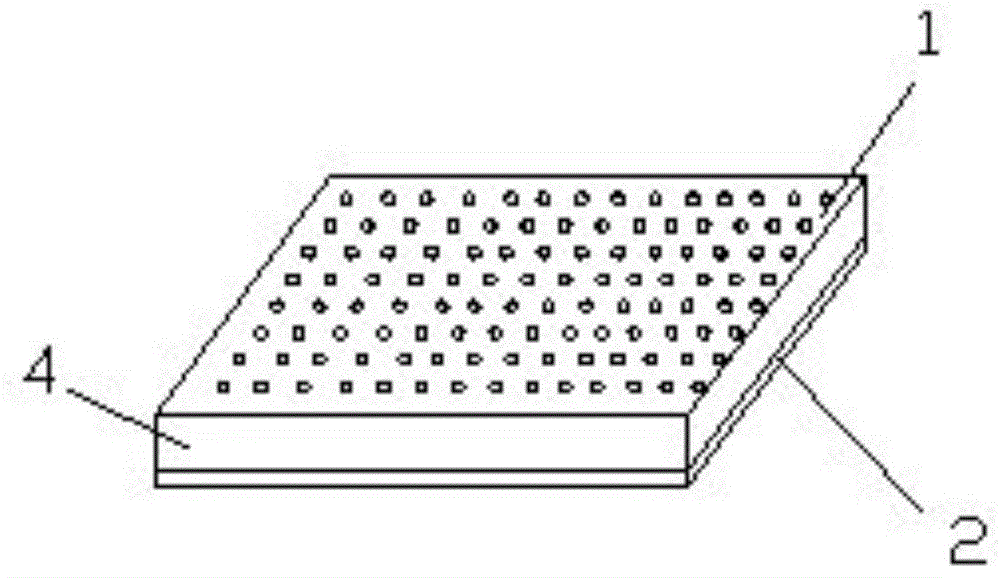

[0032] Such as figure 1 The sound-absorbing wall shown includes an inner wall, an alkali-free glass sound-absorbing cotton, a metal sound-absorbing panel, and a keel. There are embedded parts in the inner wall, and the keel is welded to the embedded part. The surface of the weld between the keel and the embedded part is It is equipped with anti-rust layer, the metal sound-absorbing panel is fixed on the keel by bolts and nuts, and the non-alkali glass sound-absorbing cotton is filled between the inner wall and the metal sound-absorbing panel;

[0033] The metal sound-absorbing board includes a metal sound-absorbing board and a fire-proof alkali-free glass fiber layer. There are sound-absorbing holes evenly distributed on the metal sound-absorbing board. The sum of the areas of all the sound-absorbing holes accounts for 45% of the area of the metal sound-absorbing board. The inner diameter of the sound-absorbing hole is 6mm; the back of the metal sound-absorbing plate is prov...

Embodiment 2

[0037] It is basically the same as Example 1, except that: the sound-absorbing wall also includes metal fiber cloth, and the metal fiber cloth is laid on the inner wall and is located between the inner wall and the non-alkali glass sound-absorbing cotton; the inner diameter of the sound-absorbing hole is 4mm; The height of the first folded edge is 15mm; the distance between the fire-proof alkali-free glass fiber layer and the metal sound-absorbing plate is 15mm; the side length of the cross-section of the hot-dip galvanized square tube is 35mm, and the wall thickness is 1.5mm. The depth of the second fold is 20mm; the thickness of the metal sound-absorbing plate is 1mm; the thickness of the fireproof non-alkali glass fiber layer is 0.5mm; the thickness of the non-alkali glass sound-absorbing cotton is 5cm. The above-mentioned metal fiber cloth is aluminum thin corrugated fiber cloth.

[0038] The principle of the sound-absorbing wall is passive noise reduction. When the sound ...

Embodiment 3

[0040] It is basically the same as Embodiment 1, except that there are more than two rows of sound-absorbing holes, and two adjacent rows of sound-absorbing holes are arranged alternately. The inner diameter of the sound-absorbing hole is 8mm; the height of the first folded edge is 25mm; the distance between the fireproof alkali-free glass fiber layer and the metal sound-absorbing plate is 25mm; the side length of the cross-section of the hot-dip galvanized square tube is 45mm, and the wall thickness is 2.5mm. The depth of the second fold is 30mm; the thickness of the metal sound-absorbing plate is 3mm; the thickness of the fireproof non-alkali glass fiber layer is 1.5mm; the thickness of the non-alkali glass sound-absorbing cotton is 7cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com