Patents

Literature

33results about How to "Will not affect transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

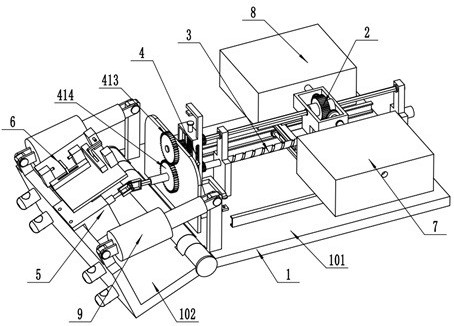

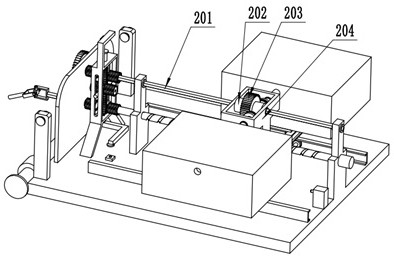

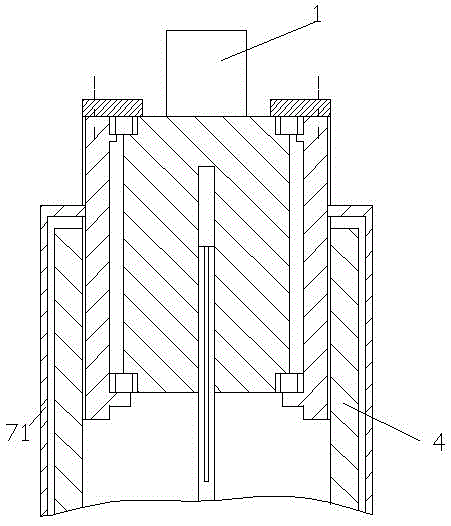

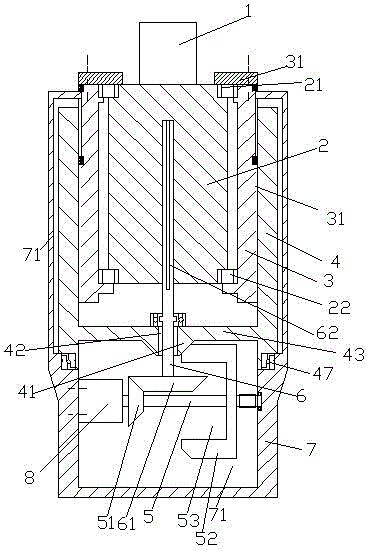

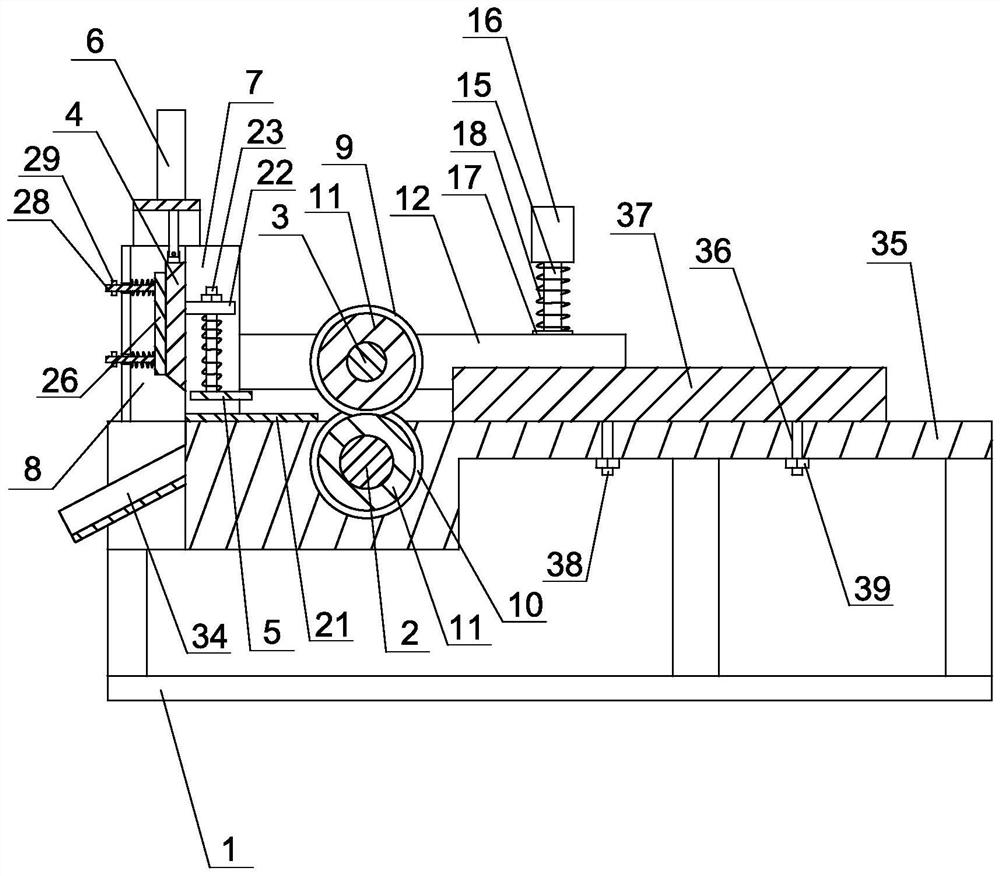

Worm machining device

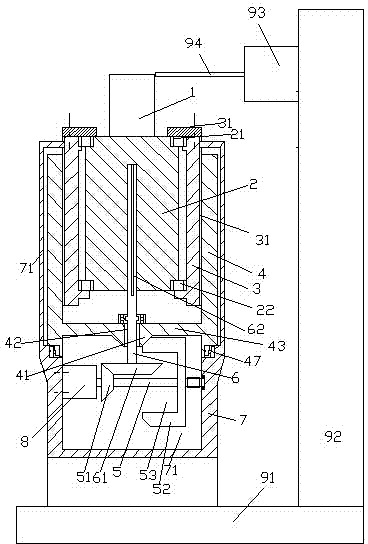

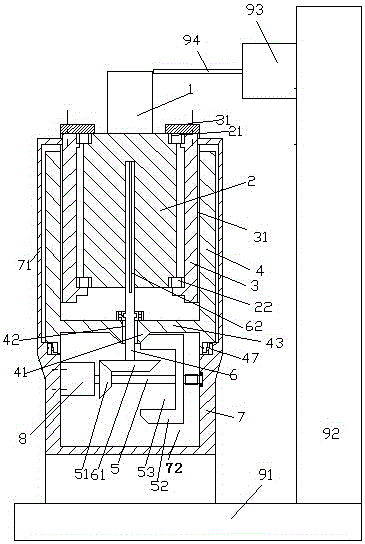

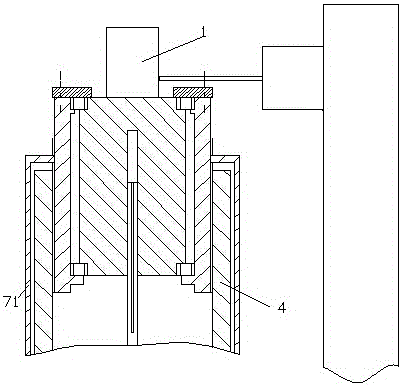

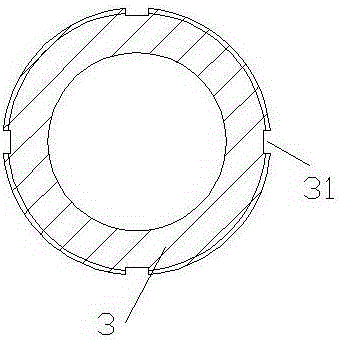

The invention provides a worm machining device. The worm machining device is used for machining a blank (1) into a worm, and comprises a movement mechanism, a base (91), an upright column (92), a milling cutter rotating driving motor (93) and a milling cutter (94); the movement mechanism is fixed on the base (91); the lower end of the upright column (92) is fixedly connected with the base (91); the milling cutter rotating driving motor (93) is mounted on the upper end of the upright column (92) and used for driving the milling cutter (94) to rotate; the milling cutter (94) is mounted on the milling cutter rotating driving motor (93) and used for cutting the blank (1); the movement mechanism comprises a blank carrying piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a frame (7).

Owner:SHENYUE FUJIAN CASTING

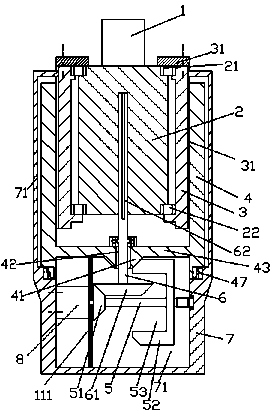

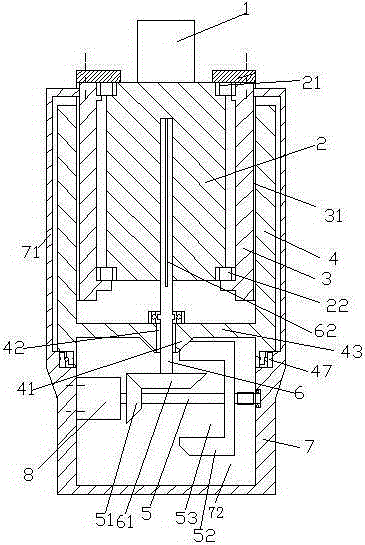

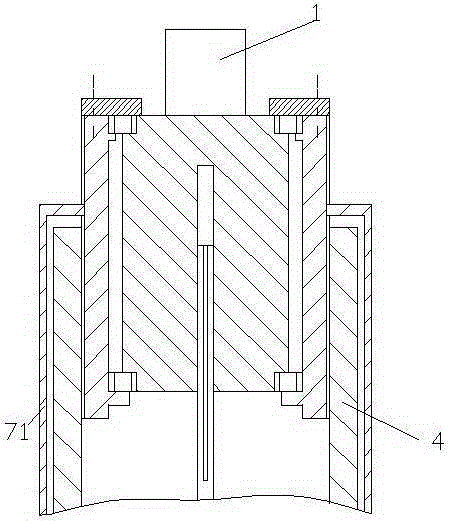

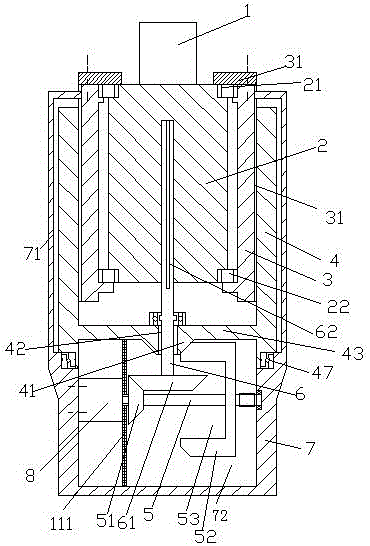

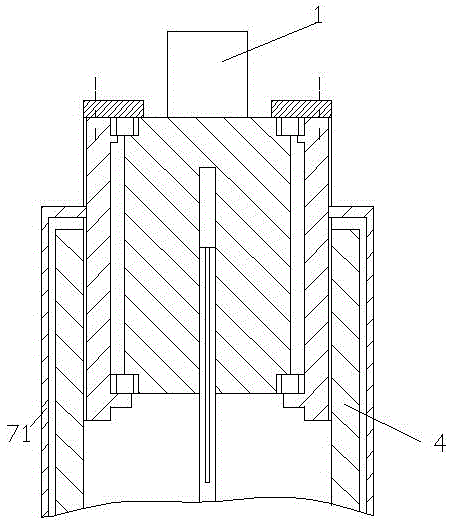

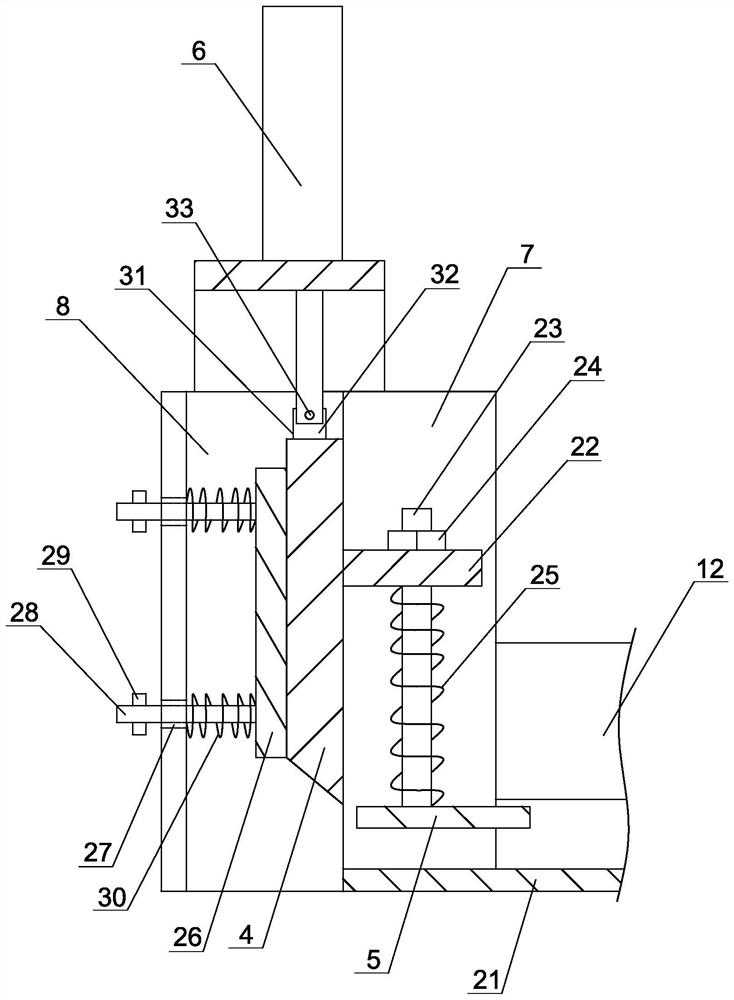

Worm processing mechanism capable of automatically radiating heat

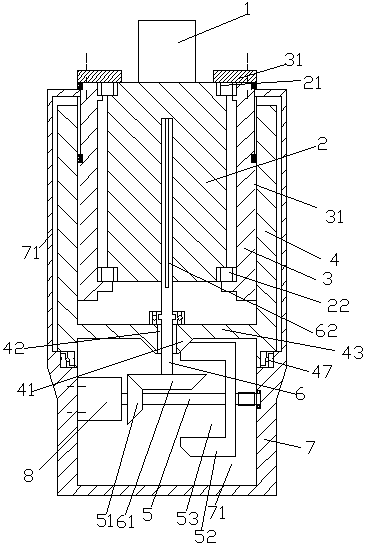

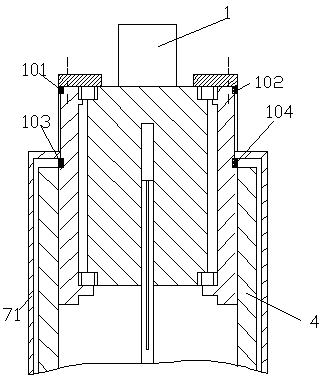

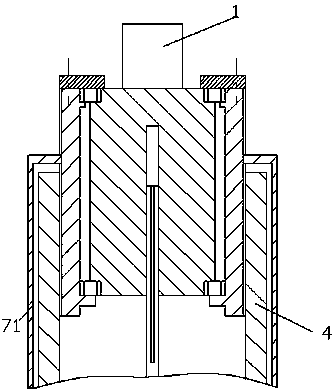

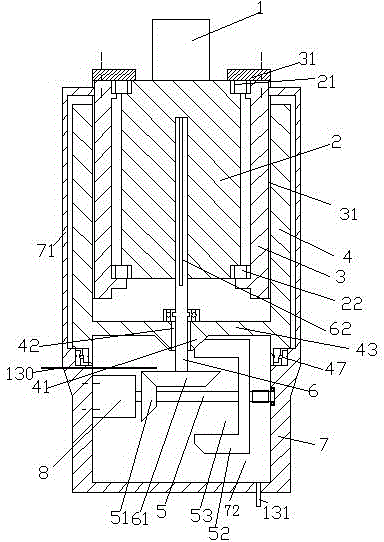

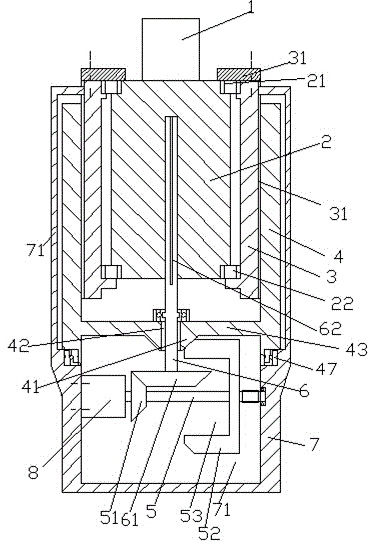

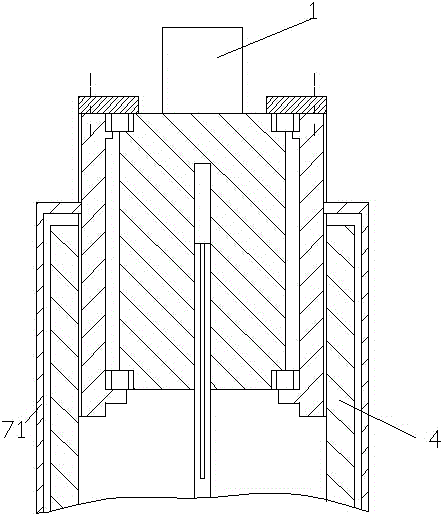

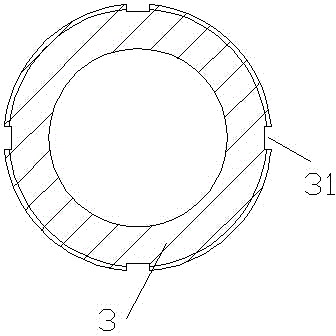

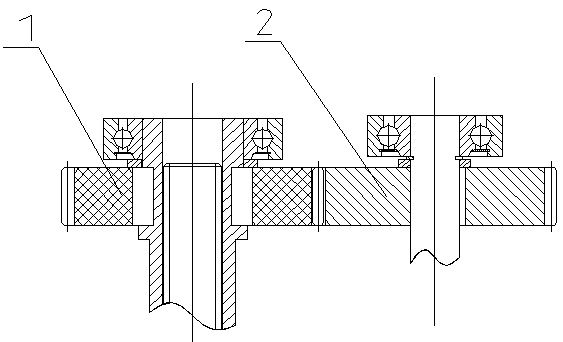

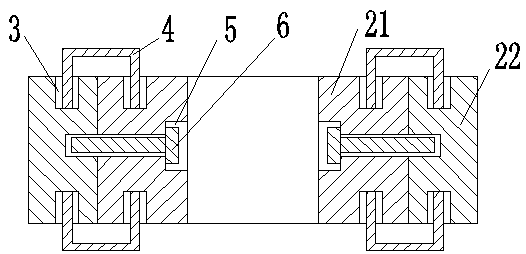

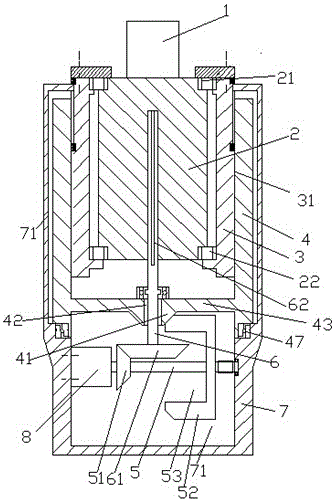

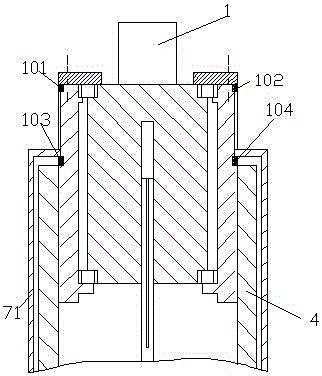

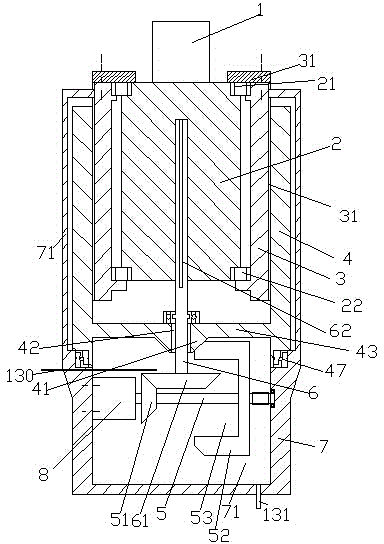

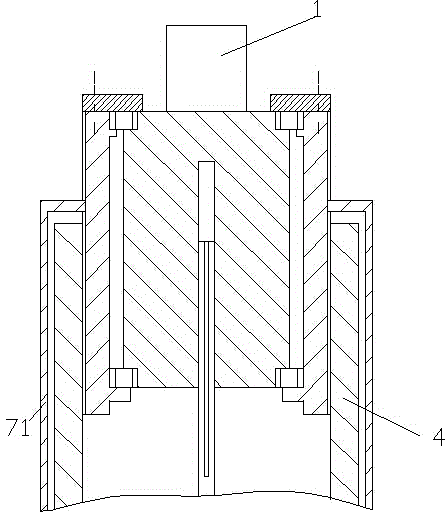

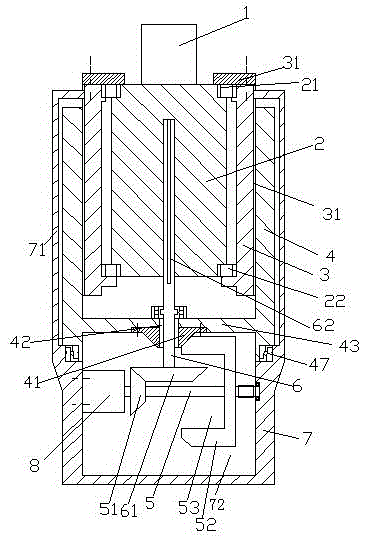

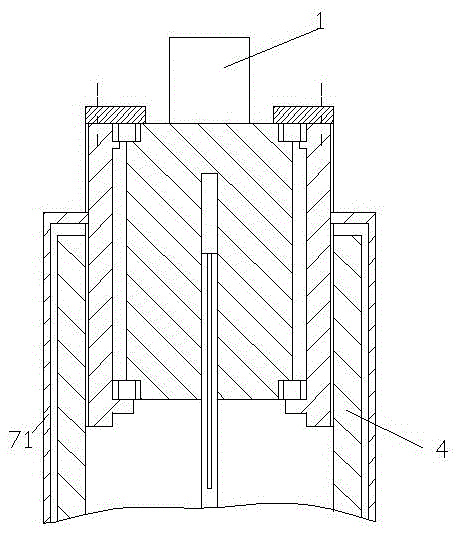

The invention discloses a worm processing mechanism capable of automatically radiating heat. The worm processing mechanism is used for processing a blank (1) into a worm. The worm processing mechanism comprises a blank bearing member (2), a sleeve (3) with an external thread, a drive sleeve (4) with an internal thread, and a rack (7), wherein the blank bearing member (2) is used for bearing the blank (1), the upper end and the lower end of the blank bearing member (2) are respectively fixedly arranged in the sleeve (3) with the external thread by means of an upper bearing (21) and a lower bearing (22) relative to the sleeve (3) with the external thread, the sleeve (3) with the external thread is in thread fit in the drive sleeve (4) with the internal thread, the lower end of the drive sleeve (4) with the internal thread can be rotatably arranged on the rack (7) by means of a thrust bearing (47), a cavity (72) is arranged inside the rack (7), and in the cavity (72), a drive motor (8) is fixedly arranged on the left-inner side wall of the cavity of the rack (7).

Owner:国网山东省电力公司沂源县供电公司

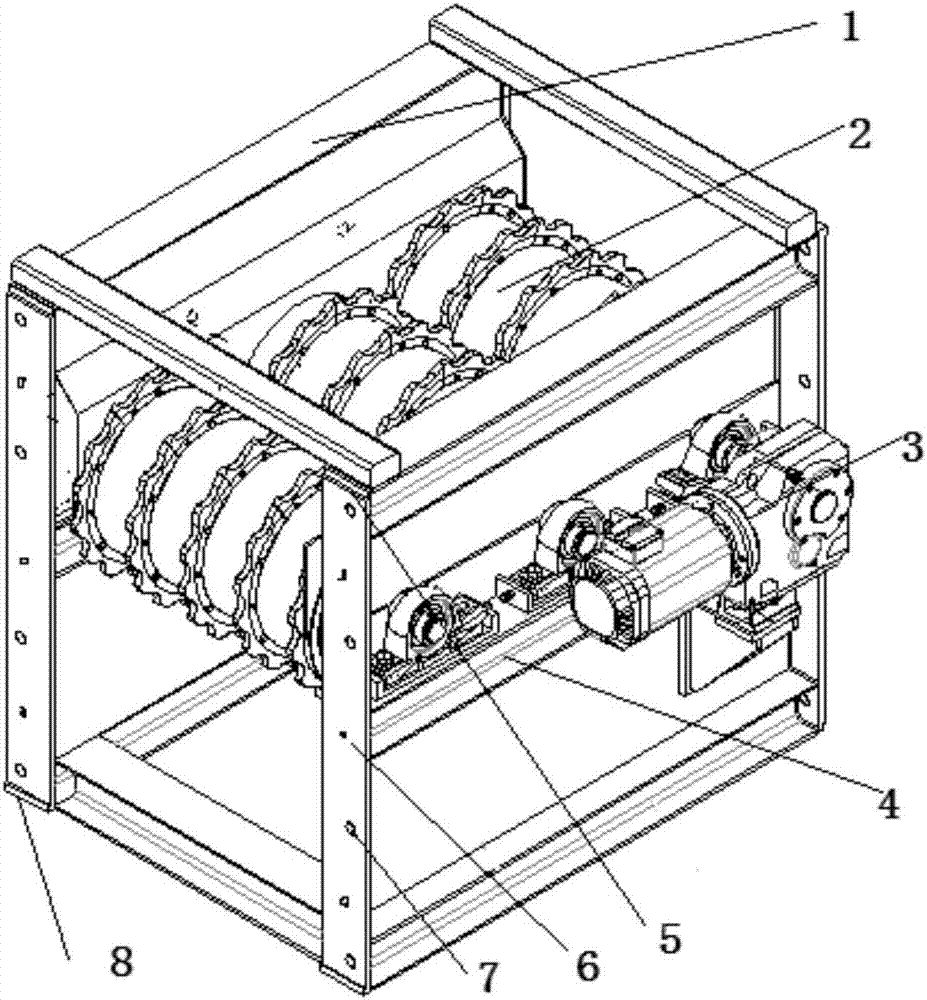

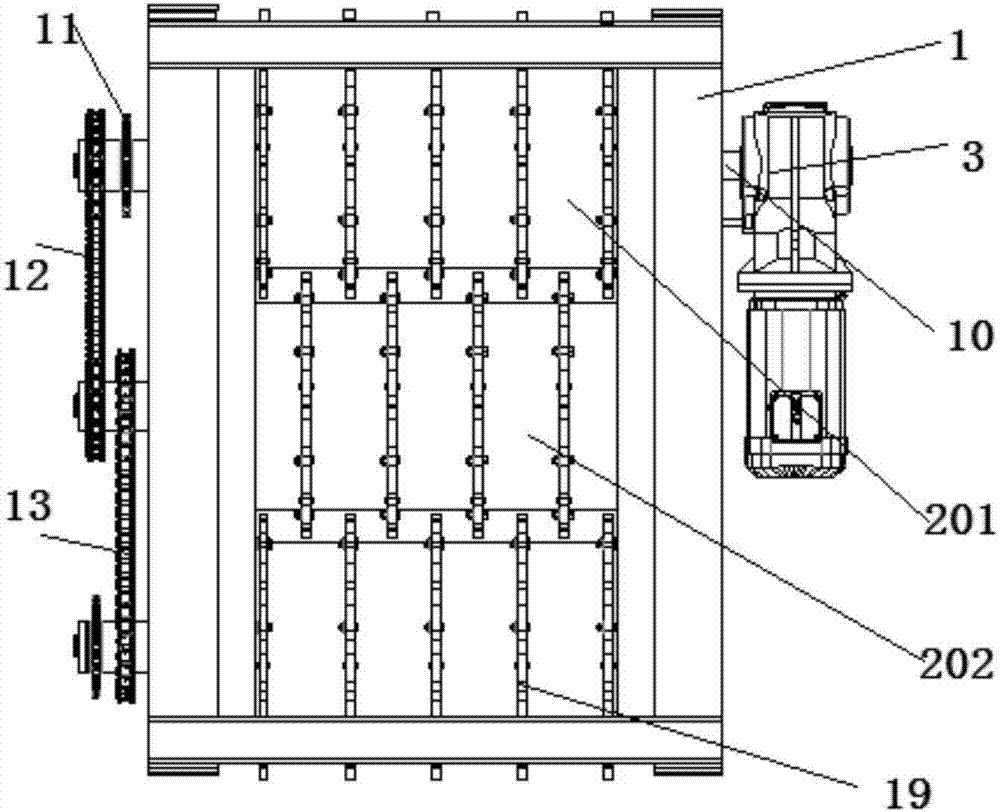

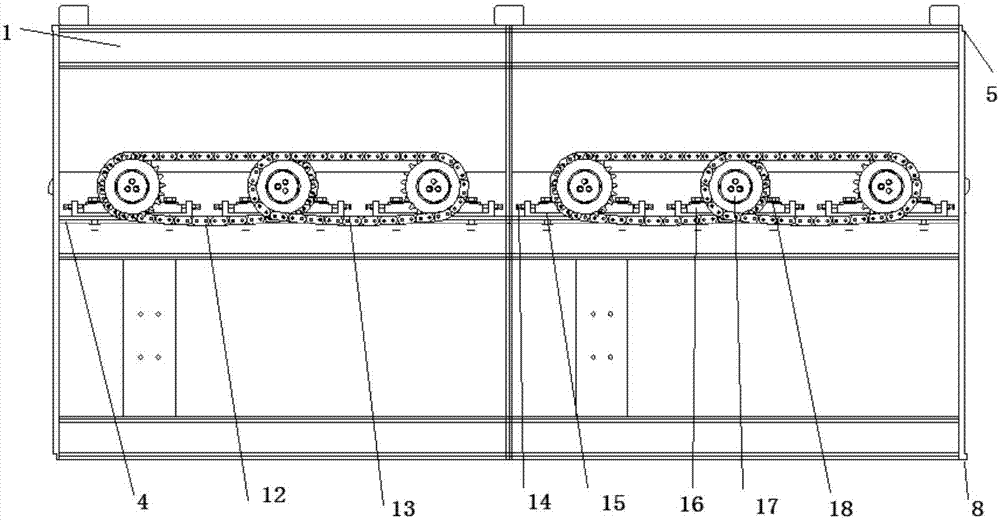

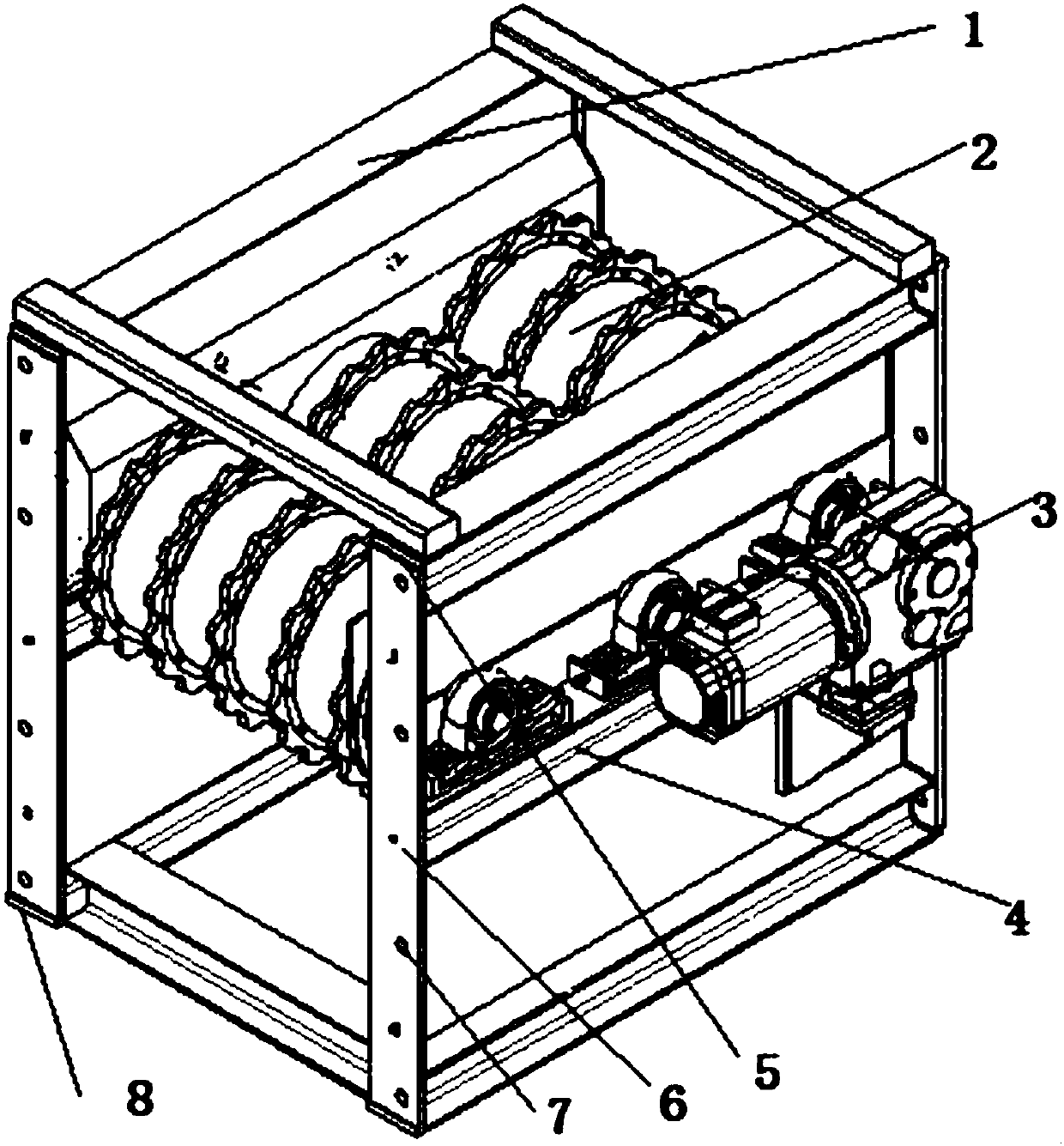

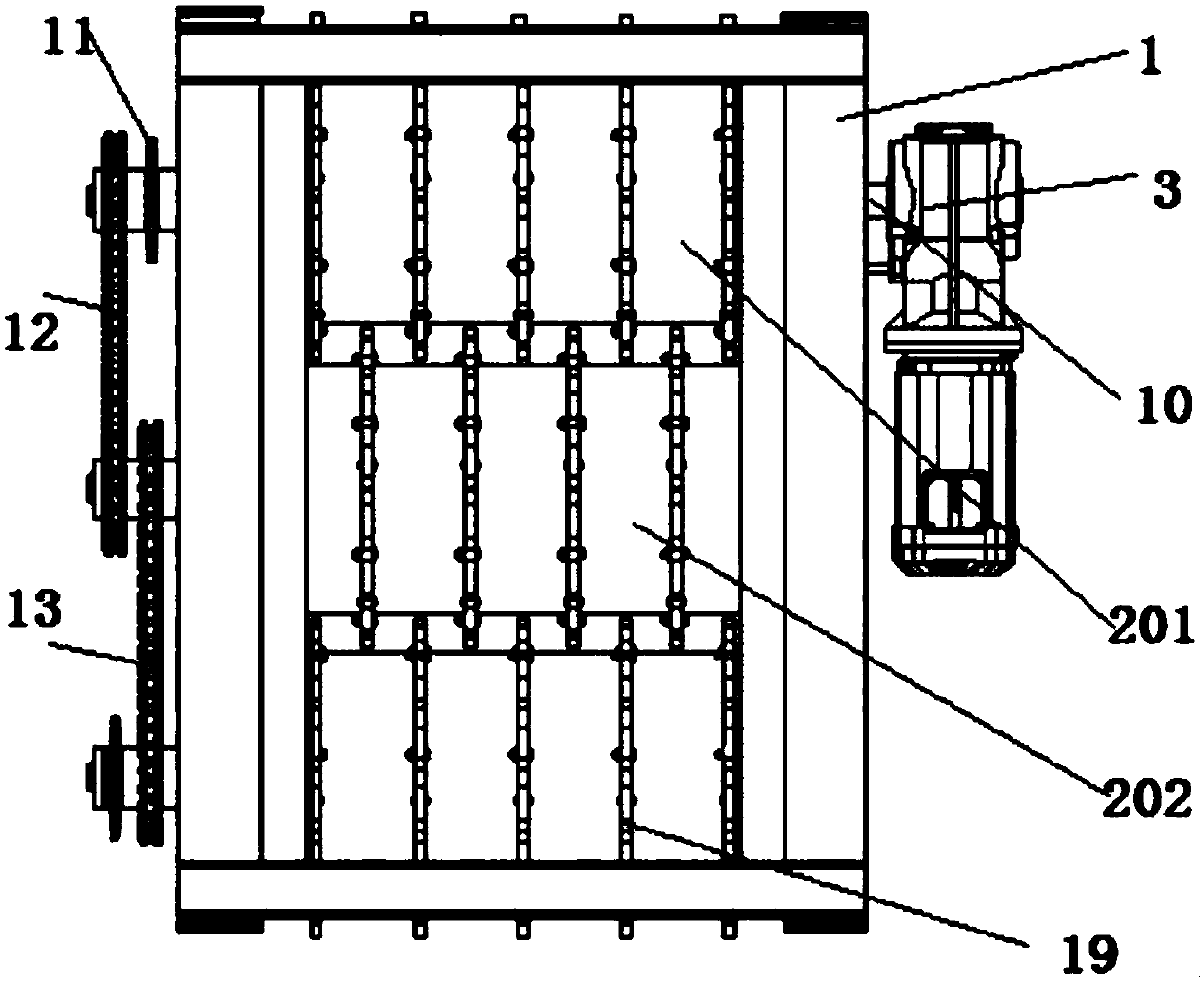

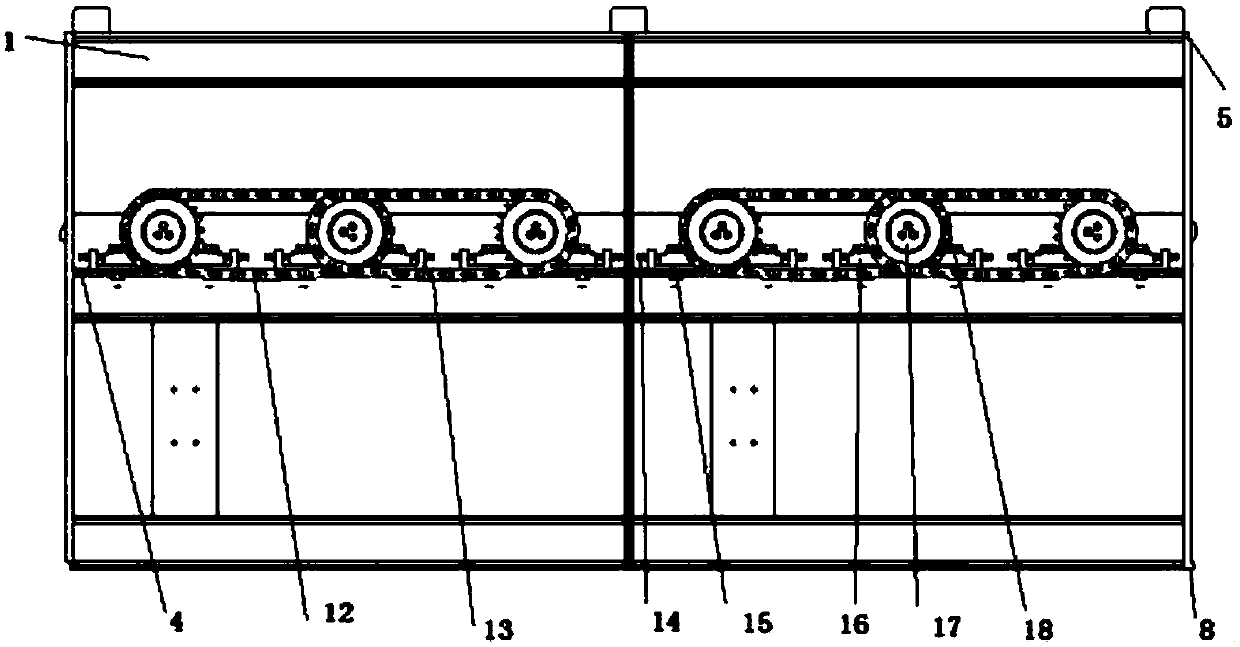

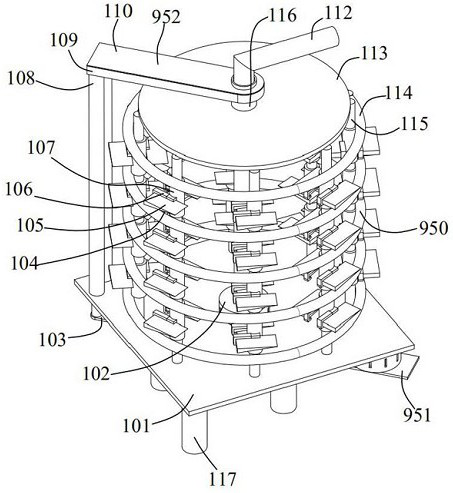

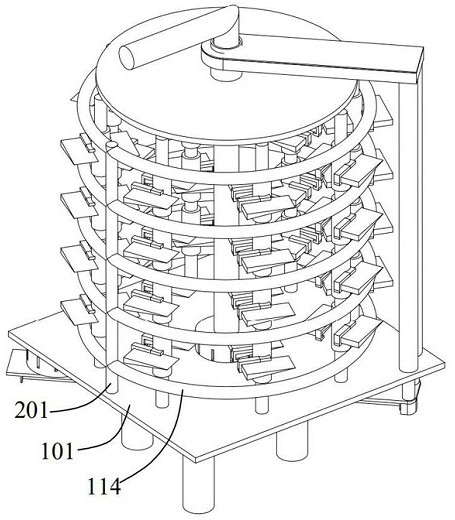

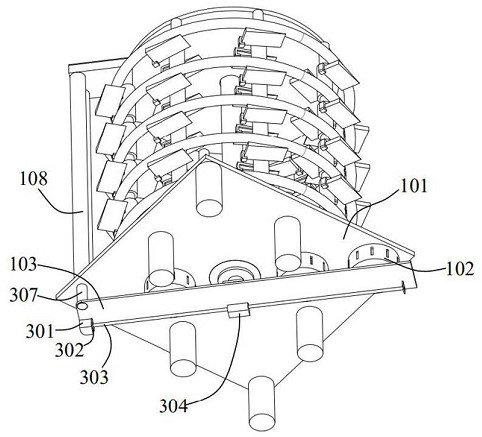

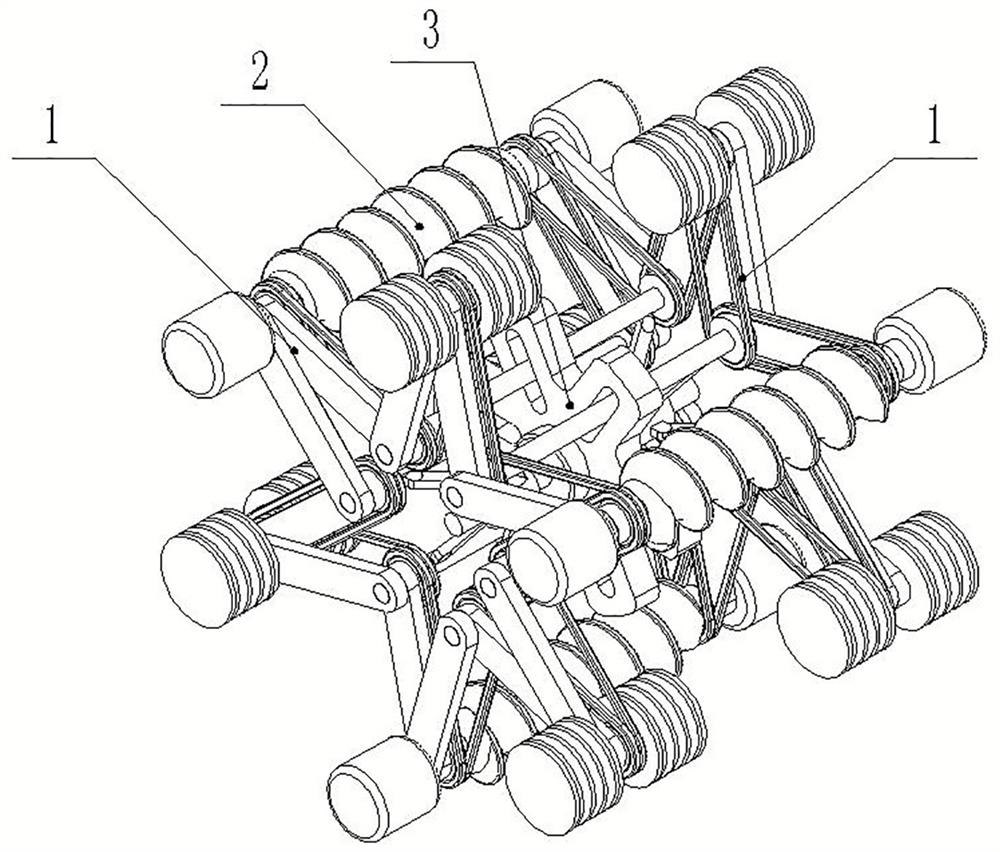

Modularized disc screening equipment for municipal solid waste

The invention provides modularized disc screening equipment for municipal solid waste. The modularized disc screening equipment comprises multiple groups of modularized screening units which are detachably connected; each modularized screening unit comprises a square support, each square support is provided with adjusting bases, the adjusting bases are symmetrically arranged on the two sides, without through holes, of the corresponding square support, every two adjusting bases are provided with no more than five rollers which are detachably connected and evenly distributed, the rollers comprise driving rollers and driven rollers which are rotatably connected with the driving rollers through chains, multiple coaxial discs which are evenly distributed are detachably connected to each roller, and multiple disc bases which are evenly distributed are integrally formed on each roller. According to the modularized disc screening equipment for the municipal solid waste, devices with different sizes are selected for different using conditions, and therefore resource waste is reduced; by arranging the detachable discs, the service life of the equipment is prolonged, the structure is stable, replacement is convenient, the equipment can be used for screening of small devices, and the cost is reduced.

Owner:天津巨杉环境技术股份有限公司

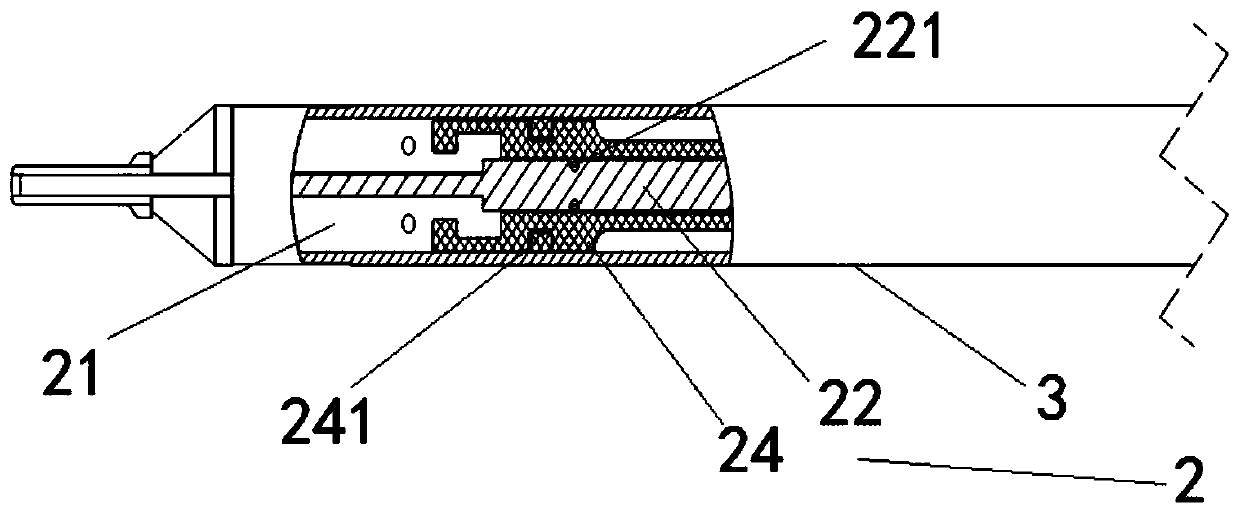

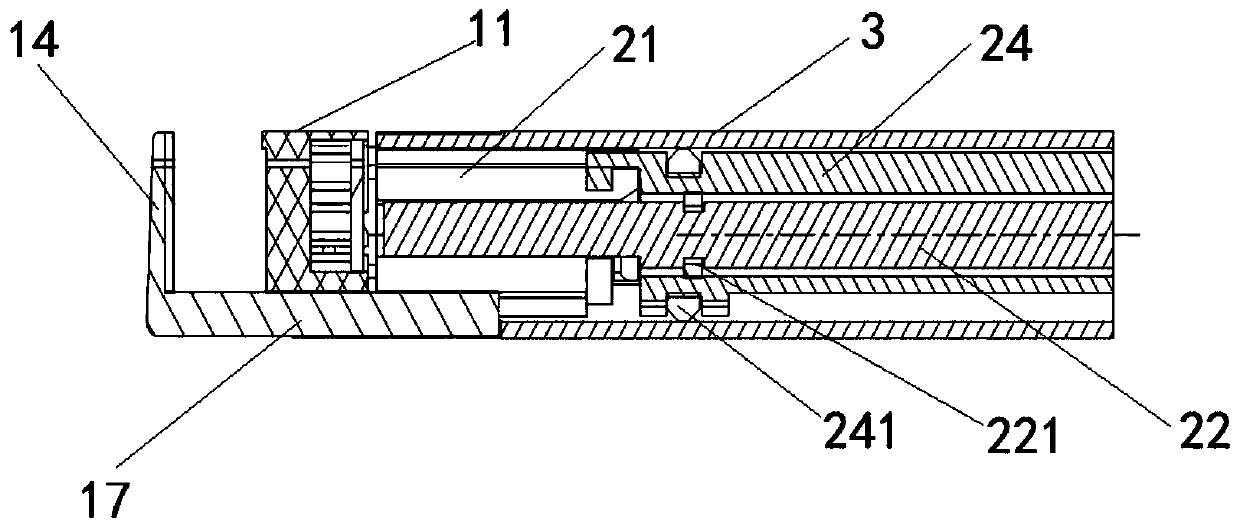

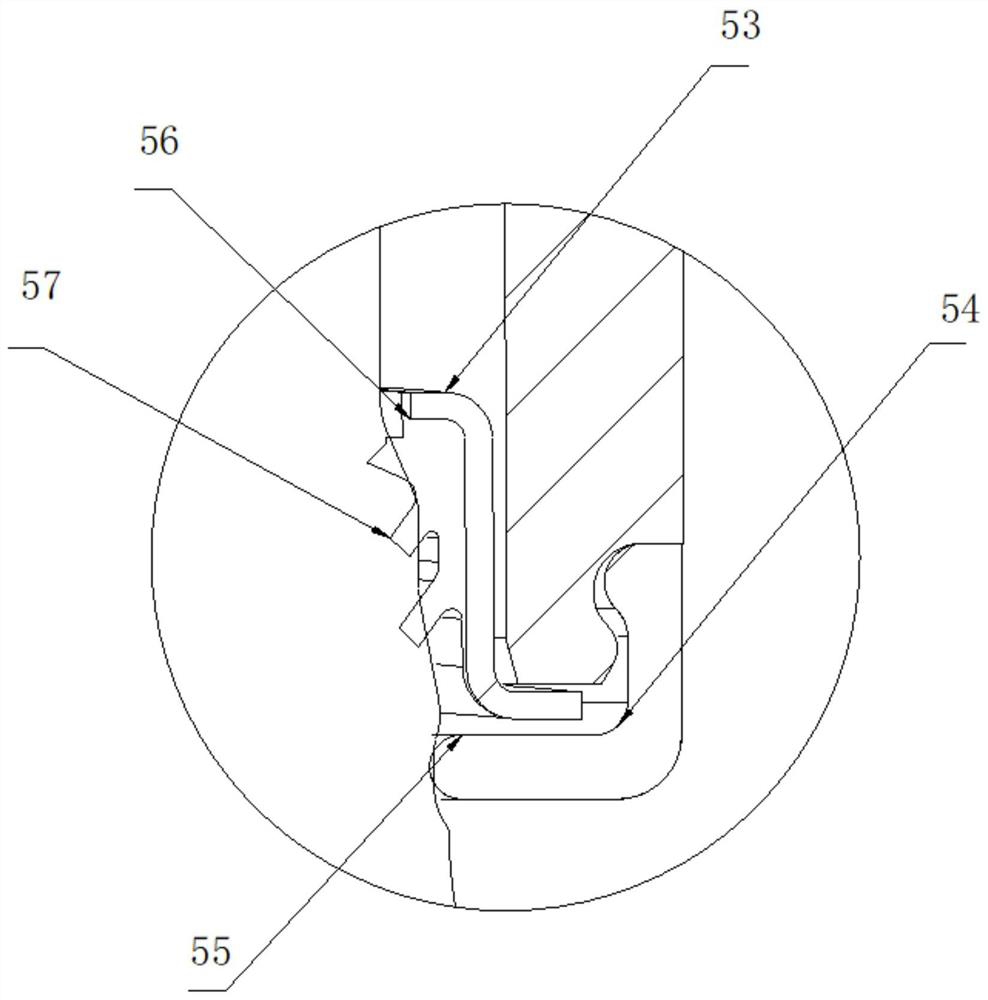

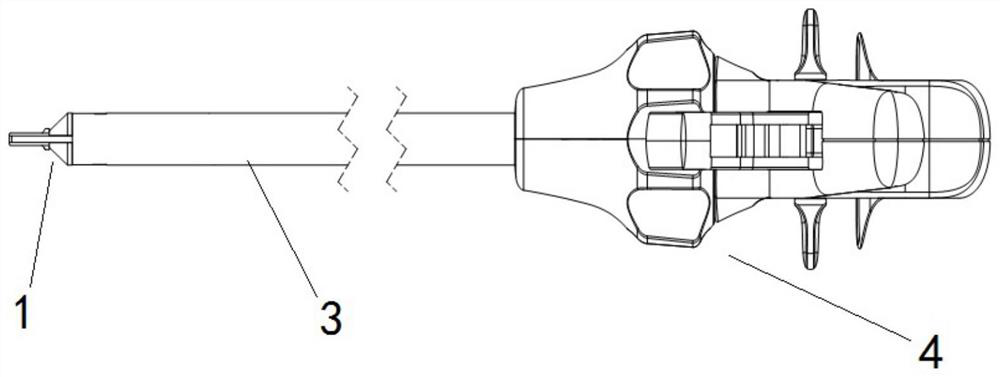

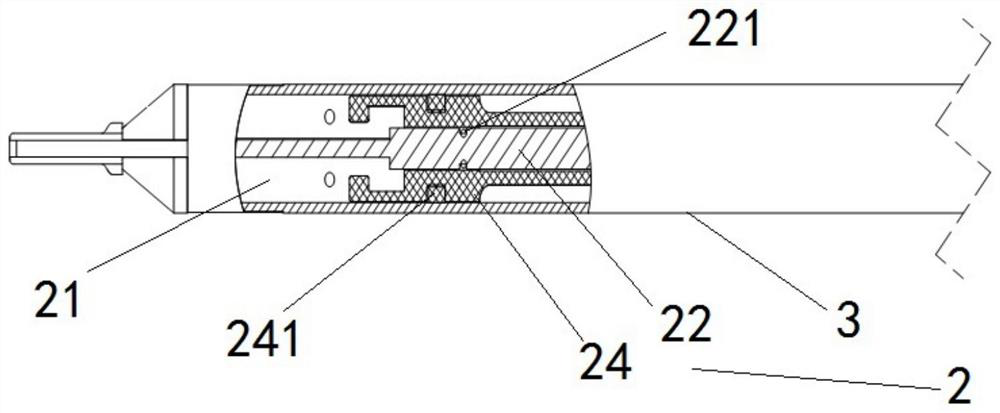

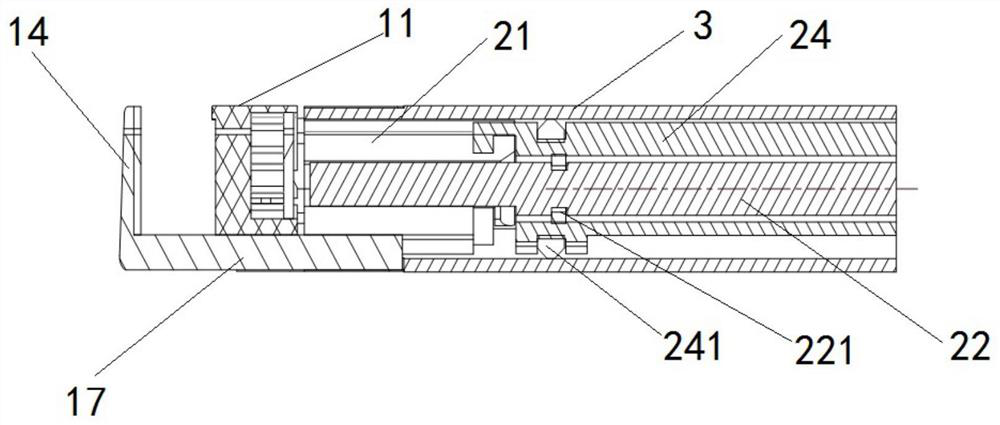

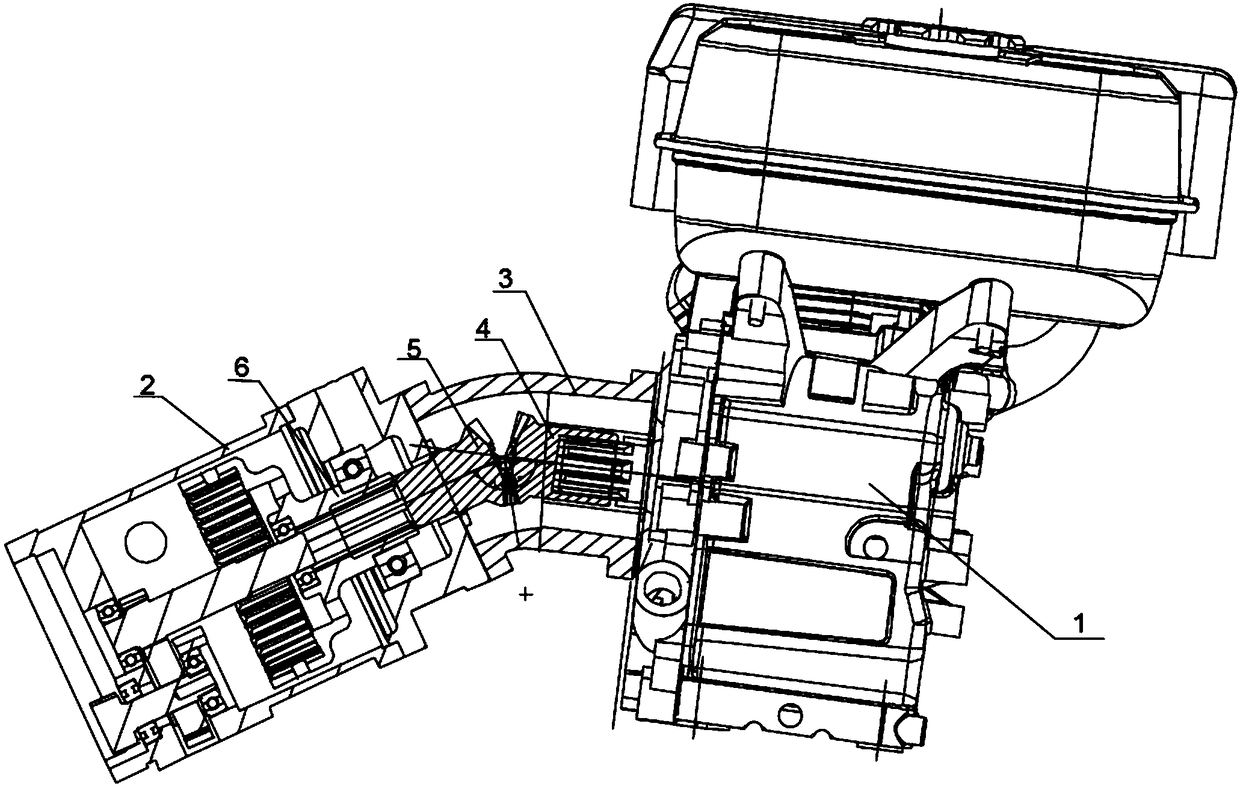

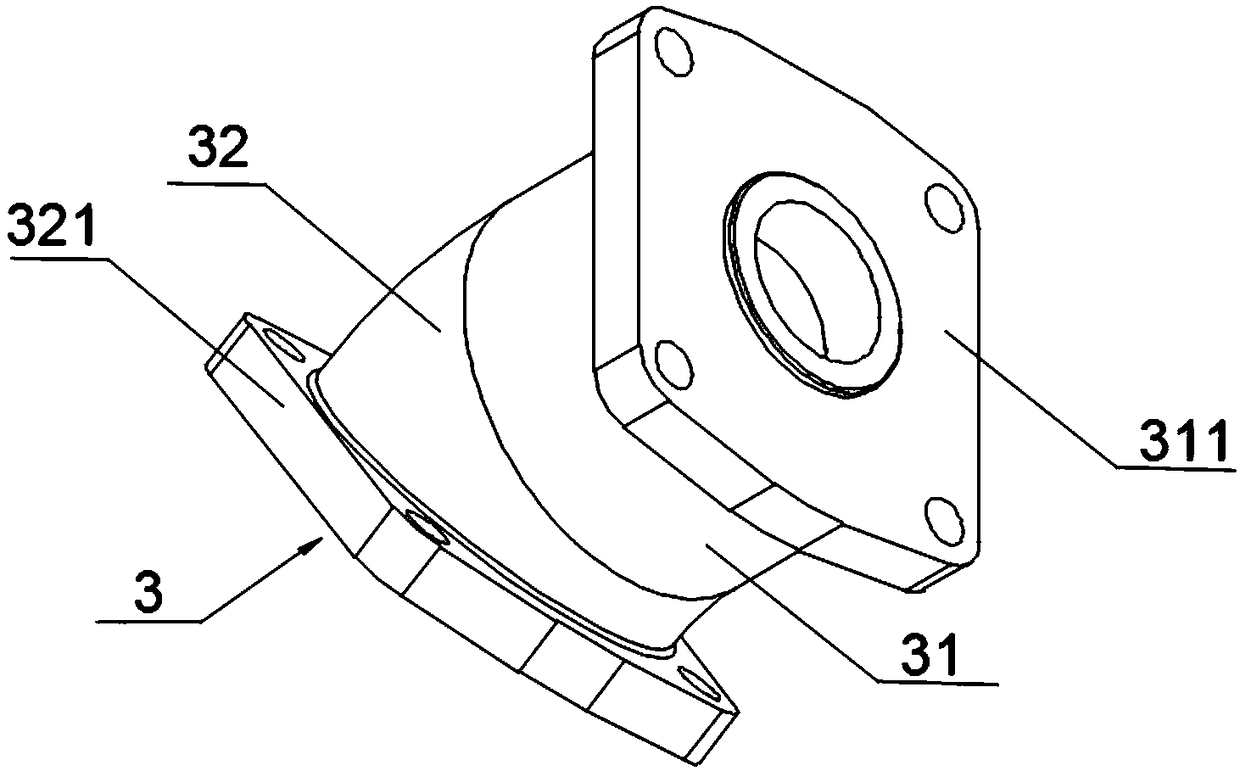

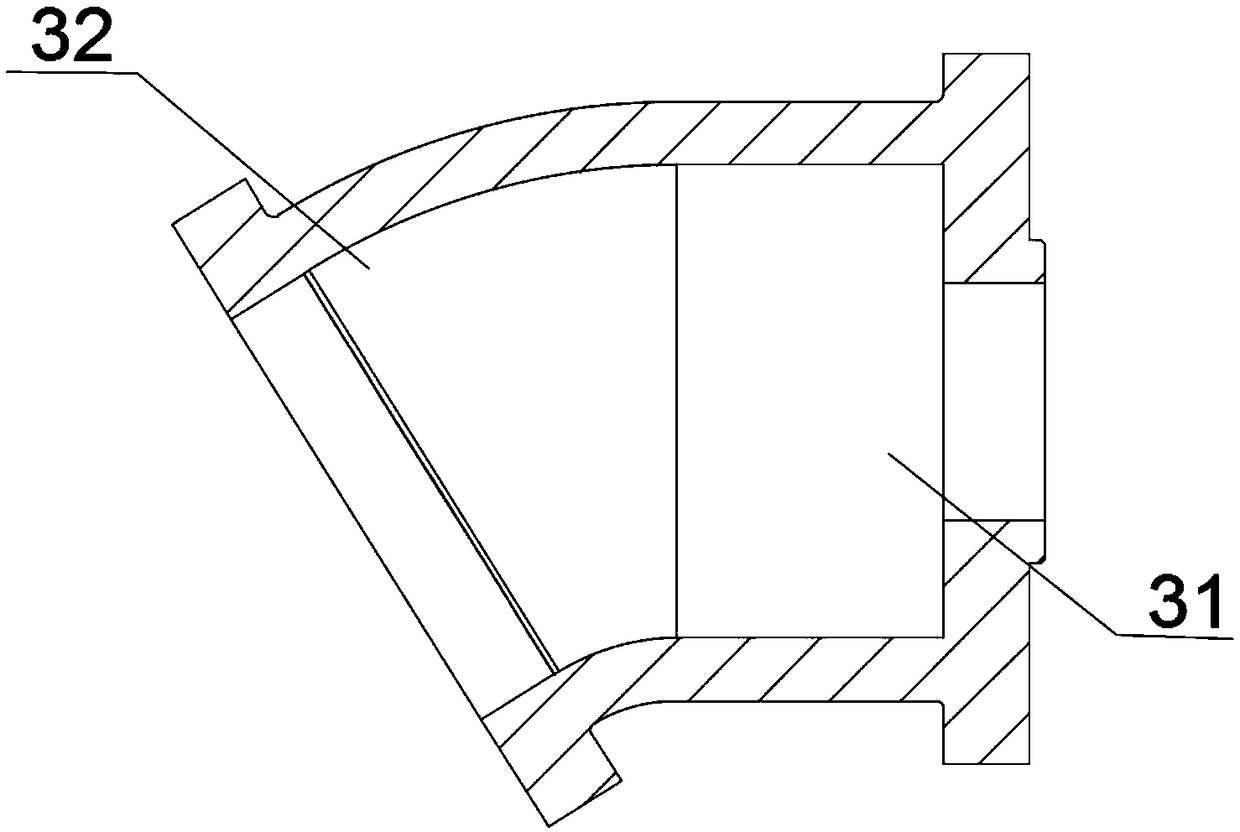

Sealing structure of stitching instrument for endoscopic surgery and stitching instrument

ActiveCN111588430AWill not affect transmissionGuaranteed tightnessSurgical staplesEndoscopic surgeryReoperative surgery

The invention provides a transverse intracavity stitching instrument with a sealing structure. The stitching instrument comprises an end executor, a connecting outer tube and a driving assembly at least partially arranged in the connecting outer tube, and is characterized in that the end executor comprises a nail bin shell, a stitching nail and a nail pushing block; the driving assembly comprisesa driving push rod and a driving shell; the driving push rod is used for driving the nail pushing block to push the stitching nail upwards; the driving shell is used for driving the nail bin shell; the near end of the driving shell is connected with a hollow driving connecting rod, and the driving push rod sequentially penetrates through an inner cavity of the hollow driving connecting rod and aninner cavity of the driving shell; a first sealing ring is arranged between the driving push rod and the hollow driving connecting rod; and a second sealing ring is arranged between the hollow drivingconnecting rod and the connecting outer pipe. The driving mechanism of the transverse stitching instrument is improved to be connected and driven by adopting a cylindrical element, and a sealing device is correspondingly arranged at the key part, so that the transmission is not influenced, the sealing property can be ensured, and the transverse stitching instrument is suitable for endoscopic surgery and the air leakage condition in the surgery process is prevented.

Owner:SUZHOU BEINUO MEDICAL EQUIP

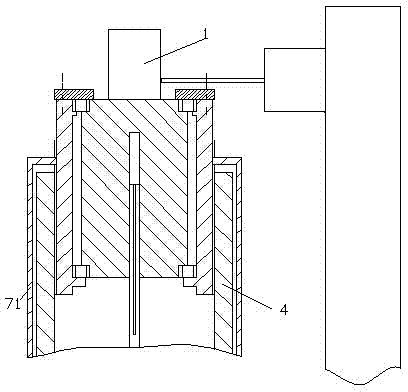

Worm machining mechanism capable of automatically performing up-down limiting

The invention discloses a worm machining mechanism capable of automatically performing up-down limiting. The worm machining mechanism is used for machining a blank (1) into a worm and comprises a blank bearing member (2), a sleeve (3) with external thread, a driving sleeve (4) with internal thread and a rack (7), wherein the blank bearing member (2) is used for bearing the blank (1); the upper and lower ends of the blank bearing member (2) are axially and fixedly arranged in the sleeve (3) with the external thread relative to the sleeve (3) with the external thread through an upper bearing (21) and a lower bearing (22) respectively; the sleeve (3) with the external thread is matched in the driving sleeve (4) with the internal thread; the lower end of the driving sleeve (4) with the internal thread is arranged on the rack (7) through a thrust bearing (47) in a rotating manner.

Owner:广州德纳科技股份有限公司

Small-scale modular household garbage screening equipment

The invention provides small-scale modular household garbage screening equipment. The equipment comprises a plurality of detachably connected modular screening units, modular screening units comprisesquare supports, protrusions and grooves are arranged at the two ends of vertical rods on one sides of the square supports, vertical rods on the other sides are provided with adjusting seats, the adjusting seats are symmetrically arranged on the two sides, without through holes, of the square supports, the two adjusting seats are provided with rollers, and the rollers comprise driving rollers anddriven rollers. According to the small-scale modular household garbage screening equipment, equipment with different sizes is selected according to different use conditions, so that the utilization rate is high, the resources waste is reduced, the service life of the equipment is prolonged, the structure is stable, the equipment can be used for screening small equipment, waste is reduced on the basis of realizing garbage separation through a simple and reliable transmission mode, and the processing cost is reduced.

Owner:长兴睿锋科技有限公司

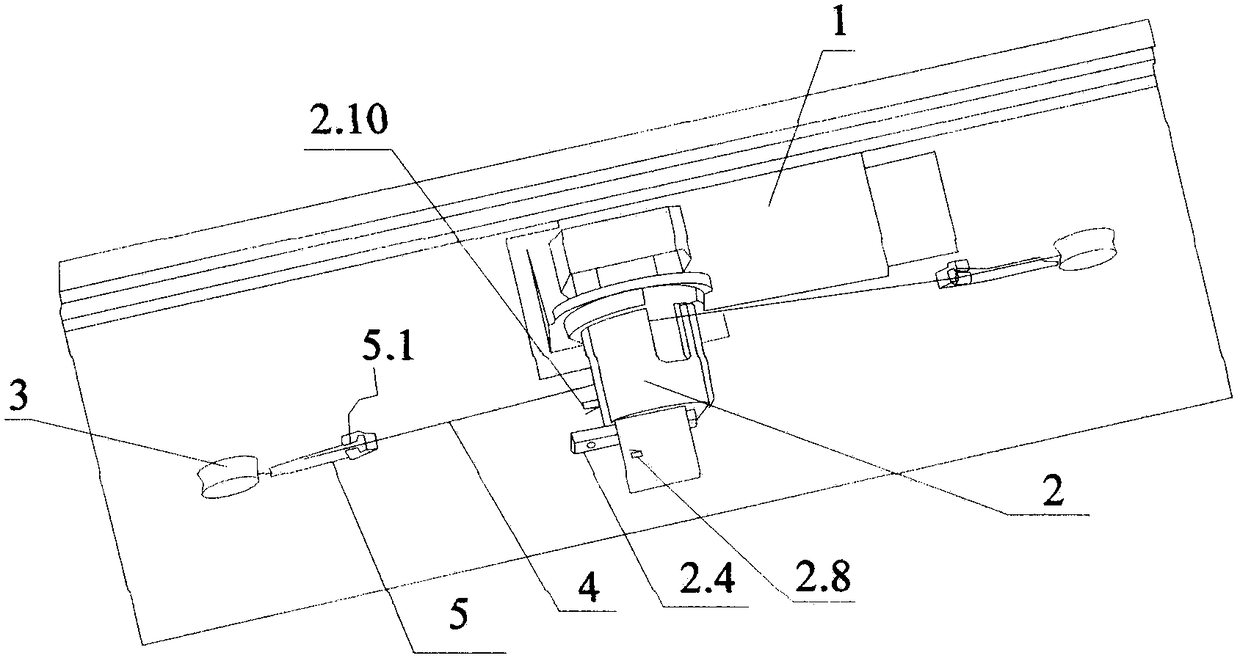

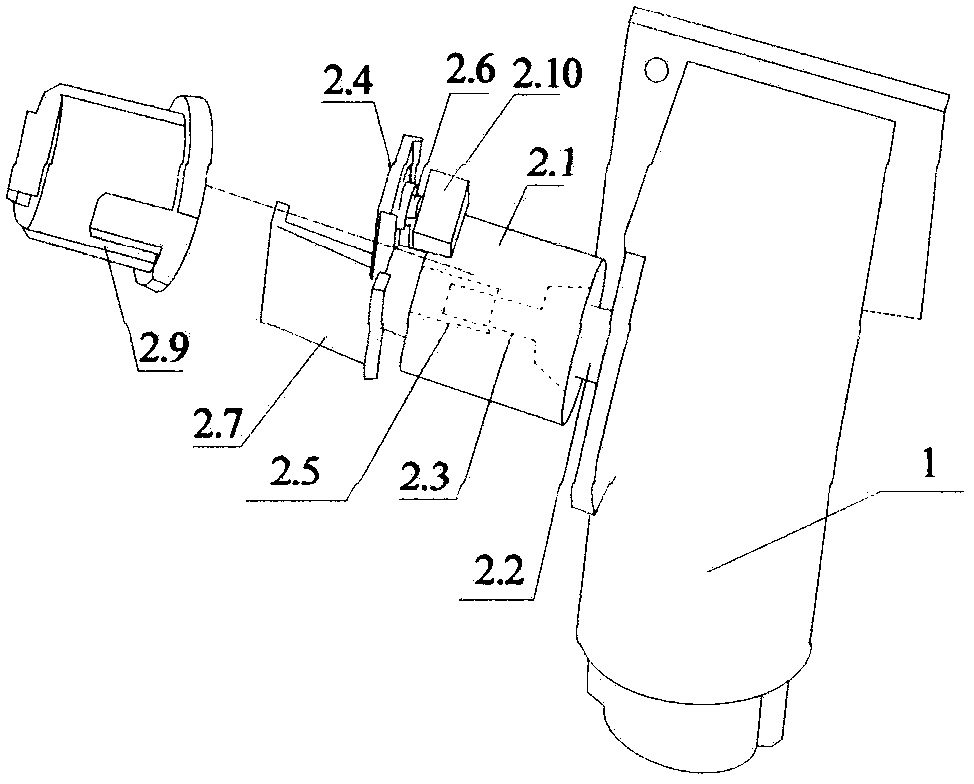

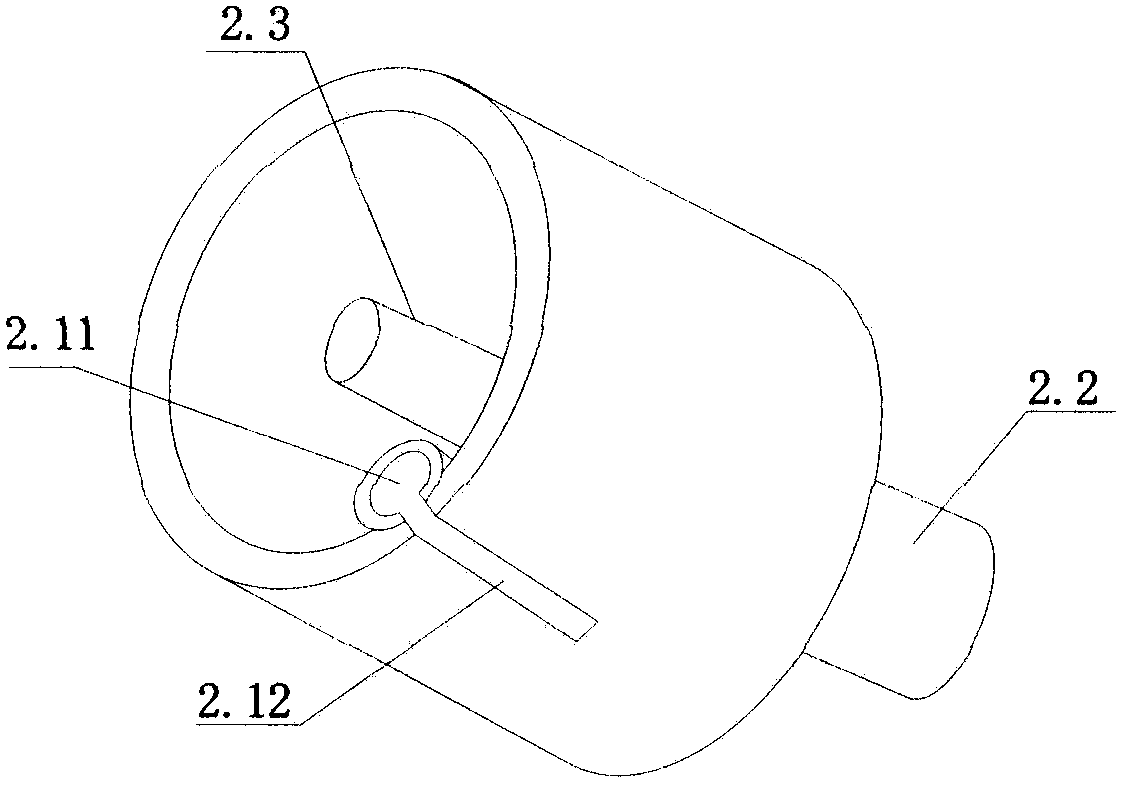

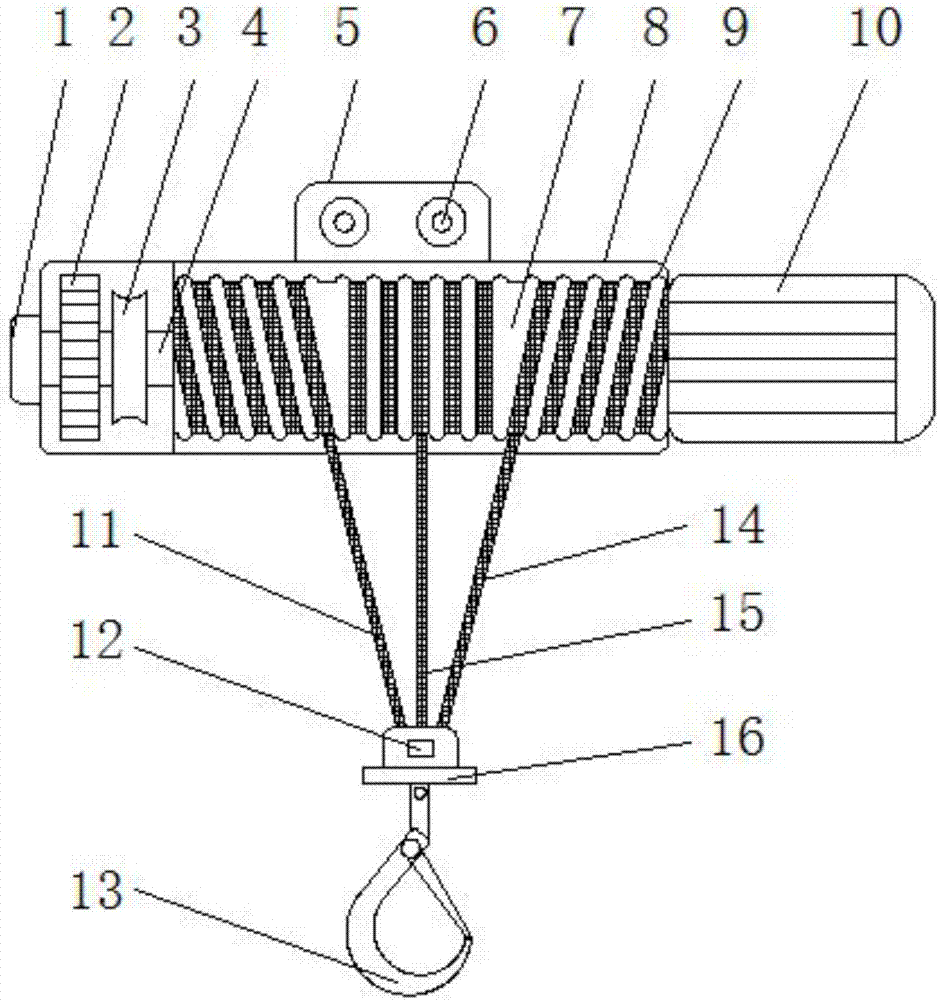

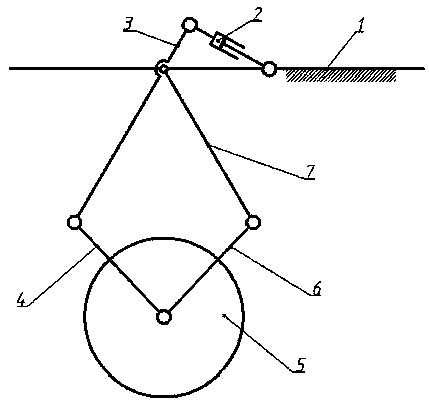

Lifting mechanism

PendingCN108100904AReduce forceWill not affect transmissionWinding mechanismsForeign matterStopped work

The invention discloses a lifting mechanism. The lifting mechanism comprises a motor (1), a winding device (2) and two pulleys (3), the winding device (2) is driven to rotate through the motor (1), digging ropes (4) on the winding device (2) are arranged on the two pulleys (3) in an extending mode, and the digging ropes (4) are connected to the two ends of a lifting object through the two pulleys(3); a rebound switch (5) is arranged between the winding device (2) and the at least one pulley (3); the digging ropes (4) are clamped into clamping grooves (5.1) in the rebound switch (5); and the rebound switch (5) is electrically connected with a controller for controlling a working state of the motor (1). According to the lifting mechanism, in the falling process of the lifting object, by designing the rebound switch, when the lifting mechanism encounters foreign matter, the rebound switch is bounded up, and the motor is controlled to stop working through the controller; and meanwhile, the structure of the winding device is skillfully designed, so that a stroke switch is controlled through a structure on the winding device.

Owner:赖季谷

A size-adjustable forklift counterweight

ActiveCN114105049BAchieve the role of balancing forkliftWill not affect transmissionVehicle body stabilisationLifting devicesClassical mechanicsControl theory

The invention discloses a size-adjustable forklift counterweight, which relates to the field of forklift counterweights, and includes a mounting frame, a counterweight I and a tilt switch. The counterweight II moves vertically, and the longitudinal adjustment device is equipped with a horizontal adjustment device, which controls the lateral movement of the counterweight I and the counterweight II. The present invention realizes the size change of the overall counterweight by changing the position of the counterweight, achieving To balance the function of the forklift, the set tilt switch can adjust the position of the counterweight according to the tilting direction of the forklift.

Owner:JIANGSU XIANGMENG PRECISION CASTING CO LTD

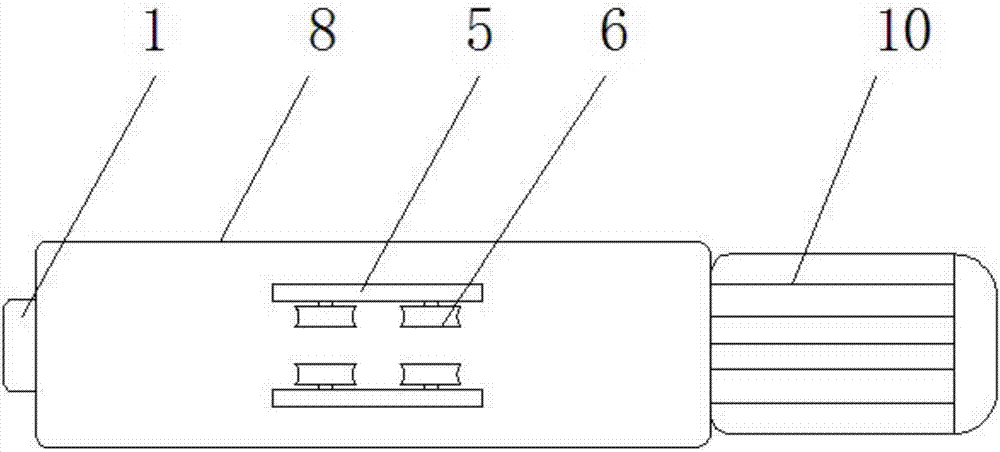

Transmission device for crane

PendingCN108002260AReal-time monitoring of moving speedAvoid threatsWinding mechanismsLoad-engaging elementsFree fallingDrive shaft

The invention discloses a transmission device for a crane. The transmission device comprises an electric hoist machine shell, a threaded groove, a standby steel wire rope and a speed sensor. A windingdrum is arranged in the electric hoist machine shell. The threaded groove is formed in the periphery of the winding drum. The standby steel wire rope is arranged in the middle of the winding drum. The transmission device has the beneficial effects that speed sensor is arranged on a hoisting hook connecting block, the moving speed of a hook is monitored in real time, after the moving speed of thehook exceeds a certain limiting value, an electromagnetic brake locks a main transmission shaft, free-fall motion of the hook is effectively prevented from threating ground crews, and the safety performance of whole equipment is improved; and the threaded groove is formed in the winding drum, thus, the steel wire rope can be orderly arranged in the winding drum in the withdrawal process, the situation that the steel wire rope is stacked somewhere is avoided, transmission of the whole equipment is not affected, and smooth conduction of the operation is ensured.

Owner:无锡市汇鼎金属制管有限公司

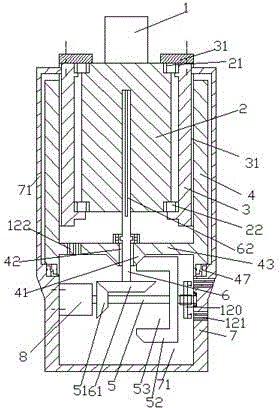

Worm rod processing mechanism with driving motor separation baffle plate

The invention relates to a worm rod processing mechanism with a driving motor separation baffle plate (111). The worm rod processing mechanism is used for processing a blank (1) into a worm rod, and comprises a blank carrying element (2), a sleeve (3) with external screw threads, a driving sleeve (4) with internal screw threads and a machine frame (7), wherein the blank carrying element (2) is used for carrying the blank (1), the upper end and the lower end of the blank carrying element (2) are respectively and fixedly arranged in the sleeve (3) with the external screw threads through an upper bearing (21) and a lower bearing (22) in a direction opposite to the axial direction of the sleeve (3) with the external screw threads, the sleeve (3) with the external screw threads is matched in the driving sleeve (4) with the internal screw threads through screw threads, and the lower end of the driving sleeve (4) with the internal screw threads is rotatablely arranged on the machine frame (7) through a thrust bearing (47).

Owner:STATE GRID CORP OF CHINA +1

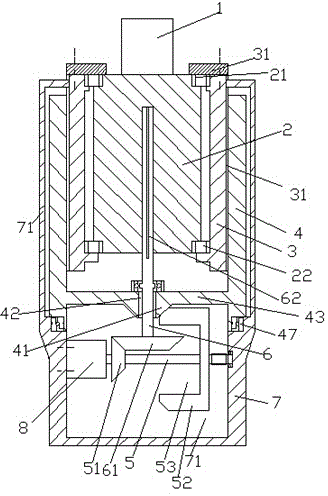

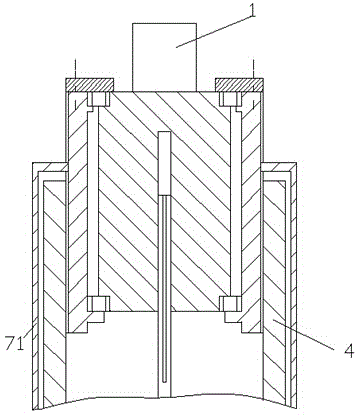

A Worm Machining Mechanism with a Lubricating Oil Supply System

InactiveCN104308280BHigh densityHigh precisionGearingGear lubrication/coolingThrust bearingEngineering

The invention discloses a worm processing mechanism with a lubricating-oil supplying system. The worm processing mechanism is used for processing a blank piece (1) into a worm and comprises a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads; the lower end of the driving sleeve (4) with the internal threads can be rotatably arranged on the rack (7) by a thrust bearing (47).

Owner:国网山东省电力公司沂源县供电公司

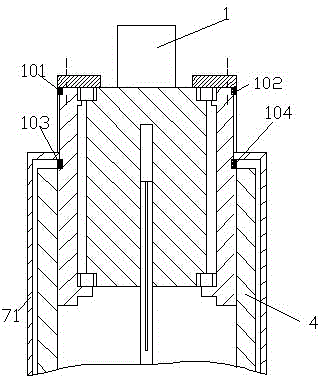

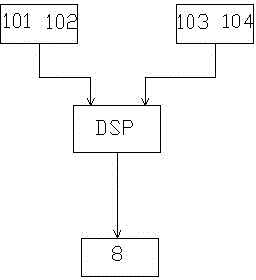

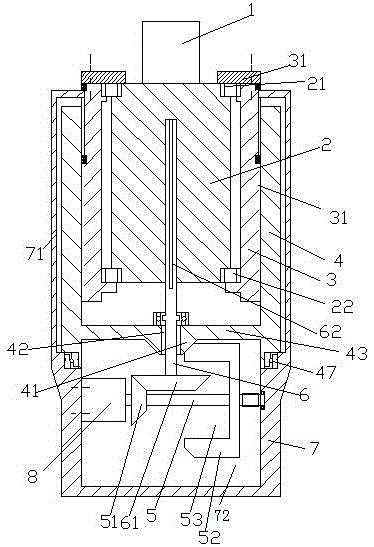

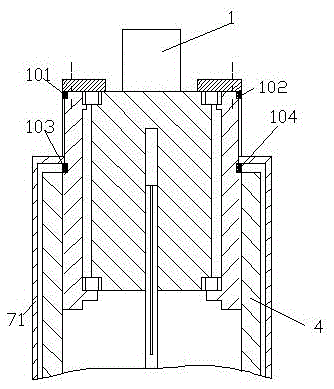

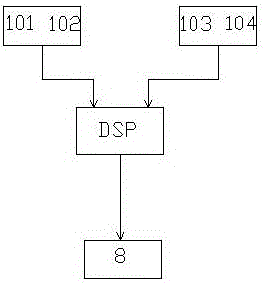

Worm processing mechanism controlled by circuit

The invention discloses a worm processing mechanism controlled by a circuit. The worm processing mechanism is used for processing a blank piece (1) into a worm and comprises a DSP (Digital Signal Processing) control circuit, a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads.

Owner:国网山东省电力公司沂源县供电公司

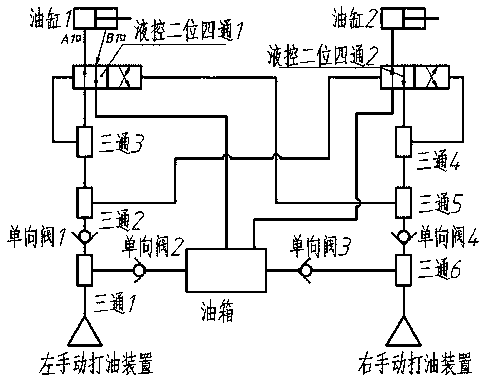

Bevel walking device

InactiveCN108791543AAchieve regulationChange angle in real timeTractorsEngineeringAgricultural machinery

The invention relates to a bevel walking device. The plane where a prime mover is located is kept level all the time through the expansion and contraction of joints, and the expansion and contractionlength of the joints is changed by means of hydraulic systems. The bevel walking device comprises expansion and contraction mechanisms and corresponding hydraulic systems, and the distance from one end of the plane where the prime mover is located to a horizontal plane is changed by changing the included angle between the expansion and contraction mechanisms so as to keep the working plane of theprime mover horizontal all the time. The requirement that the plane where the mechanism prime mover is located is in a horizontal state all the time when the ground is uneven is met, and through the combination of hydraulic components, the requirement of the mechanical system movement is met, and the problem that a walking mechanism cannot adopt to the uneven ground, such as the agricultural machinery needs to adapt to the uneven ground in the farming process is solved.

Owner:宁波协亚农业装备制造有限公司

A worm machining device

The invention provides a worm machining device. The worm machining device is used for machining a blank (1) into a worm, and comprises a movement mechanism, a base (91), an upright column (92), a milling cutter rotating driving motor (93) and a milling cutter (94); the movement mechanism is fixed on the base (91); the lower end of the upright column (92) is fixedly connected with the base (91); the milling cutter rotating driving motor (93) is mounted on the upper end of the upright column (92) and used for driving the milling cutter (94) to rotate; the milling cutter (94) is mounted on the milling cutter rotating driving motor (93) and used for cutting the blank (1); the movement mechanism comprises a blank carrying piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a frame (7).

Owner:SHENYUE FUJIAN CASTING

Spiral rising type processing equipment with four sliding grooves

The invention discloses spiral rising type processing equipment with four sliding grooves. The spiral rising type processing equipment is used for processing a blank piece (1) into a worm and comprises a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads; the lower end of the driving sleeve (4) with the internal threads can be rotatably arranged on the rack (7) by a thrust bearing (47); the rack is internally provided with a cavity (72).

Owner:STATE GRID SHANDONG ELECTRIC POWER CO LONGKOU POWER SUPPLY CO

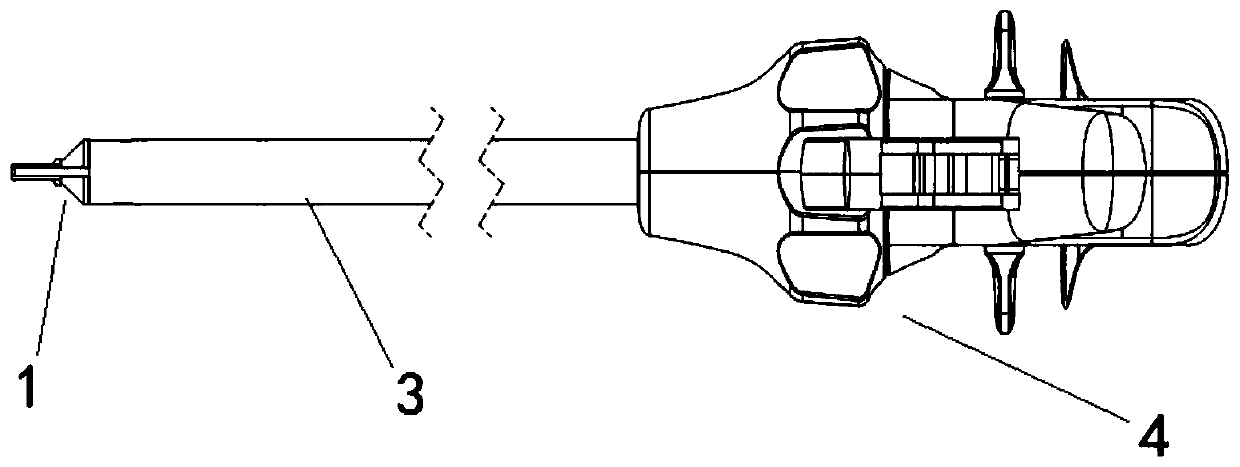

Drilling machine head box

InactiveCN109513971AIncreased strength and wear resistanceExtended service lifeBoring/drilling componentsMechanical engineeringDrilling machines

The invention relates to a drilling machine head box. A transmission device comprises a steel gear (1) and a nylon gear (2) which are matched, the nylon gear (2) comprises an inner sleeve (21) and anouter gear (22), the inner sleeve (21) is made of nylon, and the outer gear (22) is made of the nylon and fiberglass. According to the drilling machine head box, the nylon gear is arranged in a splitmode, namely the inner sleeve and the outer gear, wherein the outer gear is made of the nylon and the fiberglass, in this way, the strength and abrasion resistance of the nylon gear are enhanced, theservice life of the nylon gear is prolonged, meanwhile, the structural form of the inner sleeve and the outer gear is adopted, the using cost of the nylon gear is also lowered, and the economical efficiency is quite good.

Owner:欧普铁玛(扬州)机械有限公司

An intelligent robot for drawing and protecting water source in a fire scene

The invention discloses an intelligent robot for drawing and protecting water source in a fire site. A slide-out rod is provided, a platform box is fixed on the upper end surface of the connecting cylinder, a support plate is fixed on the upper end surface of the platform box, the platform box is a box-type structure, and the support plate and the platform box are set There is a conduit, and the outside of the conduit is provided with an outer ring restricting device to block garbage. This equipment adopts the design of the outer ring restricting device, filter box replacement device and transmission connection matching device, so that the device can be installed in the water body. Efficient blocking and removal of debris on the water supply pipe at the fire scene ensures the smooth water supply for fire rescue, greatly improves the working efficiency of the equipment, and also ensures the progress and efficiency of fire rescue.

Owner:高唐融知融智科技服务有限公司

A spiral rising processing equipment with four chutes

The invention discloses spiral rising type processing equipment with four sliding grooves. The spiral rising type processing equipment is used for processing a blank piece (1) into a worm and comprises a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads; the lower end of the driving sleeve (4) with the internal threads can be rotatably arranged on the rack (7) by a thrust bearing (47); the rack is internally provided with a cavity (72).

Owner:国网山东省电力公司沂源县供电公司

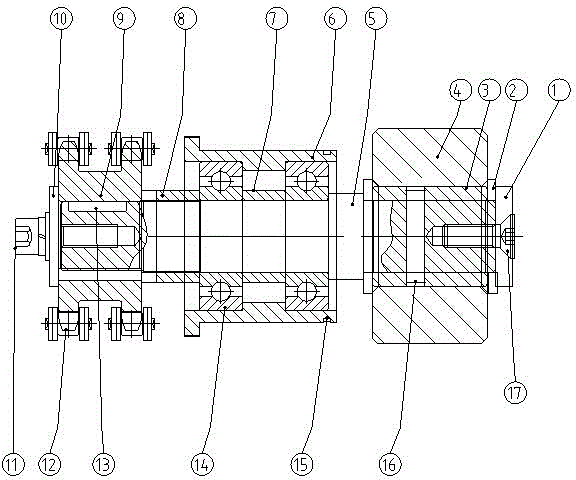

Copper shaft coupling roller

The invention relates to a copper shaft coupling roller, which comprises a first shaft end cover, an insulation pad, a self-lubricating copper sleeve, a roller, a short shaft, a bearing sleeve, a first spacer sleeve, a second spacer sleeve, a chain wheel, a second shaft end cover, a screw component, chains, a flat key, a deep groove ball bearing, an elastic check ring, a cylindrical pin and a sunk screw. According to the copper shaft coupling roller, by virtue of different friction coefficients between copper and steel, the copper shaft coupling roller in the technical scheme can unidirectionally rotate; in addition, when a plurality of copper shaft coupling rollers are arranged abreast for use, all shaft coupling rollers can rotate together in the same direction through the chains which are buckled in pairs only by virtue of one power mechanism, thereby driving a workpiece to move; moreover, when the workpiece is required to be positioned, the workpiece is only required to be blocked with very tiny force, and the copper shaft coupling roller at the positioned workpiece stops without influence on the transmission of the chain wheel by the chain.

Owner:利钛威自动化系统设备(苏州)有限公司

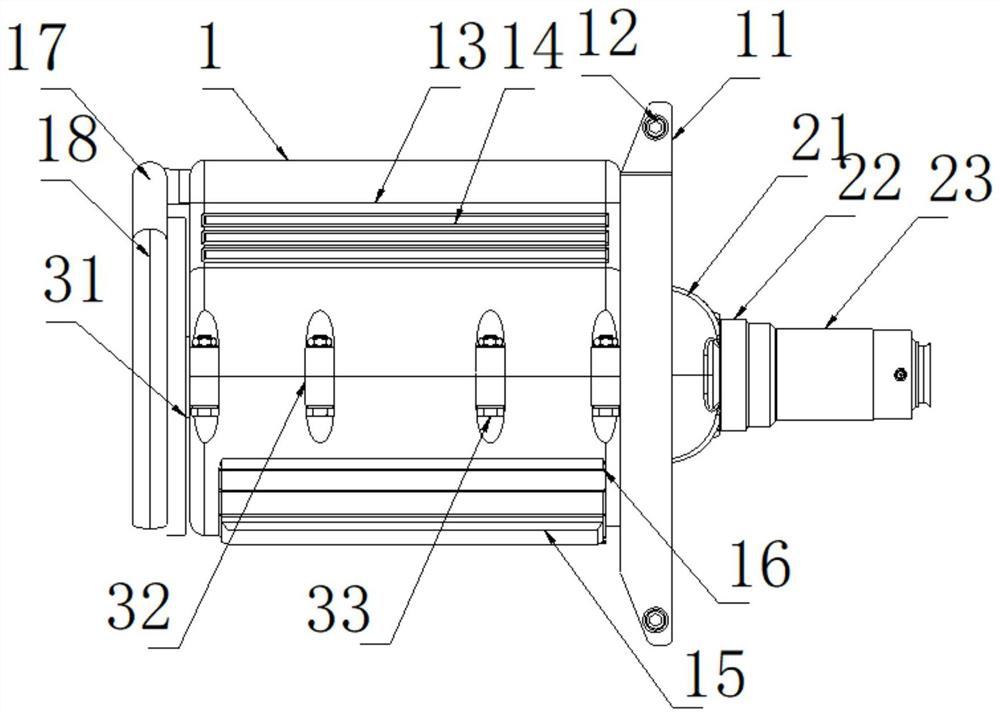

Permanent magnet synchronous motor convenient for heat dissipation

InactiveCN112018958AAdd supportImprove water cooling effectMechanical energy handlingCooling/ventillation arrangementElectric machineDrive shaft

The invention relates to the technical field of motors, and concretely relates to a permanent magnet synchronous motor convenient for heat dissipation. The motor comprises a motor body, a fixing frameis installed on the shell wall of the motor body, the two ends of the fixing frame extend outwards in a wing shape and are externally connected with locking bolts, a cooling pipe is arranged on the rear side of the motor body, a cooling pipe is mounted on the rear side wall of the motor body, the cooling pipe is of a multi-annular structure and is wound at the rear end of the motor body, the upper portion of the cooling pipe is divided into a plurality of circulation branch pipes, the circulation branch pipes are externally connected with a first water cooling frame and a second water coolingframe respectively, a heat conduction shaft is installed at the driving end of the motor body and comprises a shaft body, an inner edge shaft is arranged in the shaft body, a transmission shaft coreis further arranged in the inner edge shaft, and a plurality of heat conduction blocks are arranged on the inner edge shaft. The motor is cooled from outside to inside, and shaft transmission is not affected on the basis that heat conduction is guaranteed.

Owner:江苏航迅飞信息科技有限公司

A worm machining mechanism with a driving motor partition

Owner:STATE GRID CORP OF CHINA +1

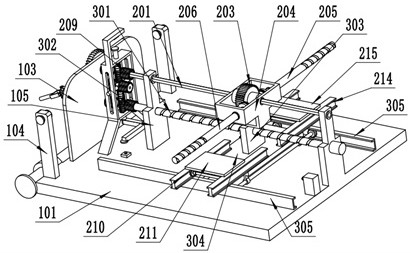

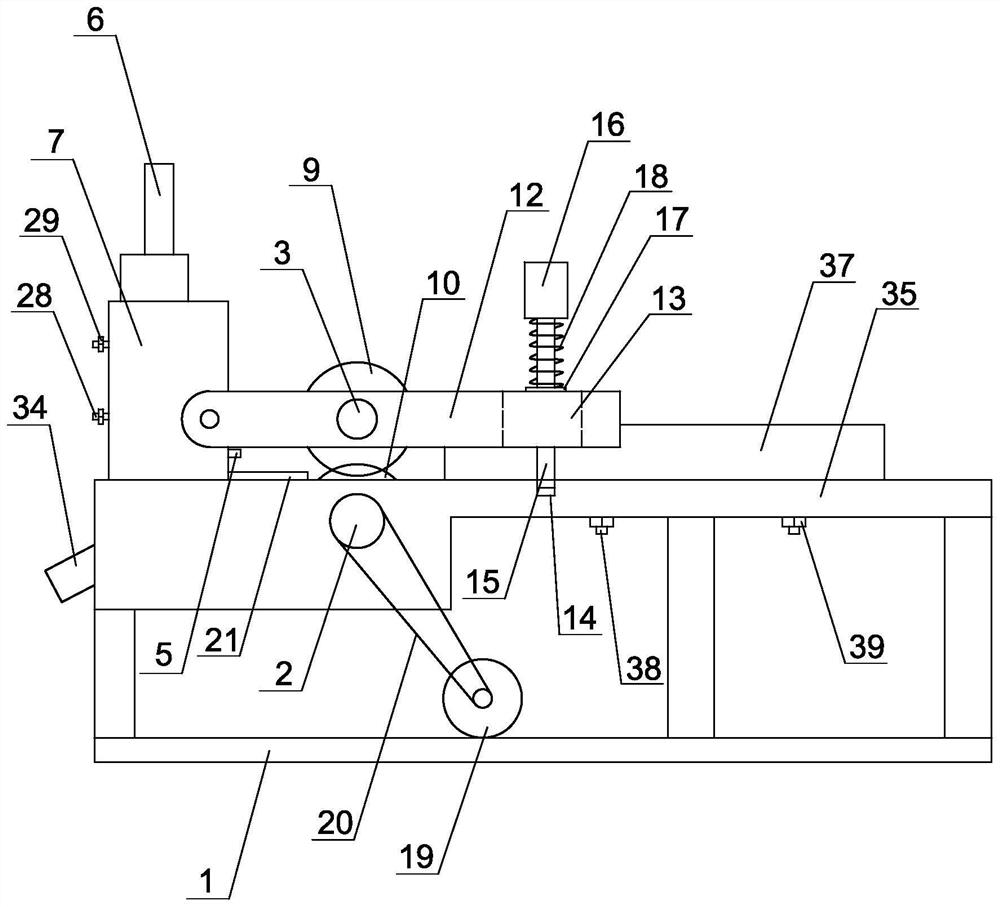

High-performance automatic cutting equipment for insulating sleeve of cable connector

PendingCN114474185AReduce labor intensityRealize automatic cuttingMetal working apparatusStructural engineeringElectric cables

The invention discloses high-performance automatic cutting equipment for an insulating sleeve of a cable connector, and is characterized in that the high-performance automatic cutting equipment comprises a rack, a conveying mechanism and a cutting mechanism, the conveying mechanism comprises a bottom transmission roller, a pressing roller and a driving mechanism, the driving mechanism drives the bottom transmission roller to rotate, and the pressing roller is driven by the driving mechanism to rotate; the pressing roller is arranged above the bottom transmission roller in parallel, and the pressing roller is connected with the bottom transmission roller through a transmission piece; the cutting mechanism comprises a cutter, a pressing plate and a vertical air cylinder, two sets of vertical plates are arranged at the top of the rack, the inner walls of the two sets of vertical plates are each provided with a vertical sliding groove, the two ends of the cutter are arranged in the two sets of vertical sliding grooves in a sliding mode, the cutter is arranged on the left side of the pressing roller, and the pressing plate is arranged on the right side of the pressing roller. The pressing plate is arranged between the cutter and the pressing roller, and the pressing plate is connected with the right side of the cutter through a connecting mechanism. According to the invention, the cutting efficiency and quality are improved, and the labor intensity of operators is reduced.

Owner:太仓泰柯尼电缆有限公司

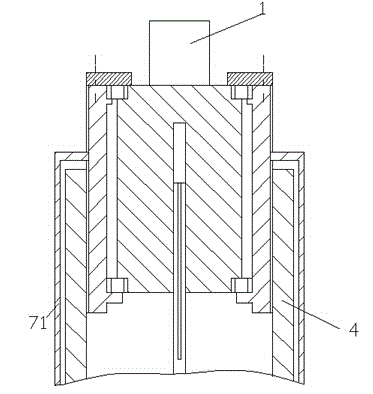

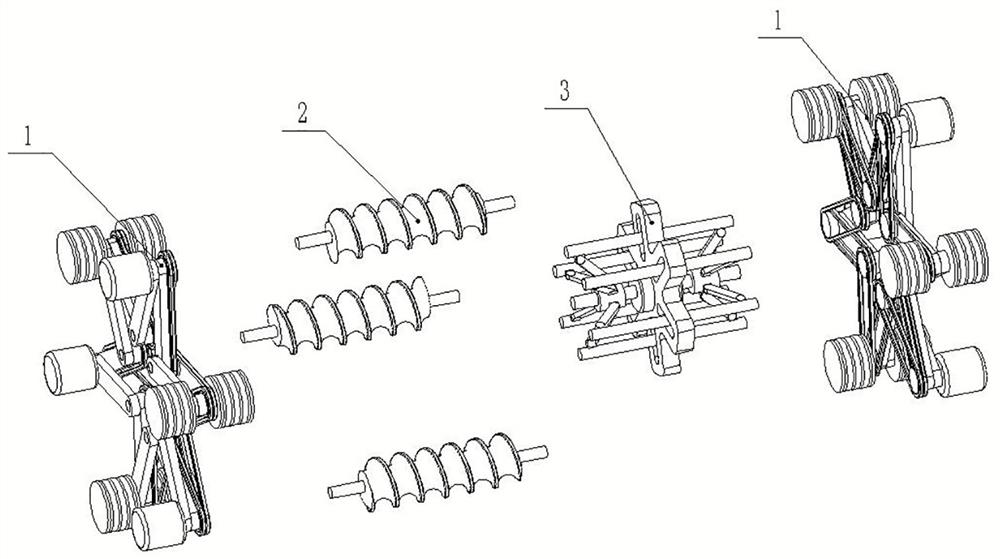

Worm machining mechanism

A worm machining mechanism is used for machining a blank (1) into a worm; the machining mechanism comprises a blank carrier (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7); the blank carrier (2) is used for carrying the blank (1); the upper end and the lower end of the blank carrier (2) are axially fixedly mounted in the sleeve (3) with the external threads relative to the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22); the sleeve (3) with the external threads is in threaded fit in the driving sleeve (4) with the internal threads; the lower end of the driving sleeve (4) with the internal threads is rotatably arranged on the rack (7) by a thrust bearing (47); a chamber (72) is arranged in the rack (7).

Owner:国网山东省电力公司沂源县供电公司

A worm processing mechanism capable of automatic upper and lower limit

Owner:广州德纳科技股份有限公司

Worm processing mechanism with lubricating-oil supplying system

InactiveCN104308280AHigh densityHigh precisionGearingGear lubrication/coolingThrust bearingEngineering

The invention discloses a worm processing mechanism with a lubricating-oil supplying system. The worm processing mechanism is used for processing a blank piece (1) into a worm and comprises a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads; the lower end of the driving sleeve (4) with the internal threads can be rotatably arranged on the rack (7) by a thrust bearing (47).

Owner:国网山东省电力公司沂源县供电公司

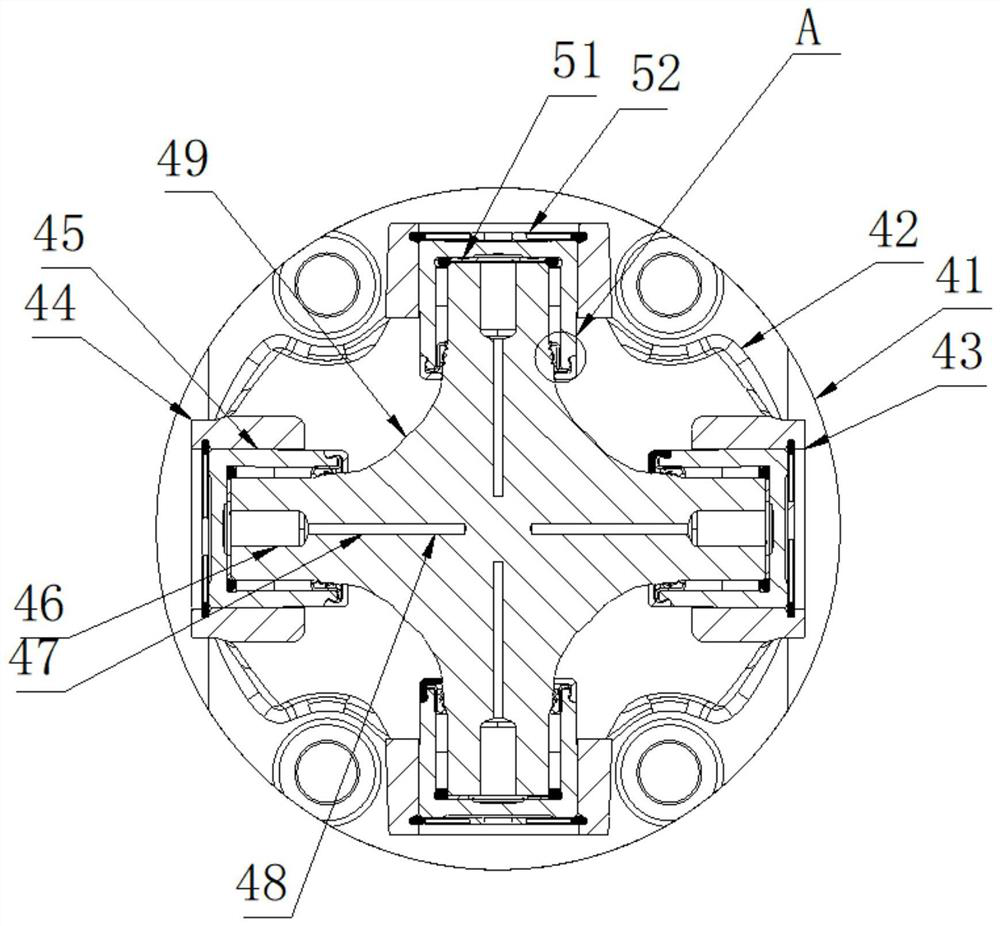

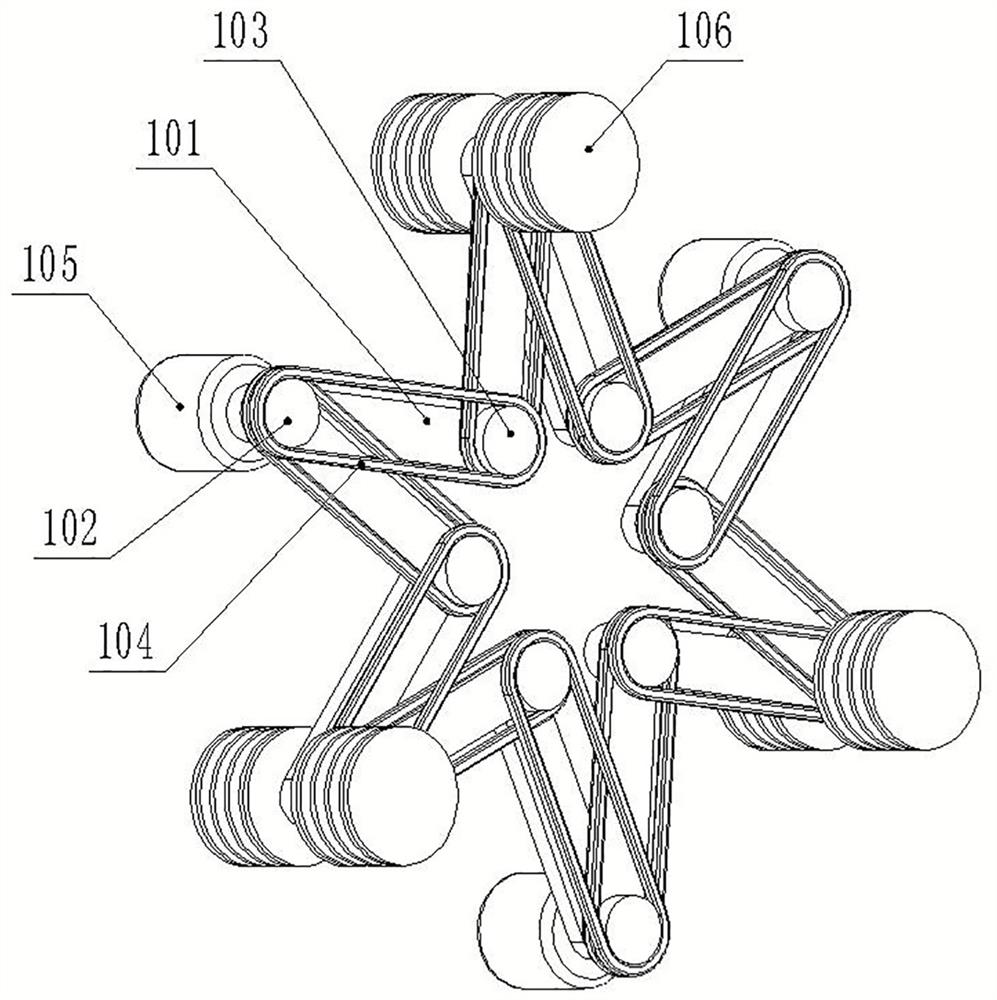

Polishing device for inner wall of pressure pipeline

ActiveCN114770352ALarge diameter rangeWide range of applicationsPolishing machinesNuclear energy generationPhysicsPolishing

The invention relates to the technical field of pipeline machining, in particular to a pressure pipeline inner wall polishing device which comprises an executing mechanism, a polishing mechanism, a polishing mechanism, a polishing mechanism and a polishing mechanism, the executing mechanism is of a regular polygon connecting rod structure formed by hinging a plurality of connecting rods, and polishing wheels are rotationally arranged at the hinged positions of the outer sides of the connecting rods; the driving mechanism is used for driving the regular polygon connecting rod structure to stretch. Spiral shafts are further rotationally arranged at the hinged positions of the outer sides of the connecting rods, and the spiral shafts and the polishing wheels are arranged at intervals. A first rotating wheel and a third rotating wheel are rotationally arranged at the outer side hinging position of the connecting rod and are arranged at an interval, and a second rotating wheel is rotationally arranged at the inner side hinging position of the connecting rod; the second rotating wheel and the first rotating wheel are in transmission through a transmission belt, and the second rotating wheel and the third rotating wheel are in transmission through a transmission belt; the spiral shaft is arranged on the first rotating wheel, and the polishing wheel is arranged on the third rotating wheel. The invention further discloses a pressure pipeline inner wall polishing method, pressure pipelines with different pipe diameters can be ground and polished, the structure is simple and compact, and the working efficiency is high.

Owner:欧米勒电气有限公司

Transversal stapler with sealing structure for laparoscopic surgery

ActiveCN111588430BWill not affect transmissionGuaranteed tightnessSurgical staplesEngineeringEndoscopic surgery

The invention provides a transverse intracavity stitching instrument with a sealing structure. The stitching instrument comprises an end executor, a connecting outer tube and a driving assembly at least partially arranged in the connecting outer tube, and is characterized in that the end executor comprises a nail bin shell, a stitching nail and a nail pushing block; the driving assembly comprisesa driving push rod and a driving shell; the driving push rod is used for driving the nail pushing block to push the stitching nail upwards; the driving shell is used for driving the nail bin shell; the near end of the driving shell is connected with a hollow driving connecting rod, and the driving push rod sequentially penetrates through an inner cavity of the hollow driving connecting rod and aninner cavity of the driving shell; a first sealing ring is arranged between the driving push rod and the hollow driving connecting rod; and a second sealing ring is arranged between the hollow drivingconnecting rod and the connecting outer pipe. The driving mechanism of the transverse stitching instrument is improved to be connected and driven by adopting a cylindrical element, and a sealing device is correspondingly arranged at the key part, so that the transmission is not influenced, the sealing property can be ensured, and the transverse stitching instrument is suitable for endoscopic surgery and the air leakage condition in the surgery process is prevented.

Owner:SUZHOU BEINUO MEDICAL EQUIP

A power transmission device of an orchard machine

InactiveCN109130846AImprove versatilityImprove stabilityPortable liftingToothed gearingsElectric power transmissionCoupling

The invention discloses a power transmission device for an orchard machine, including an engine and a transmission, the engine and the transmission are connected by means of a connector seat, the power output end of the engine is provided with a power output connecting part, the power input end of the transmission is provided with a coupling, and the connecting seat is provided with a driving gearand a driven gear which are meshed with each other, the other end of the driving gear is connected with the power output connecting part, and the other end of the driven gear is connected with the coupling; a connecting seat is arranged between the engine and the gearbox as a transitional connection, and the connecting seat can be applied to different engines, thereby improving the universality of the engine on the orchard machine and reducing the difficulty of maintenance and parts configuration of the orchard machine. In addition, a driving gear and a driven gear which are mutually meshed are arranged in the connecting seat, so that the transmission can be directly connected with the engine through the meshing of the driving gear and the driven gear, the extension deformation of the transmission can be avoided, and the speed and efficiency of the power transmission can be improved.

Owner:重庆雄狮机械有限责任公司

A circuit-controlled worm machining mechanism

The invention discloses a worm processing mechanism controlled by a circuit. The worm processing mechanism is used for processing a blank piece (1) into a worm and comprises a DSP (Digital Signal Processing) control circuit, a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads.

Owner:国网山东省电力公司沂源县供电公司

A Worm Processing Mechanism with Removable Small Bevel Gear Parts on the Horizontal Wall

A demountable worm processing mechanism of a bevel pinion piece at a horizontal wall is used for processing a blank piece (1) into a worm; the processing mechanism comprises a blank piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank piece bearing piece (2) is used for bearing the blank piece (1); the upper end and the lower end of the blank piece bearing piece (2) are respectively and fixedly mounted inside the sleeve (3) with external threads relative to the axial direction of the sleeve (3) with external threads by an upper bearing (21) and a lower bearing (22); the sleeve (3) with external threads is matched with the driving sleeve (4) with internal threads by threads; the lower end of the driving sleeve (4) with internal threads is rotatably mounted on the rack (7) by a thrust bearing (47); a cavity (72) is formed inside the rack (7).

Owner:国网山东省电力公司沂源县供电公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com