Patents

Literature

36results about How to "Does not affect the fixed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

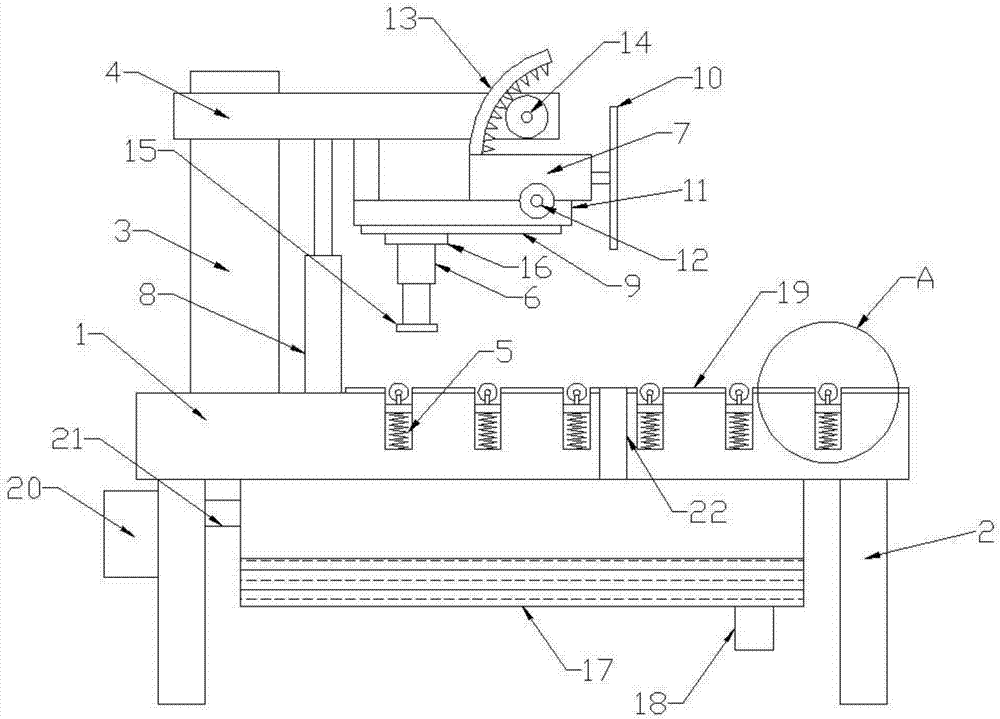

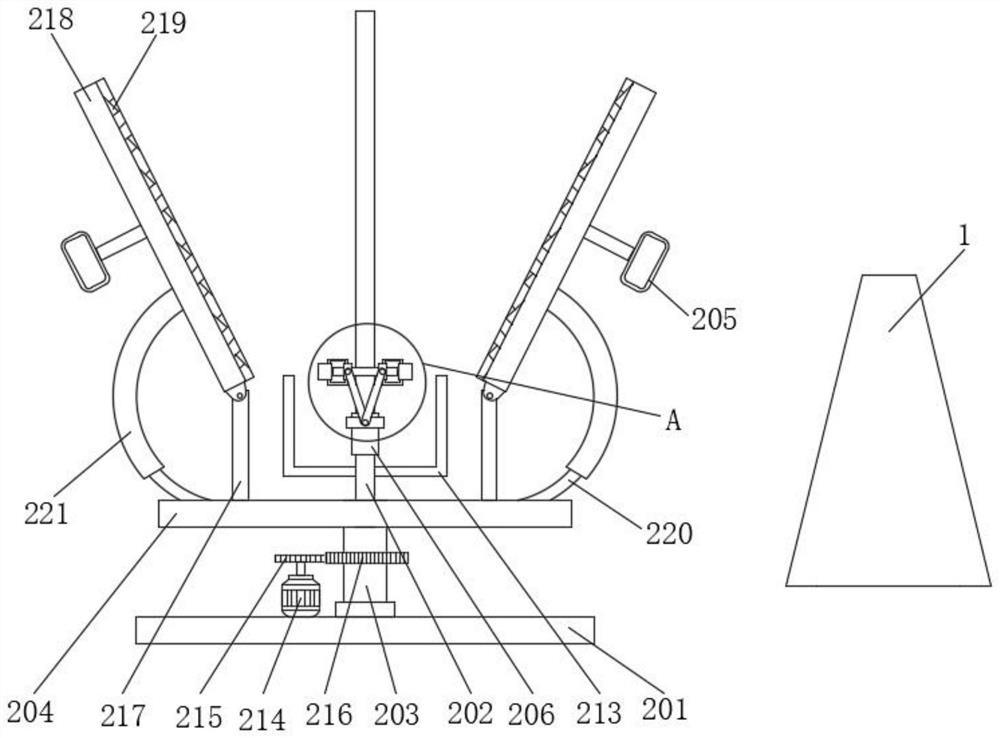

Angle-adjustable steel plate cutter

InactiveCN106964833ADoes not affect the fixedConducive to subsequent processingShearing machinesMaintainance and safety accessoriesGear driveSheet steel

The invention discloses an angle-adjustable steel plate cutting machine, which comprises a platform, supporting legs, uprights and beams; a mounting frame is fixedly installed on the lower side of the beam; a rotating shaft is installed on the end of the mounting frame; ; The upper side of the motor is fixedly connected with an arc-shaped guide rod, and a plurality of equidistant teeth are arranged on the lower side of the guide rod, and a gear is connected through the meshing of the teeth, and a water tank is communicated below the cutting opening; Several supporting mechanisms are arranged on the platform and on both sides of the cutting opening, and the supporting mechanisms are composed of grooves, springs, supporting plates and guide wheels. The invention supports the steel plate through the support mechanism, so that the steel plate can easily move left and right on the platform, reducing the labor intensity of workers; the gear drives the guide rod to move, so that the motor rotates around the rotating shaft, and the cutting of the steel plate forms an angle with the horizontal plane. Surface cutting, so that the cutting machine has a variety of functions to meet more production needs.

Owner:惠安县鑫泰信息科技有限公司

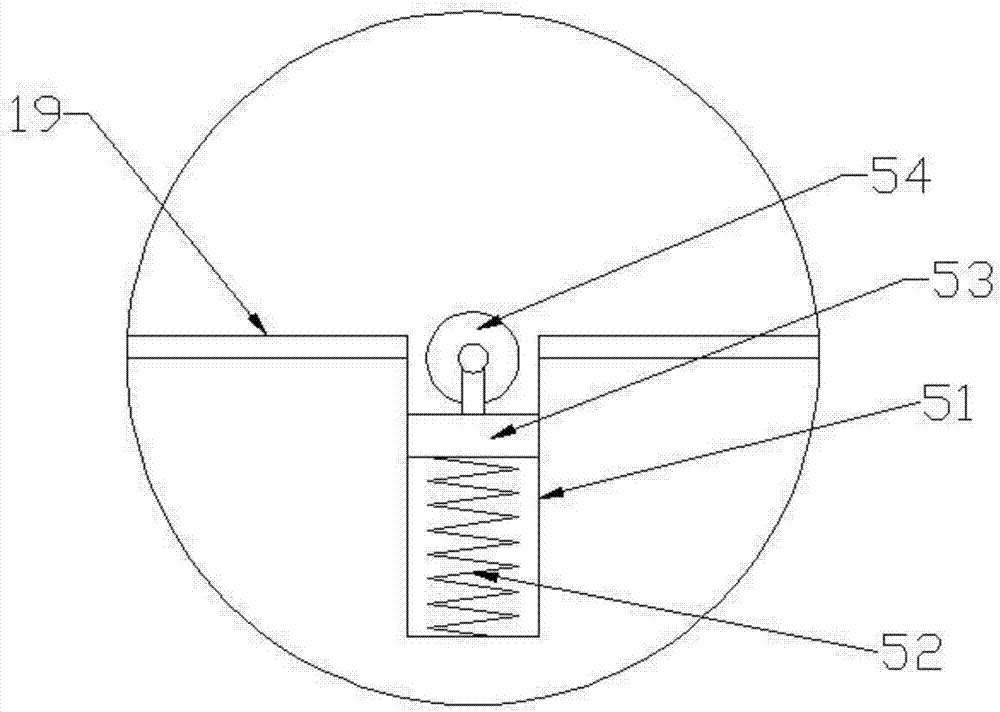

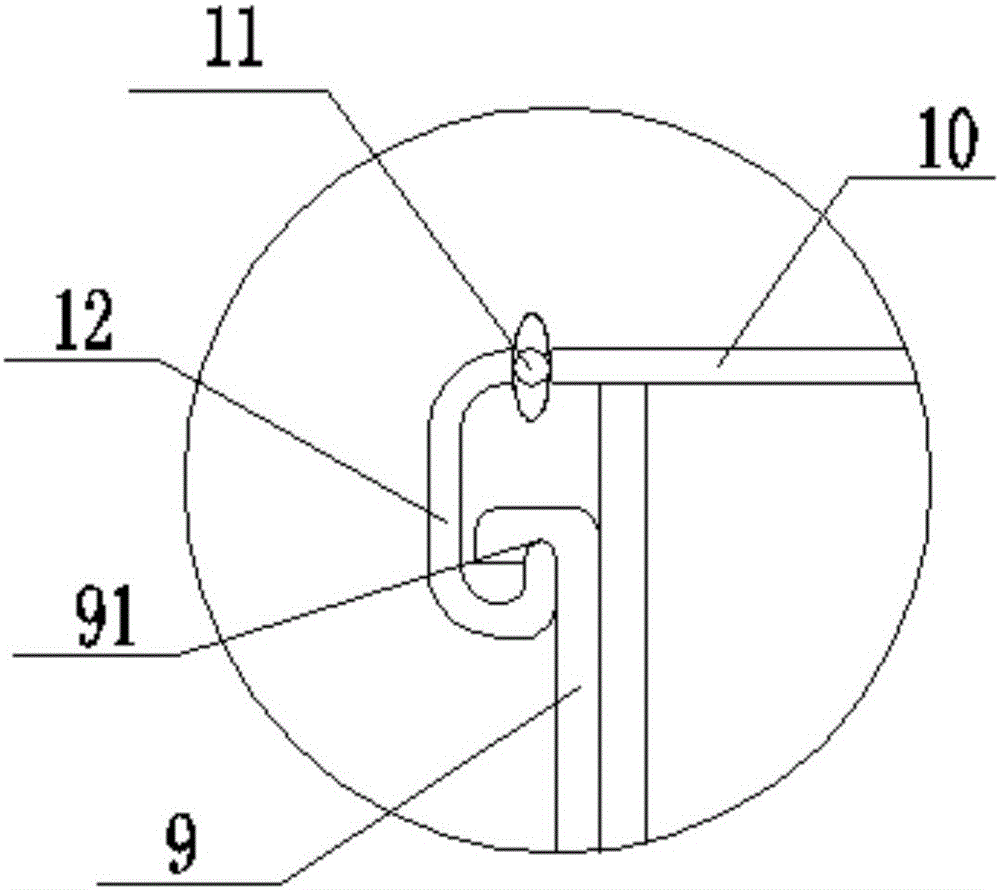

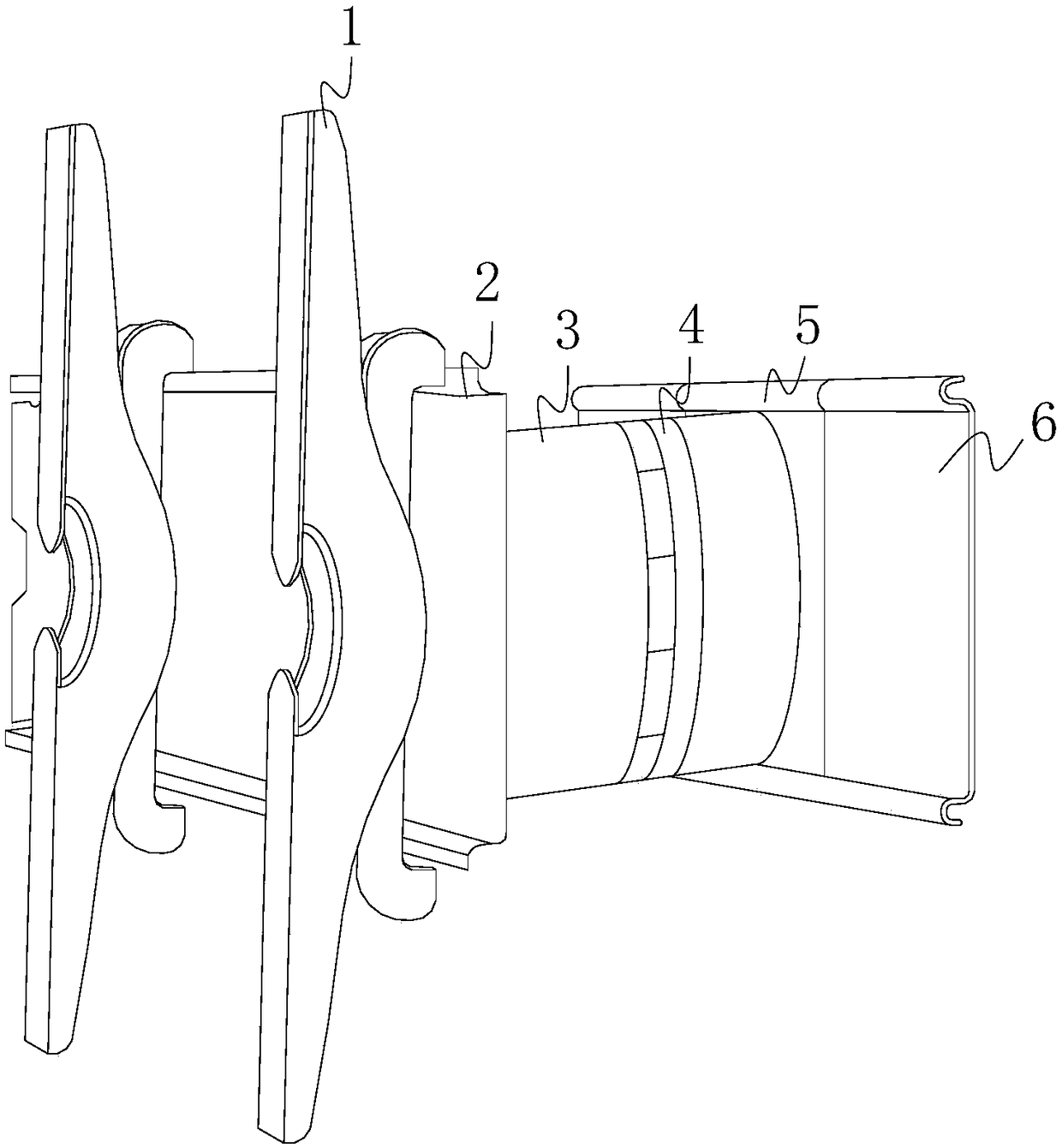

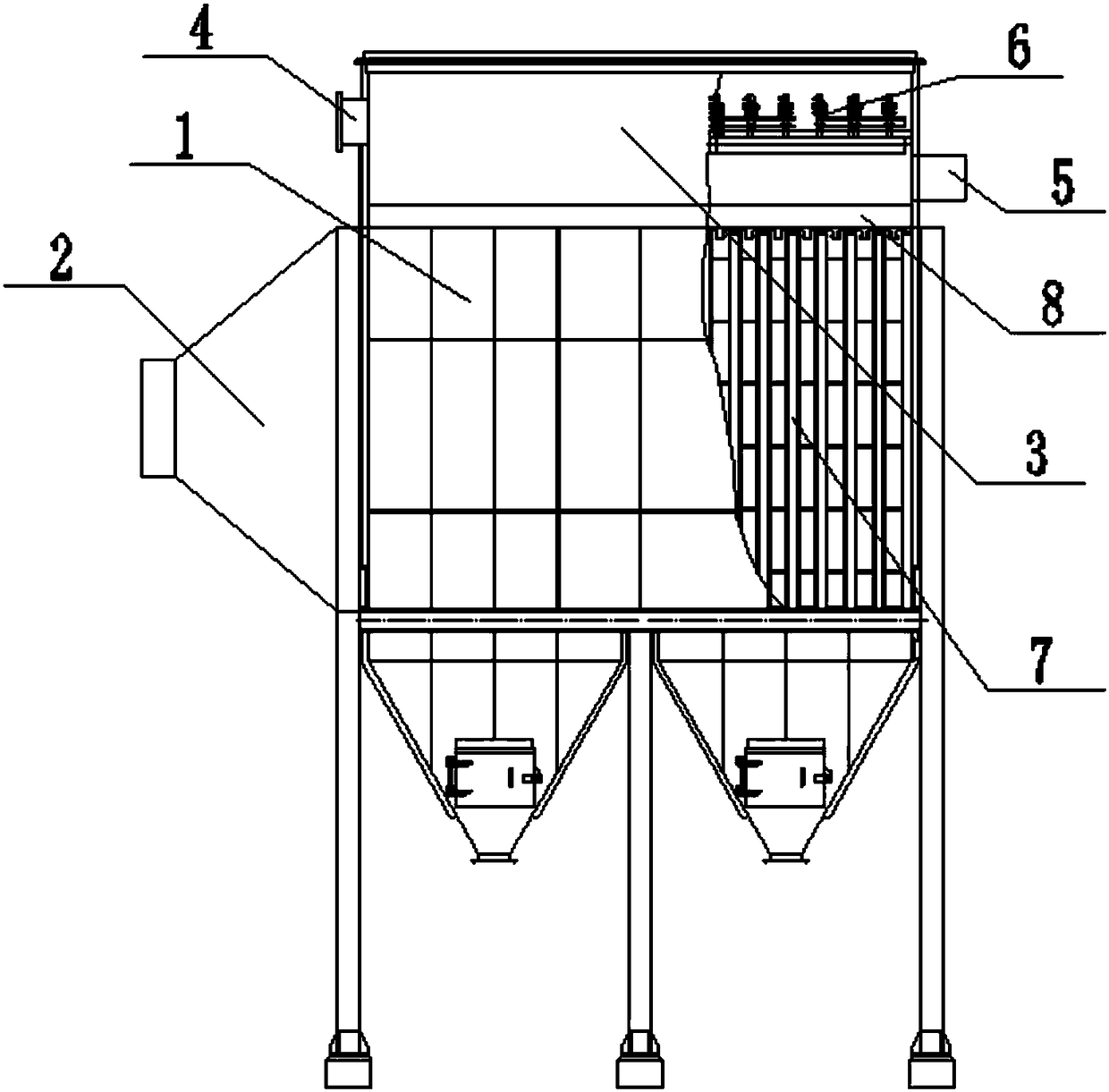

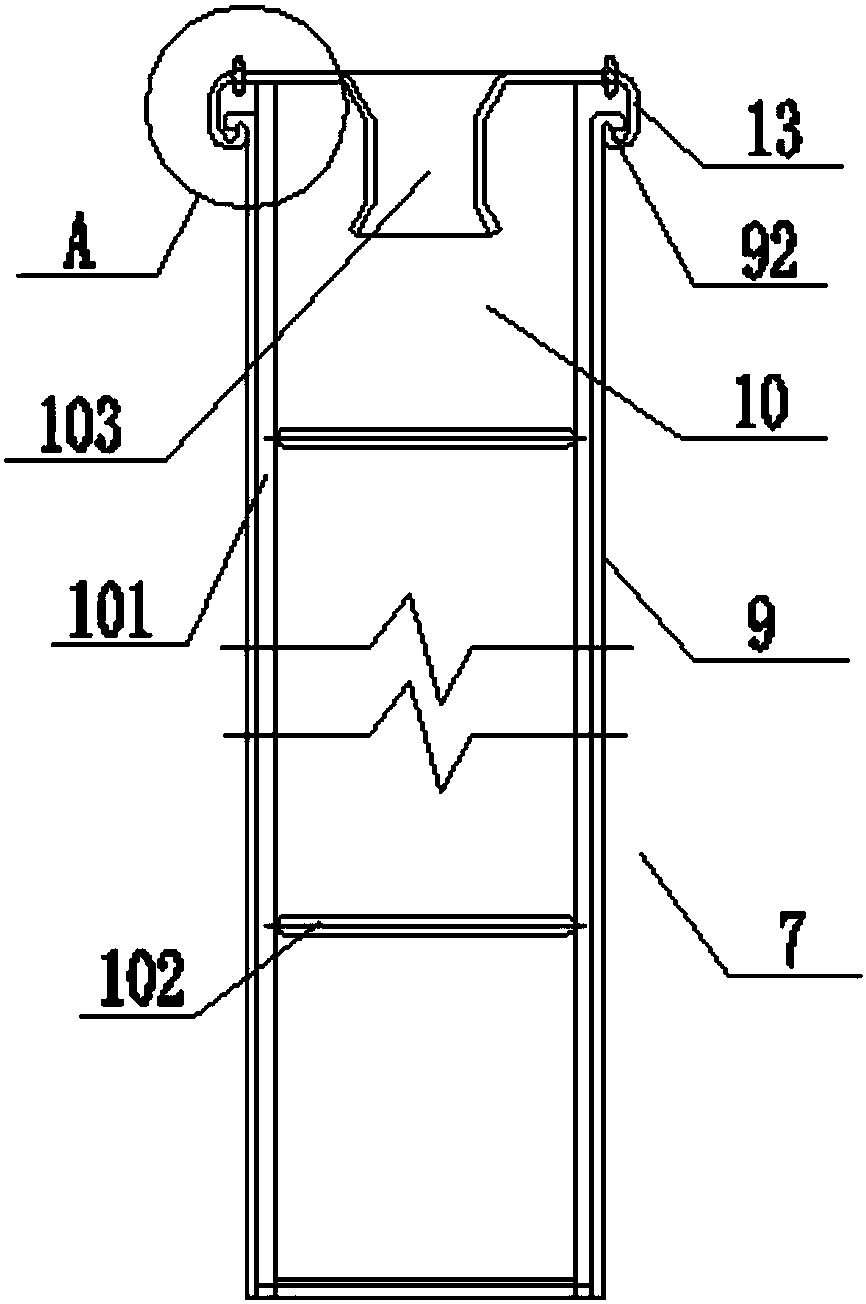

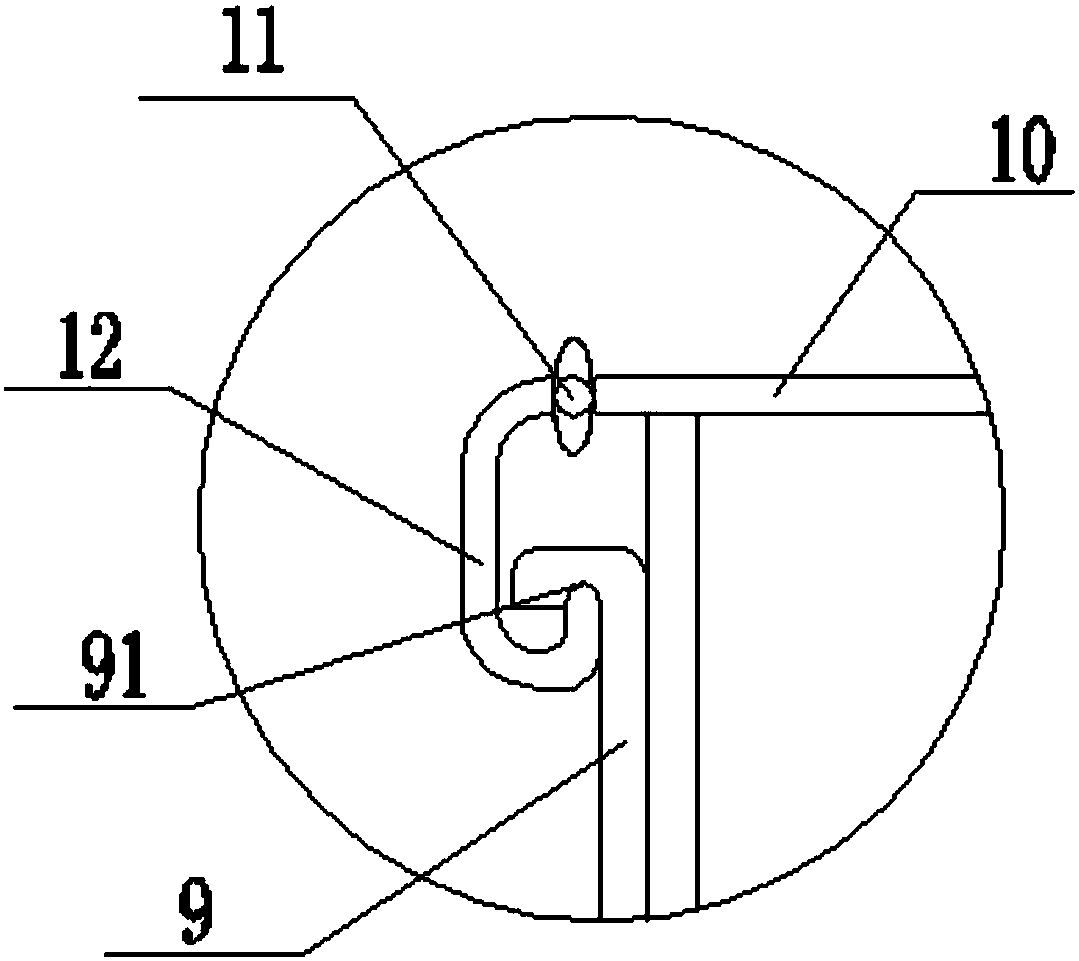

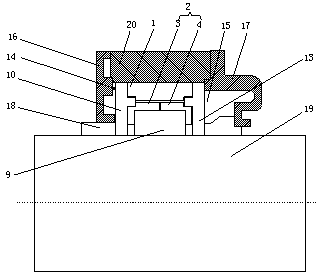

Filter bag dust collector with quick change type filter bag cage shelf combinations

ActiveCN105727643AAchieve replacementAchieve automatic reliefDispersed particle filtrationMembrane filtersEngineeringChange Type

The invention discloses a filter bag dust collector with quick change type filter bag cage shelf combinations. The filter bag dust collector comprises a box body and an air-purifying chamber, wherein one side of the box body is communicated with an inlet, the upper part of the box body is communicated with the air-purifying chamber, an air inlet used for being connected with a fan is formed in a position, where the air-purifying chamber and the inlet are on the same side, of the air-purifying chamber, an outlet is formed in the other side of the air-purifying chamber, a spray blowing system is arranged in the air-purifying chamber, the plurality of filter bag cage shelf combinations are arranged in the box body and are also arranged on a perforated plate at the top end of the box body at equal distances, and each filter bag cage shelf combination consists of a single filter bag and a single cage shelf. The filter bag dust collector disclosed by the invention has the benefits that with the adoption of the filter bag cage shelf combinations, the combination and the replacement of filter bags can be quickly realized in a rotating manner; the automatic release of the filter bags can be realized only by unscrewing clamping strips (a and b) out of clamping grooves (a and b), so that impact on cage shelves and cage shelf fixing can be avoided completely; the operation is simple, the use is convenient, and the overall working efficiency is greatly improved.

Owner:苏州保酚环境科技有限公司

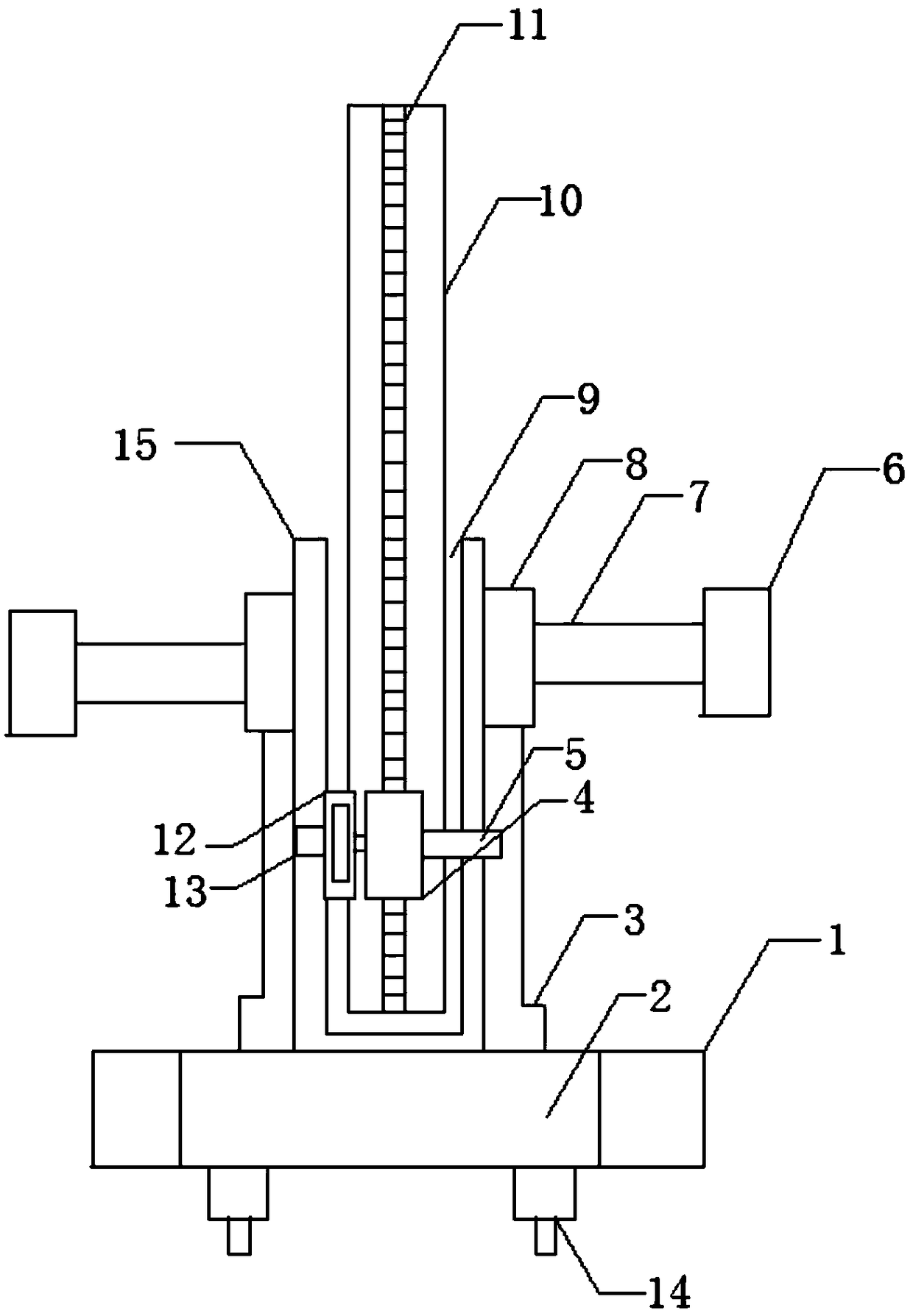

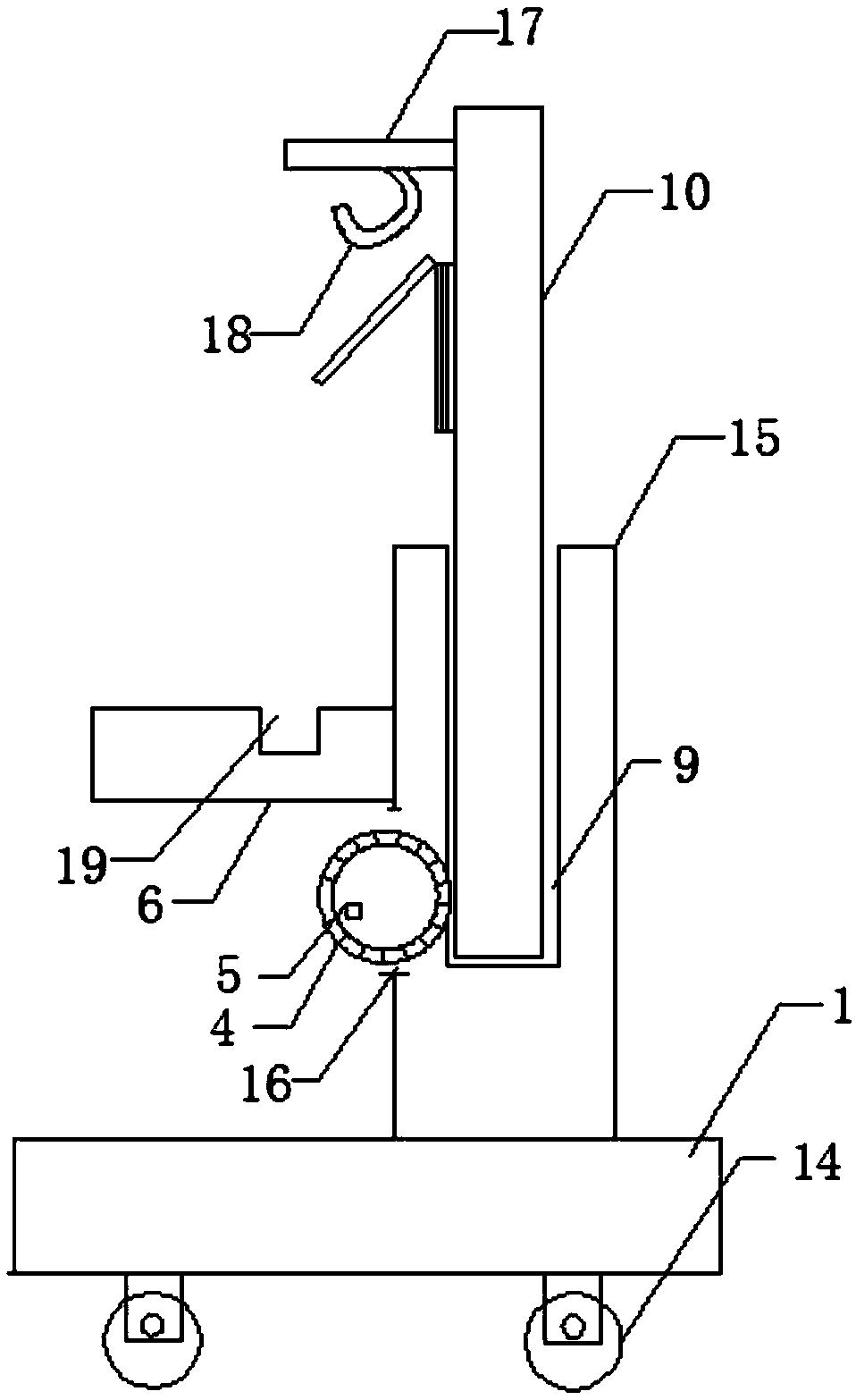

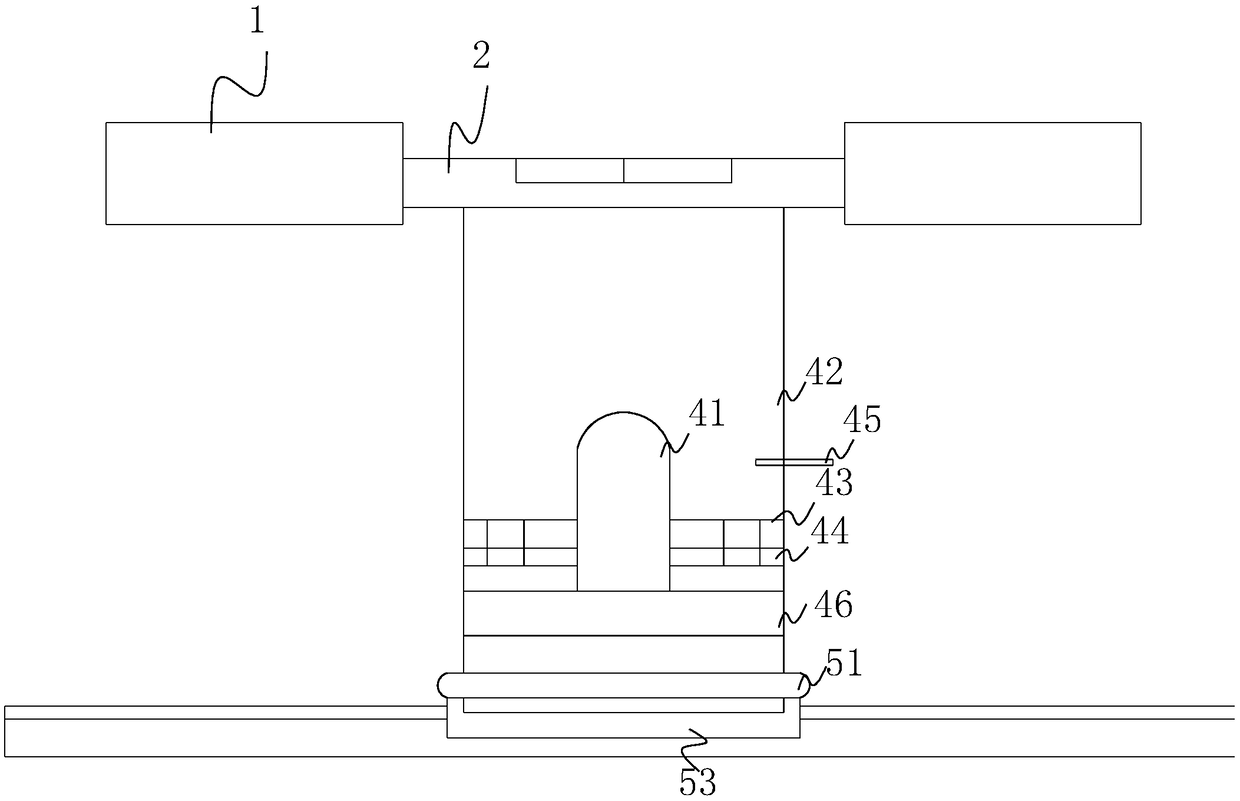

An adjustable infusion rod

The invention discloses an adjustable infusion rod including a bottom plate, wherein the bottom end of the bottom plate is provided with a universal wheel, one side of the infusion rod is provided with a gear groove, the gear is meshed and connected with the gear groove through a second groove formed on the outer wall of the pillar, the bottom end of the slide plate is provided with an electric telescopic rod, one side of the skateboard is provided with handrails, the side of the armrest is fixedly connected with a guard bar, as the gear groove is arranged on the infusion rod, and drives the infusion rod to move up and down inside the pillar through the cooperation of the gear and the gear groove, so that patient can easily adjust themselves, a protective bar and a handrail driven by an electric telescopic bar are arranged, a support force is provided for the patient when moving, the position of the armrest can be adjusted according to the patient's own situation, and a magic patch mother surface and a magic patch sub-surface can be set, and the two surfaces cooperate with each other, so that the shaking of the infusion tube at the top of the infusion tube is effectively limited when the patient moves, and the fixation of the needle is not affected when the infusion tube is transmitted to the patient's hand.

Owner:兴城市祥安畜牧养殖有限公司

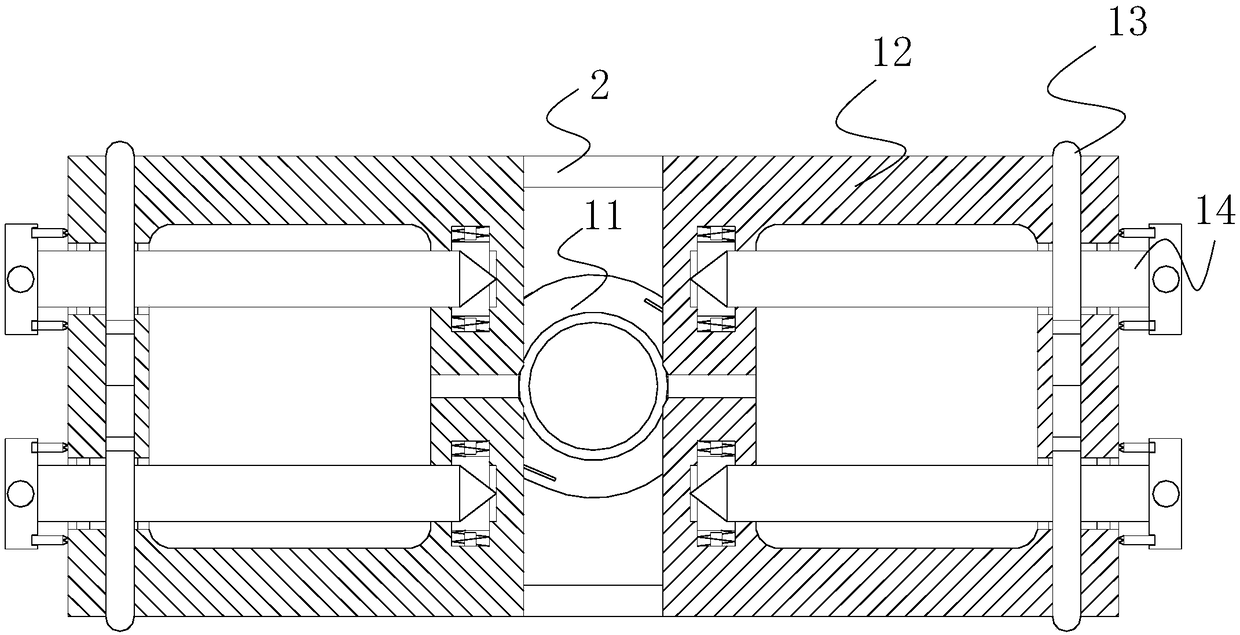

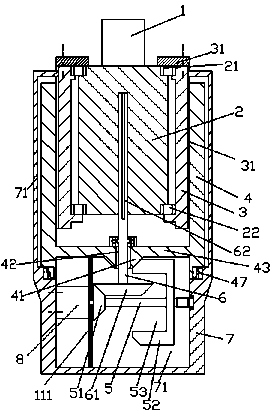

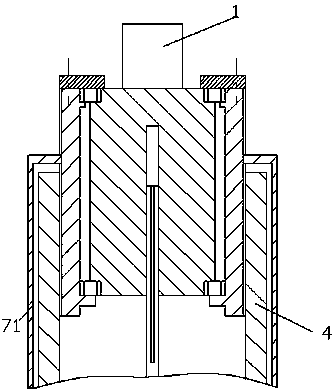

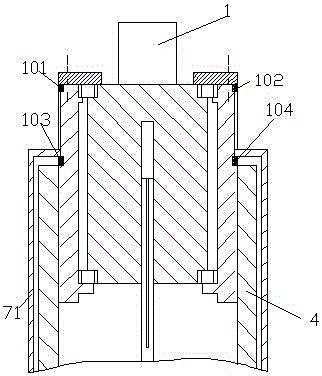

Worm machining device

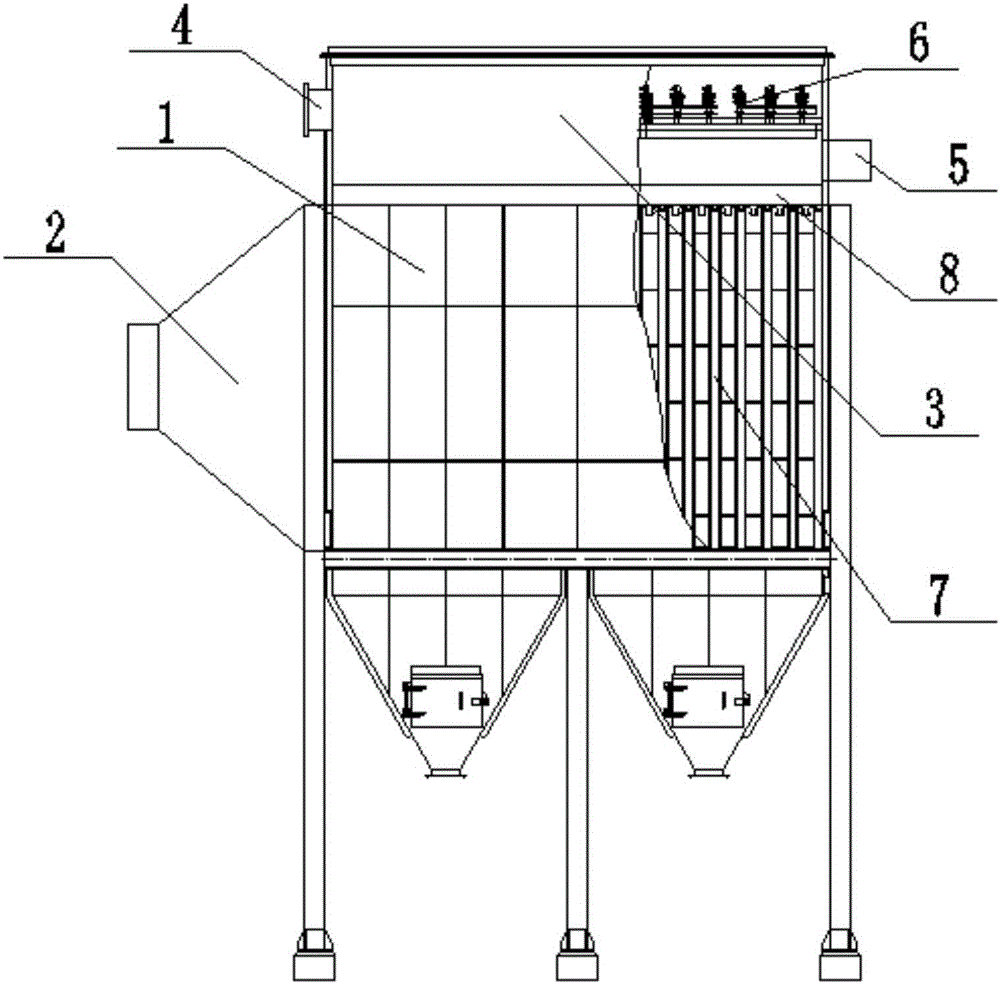

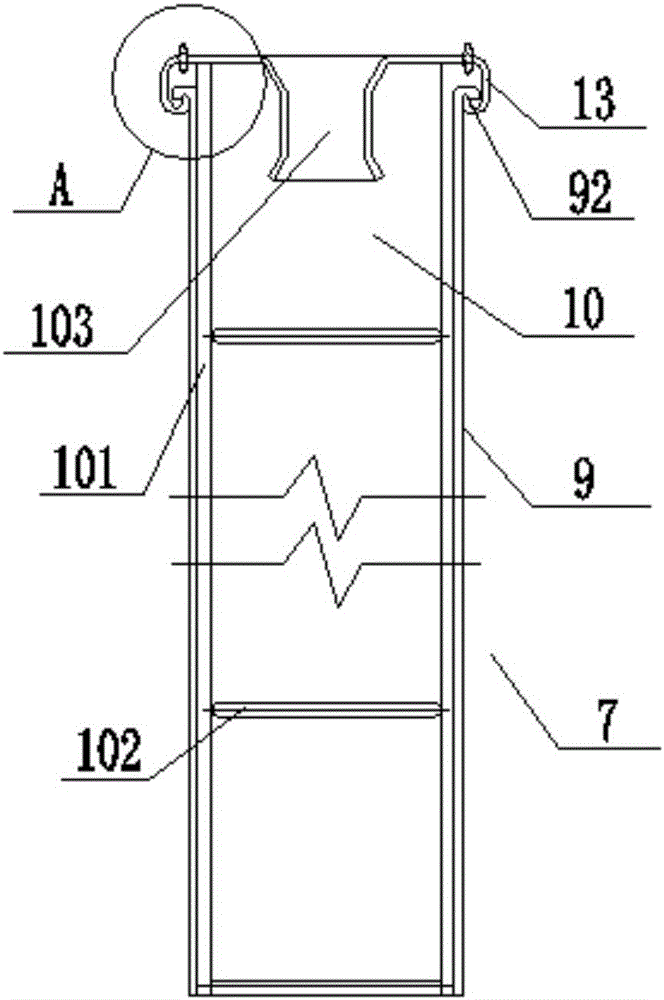

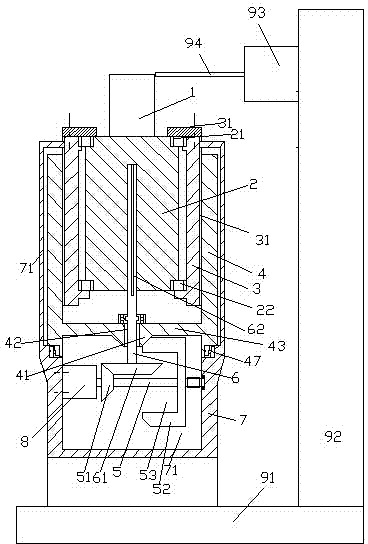

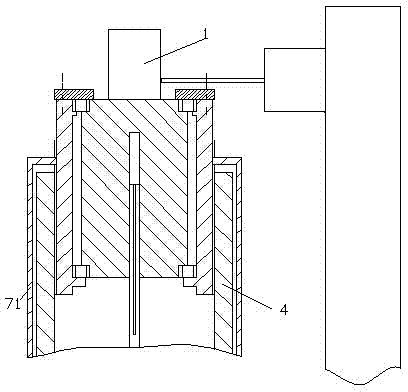

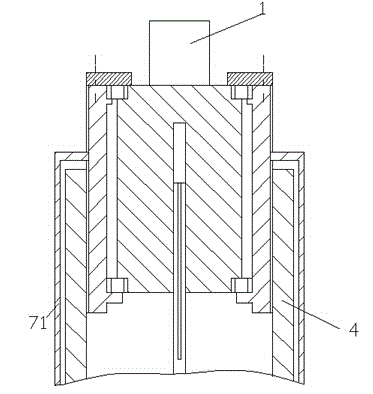

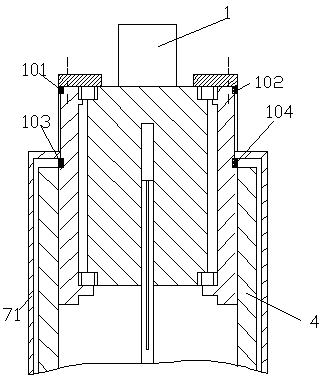

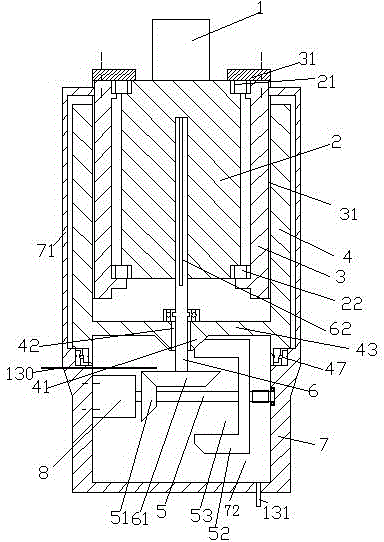

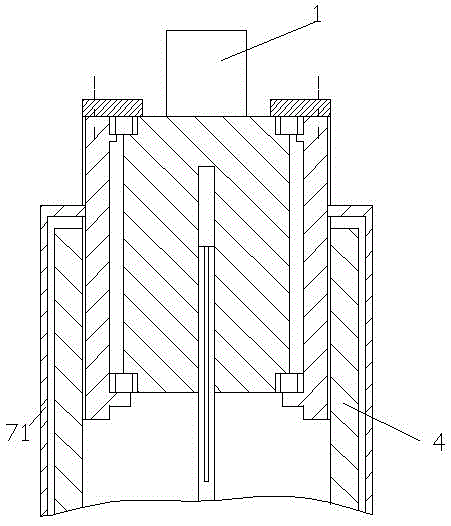

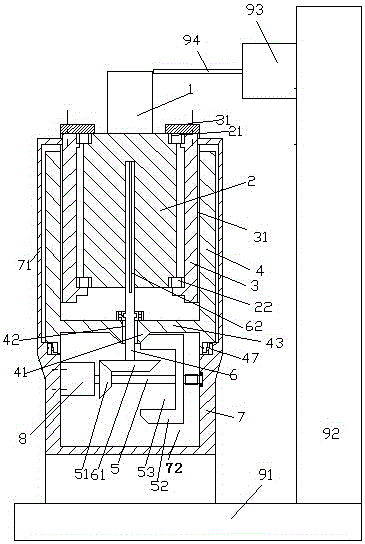

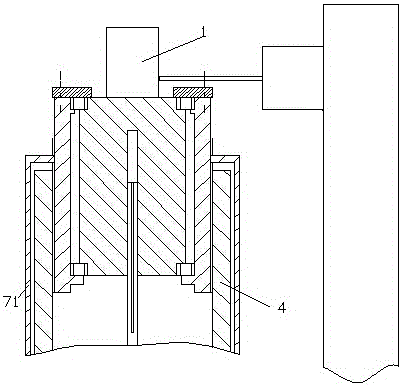

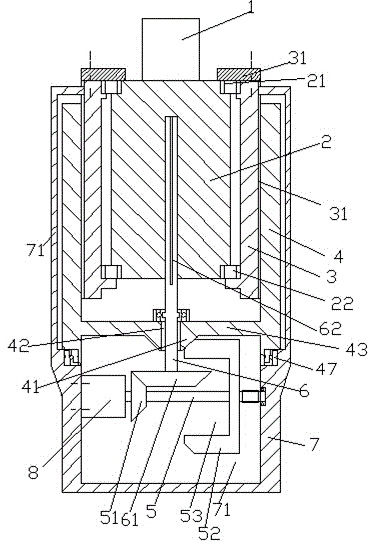

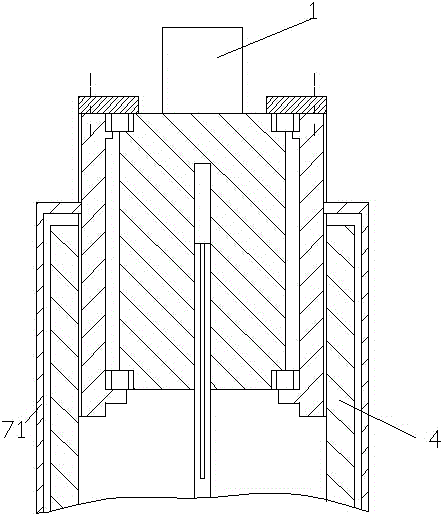

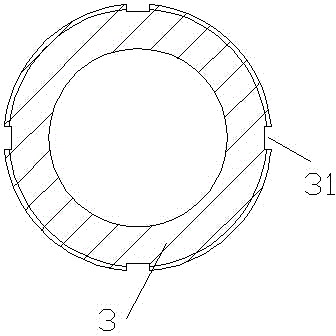

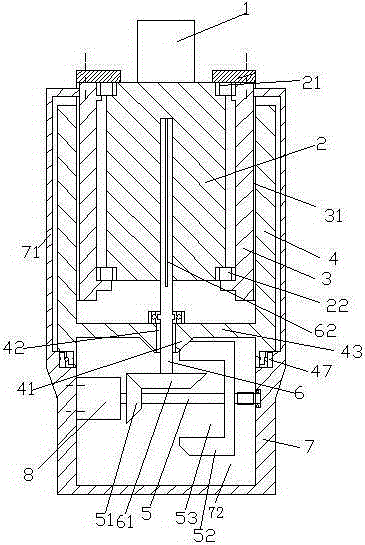

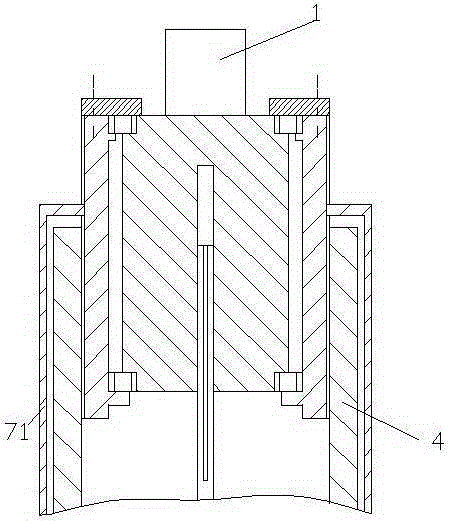

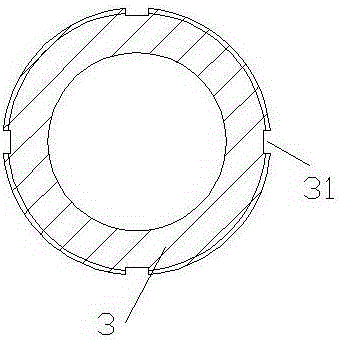

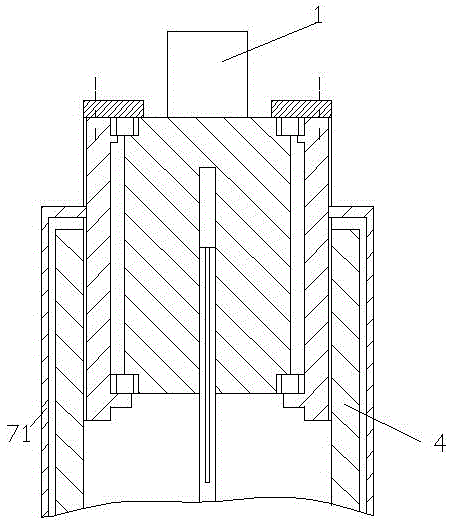

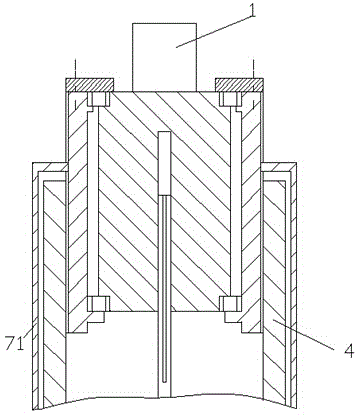

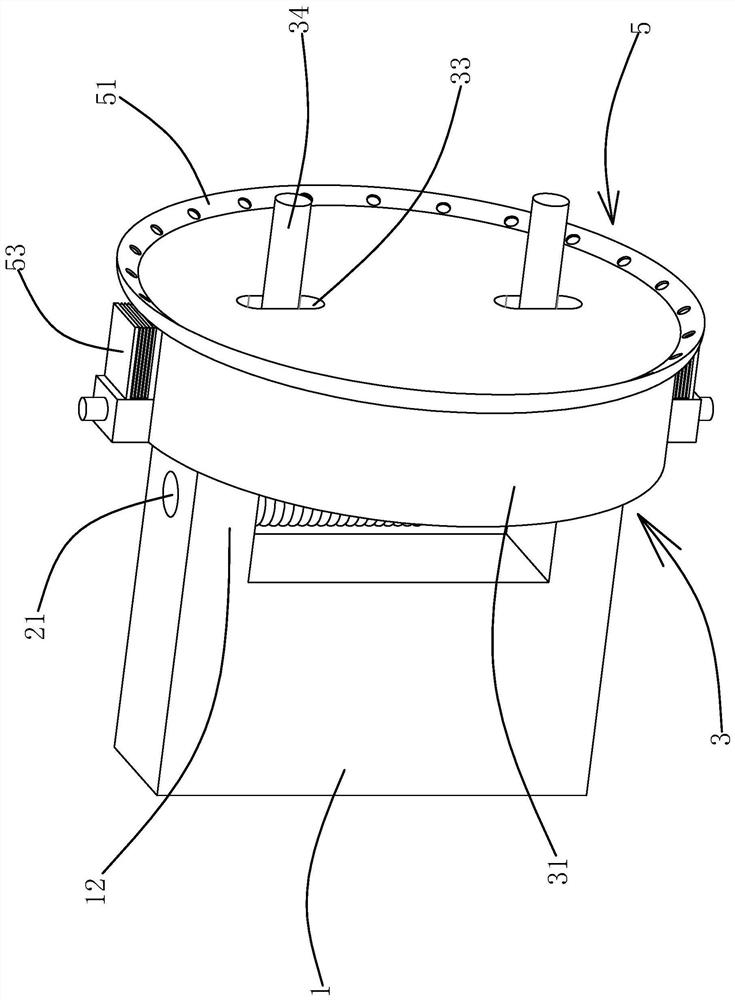

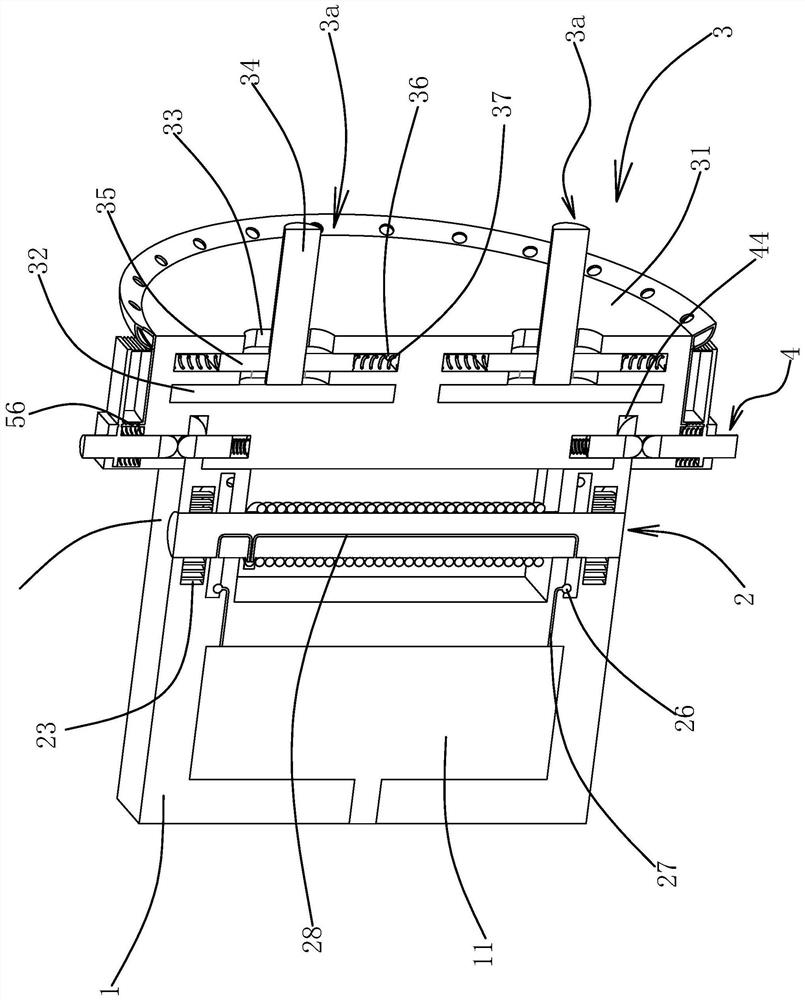

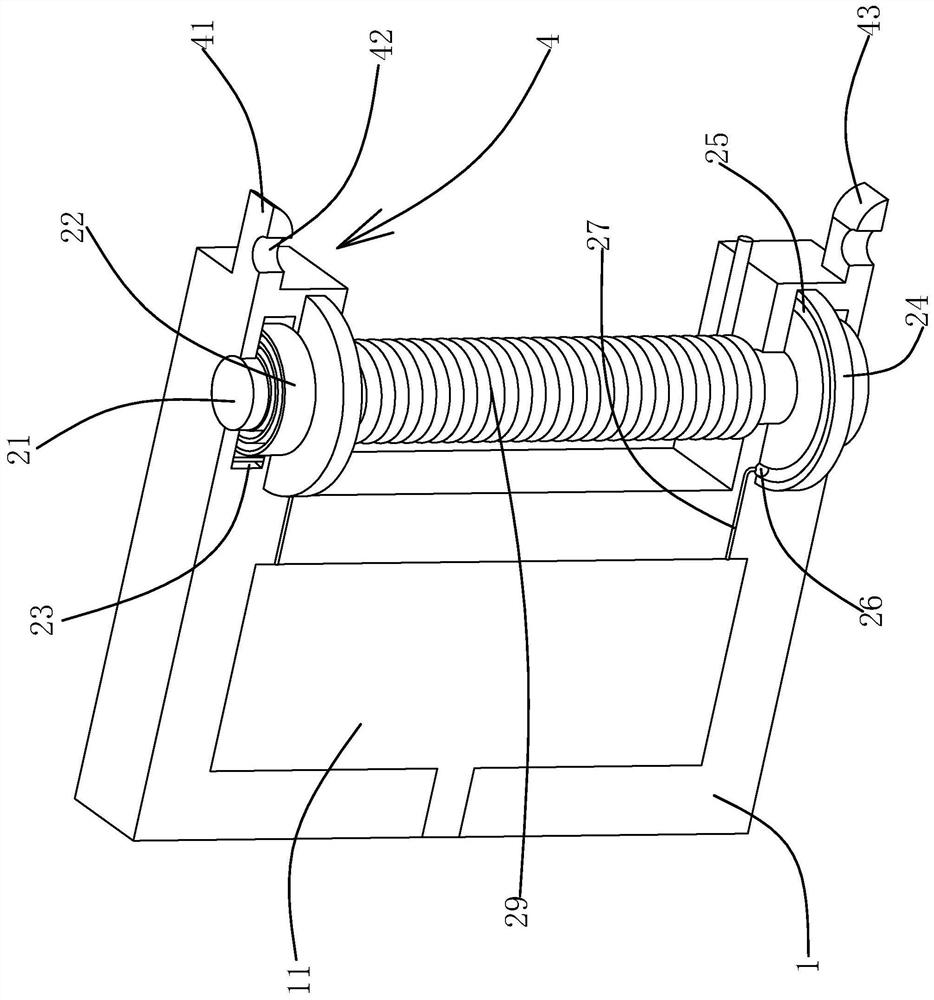

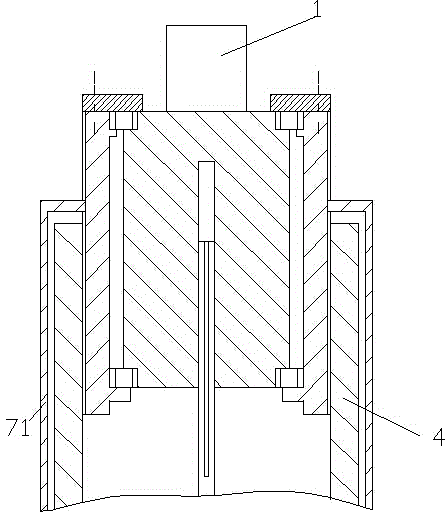

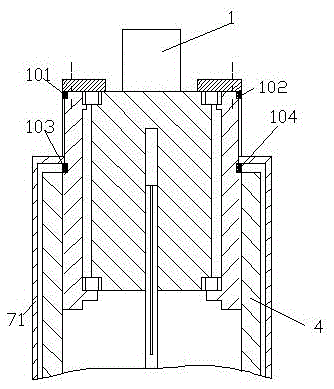

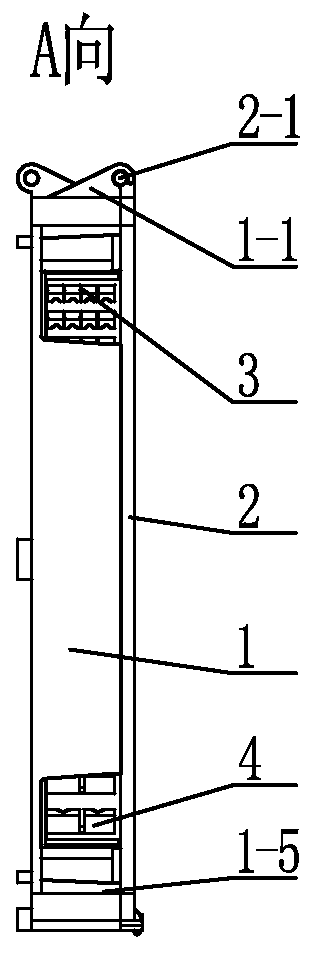

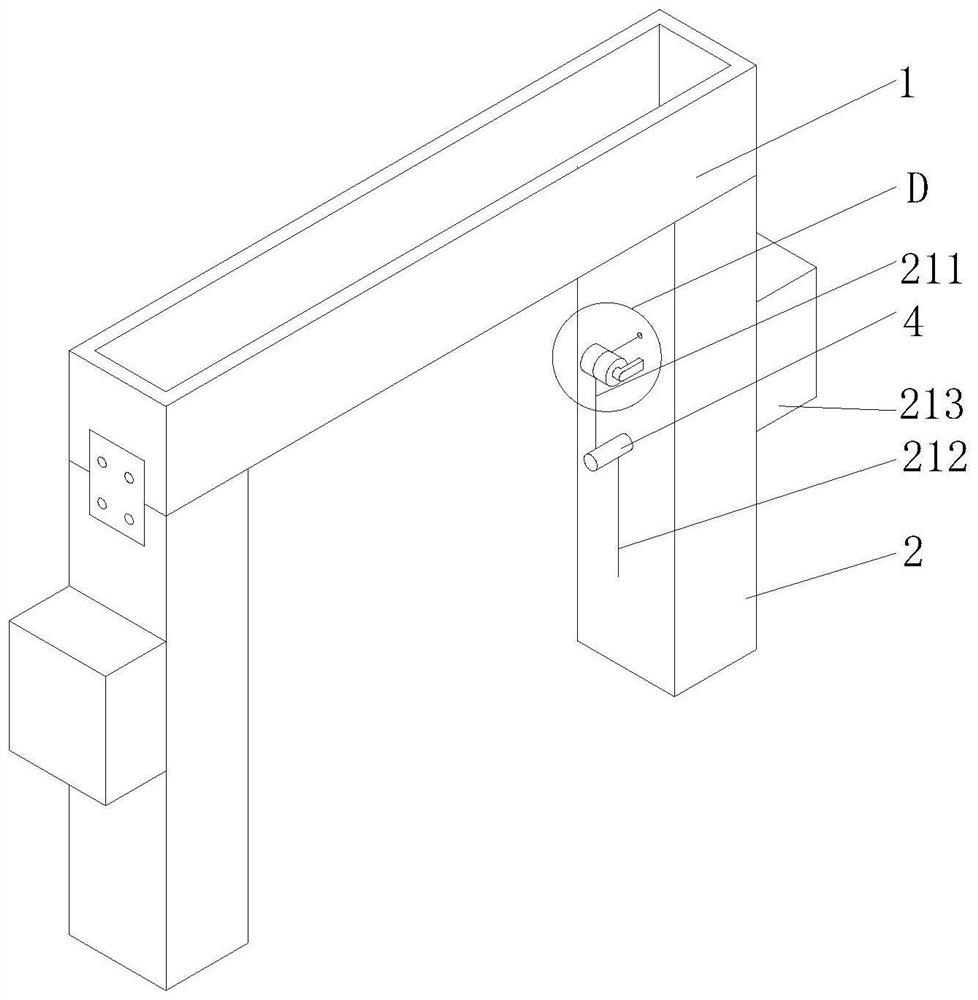

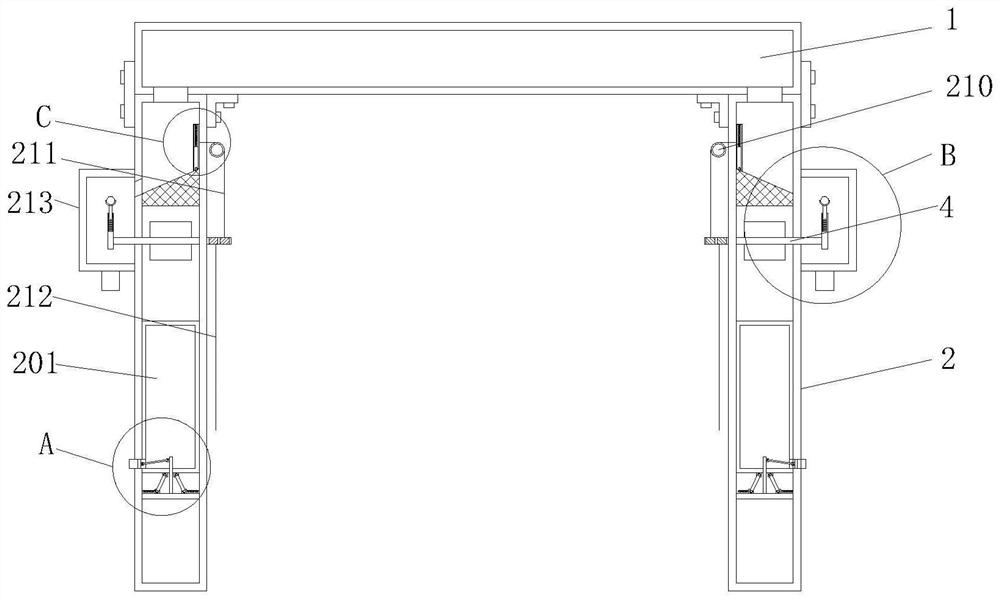

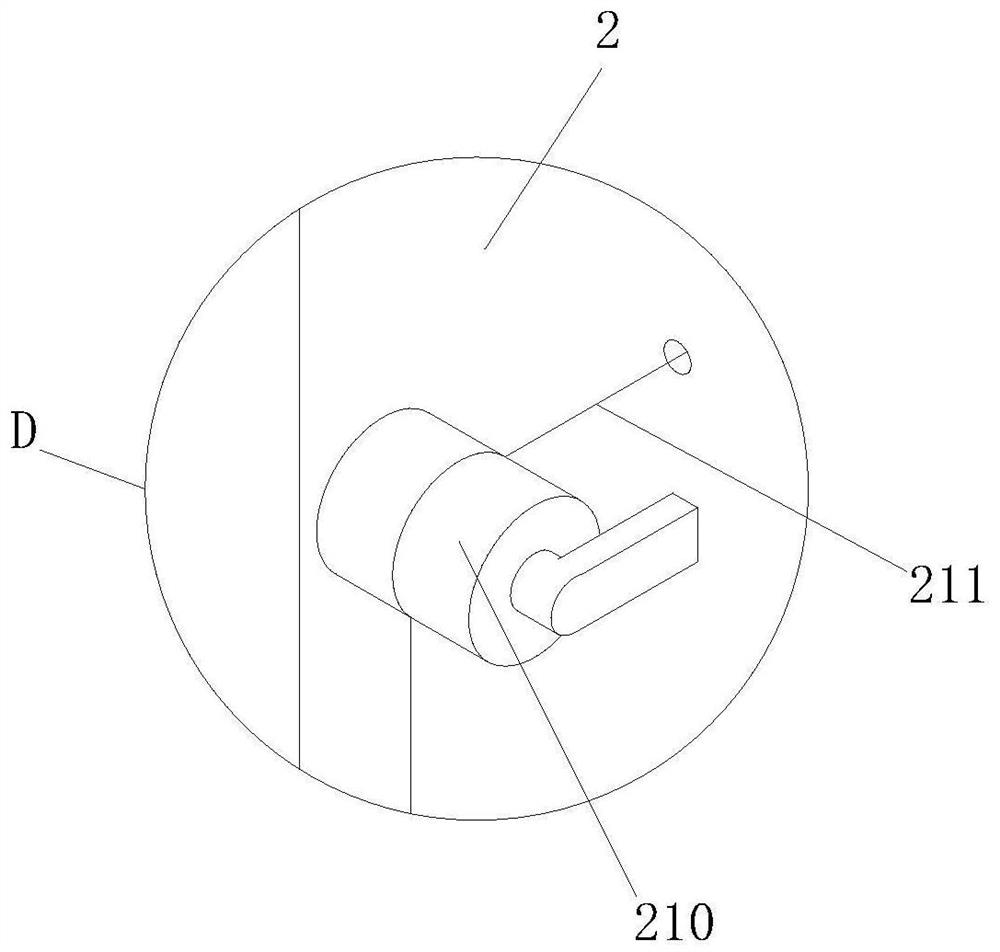

The invention provides a worm machining device. The worm machining device is used for machining a blank (1) into a worm, and comprises a movement mechanism, a base (91), an upright column (92), a milling cutter rotating driving motor (93) and a milling cutter (94); the movement mechanism is fixed on the base (91); the lower end of the upright column (92) is fixedly connected with the base (91); the milling cutter rotating driving motor (93) is mounted on the upper end of the upright column (92) and used for driving the milling cutter (94) to rotate; the milling cutter (94) is mounted on the milling cutter rotating driving motor (93) and used for cutting the blank (1); the movement mechanism comprises a blank carrying piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a frame (7).

Owner:SHENYUE FUJIAN CASTING

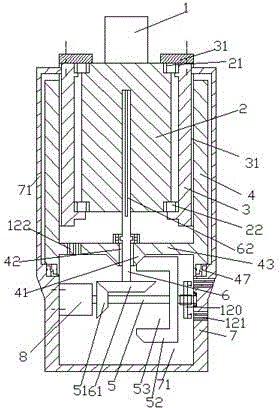

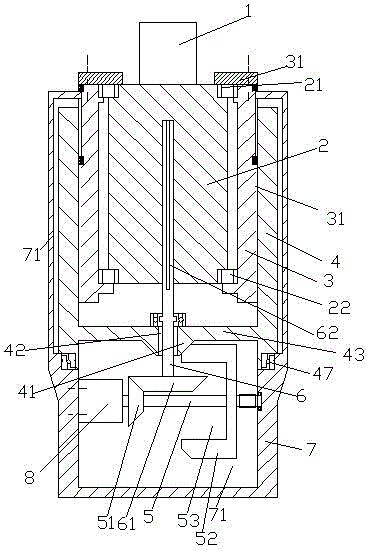

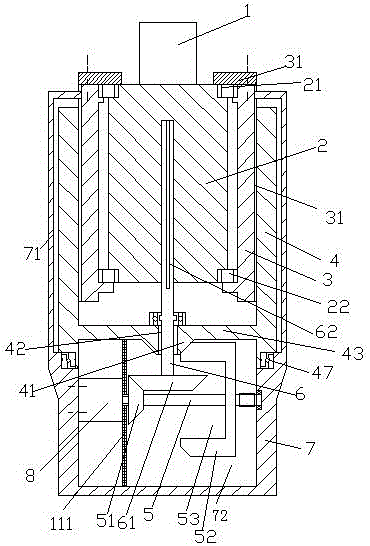

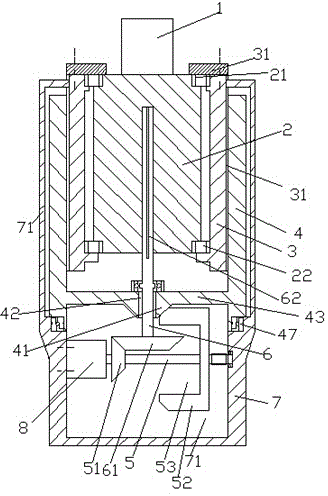

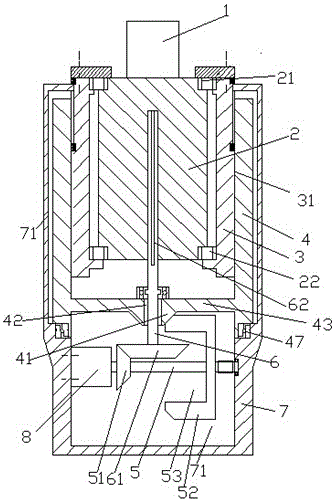

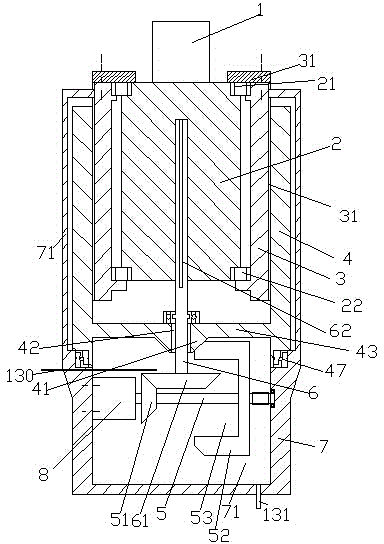

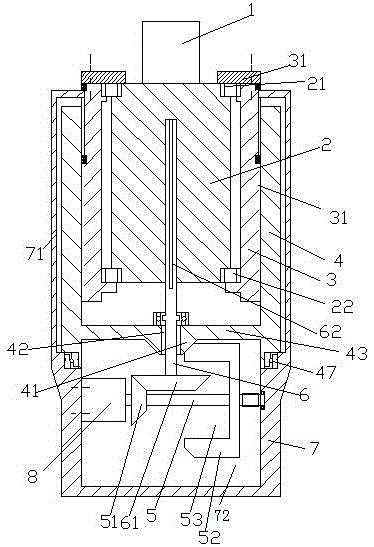

Worm processing mechanism capable of automatically radiating heat

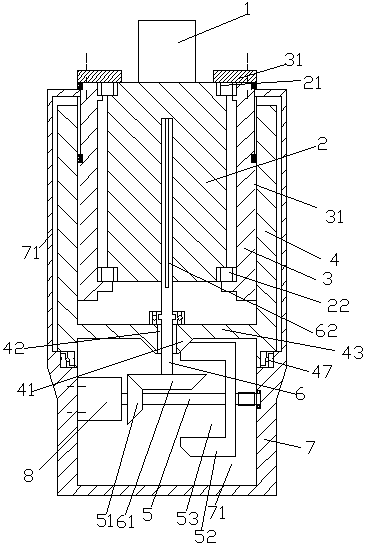

The invention discloses a worm processing mechanism capable of automatically radiating heat. The worm processing mechanism is used for processing a blank (1) into a worm. The worm processing mechanism comprises a blank bearing member (2), a sleeve (3) with an external thread, a drive sleeve (4) with an internal thread, and a rack (7), wherein the blank bearing member (2) is used for bearing the blank (1), the upper end and the lower end of the blank bearing member (2) are respectively fixedly arranged in the sleeve (3) with the external thread by means of an upper bearing (21) and a lower bearing (22) relative to the sleeve (3) with the external thread, the sleeve (3) with the external thread is in thread fit in the drive sleeve (4) with the internal thread, the lower end of the drive sleeve (4) with the internal thread can be rotatably arranged on the rack (7) by means of a thrust bearing (47), a cavity (72) is arranged inside the rack (7), and in the cavity (72), a drive motor (8) is fixedly arranged on the left-inner side wall of the cavity of the rack (7).

Owner:国网山东省电力公司沂源县供电公司

Inner winding reel casting production device and process

ActiveCN111791099AEasy to fixIncrease productivityGrinding carriagesRevolution surface grinding machinesGear wheelElectric machinery

The invention discloses an inner winding reel casting production device and process, and belongs to the technical field of winding reels. The inner winding reel casting production device comprises a winding reel and a grinding mechanism, the winding reel comprises a reel body, a center hole, a connecting groove, clamping grooves and positioning grooves, the center hole is formed in the middle of the reel body, the connecting groove is formed in the bottom end of the center hole, the clamping grooves are formed in the two sides of the connecting groove, and the two positioning grooves are formed in the outer wall of the bottom end of the reel body; and the grinding mechanism comprises a device base, a middle rod, a sleeve rod, a supporting plate, a handle, an adjusting cylinder, a linkage block, a linkage rod, a sliding rod, a sliding block, a connecting rod, a clamping block, a positioning rod, a driving motor, a driving gear, a driven gear, a supporting rod, a strip-shaped magnet, a grinding block, an arc-shaped supporting rod and the like. The winding reel can be conveniently fixed, the grinding mechanism can automatically grind the winding reel, the production efficiency of thewinding reel is improved, the labor cost is saved, and the inner winding reel casting production device is easy to operate, convenient to use and suitable for popularization.

Owner:江阴市星海铸造有限公司

Worm machining mechanism capable of automatically performing up-down limiting

The invention discloses a worm machining mechanism capable of automatically performing up-down limiting. The worm machining mechanism is used for machining a blank (1) into a worm and comprises a blank bearing member (2), a sleeve (3) with external thread, a driving sleeve (4) with internal thread and a rack (7), wherein the blank bearing member (2) is used for bearing the blank (1); the upper and lower ends of the blank bearing member (2) are axially and fixedly arranged in the sleeve (3) with the external thread relative to the sleeve (3) with the external thread through an upper bearing (21) and a lower bearing (22) respectively; the sleeve (3) with the external thread is matched in the driving sleeve (4) with the internal thread; the lower end of the driving sleeve (4) with the internal thread is arranged on the rack (7) through a thrust bearing (47) in a rotating manner.

Owner:广州德纳科技股份有限公司

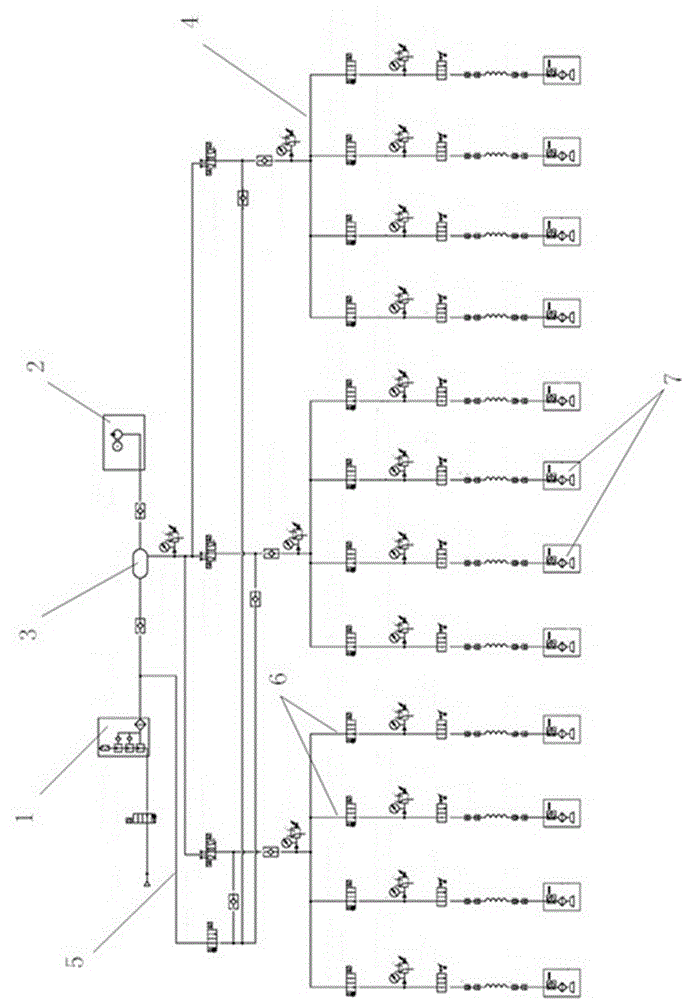

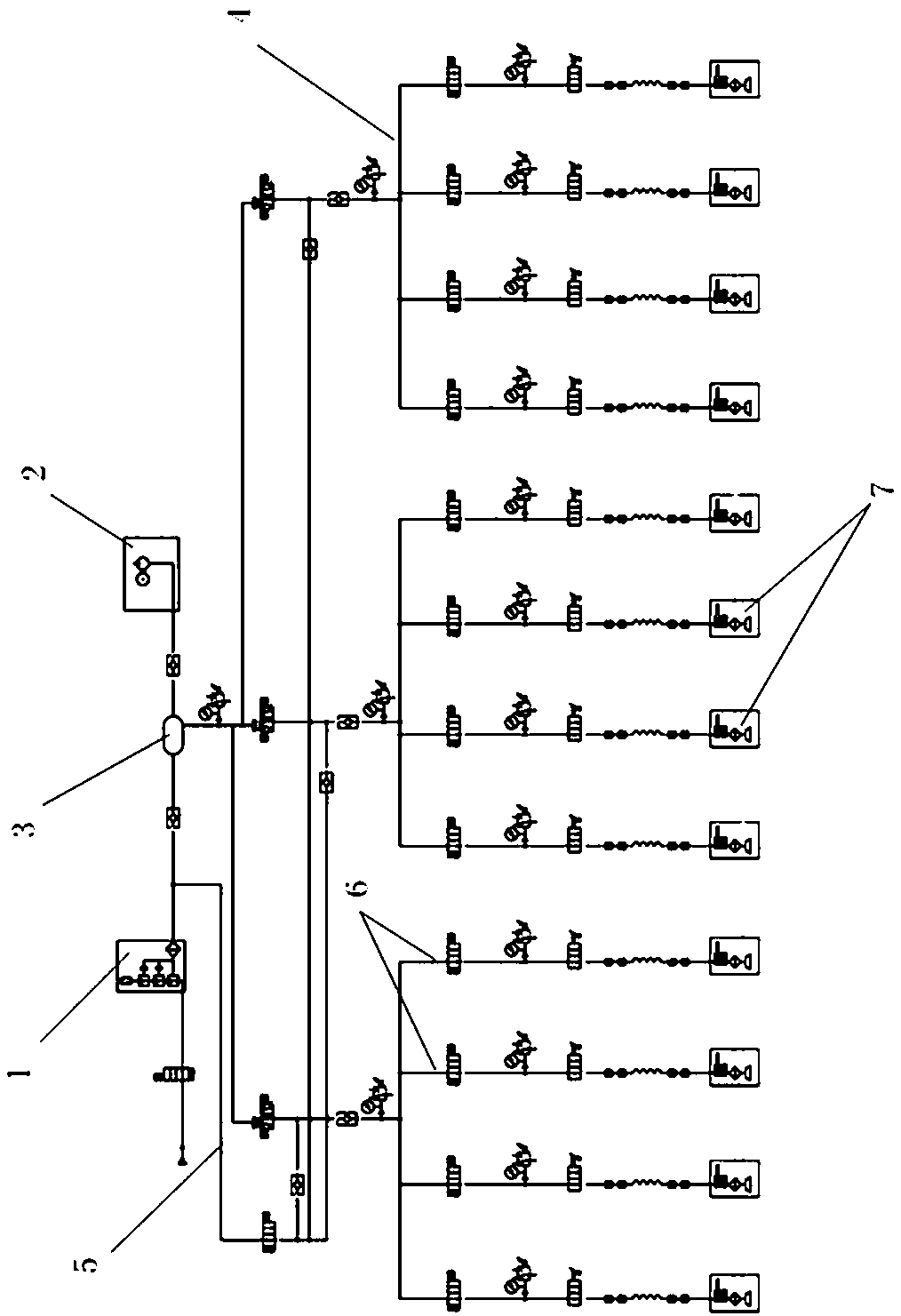

Portable track vacuum control system

The invention discloses a portable track vacuum control system. The portable track vacuum control system is characterized in that the control system comprises a multi-stage vacuum generator (1) and a vacuum pump (2), and the multi-stage vacuum generator (1) and the vacuum pump (2) are connected with a vacuum tank (3); the vacuum tank (3) is connected with a plurality of sets of track vacuum management units (4) through a main pipeline, and a valve and a pressure gauge are arranged between the vacuum tank (3) and each track vacuum management unit (4); a branch pipeline (5) is connected to the pipeline between the multi-stage vacuum generator (1) and the vacuum tank (3) and connected with all the track vacuum management units (4), and a valve is also arranged on the branch pipeline (5); each track vacuum management unit (4) comprises four sub-pipelines (6) connected in parallel; and a suction cup (7) is arranged at the tail end of each sub-pipeline (6), and an electric valve, a pressure gauge and a manual valve are arranged on each sub-pipeline (6).

Owner:大连四达高技术发展有限公司

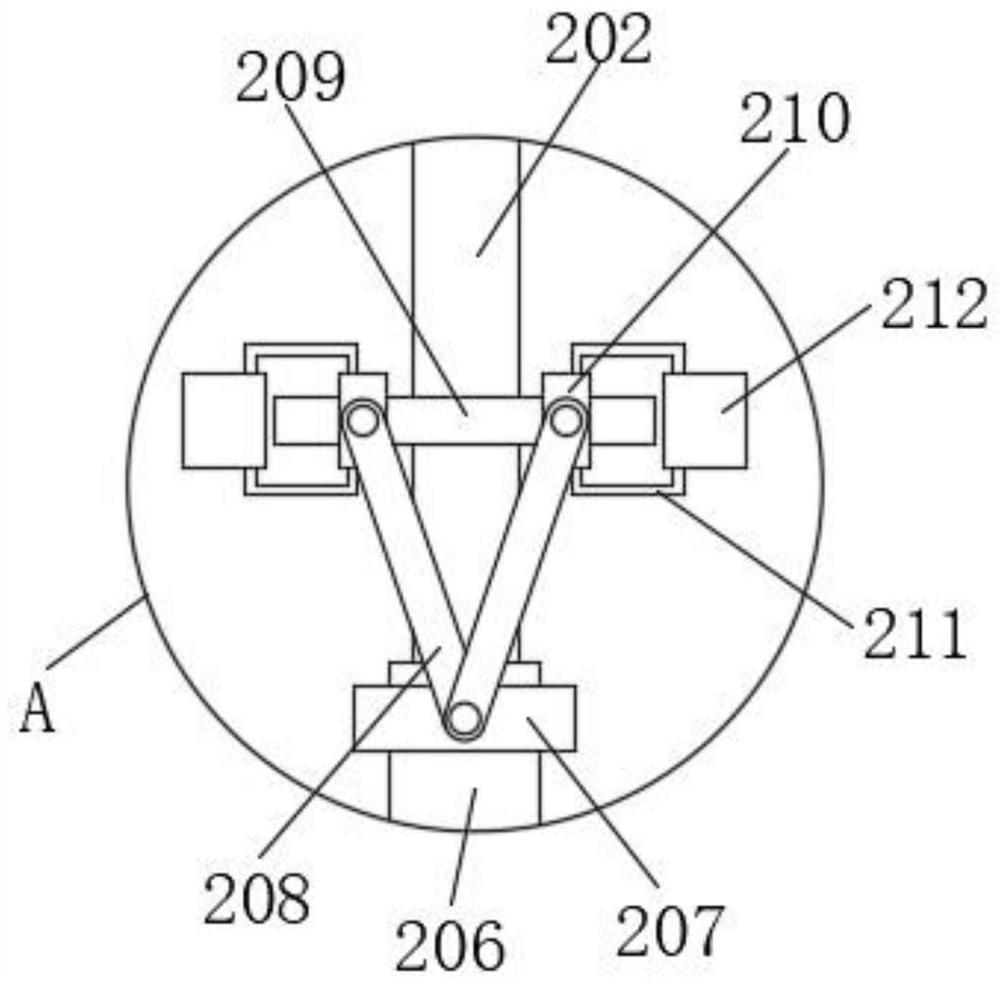

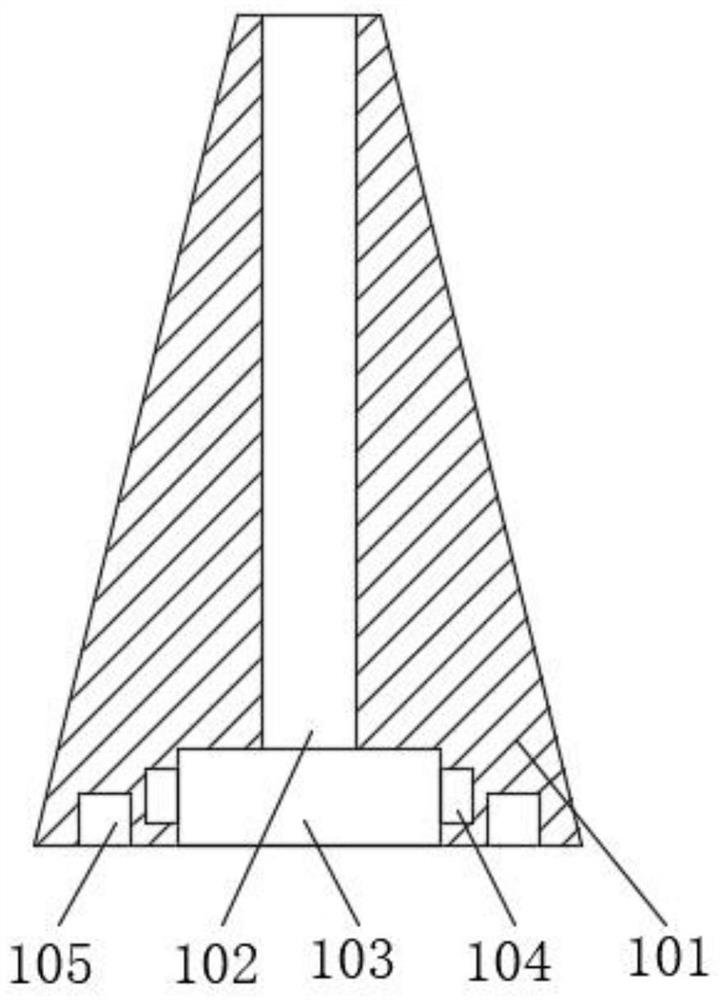

Extensible multi-direction smart home rotary base

InactiveCN108736235AIncrease frictionImprove stabilityCoupling parts mountingFlexible/turnable line connectorsEngineeringMechanical engineering

The invention discloses an extensible multi-direction smart home rotary base, the extensible multi-direction smart home rotary base structurally comprises an extending unfolding structure, a balance platform, a support column, a direction adjusting device, a sliding buckling structure and a base plate, wherein the balance platform is parallel to the base plate and is in vertical mechanical connection with the base plate through the support column, the siding buckling structure is mounted at the middle of the base plate, the support column is cut into an upper support column and a lower supportcolumn and the direction adjusting device is mounted between the upper support column and the lower support column, the lower support column is in sliding fit with the sliding buckling structure of the base plate, the extending unfolding structure is mounted at two horizontal ends of the balance platform, the extending unfolding structure is provided with a rope winder, a plug placing structure,a sliding rod and a buckle locking structure, and the rope winder is mounted at the middle of the balance platform. The extending unfolding structure, the direction adjusting device and the sliding buckling structure are used for adjusting distance of an electrical plug, the extensible multi-direction smart home rotary base can rotate roundly, the direction of the electrical plug can be adjusted,thus, convenience in usage is improved, and the extensible multi-direction smart home rotary base can be more suitable for small-area residential zones.

Owner:李政远

Worm rod processing mechanism with driving motor separation baffle plate

The invention relates to a worm rod processing mechanism with a driving motor separation baffle plate (111). The worm rod processing mechanism is used for processing a blank (1) into a worm rod, and comprises a blank carrying element (2), a sleeve (3) with external screw threads, a driving sleeve (4) with internal screw threads and a machine frame (7), wherein the blank carrying element (2) is used for carrying the blank (1), the upper end and the lower end of the blank carrying element (2) are respectively and fixedly arranged in the sleeve (3) with the external screw threads through an upper bearing (21) and a lower bearing (22) in a direction opposite to the axial direction of the sleeve (3) with the external screw threads, the sleeve (3) with the external screw threads is matched in the driving sleeve (4) with the internal screw threads through screw threads, and the lower end of the driving sleeve (4) with the internal screw threads is rotatablely arranged on the machine frame (7) through a thrust bearing (47).

Owner:STATE GRID CORP OF CHINA +1

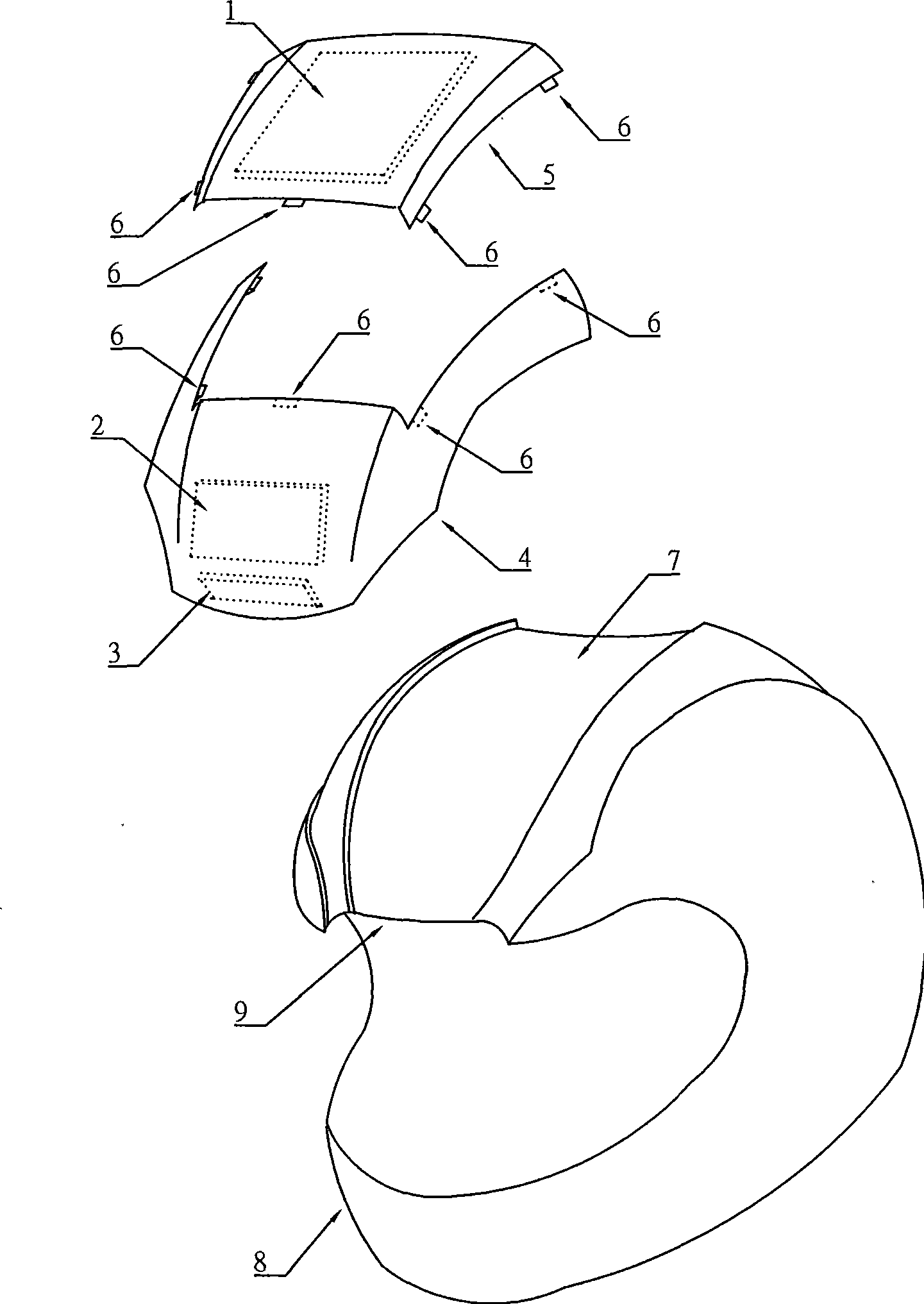

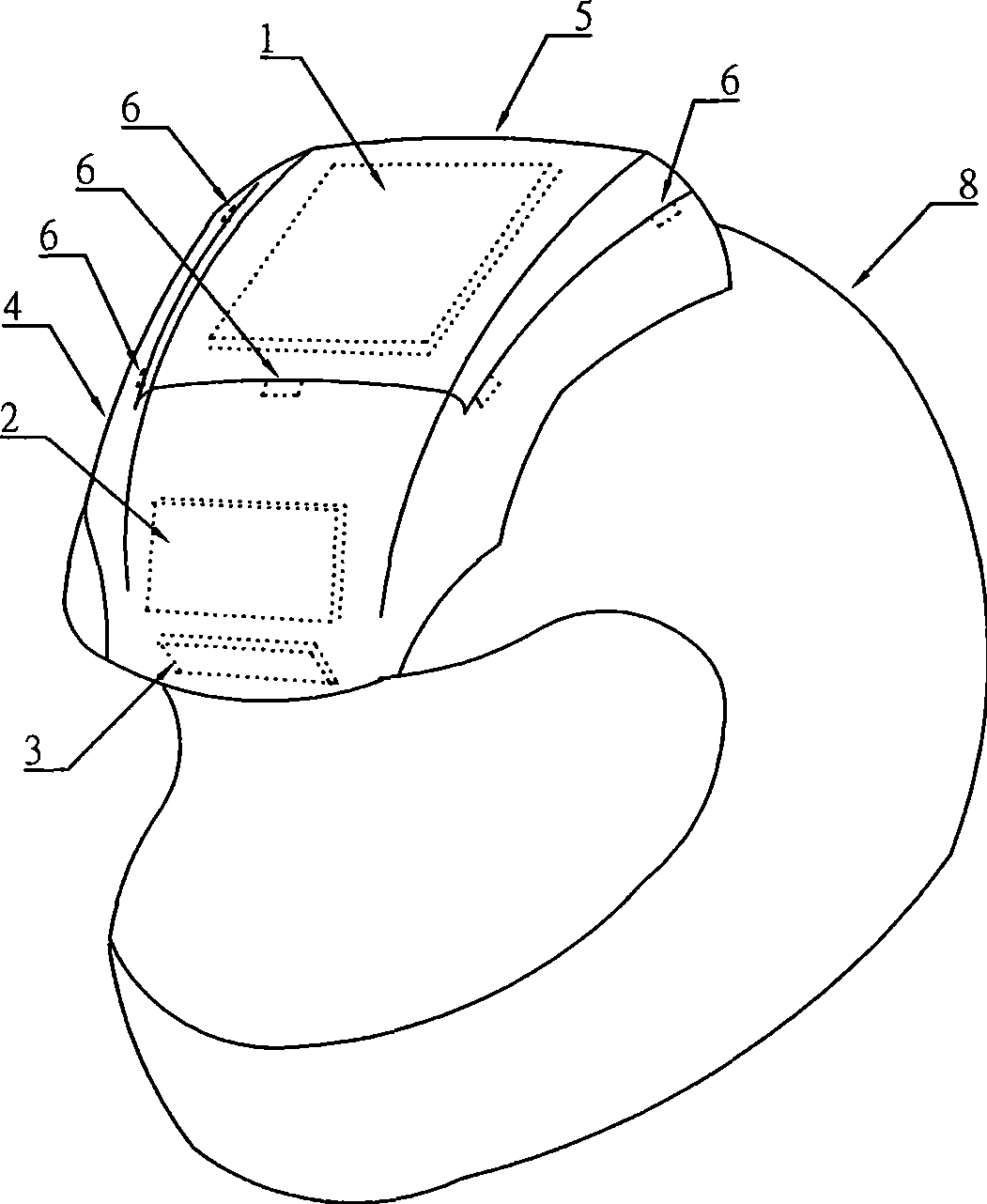

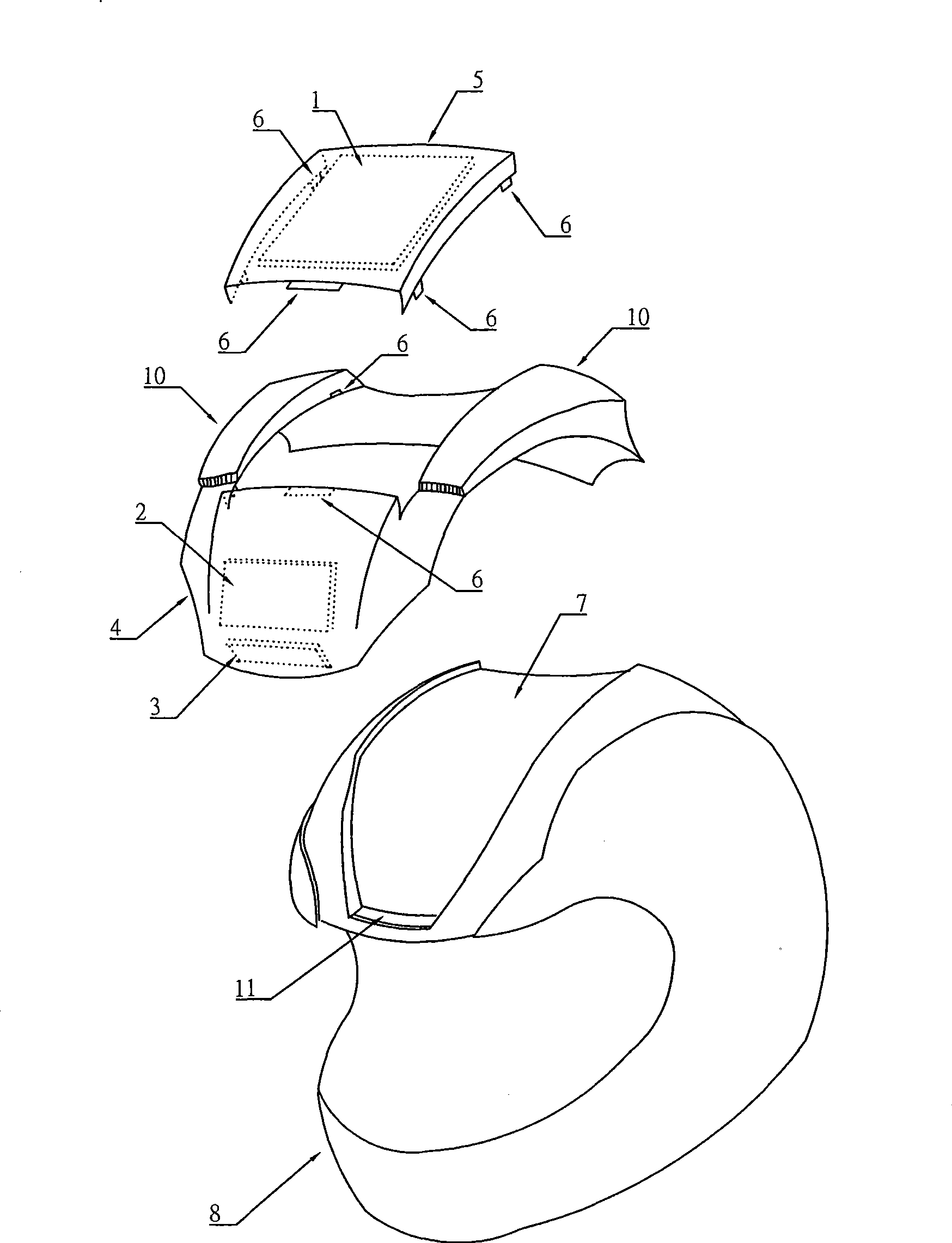

Protective helmet shell dismounting structure with rear view function

InactiveCN101496651ADoes not affect the fixedEasy to assemble and disassembleHelmetsHelmet coversComputer science

Owner:赖添德

A Worm Machining Mechanism with a Lubricating Oil Supply System

InactiveCN104308280BHigh densityHigh precisionGearingGear lubrication/coolingThrust bearingEngineering

The invention discloses a worm processing mechanism with a lubricating-oil supplying system. The worm processing mechanism is used for processing a blank piece (1) into a worm and comprises a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads; the lower end of the driving sleeve (4) with the internal threads can be rotatably arranged on the rack (7) by a thrust bearing (47).

Owner:国网山东省电力公司沂源县供电公司

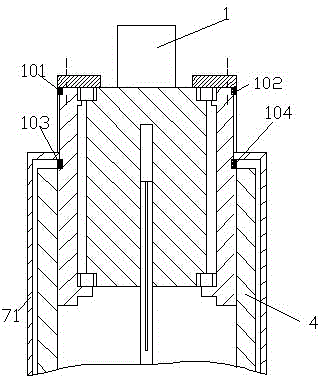

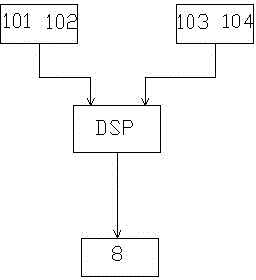

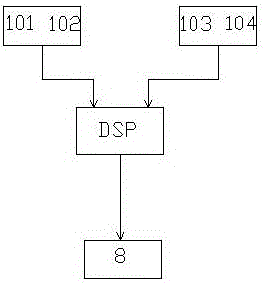

Worm processing mechanism controlled by circuit

The invention discloses a worm processing mechanism controlled by a circuit. The worm processing mechanism is used for processing a blank piece (1) into a worm and comprises a DSP (Digital Signal Processing) control circuit, a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads.

Owner:国网山东省电力公司沂源县供电公司

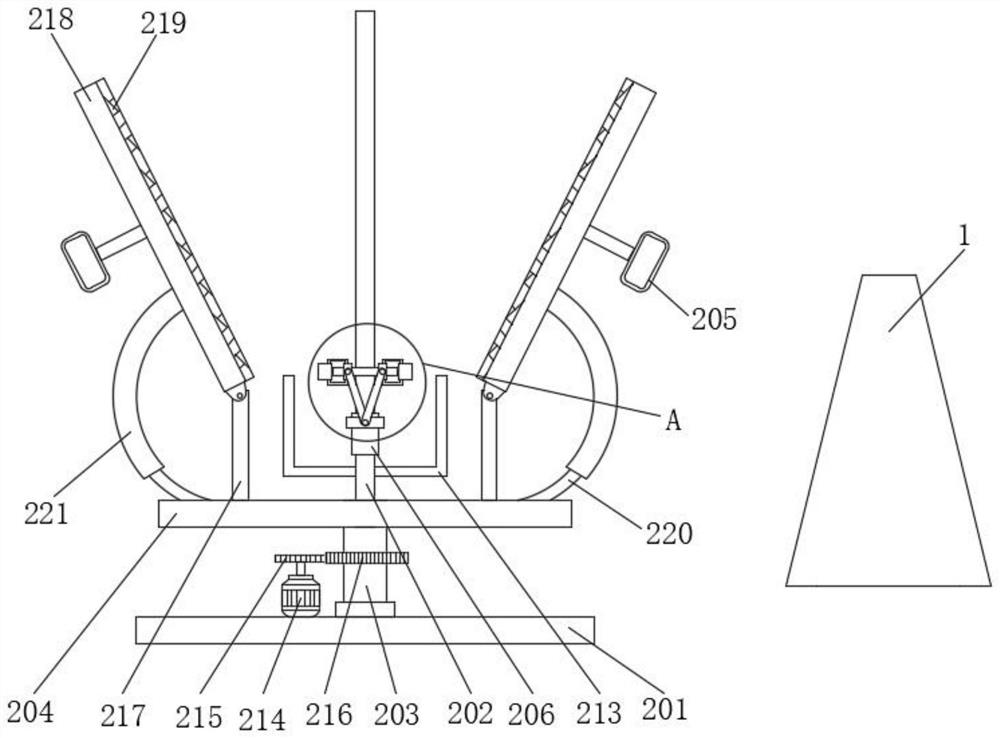

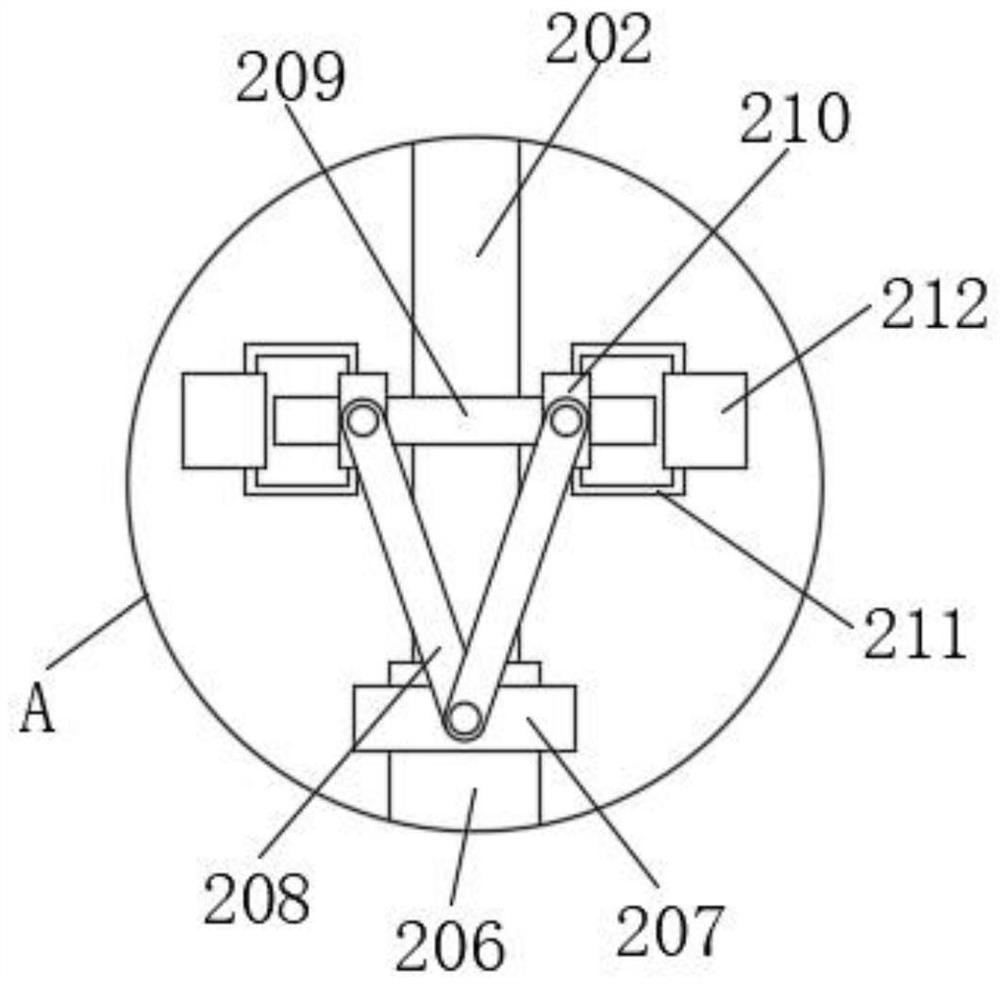

A worm machining device

The invention provides a worm machining device. The worm machining device is used for machining a blank (1) into a worm, and comprises a movement mechanism, a base (91), an upright column (92), a milling cutter rotating driving motor (93) and a milling cutter (94); the movement mechanism is fixed on the base (91); the lower end of the upright column (92) is fixedly connected with the base (91); the milling cutter rotating driving motor (93) is mounted on the upper end of the upright column (92) and used for driving the milling cutter (94) to rotate; the milling cutter (94) is mounted on the milling cutter rotating driving motor (93) and used for cutting the blank (1); the movement mechanism comprises a blank carrying piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a frame (7).

Owner:SHENYUE FUJIAN CASTING

Spiral rising type processing equipment with four sliding grooves

The invention discloses spiral rising type processing equipment with four sliding grooves. The spiral rising type processing equipment is used for processing a blank piece (1) into a worm and comprises a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads; the lower end of the driving sleeve (4) with the internal threads can be rotatably arranged on the rack (7) by a thrust bearing (47); the rack is internally provided with a cavity (72).

Owner:STATE GRID SHANDONG ELECTRIC POWER CO LONGKOU POWER SUPPLY CO

Portable Orbital Vacuum Control System

Owner:大连四达高技术发展有限公司

A filter bag dust collector with a quick-change filter bag cage combination

ActiveCN105727643BAchieve replacementAchieve automatic reliefDispersed particle filtrationMembrane filtersEngineeringChange Type

The invention discloses a filter bag dust collector with quick change type filter bag cage shelf combinations. The filter bag dust collector comprises a box body and an air-purifying chamber, wherein one side of the box body is communicated with an inlet, the upper part of the box body is communicated with the air-purifying chamber, an air inlet used for being connected with a fan is formed in a position, where the air-purifying chamber and the inlet are on the same side, of the air-purifying chamber, an outlet is formed in the other side of the air-purifying chamber, a spray blowing system is arranged in the air-purifying chamber, the plurality of filter bag cage shelf combinations are arranged in the box body and are also arranged on a perforated plate at the top end of the box body at equal distances, and each filter bag cage shelf combination consists of a single filter bag and a single cage shelf. The filter bag dust collector disclosed by the invention has the benefits that with the adoption of the filter bag cage shelf combinations, the combination and the replacement of filter bags can be quickly realized in a rotating manner; the automatic release of the filter bags can be realized only by unscrewing clamping strips (a and b) out of clamping grooves (a and b), so that impact on cage shelves and cage shelf fixing can be avoided completely; the operation is simple, the use is convenient, and the overall working efficiency is greatly improved.

Owner:苏州保酚环境科技有限公司

A spiral rising processing equipment with four chutes

The invention discloses spiral rising type processing equipment with four sliding grooves. The spiral rising type processing equipment is used for processing a blank piece (1) into a worm and comprises a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads; the lower end of the driving sleeve (4) with the internal threads can be rotatably arranged on the rack (7) by a thrust bearing (47); the rack is internally provided with a cavity (72).

Owner:国网山东省电力公司沂源县供电公司

A production device and process for inner bobbin castings

ActiveCN111791099BEasy to fixIncrease productivityGrinding carriagesRevolution surface grinding machinesBobbinGear wheel

The invention discloses a production device and process of an inner bobbin casting, which belongs to the technical field of bobbins. An inner bobbin casting production device includes a bobbin and a grinding mechanism. The bobbin includes a cylinder body and a center hole. , connection groove, card groove, positioning groove, the middle part of the cylinder is provided with a middle hole, the bottom of the middle hole is provided with a connection groove, both sides of the connection groove are provided with card grooves, and the outer wall of the bottom end of the cylinder is provided with two The grinding mechanism includes the base of the device, the middle rod, the sleeve rod, the support plate, the handle, the adjustment cylinder, the linkage block, the linkage rod, the slider, the slider, the connecting rod, the block, the positioning rod, the drive motor, the driving gear , Driven gears, support rods, bar magnets, grinding blocks, arc-shaped struts, etc. The bobbin can be easily fixed, the grinding mechanism can automatically polish the bobbin, the production efficiency of the bobbin is improved, the labor cost is saved, the operation is simple, the use is convenient, and it is suitable for popularization.

Owner:江阴市星海铸造有限公司

A worm machining mechanism with a driving motor partition

Owner:STATE GRID CORP OF CHINA +1

Worm machining mechanism

A worm machining mechanism is used for machining a blank (1) into a worm; the machining mechanism comprises a blank carrier (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7); the blank carrier (2) is used for carrying the blank (1); the upper end and the lower end of the blank carrier (2) are axially fixedly mounted in the sleeve (3) with the external threads relative to the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22); the sleeve (3) with the external threads is in threaded fit in the driving sleeve (4) with the internal threads; the lower end of the driving sleeve (4) with the internal threads is rotatably arranged on the rack (7) by a thrust bearing (47); a chamber (72) is arranged in the rack (7).

Owner:国网山东省电力公司沂源县供电公司

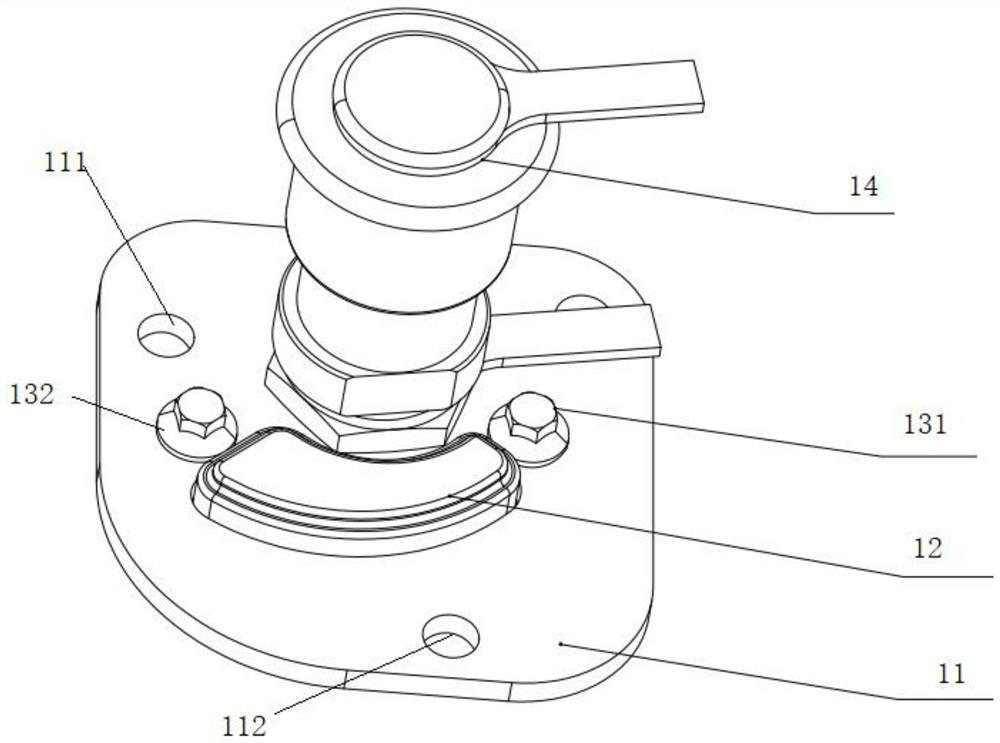

A car charging head suitable for new energy vehicles

ActiveCN112009279BDoes not affect the fixedEasy to tightenCharging stationsElectric vehicle charging technologyIn vehicleNew energy

Owner:义乌市一平汽车贸易有限公司

Infrared transmission module applied to hydrogen supply system

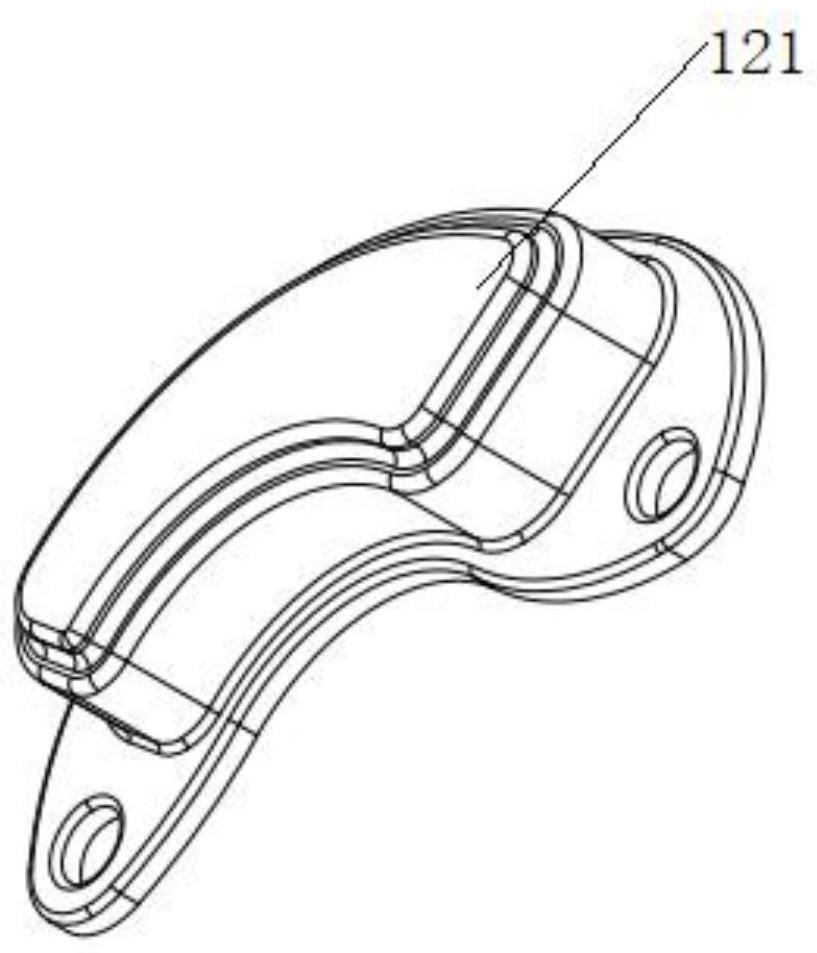

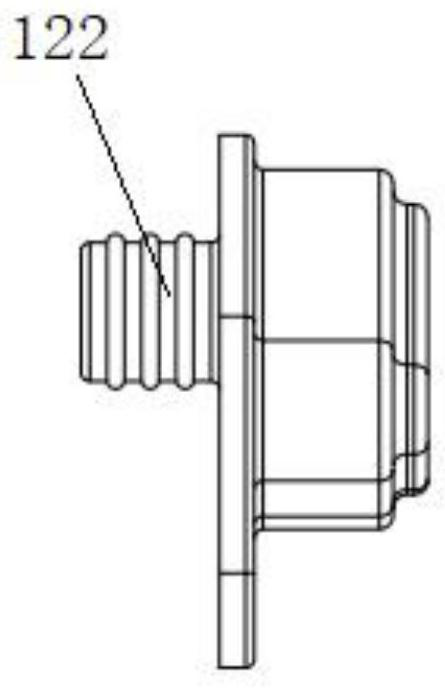

PendingCN112145961ADoes not affect the fixedReal-time transmissionContainer filling methodsPropulsion by batteries/cellsEngineeringHydrogen supply

The invention provides an infrared transmission module applied to a hydrogen supply system. The infrared transmission module is characterized in that an infrared transmission module and a hydrogenation port are fixed on a hydrogenation panel; the infrared transmission module is fixed on the hydrogenation panel through a corresponding connecting end of the infrared transmission module; the infraredtransmission module is of a half-moon-shaped structure; an emission line of the infrared transmission module is arranged in the hydrogenation panel, and the emission line is connected to the interiorof a hydrogen system through the hydrogenation panel; an infrared transmission point is integrated in the infrared transmission module and coincides with a receiving point integrated with a hydrogenation gun; According to the infrared transmission module applied to the hydrogen supply system, through the novel infrared transmission module, fixation of the infrared transmission module cannot be affected by different appearances and sizes of the hydrogenation port, meanwhile, the hydrogenation port does not need to increase the overall appearance length due to consideration of fixation of the infrared transmission module. The infrared transmission point is integrated in the half-moon-shaped structure and coincides with the receiving point integrated with the hydrogenation gun, data can be transmitted in real time in the hydrogenation process, and rapid hydrogenation is achieved.

Owner:上海舜华新能源系统有限公司

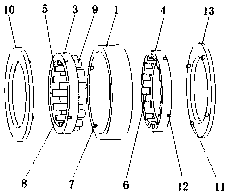

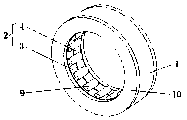

Bearing installing device

InactiveCN109210090AExtended service lifeAvoid scratchesBearing unit rigid supportEngineeringMechanical engineering

The invention discloses a bearing installing device. The bearing installing device comprises a bearing, a bearing chamber, an elastic piece, a bearing outer cover and a bearing inner cover. The bearing is arranged in the bearing chamber. A fixing piece is arranged between the bearing outer cover and the bearing inner cover. The bearing is fixedly connected with the fixing piece in a face contact manner. The bearing comprises a first ring body and a second ring body, wherein the first ring body is arranged on the inner circle side of the second ring body, one end side of the first ring body isprovided with an annular sealing cover A, the other end side is provided with an annular sealing cover B, and the elastic piece is arranged between the bearing outer cover and the annular sealing cover A. The elastic piece arranged between the bearing outer cover and the annular sealing cover A is utilized for providing pre-tightening pressure for the annular sealing cover A, the annular sealing cover A and the opposite annular sealing cover B are fixed in the bearing chamber formed by the bearing outer cover and the bearing inner cover, scratching caused by bearing rotation in the prior art is avoided, and the service life of the bearing can be prolonged.

Owner:贵州元诚实业有限公司

A worm processing mechanism capable of automatic upper and lower limit

Owner:广州德纳科技股份有限公司

Worm processing mechanism with lubricating-oil supplying system

InactiveCN104308280AHigh densityHigh precisionGearingGear lubrication/coolingThrust bearingEngineering

The invention discloses a worm processing mechanism with a lubricating-oil supplying system. The worm processing mechanism is used for processing a blank piece (1) into a worm and comprises a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads; the lower end of the driving sleeve (4) with the internal threads can be rotatably arranged on the rack (7) by a thrust bearing (47).

Owner:国网山东省电力公司沂源县供电公司

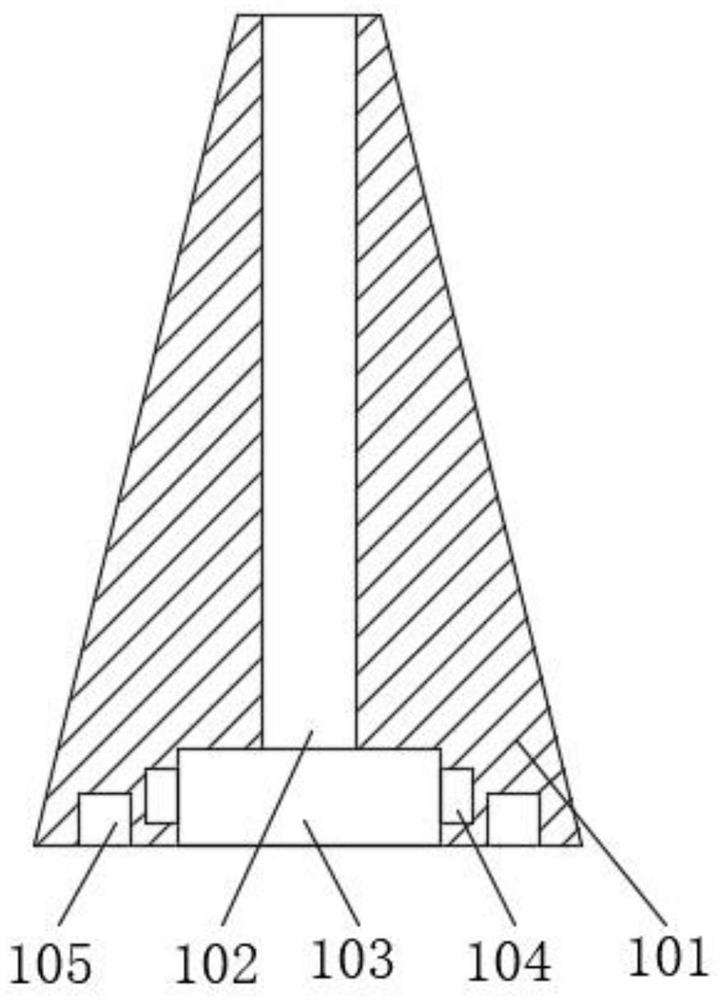

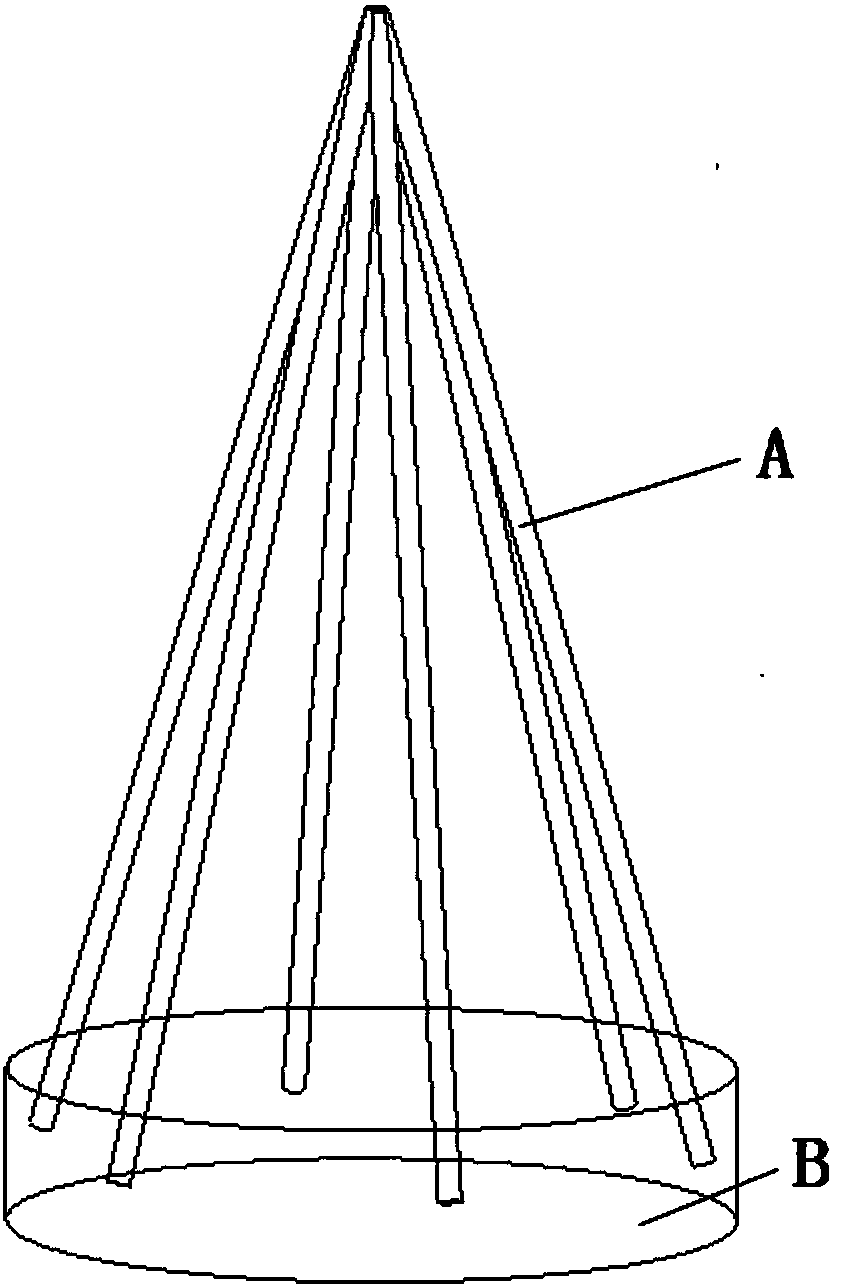

Protection film for implanting and releasing conical cavity vein filter

The invention relates to a protection film for implanting and releasing a conical cavity vein filter, and belongs to the field of medical instruments. The protection film wraps one end of the filter close to a supporting leg, is made of degradable materials and has elasticity, the protection film can be unfolded along with unfolding of the filter when the filter is implanted and released, the protection film is thin, and the thickness of the protection film is smaller than 0.2 millimeter after the filter is unfolded. According to the protection film, force released by the filter is effectivelyrelieved in the unfolding process of the filter, so that damage of supporting leg hooked spines to blood vessel walls is reduced, fixing of the filter on the blood vessel walls cannot be affected asthe protection film is thin, the protection film is marked by an iodide compound, a degradation position of the protection film in a human body is easily traced by a medical image, a blood vessel injury resisting drug on the protection film helps to protect blood vessels, and complication of filter implantation is decreased. The protection film solves the problem that the blood vessels are damagedwhen the filter is unfolded and has important clinical application values.

Owner:BEIHANG UNIV +1

A circuit-controlled worm machining mechanism

The invention discloses a worm processing mechanism controlled by a circuit. The worm processing mechanism is used for processing a blank piece (1) into a worm and comprises a DSP (Digital Signal Processing) control circuit, a blank-piece bearing piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a rack (7), wherein the blank-piece bearing piece (2) is used for bearing the blank piece (1); relative to the sleeve (3) with the external threads, the upper end and the lower end of the blank-piece bearing piece (2) are respectively and fixedly arranged in the sleeve (3) with the external threads by an upper bearing (21) and a lower bearing (22) in an axial manner; the sleeve (3) with the external threads is matched in the driving sleeve (4) with the internal threads by threads.

Owner:国网山东省电力公司沂源县供电公司

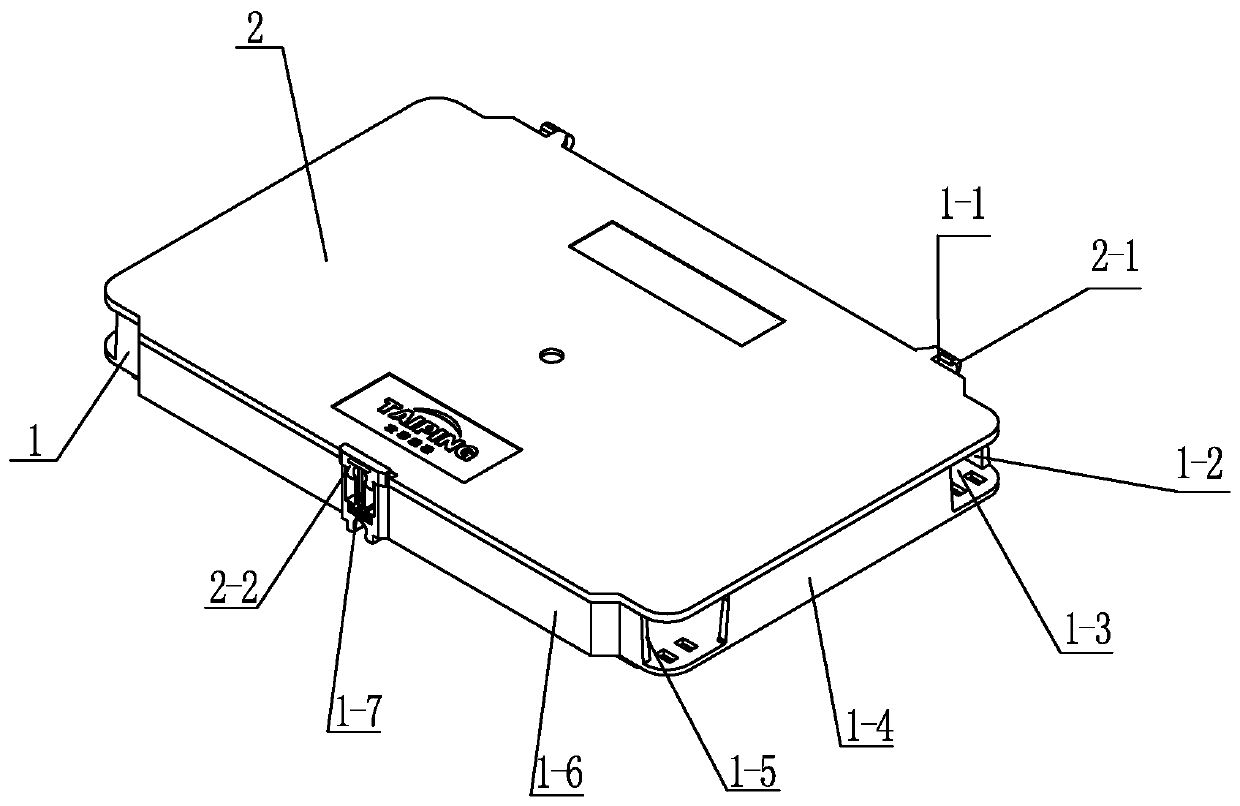

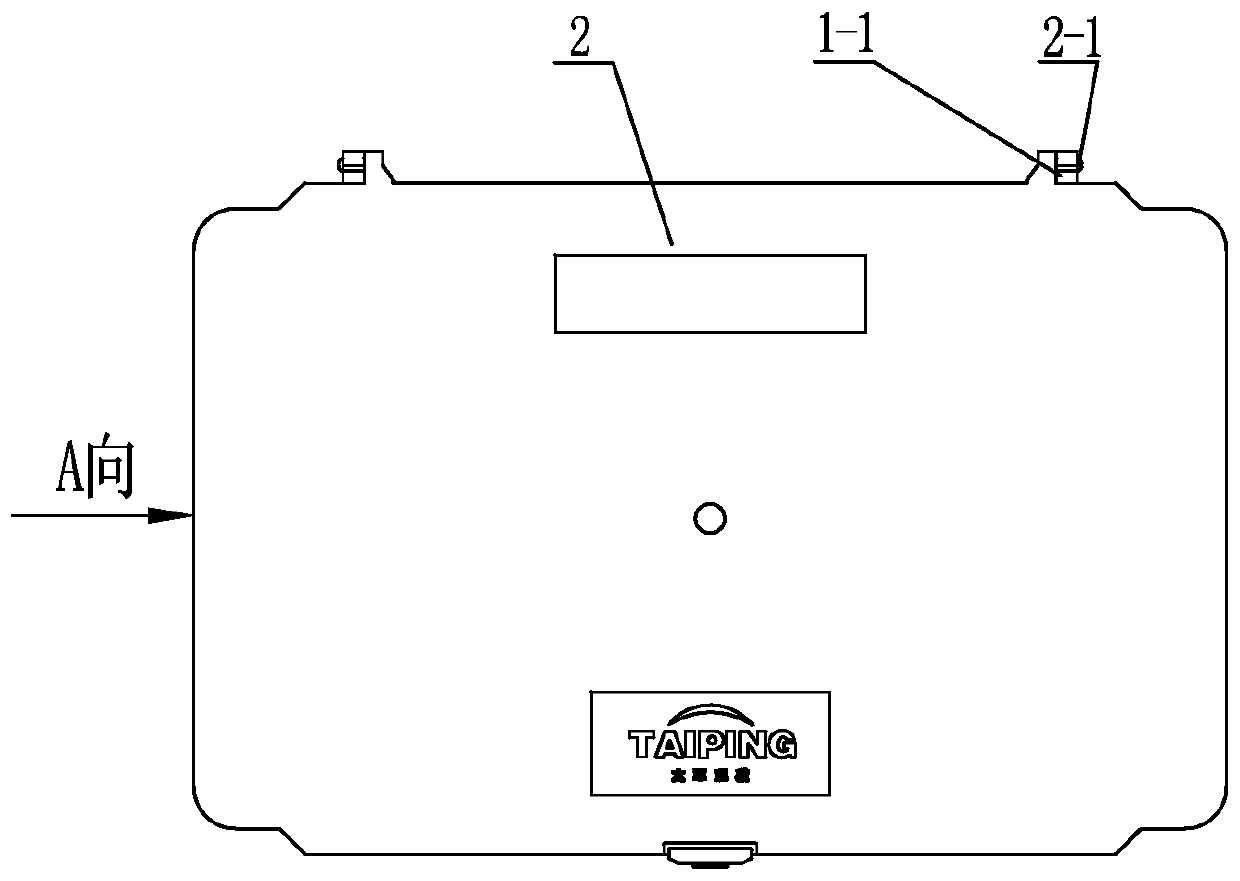

Universal Fiber Splice Tray

ActiveCN107121728BDoes not affect the fixedEasy maintenance and operationCoupling light guidesFiberEngineering

Owner:CHANGZHOU TAIPING COMM SCI & TECH

Green building steel structure

PendingCN114293661AWon't overflowAvoid blockageFatty/oily/floating substances removal devicesGeneral water supply conservationMechanical engineeringStormwater

The invention belongs to the field of green buildings, and particularly relates to a green building steel structure which comprises a steel tank, supporting steel is fixedly connected to the lower surface of the steel tank through bolts, a supporting rod is connected to the interior of the supporting steel in a welded mode, a rotating rod is arranged in the supporting steel, and a rotating block is connected to the tail end of the supporting rod in a welded mode. A filter screen is fixedly connected to the interior of the supporting steel through bolts, and a pushing block is arranged in the supporting steel. The device solves the problems that when some existing green building steel structures are used, rainwater is collected through a steel tank, meanwhile, the side faces of a house are supported through supporting steel, tiles are generally laid after a steel structure building is built, and after the tiles are used for a period of time, fragments can be brought into the steel tank through impact of the rainwater, so that the service life of the steel structure building is prolonged. And in addition, rainwater cannot be collected and utilized by the whole device, so that the whole device is not energy-saving enough.

Owner:张优温

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com