High-performance automatic cutting equipment for insulating sleeve of cable connector

A technology of cable connectors and insulating sleeves, which is applied in the field of high-performance automatic cutting equipment for insulating sleeves, can solve the problems of low cutting efficiency, high labor intensity of operators, and insufficient cutting quality, so as to improve the cutting application Range, improve cutting stability and quality, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

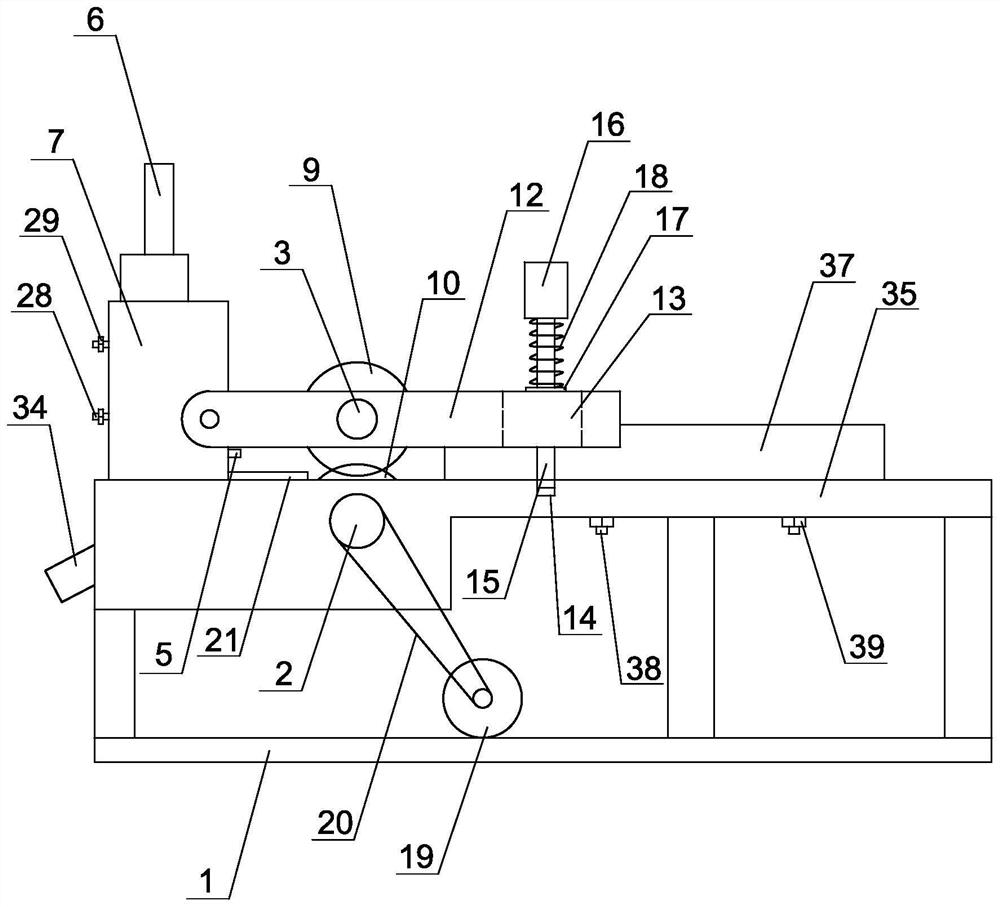

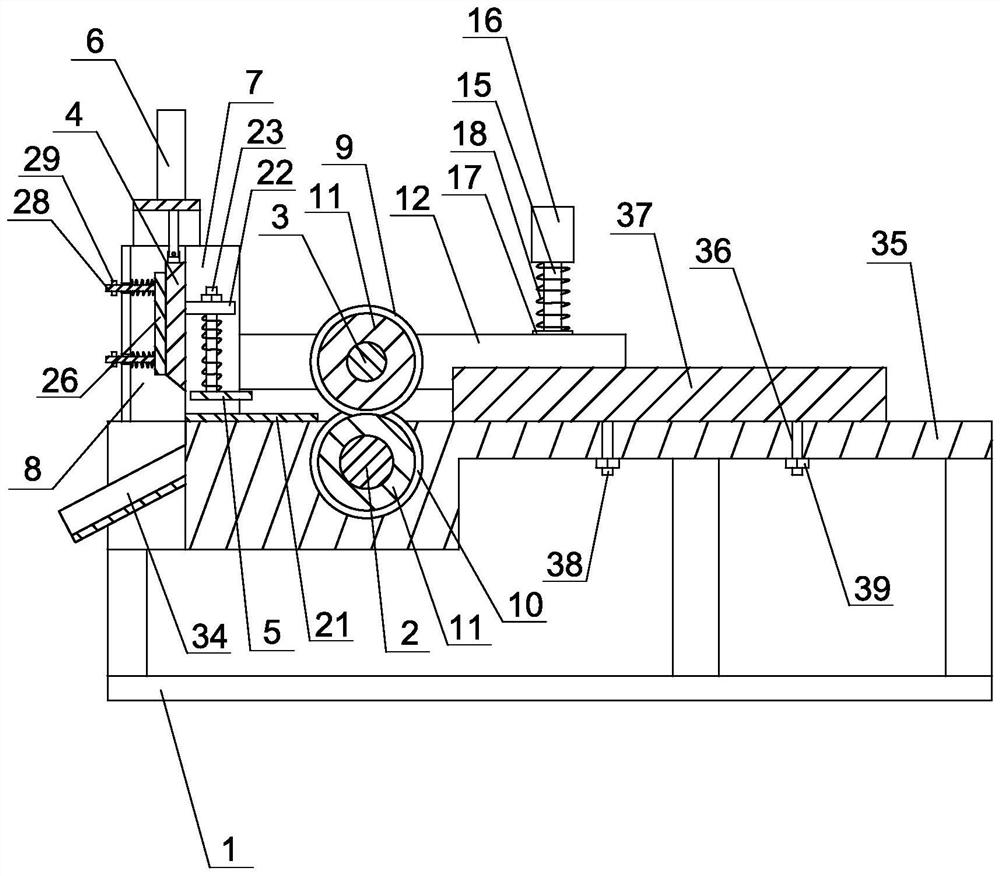

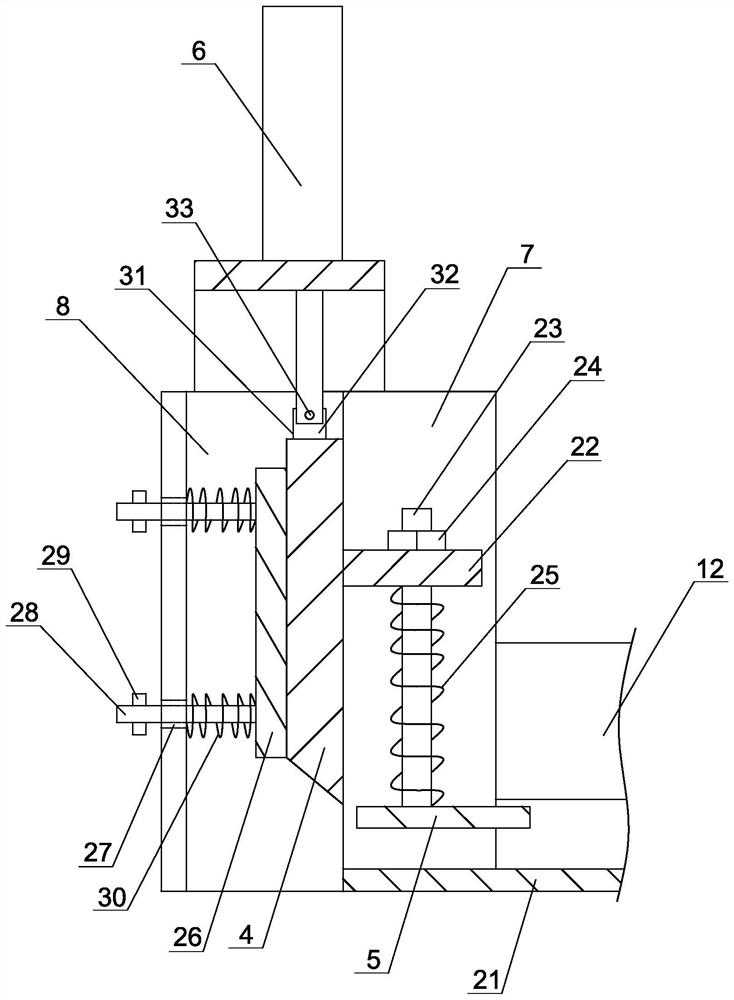

[0026] Example 1: see Figures 1 to 3 As shown, a high-performance automatic cutting device for insulating sleeves of a cable connector includes a frame 1, a conveying mechanism and a cutting mechanism arranged on the frame, and the conveying mechanism is arranged on the left side of the cutting mechanism;

[0027] The conveying mechanism includes a bottom driving roller 2, a pressing roller 3 and a driving mechanism. The bottom driving roller is rotatably connected to the frame, the driving mechanism drives the bottom driving roller to rotate, and the pressing roller is arranged in parallel with the frame. Above the bottom driving roller, the pressing roller is connected with the bottom driving roller through a transmission member, and when the bottom driving roller rotates, the pressing roller is driven to rotate synchronously by the driving member;

[0028] The cutting mechanism includes a cutter 4, a pressing plate 5 and a vertical cylinder 6, two sets of vertical plates 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com