Drilling machine head box

A headstock and inner sleeve technology is applied in the components of boring machines/drilling machines, drilling/drilling equipment, metal processing equipment, etc. Abrasion resistance, good connection effect, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

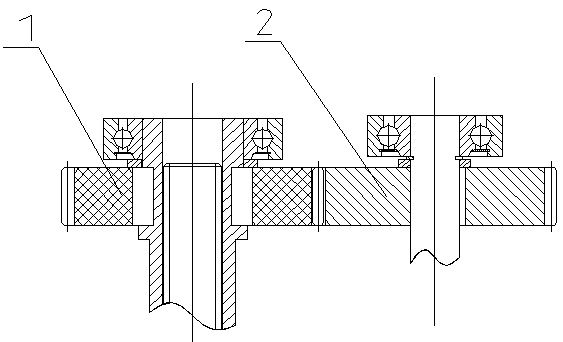

[0014] The present invention comprises transmission device, and described transmission device comprises steel gear 1 and nylon gear 2 that cooperate, and described nylon gear 2 comprises inner sleeve 21 and outer gear 22, and described inner sleeve 21 is made of nylon, and described outer gear 22 made of nylon and fiberglass.

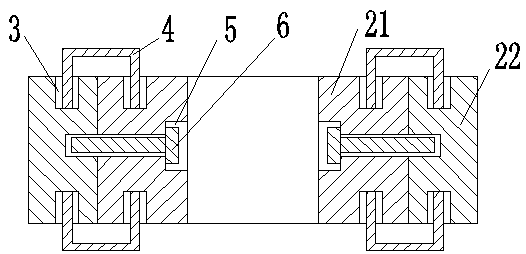

[0015] Corresponding connecting holes 3 are respectively provided on the upper and lower surfaces of the inner sleeve 21 and the outer gear 22 , and door-shaped connectors 4 are provided to pass through the connecting holes 3 to form the connection between the inner sleeve 21 and the outer gear 22 .

[0016] The inner sleeve 21 and the outer gear 22 are provided with a radial fastening hole 5 along the radial direction, and a fastener 6 is provided to pass through the fastening hole 5 to form a connection between the inner sleeve 21 and the outer gear 22 .

[0017] The fastening holes 5 of the inner sleeve 21 form steps, and the fasteners 6 are recessed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com