Copper shaft coupling roller

A technology of copper coupling shaft and roller, applied in the field of mechanical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

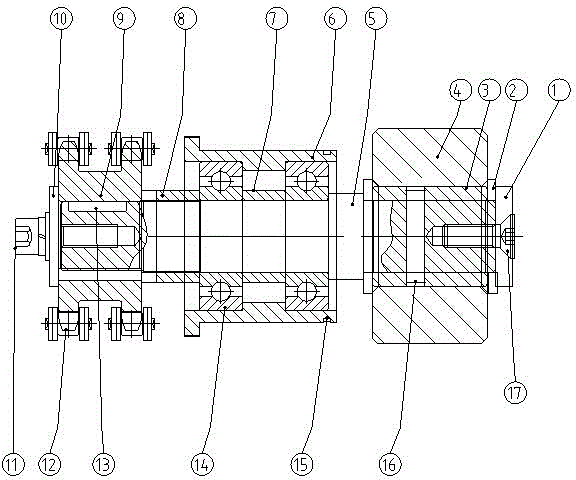

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] Copper coupling roller, including shaft end cover 1, spacer 2, self-lubricating copper sleeve 3, roller 4, short shaft 5, bearing sleeve 6, spacer 1 7, spacer 2 8, sprocket 9, shaft end cover 210. Screw assembly 11, chain 12, flat key 13, deep groove ball bearing 14, circlip 15, cylindrical pin 16, countersunk screw 17, characterized in that the self-lubricating copper sleeve 3 is set on one end of the short shaft 5, A roller 4 is arranged outside the self-lubricating copper sleeve 3, and one end of the self-lubricating copper sleeve 3 and the short shaft 5 is fixed by a cylindrical pin 16, and the shaft end cover 1 is limited by the spacer 2 to the self-lubricating copper sleeve 3 and the roller 4 , the shaft end cover 1 is fixed by countersunk head screws 17, the middle part of the short shaft 5 is provided with a spacer 7, and the two ends of the spacer 17 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com