Worm rod processing mechanism with driving motor separation baffle plate

A technology for driving motors and processing mechanisms, applied to components with teeth, worms, mechanical equipment, etc., can solve problems such as troublesome worm gear tooth shape, difficulty in meeting cost reduction, improving processing speed and precision, and low efficiency of worm transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

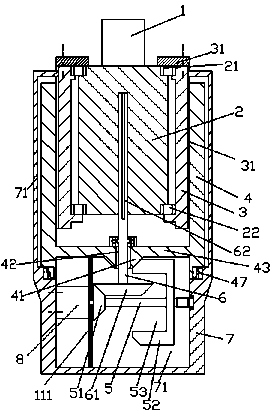

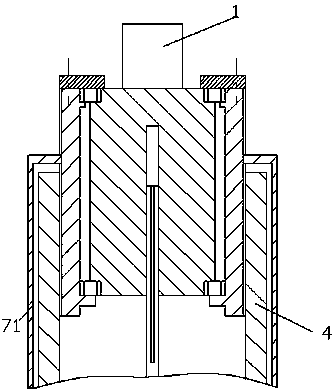

[0014] Attached below Figure 1-2 , the present invention will be described in detail.

[0015] A worm processing mechanism with a drive motor baffle plate 111, used to process a blank 1 into a worm, the processing mechanism includes a blank carrier 2, a sleeve 3 with external threads, and a drive sleeve with internal threads The cylinder 4 and the frame 7, the blank carrier 2 is used to carry the blank 1, the upper end and the lower end of the blank carrier 2 are respectively relative to the sleeve 3 with external thread through the upper bearing 21 and the lower bearing 22 Axially fixedly installed in the sleeve 3 with external thread, the sleeve 3 with external thread is screwed into the drive sleeve 4 with internal thread, and the drive sleeve with internal thread The lower end of 4 is rotatably mounted on the frame 7 through the thrust bearing 47, and the inside of the frame 7 has a chamber 72, and in the chamber 72, a drive is fixed on the left inner wall of the chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com