Spiral rising type processing equipment with four sliding grooves

A kind of processing equipment, spiral rising technology, applied in the direction of metal processing equipment, components with teeth, mechanical equipment, etc., can solve the problem of worm gear tooth shape, it is difficult to meet the cost reduction and improve the processing speed and accuracy, and it is difficult to ensure the shape of the tooth groove bit precision etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

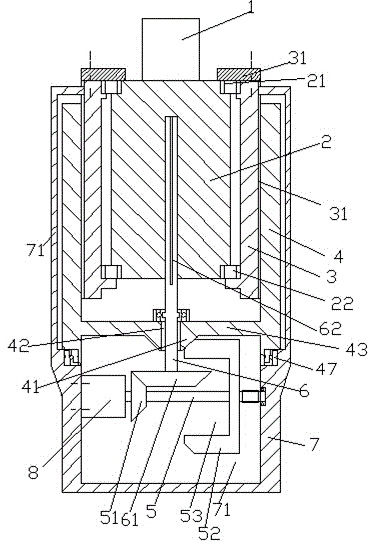

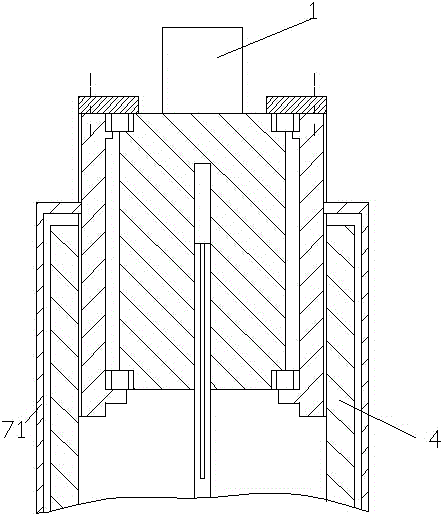

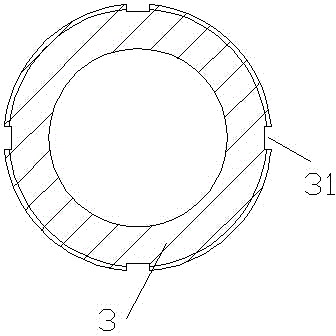

[0014] Attached below Figure 1-2 , the present invention will be described in detail.

[0015] A spiral-rising processing equipment with four chutes for processing a blank 1 into a worm, the processing equipment includes a blank carrier 2, a sleeve 3 with external threads, and a drive sleeve with internal threads 4 and the frame 7, the blank carrier 2 is used to carry the blank 1, and the upper end and the lower end of the blank carrier 2 pass through the upper bearing 21 and the lower bearing 22 respectively relative to the sleeve 3 shafts with external threads It is fixedly installed in the sleeve 3 with external thread, and the sleeve 3 with external thread is screwed into the drive sleeve 4 with internal thread, and the drive sleeve 4 with internal thread The lower end of the frame 7 can be rotatably installed on the frame 7 through the thrust bearing 47, and the inside of the frame 7 has a chamber 72, and in the cavity 72, a driving motor is fixed on the left inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com