Permanent magnet synchronous motor convenient for heat dissipation

A permanent magnet synchronous motor and body technology, which is applied to electrical components, electromechanical devices, electric components, etc., can solve the problems of motor burnout, inability to cool the motor, and the ideal heat dissipation effect is not very good, so as to expand the contact area and improve the support force. , Improve the effect of water cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

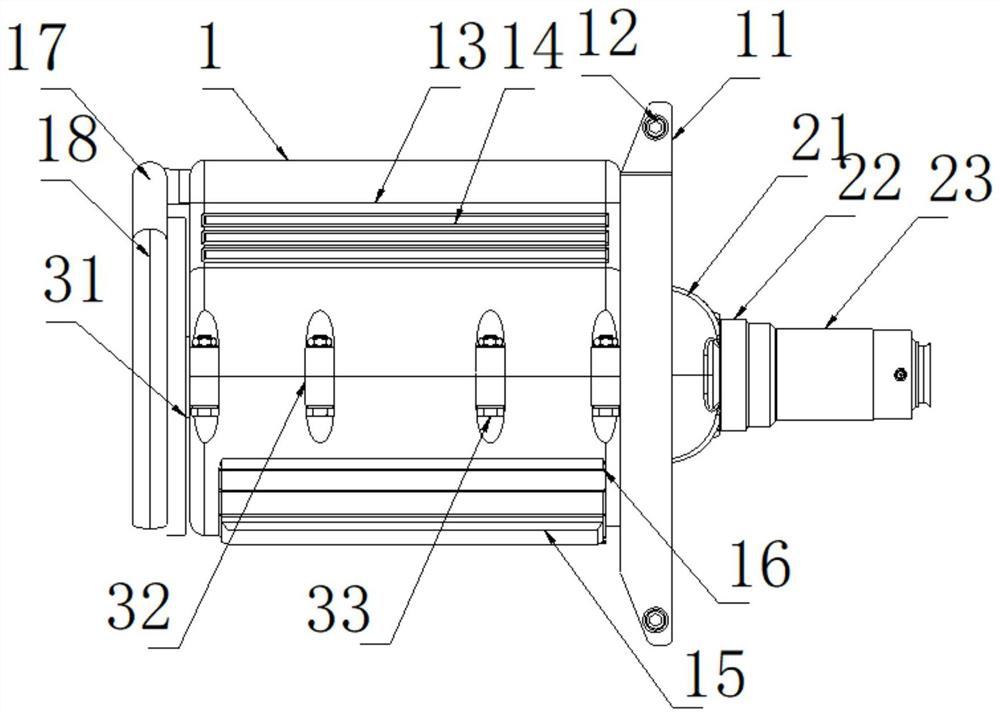

[0027] see figure 1 and figure 2 , a permanent magnet synchronous motor that facilitates heat dissipation, including a motor body 1, a fixed frame 11 is installed on the housing wall of the motor body 1, and the two ends of the fixed frame 11 extend outward in a wing shape and are externally connected with a lock Bolt 12, the rear side of the motor body 1 is provided with a cooling pipe 17, the cooling pipe 17 is installed on the rear side wall of the motor body 1, the cooling pipe 17 has multiple ring structures and is wound around the rear of the motor body 1 end, the upper branch of the cooling pipe 17 is divided into several circulation branch pipes 18, and the circulation branch pipes 18 are respectively externally connected with a first water cooling frame 13 and a second water cooling frame 15, and the first water cooling frame 13 and the second water cooling frame 15 Several channels are provided and installed on the casing of the motor body 1, the first water coolin...

Embodiment 2

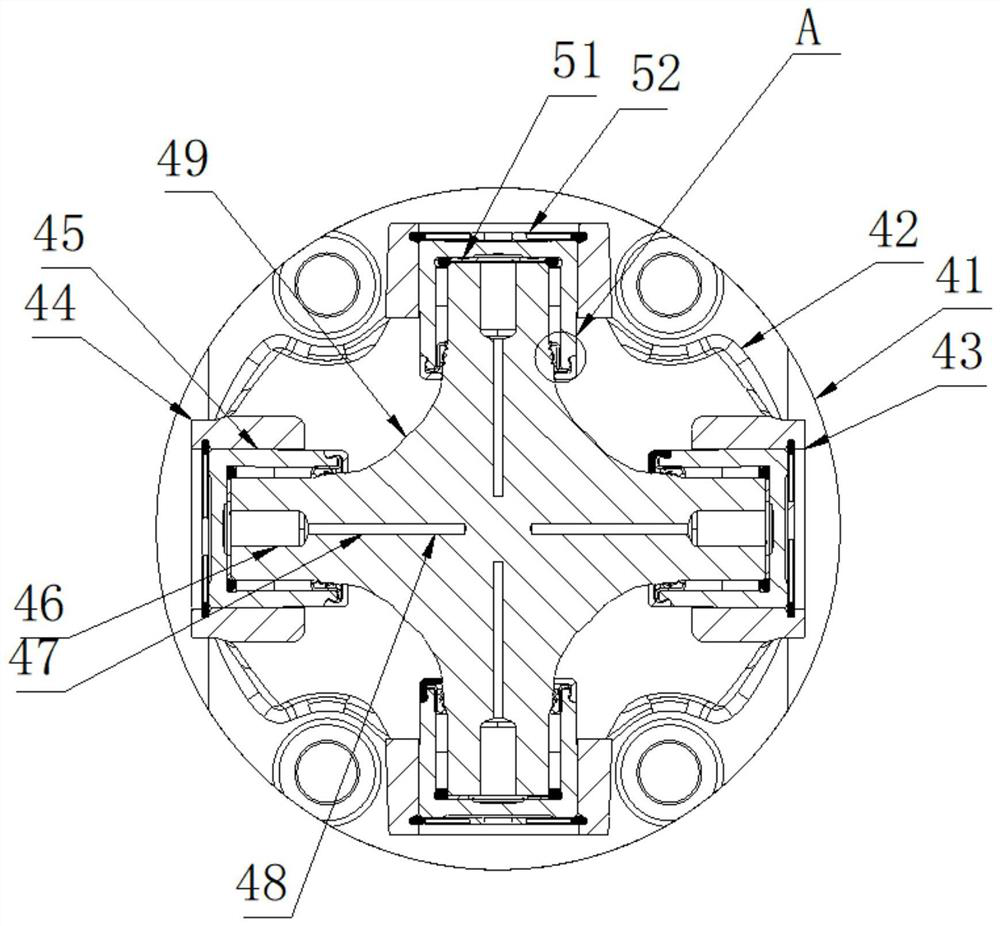

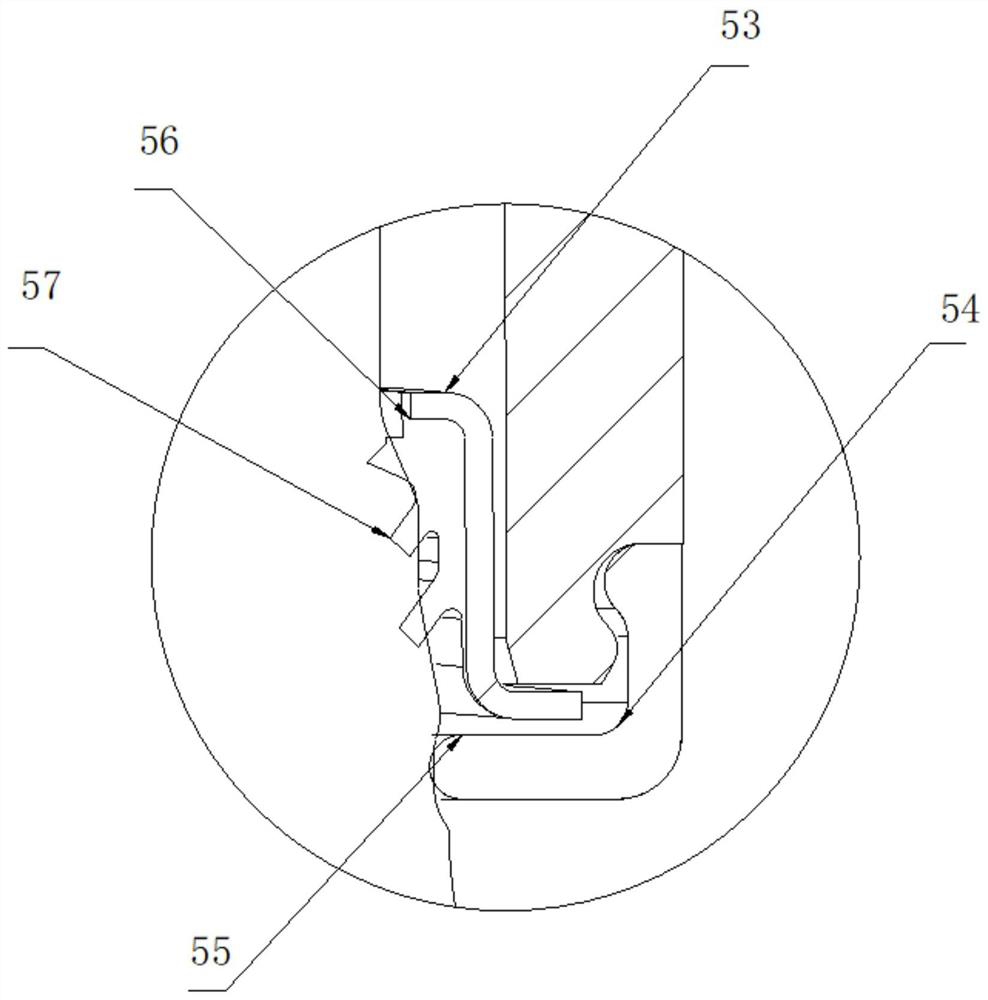

[0034] see figure 2 and image 3 , this embodiment serves as a further optimization of Embodiment 1. On the basis of this, the outer conduction block 44 and the inner conduction block 45 are installed and fixed through the first inner frame 51, and the inner conduction block 45. The embedded block 46 is installed and fixed through the second inner frame 52, and the bottom ends of the first inner frame 51 and the second inner frame 52 are respectively provided with a first chassis end 53 and a second chassis end 54 , the first chassis end 53 and the second chassis end 54 are fixed into an integrated structure through the arc-shaped connection end 55, and the side of the arc-shaped connection end 55 is also provided with an inner cog groove 56, the The internal cogging groove 56 is engaged with the drive shaft core 49 in the form of internal teeth.

[0035] For the structure of the heat conduction shaft 23, the application also needs to maintain its stability. The outer layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com