Patents

Literature

47results about How to "Meet the requirements of cost control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

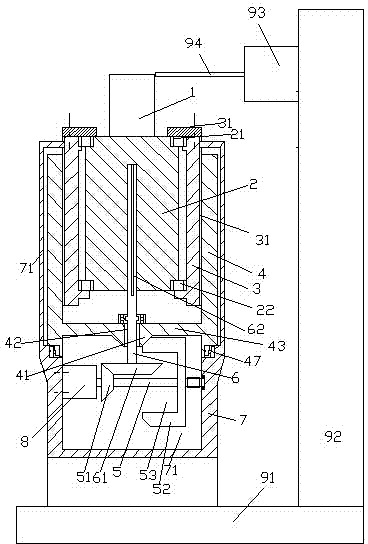

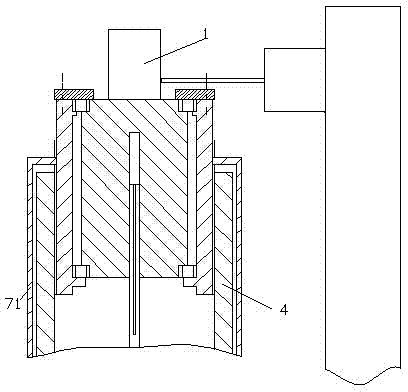

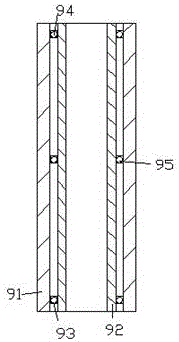

Worm machining device

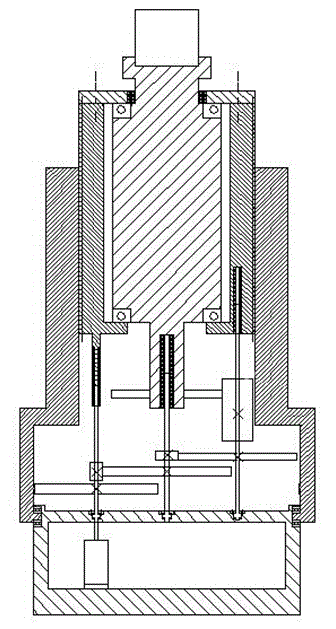

The invention provides a worm machining device. The worm machining device is used for machining a blank (1) into a worm, and comprises a movement mechanism, a base (91), an upright column (92), a milling cutter rotating driving motor (93) and a milling cutter (94); the movement mechanism is fixed on the base (91); the lower end of the upright column (92) is fixedly connected with the base (91); the milling cutter rotating driving motor (93) is mounted on the upper end of the upright column (92) and used for driving the milling cutter (94) to rotate; the milling cutter (94) is mounted on the milling cutter rotating driving motor (93) and used for cutting the blank (1); the movement mechanism comprises a blank carrying piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a frame (7).

Owner:SHENYUE FUJIAN CASTING

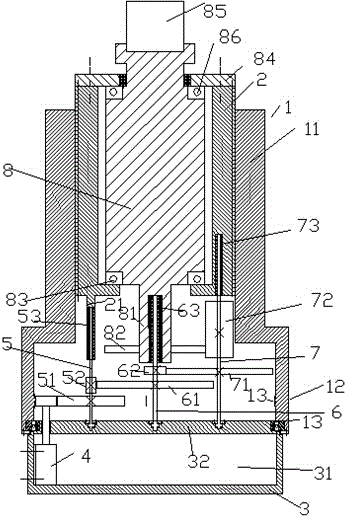

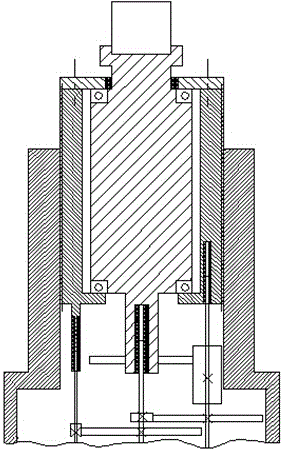

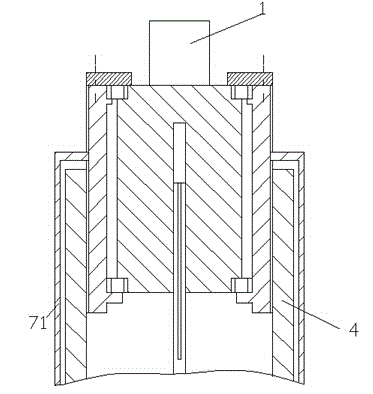

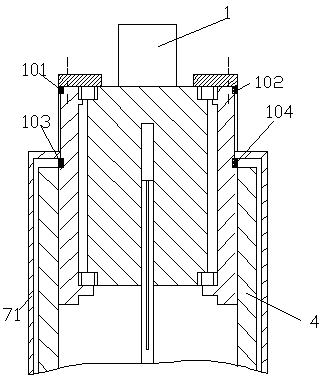

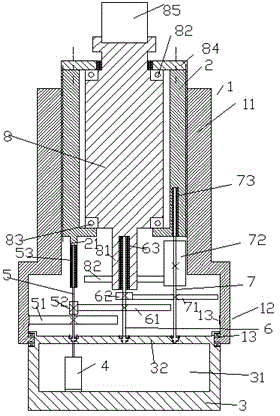

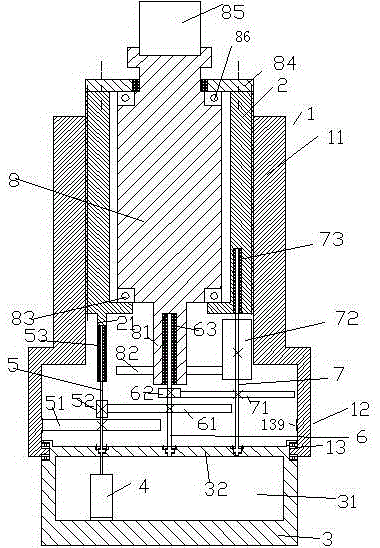

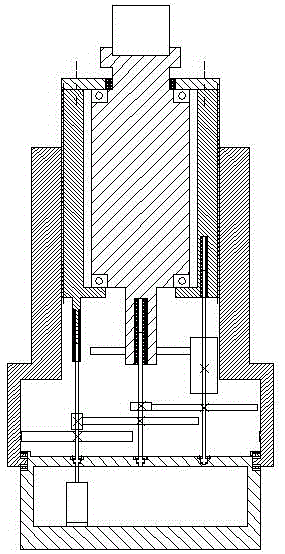

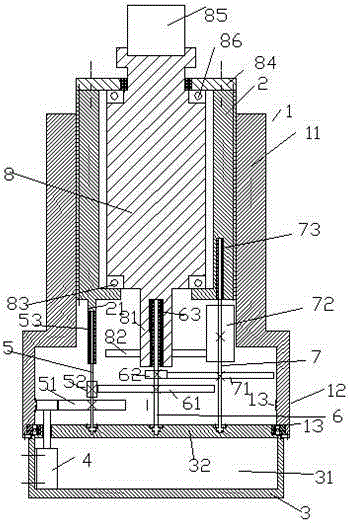

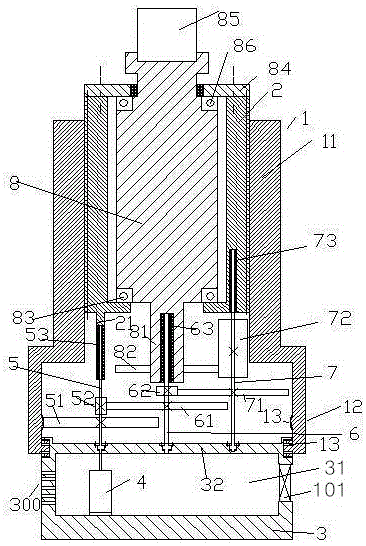

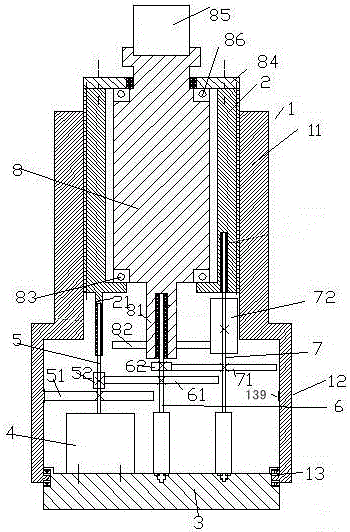

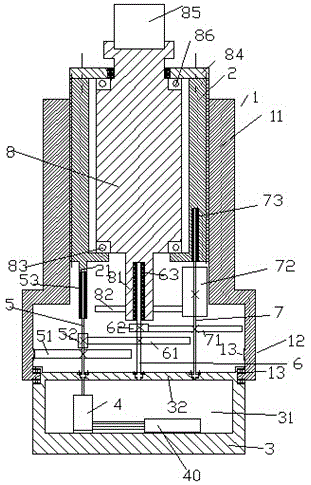

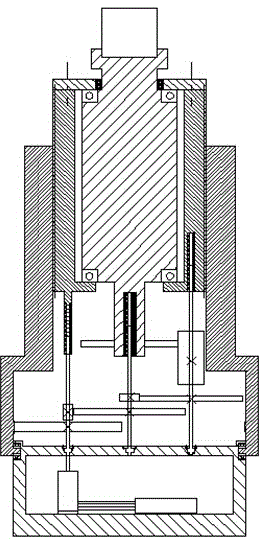

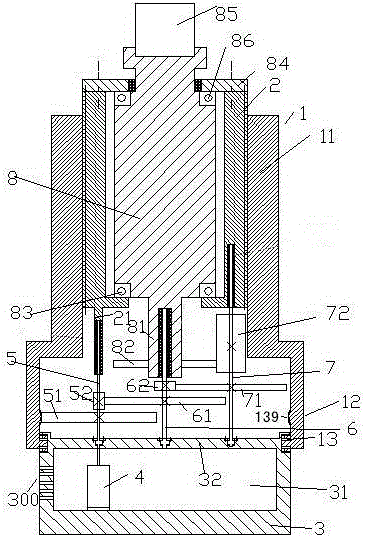

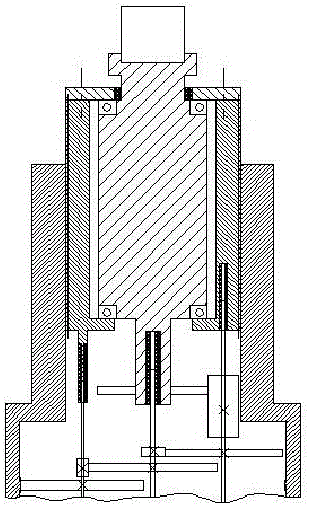

Four-axis driving-type helical gear processing mechanism

InactiveCN104400139AGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusMotor driveEngineering

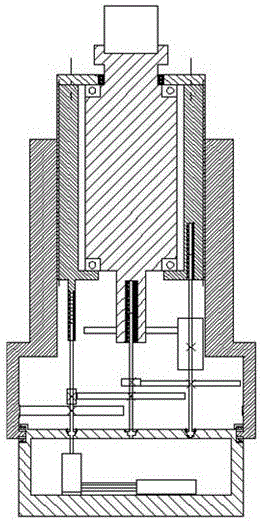

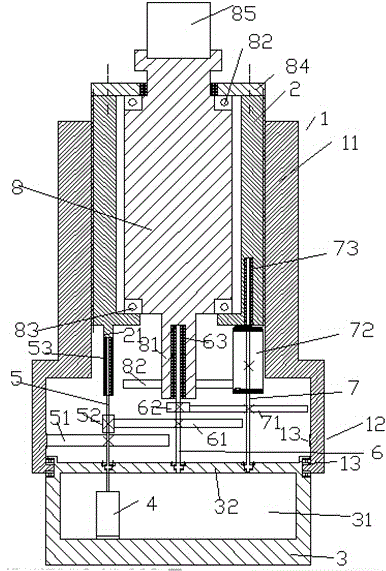

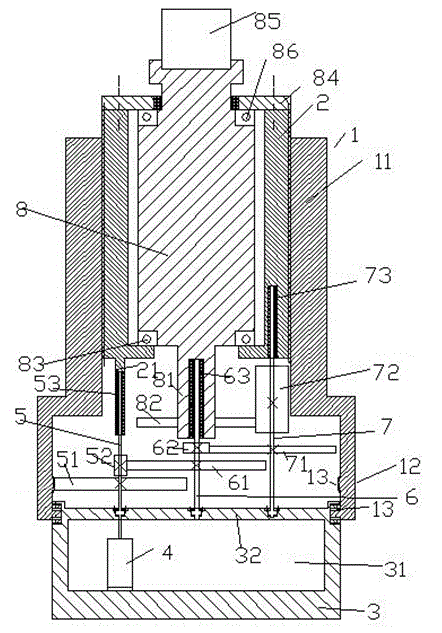

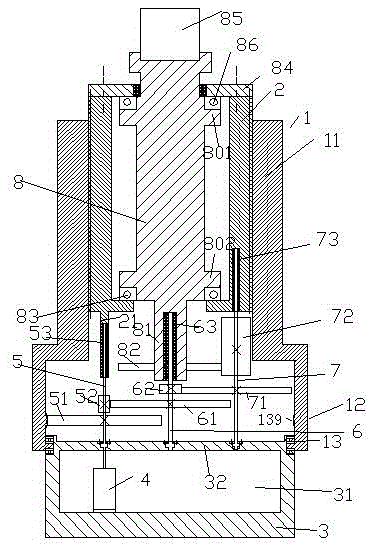

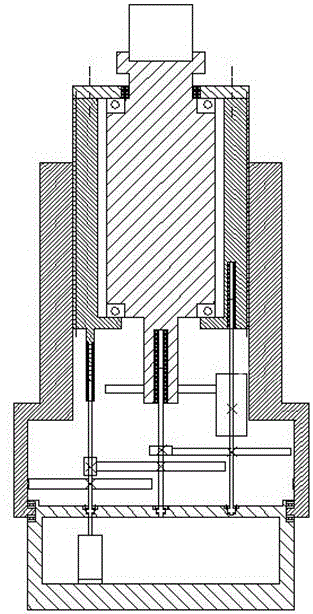

The invention provides a four-axis driving-type helical gear processing mechanism which is used for processing a blank (85). The four-axis driving-type helical gear processing mechanism comprises a base (3), a rotary internal thread piece (1), an external thread piece (2) and a cylindrical workpiece carrying piece (8), wherein the rotary internal thread piece (1) comprises an upper cylinder part (11) and a lower cavity part (12); the lower cavity part (12) is connected with the base (3) by virtue of a bearing device (13) in a circumferential rotation and axial fixation manner; the external thread piece (2) is cylindrical, and the outer periphery surface of the external thread piece (2) is provided with external threads jointed with internal threads in the upper cylinder part (11); the base (3) is internally provided with a cavity (31); the cavity (31) is provided with a top wall (32); the cavity (31) is internally provided with a driving motor (4); the driving motor (4) is connected with the lower end of a motor driving shaft.

Owner:SHENYUE FUJIAN CASTING

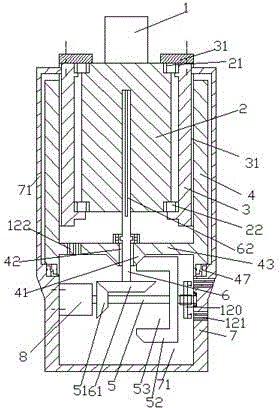

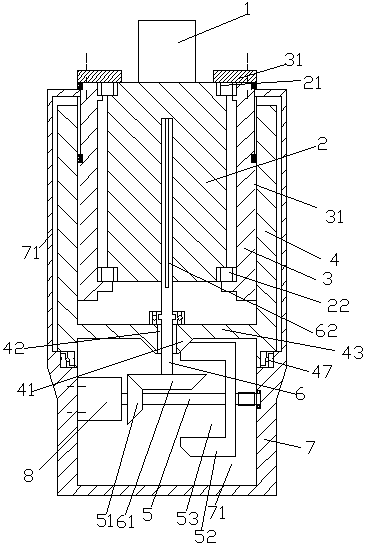

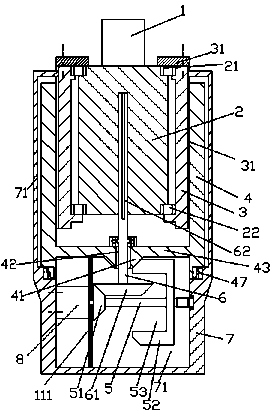

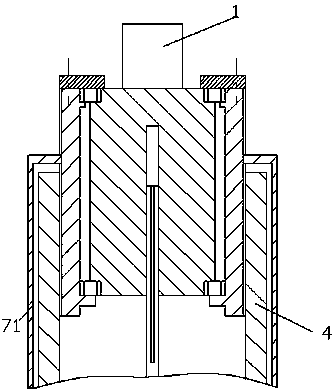

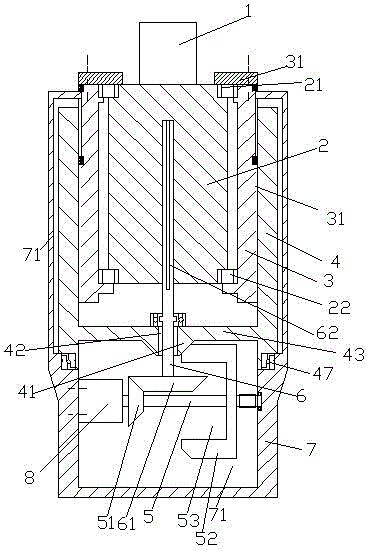

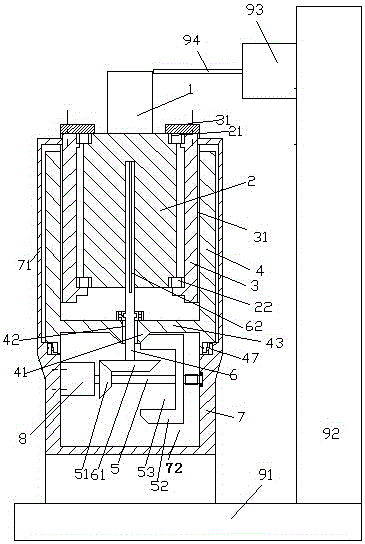

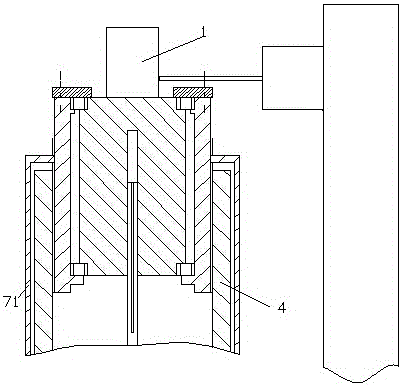

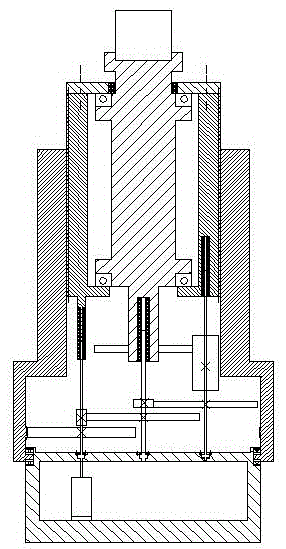

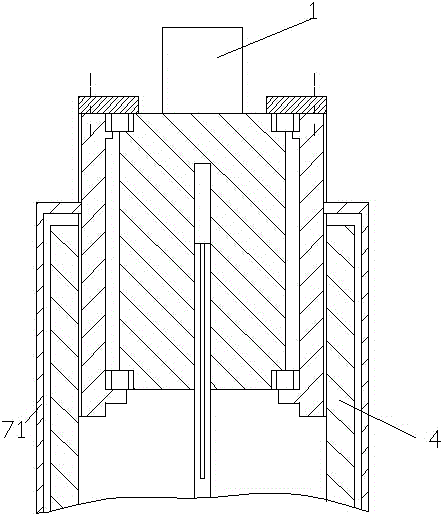

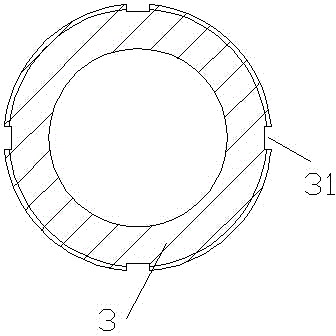

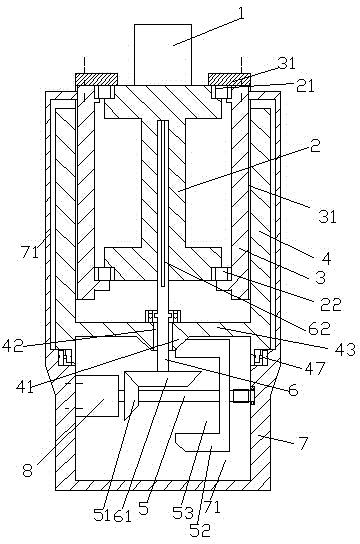

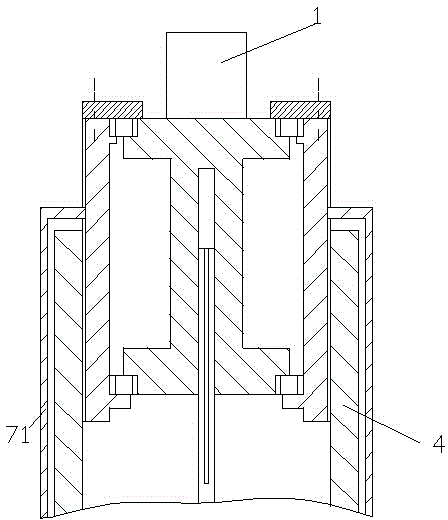

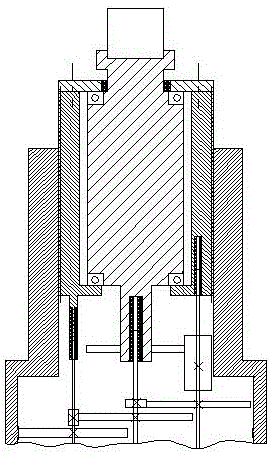

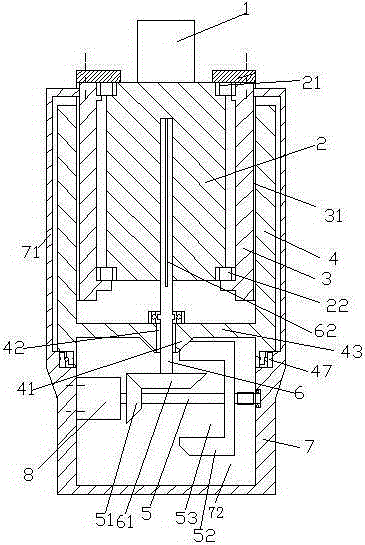

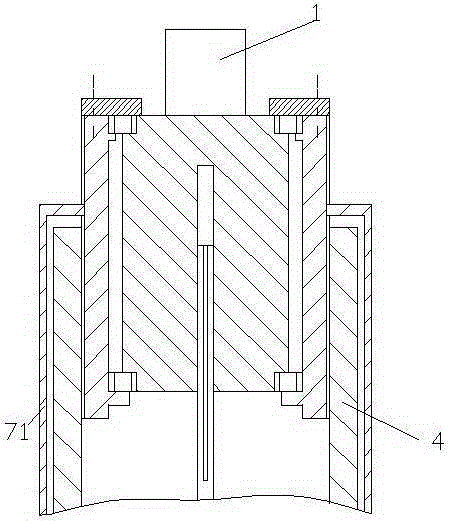

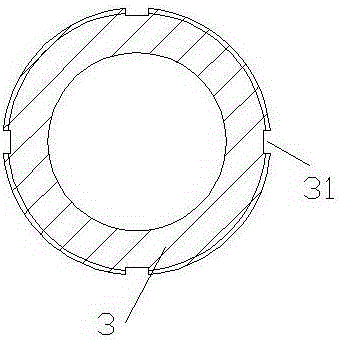

Worm processing mechanism capable of automatically radiating heat

The invention discloses a worm processing mechanism capable of automatically radiating heat. The worm processing mechanism is used for processing a blank (1) into a worm. The worm processing mechanism comprises a blank bearing member (2), a sleeve (3) with an external thread, a drive sleeve (4) with an internal thread, and a rack (7), wherein the blank bearing member (2) is used for bearing the blank (1), the upper end and the lower end of the blank bearing member (2) are respectively fixedly arranged in the sleeve (3) with the external thread by means of an upper bearing (21) and a lower bearing (22) relative to the sleeve (3) with the external thread, the sleeve (3) with the external thread is in thread fit in the drive sleeve (4) with the internal thread, the lower end of the drive sleeve (4) with the internal thread can be rotatably arranged on the rack (7) by means of a thrust bearing (47), a cavity (72) is arranged inside the rack (7), and in the cavity (72), a drive motor (8) is fixedly arranged on the left-inner side wall of the cavity of the rack (7).

Owner:国网山东省电力公司沂源县供电公司

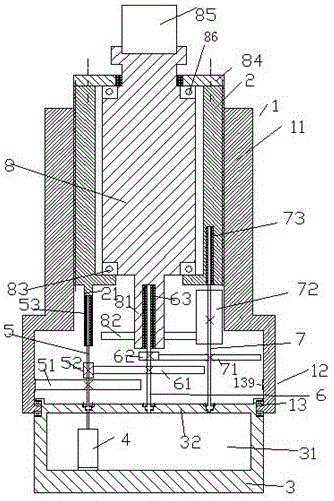

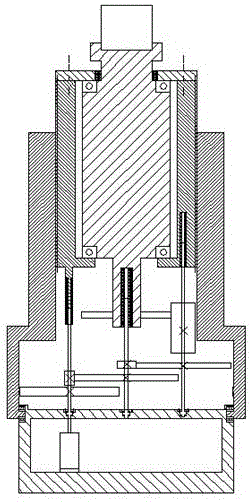

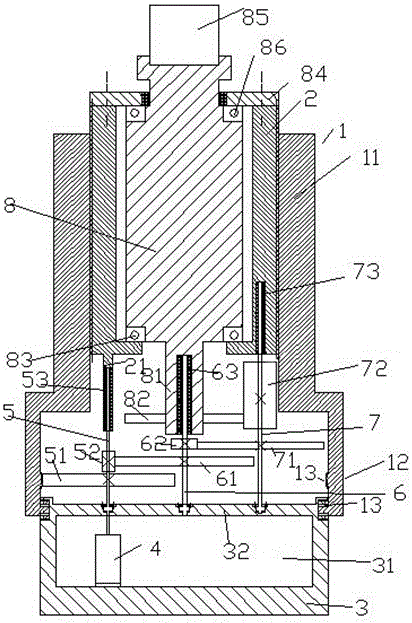

Spiral gear machining mechanism capable of quickly radiating heat

InactiveCN104400136AGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusEngineeringDrive motor

The invention relates to a spiral gear machining mechanism capable of quickly radiating heat, which is used for machining a blank (85). The spiral gear machining mechanism capable of quickly radiating heat comprises a base (3), a rotatable internal threaded piece (1), an external threaded piece (2) and a cylindrical workpiece bearing piece (8), wherein the rotatable internal threaded piece (1) comprises an upper cylindrical portion (11) and a lower chamber portion (12), the lower chamber portion (12) is connected with the base (3) through a bearing device 13) in a circumferentially rotatable and axial fixed manner, the external threaded piece (2) is cylindrical, external threads are arranged on the external circumferential surface of the external threaded piece (2) and are jointed with internal threads in the upper cylindrical portion (11), and a cavity (31) is formed in the base (3), the cavity (31) has a top wall (32) and a driving motor (4) is installed in the cavity (31).

Owner:吕英芬

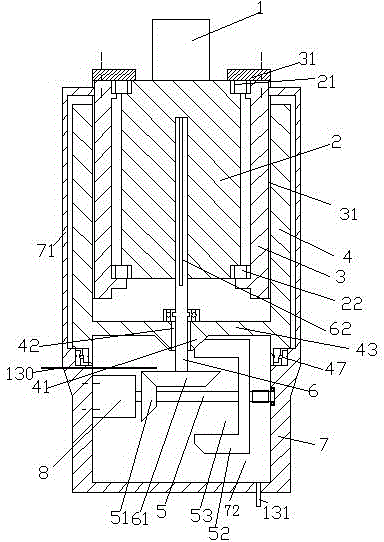

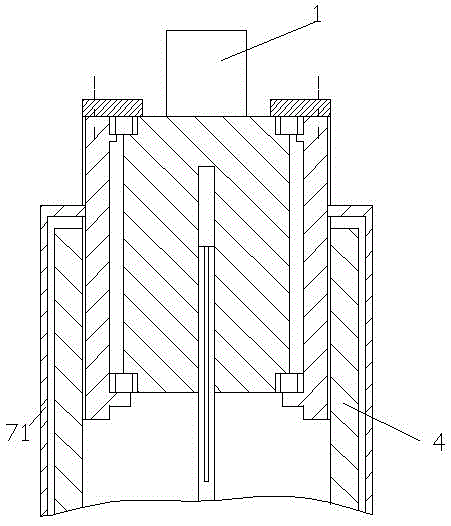

Worm machining mechanism capable of automatically performing up-down limiting

The invention discloses a worm machining mechanism capable of automatically performing up-down limiting. The worm machining mechanism is used for machining a blank (1) into a worm and comprises a blank bearing member (2), a sleeve (3) with external thread, a driving sleeve (4) with internal thread and a rack (7), wherein the blank bearing member (2) is used for bearing the blank (1); the upper and lower ends of the blank bearing member (2) are axially and fixedly arranged in the sleeve (3) with the external thread relative to the sleeve (3) with the external thread through an upper bearing (21) and a lower bearing (22) respectively; the sleeve (3) with the external thread is matched in the driving sleeve (4) with the internal thread; the lower end of the driving sleeve (4) with the internal thread is arranged on the rack (7) through a thrust bearing (47) in a rotating manner.

Owner:广州德纳科技股份有限公司

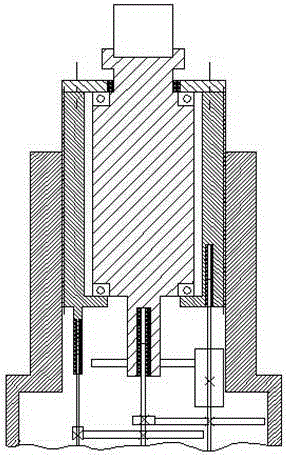

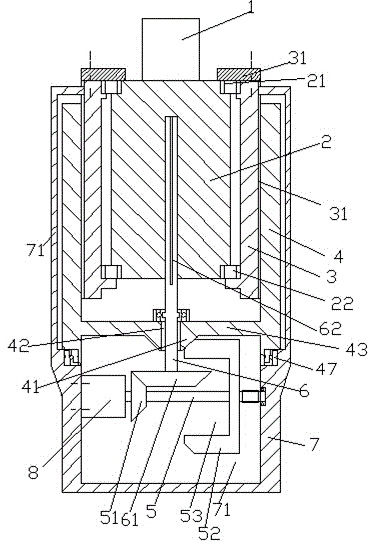

Spiral gear machining mechanism

InactiveCN104308278AGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusEngineeringScrew thread

A spiral gear machining mechanism used during machining of a blank (85) comprises a base (3), a rotatable inner threaded part (1), an outer threaded part (2) and a cylindrical workpiece bearing part (8). The rotatable inner threaded part (1) comprises an upper cylinder (11) and a lower cavity (12). The lower cavity (12) is connected to the base (3) in a circumferential rotatable and axial fixed manner. The outer threaded part (2) is cylindrical. The outer threads on the outer circumferential surface are connected with the inner threads in the upper cylinder (11) in a matched manner. A cavity (31) is arranged in the base (3) and provided with a top wall (32).

Owner:国网山东省电力公司沂源县供电公司

A helical gear machining mechanism

InactiveCN104308278BGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusEngineeringScrew thread

A spiral gear machining mechanism used during machining of a blank (85) comprises a base (3), a rotatable inner threaded part (1), an outer threaded part (2) and a cylindrical workpiece bearing part (8). The rotatable inner threaded part (1) comprises an upper cylinder (11) and a lower cavity (12). The lower cavity (12) is connected to the base (3) in a circumferential rotatable and axial fixed manner. The outer threaded part (2) is cylindrical. The outer threads on the outer circumferential surface are connected with the inner threads in the upper cylinder (11) in a matched manner. A cavity (31) is arranged in the base (3) and provided with a top wall (32).

Owner:国网山东省电力公司沂源县供电公司

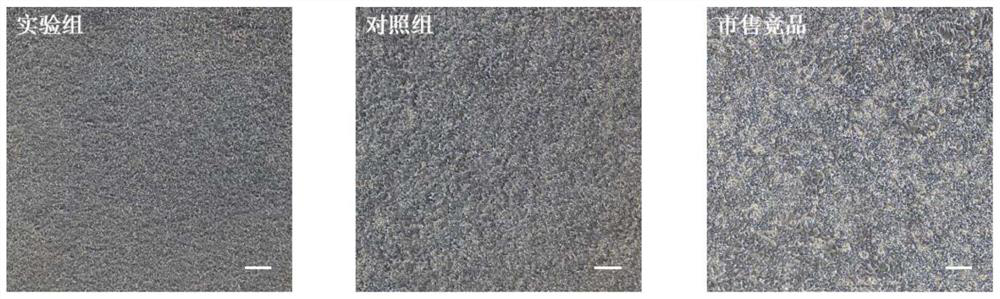

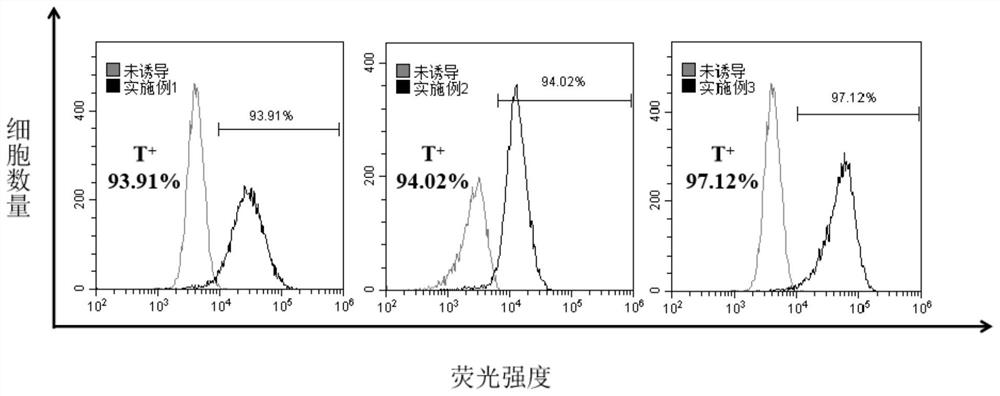

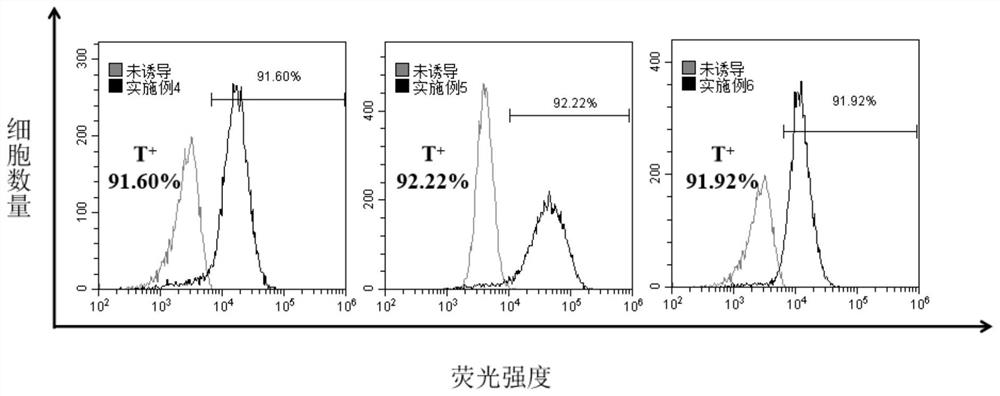

Differential culture medium of human pluripotent stem cell derived mesoderm cells and application of differential culture medium

ActiveCN112553146AClear ingredientsLow costGenetically modified cellsCulture processMesodermKinase inhibition

The invention discloses a differentiation culture medium of human pluripotent stem cell derived mesoderm cells and application of the differentiation culture medium. The invention firstly discloses the differentiation culture medium of human pluripotent stem cell derived mesoderm cells. The differentiation culture medium comprises the following components of a basal culture medium, a compound combination and a glycogen synthase kinase 3 (GSK-3) inhibitor, wherein the compound combination comprises the following components of D-piperidine acid, triiodo-L-thyronine and thiamine hydrochloride. The invention further discloses application of the differentiation culture medium in inducing differentiation of the human pluripotent stem cells into mesoderm cells and / or mesoderm downstream derived cells. The differentiation culture medium for the pluripotent stem cell derived mesoderm cells is high in raw material level and low in cost, is high in batch-to-batch stability, high in differentiation efficiency and high in universality when used for inducing the human pluripotent stem cells to differentiate into the mesoderm cells, and has very high industrial transformation and clinical application values.

Owner:BEIJING TRANSGEN BIOTECH CO LTD

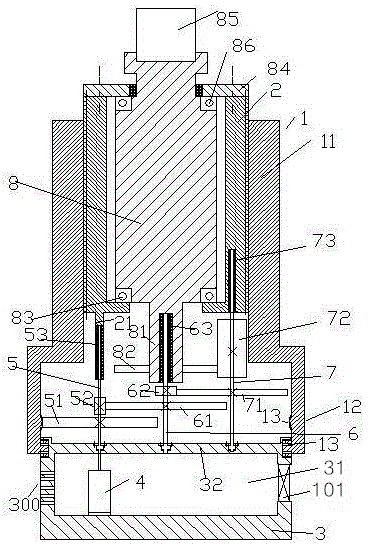

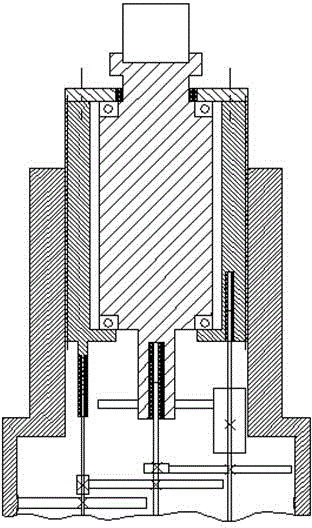

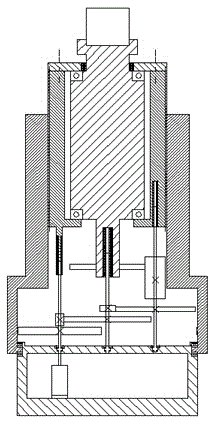

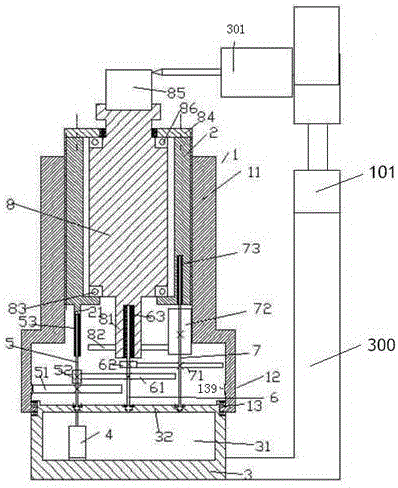

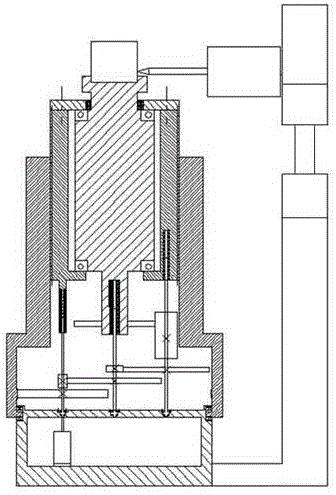

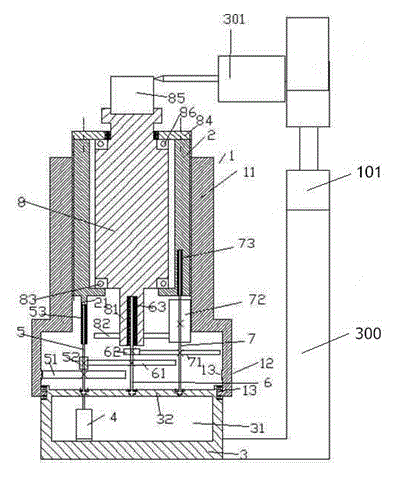

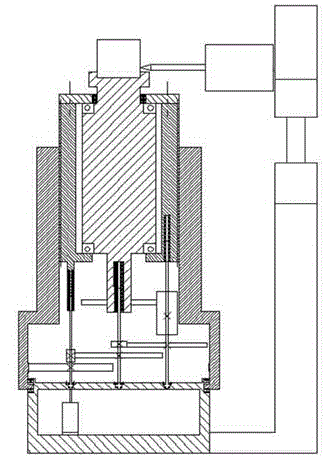

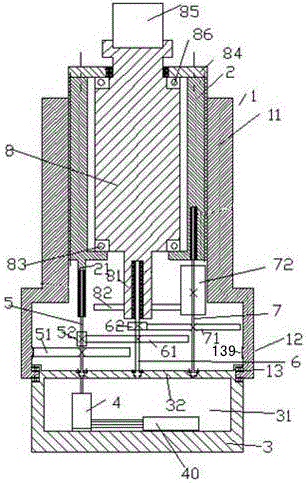

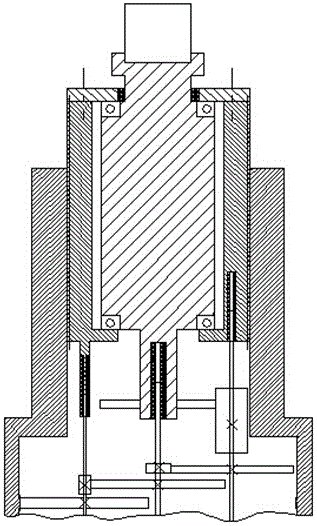

A lifting helical gear processing equipment

InactiveCN104439533BGuaranteed accuracyConstant proportional relationshipFeeding apparatusGear teethMilling cutterEngineering

Spiral gear machining equipment capable of ascending and descending is used when a blank (85) is machined. The spiral gear machining equipment comprises a base (3), a stand column (300), a milling head (301), a rotary inner threaded part (1), an outer threaded part (2) and a cylindrical workpiece bearing part (8), wherein the base (3) is fixedly connected with the lower end of the stand column (300), a lifting device (101) is installed at the upper end of the stand column (300), a milling head (301) is installed at the upper end of the lifting device (101) and can mill the blank (85) through rotation of a milling cutter, the rotary inner threaded part (1) comprises an upper barrel part (11) and a lower cavity part (12), the lower cavity part (12) is rotationally connected with the base (3) in the peripheral direction and fixedly connected with the base (3) in the axial direction trough a bearing device (13), and the outer threaded part (2) is cylindrical.

Owner:刘佳艺

Worm rod processing mechanism with driving motor separation baffle plate

The invention relates to a worm rod processing mechanism with a driving motor separation baffle plate (111). The worm rod processing mechanism is used for processing a blank (1) into a worm rod, and comprises a blank carrying element (2), a sleeve (3) with external screw threads, a driving sleeve (4) with internal screw threads and a machine frame (7), wherein the blank carrying element (2) is used for carrying the blank (1), the upper end and the lower end of the blank carrying element (2) are respectively and fixedly arranged in the sleeve (3) with the external screw threads through an upper bearing (21) and a lower bearing (22) in a direction opposite to the axial direction of the sleeve (3) with the external screw threads, the sleeve (3) with the external screw threads is matched in the driving sleeve (4) with the internal screw threads through screw threads, and the lower end of the driving sleeve (4) with the internal screw threads is rotatablely arranged on the machine frame (7) through a thrust bearing (47).

Owner:STATE GRID CORP OF CHINA +1

A four-axis transmission type helical gear machining mechanism

InactiveCN104400139BGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusMotor driveDrive motor

The invention provides a four-axis driving-type helical gear processing mechanism which is used for processing a blank (85). The four-axis driving-type helical gear processing mechanism comprises a base (3), a rotary internal thread piece (1), an external thread piece (2) and a cylindrical workpiece carrying piece (8), wherein the rotary internal thread piece (1) comprises an upper cylinder part (11) and a lower cavity part (12); the lower cavity part (12) is connected with the base (3) by virtue of a bearing device (13) in a circumferential rotation and axial fixation manner; the external thread piece (2) is cylindrical, and the outer periphery surface of the external thread piece (2) is provided with external threads jointed with internal threads in the upper cylinder part (11); the base (3) is internally provided with a cavity (31); the cavity (31) is provided with a top wall (32); the cavity (31) is internally provided with a driving motor (4); the driving motor (4) is connected with the lower end of a motor driving shaft.

Owner:SHENYUE FUJIAN CASTING

A Worm Machining Mechanism with a Lubricating Oil Supply System

InactiveCN104308280BHigh densityHigh precisionGearingGear lubrication/coolingThrust bearingEngineering

The invention discloses a worm processing mechanism with a lubricating-oil supplying system. The worm processing mechanism is used for processing a blank piece (1) into a worm and comprises a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads; the lower end of the driving sleeve (4) with the internal threads can be rotatably arranged on the rack (7) by a thrust bearing (47).

Owner:国网山东省电力公司沂源县供电公司

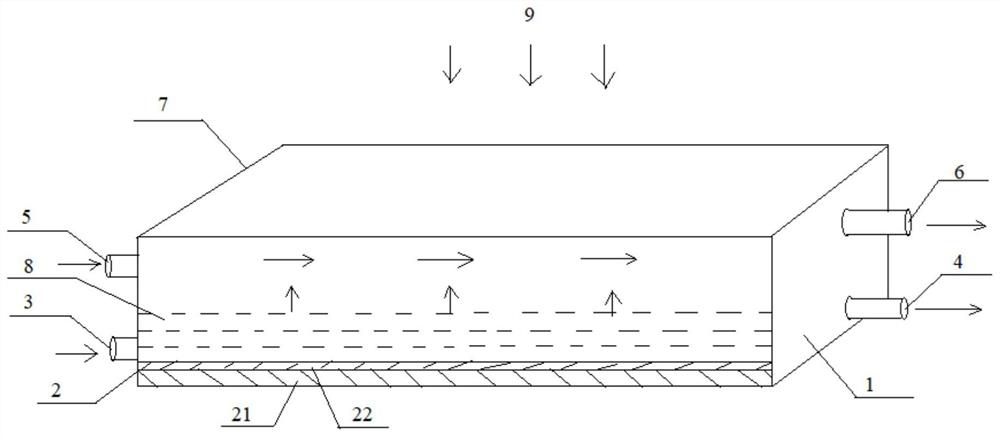

Recovery device for zirconium oxide powder production waste liquid

InactiveCN112537815ALow costMeet the requirements of cost controlGeneral water supply conservationWater/sewage treatmentEnvironmental engineeringSolar heat

The invention discloses a recovery device for zirconium oxide powder production waste liquid. The recovery device comprises a solar evaporation tank, a solar heat absorption bottom plate laid at the bottom in the solar evaporation tank, a liquid inlet, a liquid outlet, an air inlet, an air outlet, a transparent cover plate and the like. According to the recovery device, waste liquid flows throughthe solar evaporation tank with the solar heat absorption bottom plate, the waste liquid is heated, evaporated and concentrated by solar energy, low-cost waste liquid recovery is realized, the requirement of cost control of a production enterprise is met, the concentrated waste liquid can be used as a fertilizer or a fertilizer raw material, and waste is turned into wealth. The recovery device isreasonable in design, simple, practical, low in recovery cost, high in recovery efficiency, energy-saving, environment-friendly and particularly suitable for large-scale treatment of zirconium oxide powder production waste liquid.

Owner:HUBEI XITIAN TECH CO LTD

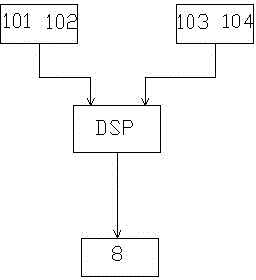

Worm processing mechanism controlled by circuit

The invention discloses a worm processing mechanism controlled by a circuit. The worm processing mechanism is used for processing a blank piece (1) into a worm and comprises a DSP (Digital Signal Processing) control circuit, a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads.

Owner:国网山东省电力公司沂源县供电公司

Spiral gear machining equipment capable of ascending and descending

InactiveCN104439533AGuaranteed accuracyConstant proportional relationshipFeeding apparatusGear teethMilling cutterEngineering

Spiral gear machining equipment capable of ascending and descending is used when a blank (85) is machined. The spiral gear machining equipment comprises a base (3), a stand column (300), a milling head (301), a rotary inner threaded part (1), an outer threaded part (2) and a cylindrical workpiece bearing part (8), wherein the base (3) is fixedly connected with the lower end of the stand column (300), a lifting device (101) is installed at the upper end of the stand column (300), a milling head (301) is installed at the upper end of the lifting device (101) and can mill the blank (85) through rotation of a milling cutter, the rotary inner threaded part (1) comprises an upper barrel part (11) and a lower cavity part (12), the lower cavity part (12) is rotationally connected with the base (3) in the peripheral direction and fixedly connected with the base (3) in the axial direction trough a bearing device (13), and the outer threaded part (2) is cylindrical.

Owner:刘佳艺

A Helical Gear Machining Mechanism with Adjustable Machining Speed

ActiveCN104400140BGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusDrive motorEngineering

The invention discloses a spiral gear processing mechanism with an adjustable processing speed. The spiral gear processing mechanism is used when a blank (85) is processed, and comprises a base (3), a rotatable internal thread element (1), an external thread element (2) and a cylindrical work-piece bearing element (8), wherein the rotatable internal thread element (1) comprises an upper cylinder section (11) and a lower chamber section (12); the lower chamber section (12) and the base (3) can circumferentially rotate and axially fixedly connected through a bearing device (13); the external thread element (2) is in a cylindrical shape; external threads are arranged at the outer circumference surface and are jointed with internal threads in the upper cylinder section (11); a hollow cavity (31) is formed in the base (3), and is provided with a top wall (32); a drive motor (4) is arranged in the hollow cavity (31).

Owner:ZHENXIN TAISHAN SPEED CHANGING GEAR BOXES

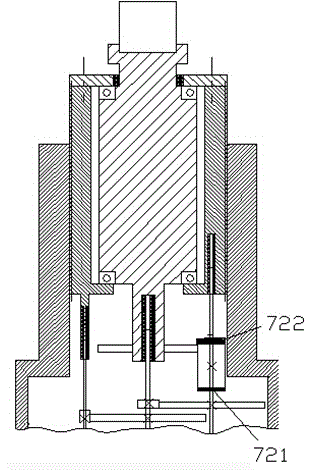

Spiral gear machining mechanism capable of flexibly limiting vertical motion

ActiveCN104439535AGuaranteed accuracyConstant proportional relationshipFeeding apparatusGear teethDrive motorSpur gear

A spiral gear machining mechanism capable of flexibly limiting vertical motion is used for machining a blank (85) and comprises a base (3), a rotatable internal thread part (1), an external thread part (2) and a cylindrical workpiece bearing part (8). The rotatable internal thread part (1) comprises an upper cylinder part (11) and a lower chamber part (12), the lower chamber part (12) is connected with the base (3) through a bearing device (13) in the mode that the lower chamber part (12) can be rotated in the circumferential direction and fixed in the axial direction, the external thread part (2) is cylindrical, an external thread is arranged on the outer circumferential face of the external thread part (2) and connected with an internal thread in the upper cylinder part (11), a cavity (31) is formed in the base (3) and provided with a top wall (32), and a driving motor (4) is installed in the cavity (31).

Owner:扬州安特自动化科技有限公司

Spiral gear machining mechanism capable of conducting lubricating oil renewal

ActiveCN104400138AGuaranteed accuracyConstant proportional relationshipGear lubrication/coolingFeeding apparatusEngineeringSpur gear

The invention relates to a spiral gear machining mechanism capable of conducting lubricating oil renewal, which is used for machining a blank (85). The spiral gear machining mechanism capable of conducting lubricating oil renewal comprises a base (3), a rotatable internal threaded piece (1), an external threaded piece (2) and a cylindrical workpiece bearing piece (8), wherein the rotatable internal threaded piece (1) comprises an upper cylindrical portion (11) and a lower chamber portion (12), the lower chamber portion (12) is connected with the base (3) through a bearing device 13) in a circumferentially rotatable and axial fixed manner, the external threaded piece (2) is cylindrical, external threads are arranged on the external circumferential surface of the external threaded piece (2) and are jointed with internal threads in the upper cylindrical portion (11), and a cavity (31) is formed in the base (3).

Owner:中山迈雷特智能装备有限公司

A worm machining device

The invention provides a worm machining device. The worm machining device is used for machining a blank (1) into a worm, and comprises a movement mechanism, a base (91), an upright column (92), a milling cutter rotating driving motor (93) and a milling cutter (94); the movement mechanism is fixed on the base (91); the lower end of the upright column (92) is fixedly connected with the base (91); the milling cutter rotating driving motor (93) is mounted on the upper end of the upright column (92) and used for driving the milling cutter (94) to rotate; the milling cutter (94) is mounted on the milling cutter rotating driving motor (93) and used for cutting the blank (1); the movement mechanism comprises a blank carrying piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a frame (7).

Owner:SHENYUE FUJIAN CASTING

A helical gear processing mechanism with two ring-shaped protrusions on the workpiece bearing shaft

ActiveCN104439532BGuaranteed accuracyConstant proportional relationshipFeeding apparatusGear teethGear wheelScrew thread

The invention provides a spiral gear machining mechanism with a workpiece bearing shaft provided with two annular protrusions. The spiral gear machining mechanism is used for machining a blank (85) and comprises a base (3), a rotary inner thread piece (1), an outer thread piece (2) and the cylindrical workpiece bearing shaft (8). The rotary inner thread piece (1) comprises an upper cylinder portion (11) and a lower cavity portion (12). The lower cavity portion (12) is connected with the base (3) through a bearing device (13) in a peripherally rotating and axially fixed mode. The outer thread piece (2) is cylindrical. The outer peripheral surface of the outer thread piece (2) is provided with outer threads jointed with inner threads in the upper cylinder portion (11). The base (3) is internally provided with a cavity (31), and the cavity (31) is provided with a top wall (32).

Owner:广州优云机械制造有限责任公司

A Helical Gear Machining Mechanism Capable of Rapid Heat Dissipation

InactiveCN104400136BGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusDrive motorEngineering

Owner:吕英芬

Spiral rising type processing equipment with four sliding grooves

The invention discloses spiral rising type processing equipment with four sliding grooves. The spiral rising type processing equipment is used for processing a blank piece (1) into a worm and comprises a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads; the lower end of the driving sleeve (4) with the internal threads can be rotatably arranged on the rack (7) by a thrust bearing (47); the rack is internally provided with a cavity (72).

Owner:STATE GRID SHANDONG ELECTRIC POWER CO LONGKOU POWER SUPPLY CO

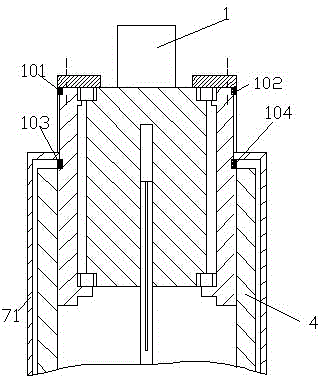

Worm machining mechanism lower in weight

A worm machining mechanism lower in weight is used for machining a blank (1) into a worm. The machining mechanism comprises a blank bearing part (2), a sleeve (3) with an external thread, a driving sleeve (4) with an internal thread and a rack (7). An upper ring-shaped flange (211) is arranged at the upper end of the blank bearing part (2), a lower ring-shaped flange (212) is arranged at the lower end of the blank bearing part (2), a ring-shaped cavity (23) is formed between the upper ring-shaped flange (211) and the lower ring-shaped flange (212), and the blank bearing part (2) with the ring-shaped cavity (23) makes the weight of the worm machining mechanism be reduced.

Owner:JIANGSU HUAXIA HEAVY IND

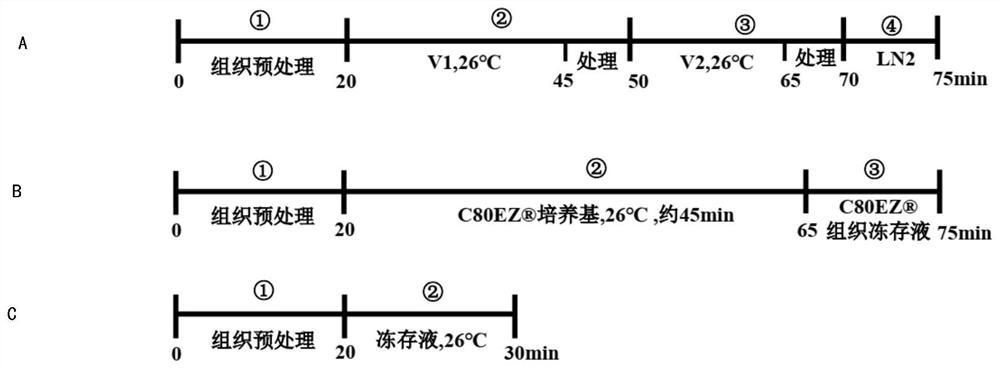

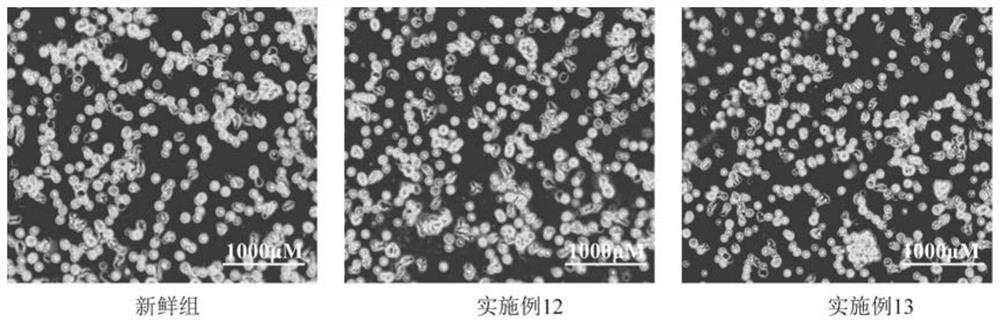

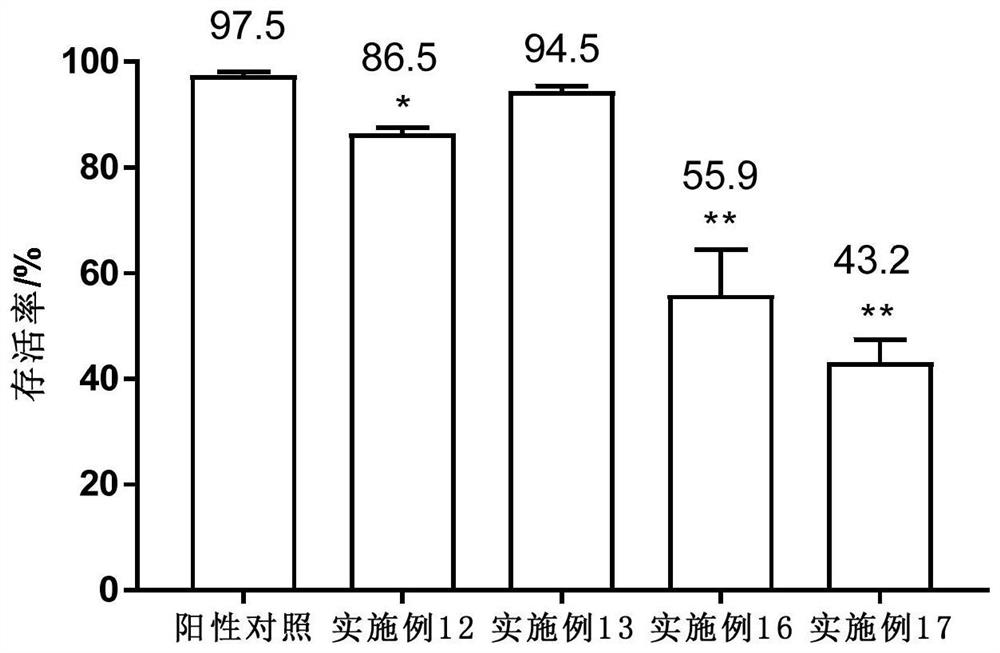

Whole-drug-grade raw material tumor tissue cryopreservation liquid and application thereof

ActiveCN113475500AIndustrial Transformation ToolClinical application valueDead animal preservationHuman tumorPolyethylene glycol

The invention provides a whole-drug-grade raw material tumor tissue cryopreservation liquid and application thereof, and the tissue cryopreservation liquid comprises the following components: a cryoprotectant, a human albumin injection and a compound electrolyte injection, wherein the cryoprotectant is selected from any one or more of dimethyl sulfoxide, ethylene glycol, polyethylene glycol, polyvinylpyrrolidone, sucrose and trehalose. The invention also provides a method for cryopreserving tumor tissues by using the tissue cryopreservation liquid, and application of the tissue cryopreservation liquid in cryopreservation of human tumor tissues and preparation of human tumor tissue cryopreservation products and the like. By using the tissue cryopreservation liquid, the tumor tissue can be stably cryopreserved for 12 months under the liquid nitrogen condition, the relative activity after resuscitation is high, the cell viability in the tissue is high, the number is large, the types are rich, and the integrity of nucleic acid and protein in the tissue is good.

Owner:SHANGHAI CELL THERAPY GRP CO LTD

A helical gear machining mechanism driven by a motor

ActiveCN104439531BGuaranteed accuracyConstant proportional relationshipFeeding apparatusGear teethGear wheelElectric machinery

A spiral gear machining mechanism driven by a motor is used for machining blanks (85). The spiral gear machining mechanism comprises a base (3), a rotary internally threaded piece (1), an externally threaded piece (2) and a cylindrical workpiece bearing piece (8). The rotary internally threaded piece (1) comprises an upper cylinder portion (11) and a lower cavity portion (12). The lower cavity portion (12) can rotate relative to the base (3) in the circumferential direction through a bearing device (13) and can be fixedly connected with the base (3) in the axial direction. The externally threaded piece (2) is cylindrical, and external threads located on the circumferential face of the outer circle of the externally threaded piece (2) are in joint with internal threads located in the upper cylinder portion (11). A drive motor (4) is arranged in the lower cavity portion (12) and located on the upper side of the base (3) and connected with the lower end of a first shaft (5).

Owner:山东格新精工有限公司

A spiral rising processing equipment with four chutes

The invention discloses spiral rising type processing equipment with four sliding grooves. The spiral rising type processing equipment is used for processing a blank piece (1) into a worm and comprises a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads; the lower end of the driving sleeve (4) with the internal threads can be rotatably arranged on the rack (7) by a thrust bearing (47); the rack is internally provided with a cavity (72).

Owner:国网山东省电力公司沂源县供电公司

Spiral gear processing mechanism with adjustable processing speed

ActiveCN104400140AGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusDrive motorEngineering

The invention discloses a spiral gear processing mechanism with an adjustable processing speed. The spiral gear processing mechanism is used when a blank (85) is processed, and comprises a base (3), a rotatable internal thread element (1), an external thread element (2) and a cylindrical work-piece bearing element (8), wherein the rotatable internal thread element (1) comprises an upper cylinder section (11) and a lower chamber section (12); the lower chamber section (12) and the base (3) can circumferentially rotate and axially fixedly connected through a bearing device (13); the external thread element (2) is in a cylindrical shape; external threads are arranged at the outer circumference surface and are jointed with internal threads in the upper cylinder section (11); a hollow cavity (31) is formed in the base (3), and is provided with a top wall (32); a drive motor (4) is arranged in the hollow cavity (31).

Owner:ZHENXIN TAISHAN SPEED CHANGING GEAR BOXES

A Helical Gear Machining Mechanism with Long Cylindrical Bearings

InactiveCN104400135BGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusEngineeringDrive motor

The invention relates to a spiral gear machining mechanism with a long cylindrical bearing. The spiral gear machining mechanism with the long cylindrical bearing is used for machining a blank (85) and comprises a long cylindrical bearing, a base (3), a rotatable internal threaded part (1), an external threaded part (2) and a cylindrical workpiece bearing part (8), wherein the rotatable internal threaded part (1) comprises an upper cylindrical portion (11) and a lower chamber portion (12), the lower chamber portion (12) can circumferentially rotate and is axially fixedly connected with the base (3) through a bearing device (13), the external threaded part (2) is cylindrical, external threads are arranged on the outer circumferential surface and are jointed with internal threads in the upper cylindrical part (11), a cavity (31) is formed in the base (3), the cavity (31) has a top wall (32) and a driving motor (4) is installed in the cavity (31).

Owner:HUNAN INSTITUTE OF ENGINEERING

A Helical Gear Machining Mechanism with Heat Dissipation Windows

InactiveCN104400137BGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusDrive motorEngineering

Owner:重庆隆永新材料技术有限公司

A Helical Gear Machining Mechanism Capable of Lubricating Oil Renewal

ActiveCN104400138BGuaranteed accuracyConstant proportional relationshipGear lubrication/coolingFeeding apparatusEngineeringLubricant

The invention relates to a spiral gear machining mechanism capable of conducting lubricating oil renewal, which is used for machining a blank (85). The spiral gear machining mechanism capable of conducting lubricating oil renewal comprises a base (3), a rotatable internal threaded piece (1), an external threaded piece (2) and a cylindrical workpiece bearing piece (8), wherein the rotatable internal threaded piece (1) comprises an upper cylindrical portion (11) and a lower chamber portion (12), the lower chamber portion (12) is connected with the base (3) through a bearing device 13) in a circumferentially rotatable and axial fixed manner, the external threaded piece (2) is cylindrical, external threads are arranged on the external circumferential surface of the external threaded piece (2) and are jointed with internal threads in the upper cylindrical portion (11), and a cavity (31) is formed in the base (3).

Owner:中山迈雷特智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com