Recovery device for zirconium oxide powder production waste liquid

A recovery device and technology of zirconia powder, which is applied in the direction of general water supply saving, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of high energy consumption, failure to meet the cost control of production enterprises, and high cost, and achieve recovery efficiency High, low recycling cost, and the effect of low-cost recycling waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments are provided below and the present invention is further described in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

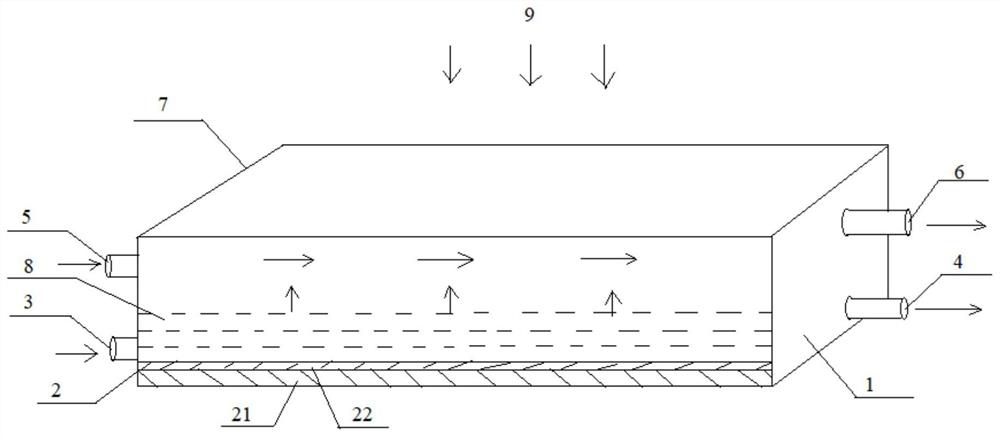

[0026] Such as figure 1 As shown, the zirconia powder production waste liquid recovery device of the present invention includes a solar evaporation pool 1, and the solar evaporation pool includes side walls and bottoms, and the side walls and the bottom surround a container for treating waste liquids. setting space.

[0027] A layer of solar heat absorbing bottom plate 2 is laid on the bottom in the solar evaporation pool 1 . The solar heat-absorbing bottom plate is composed of a substrate 21 and a heat-absorbing coating 22 , and the heat-absorbing coating 22 is laid on at least one side of the substrate 21 . Substrate 21 is flat plate shape usually, also can be the shape of other existing solar heat absorbing panels such as corrugated shape, fin shape etc.; The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com