Construction waste cleaning device

A technology for construction waste and cleaning equipment, which is applied in the direction of construction waste recycling, cleaning methods and tools, and solid waste removal, can solve problems affecting personnel work, difficulty in cleaning construction waste in all directions, and reduce equipment work efficiency, etc., to improve The effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

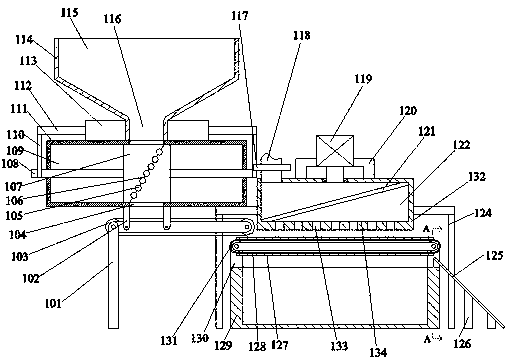

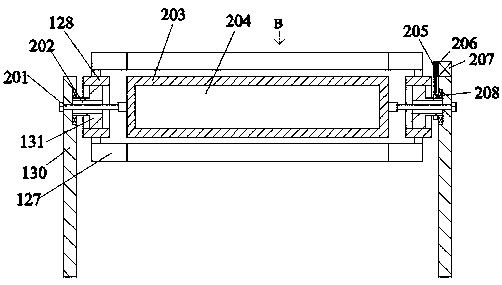

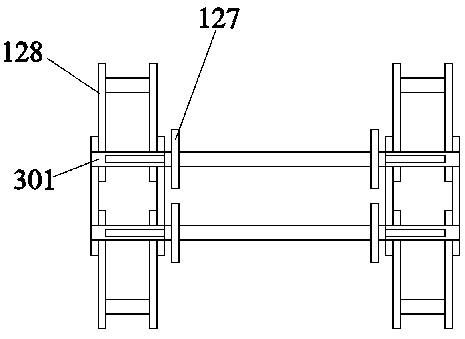

[0021] Such as Figure 1-Figure 3 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent. A construction waste cleaning device of the present invention includes a bracket 101, and a motor-driven conveyor 103 is arranged inside the bracket 101. The front and rear sides of the conveyor 103 are provided with construction A crushing device for preliminary crushing of materials, the right side of the bracket 101 is provided with a support pole 124, and the support pole 124 is provided with a water liquid spraying device for periodically spraying the water liquid. A cleaning device for transporting construction waste for efficient cleaning is provided on the lower side of the discharge device, so that the above-mentioned device can realize efficient crushing and cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com