A lifting helical gear processing equipment

A technology for processing equipment and helical gears, which is applied in metal processing equipment, mechanical equipment, belts/chains/gears, etc., can solve the problem of difficulty in ensuring the shape and position accuracy of tooth grooves, troublesome manufacturing of helical gears, difficulty in meeting cost reduction and increasing processing speed and accuracy issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

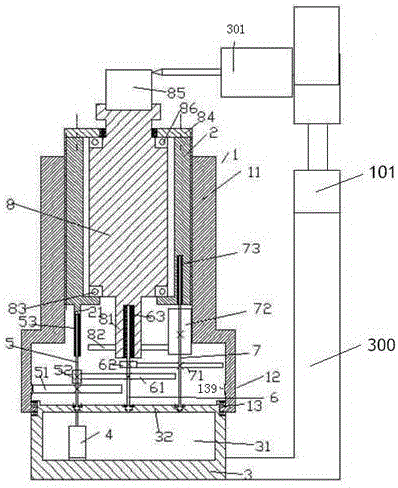

[0012] Attached below Figure 1-2 , the present invention will be described in detail.

[0013] A helical gear processing equipment that can be raised and lowered, used for processing the blank 85, it includes: a base 3, a column 300, a milling processing head 301, a rotatable internal threaded part 1, an external threaded part 2 and a cylindrical The workpiece carrier 8, wherein the base 3 is fixedly connected to the lower end of the column 300, the upper end of the column 300 is equipped with a lifting device 101, and the upper end of the lifting device 101 is equipped with a milling processing head 301, and the milling processing head 301 can be rotated by the milling cutter. The blank 85 is cut, and the rotatable internal threaded part 1 includes an upper cylindrical part 11 and a lower chamber part 12, and the lower chamber part 12 is connected to the base 3 in a circumferentially rotatable and axially fixed way through a bearing device 13 , the externally threaded membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com