A helical gear processing mechanism with two ring-shaped protrusions on the workpiece bearing shaft

A ring-shaped convex and helical gear technology, applied in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the trouble of helical gear manufacturing, reduce costs, improve processing speed and accuracy, and ensure cogging Geometric accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

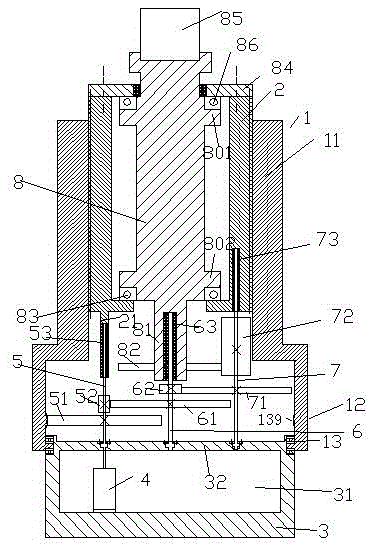

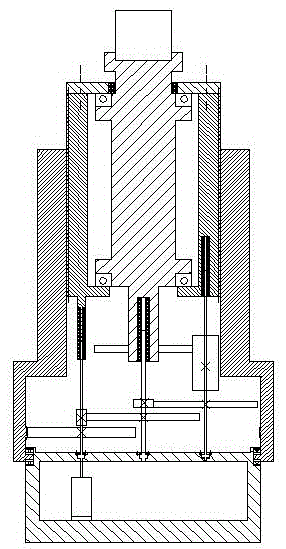

[0012] Attached below Figure 1-2 , the present invention will be described in detail.

[0013] A helical gear processing mechanism with two ring-shaped protrusions on a workpiece bearing shaft, used for processing a blank 85, which includes: a base 3, a rotatable internal threaded part 1, an external threaded part 2 and a cylindrical The workpiece carrying shaft 8, wherein the rotatable internal screw member 1 includes an upper cylindrical portion 11 and a lower chamber portion 12, the lower chamber portion 12 is connected to the base 3 in a circumferentially rotatable and axially fixed manner through a bearing device 13, The externally threaded part 2 is cylindrical, and an external thread is provided on its outer peripheral surface to engage with the internal thread in the upper cylindrical part 11. A cavity 31 is provided in the base 3, and the cavity 31 has a top wall 32. Drive motor 4 is installed in described cavity 31, and drive motor 4 is connected with the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com