Patents

Literature

30results about How to "Does not affect normal transportation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

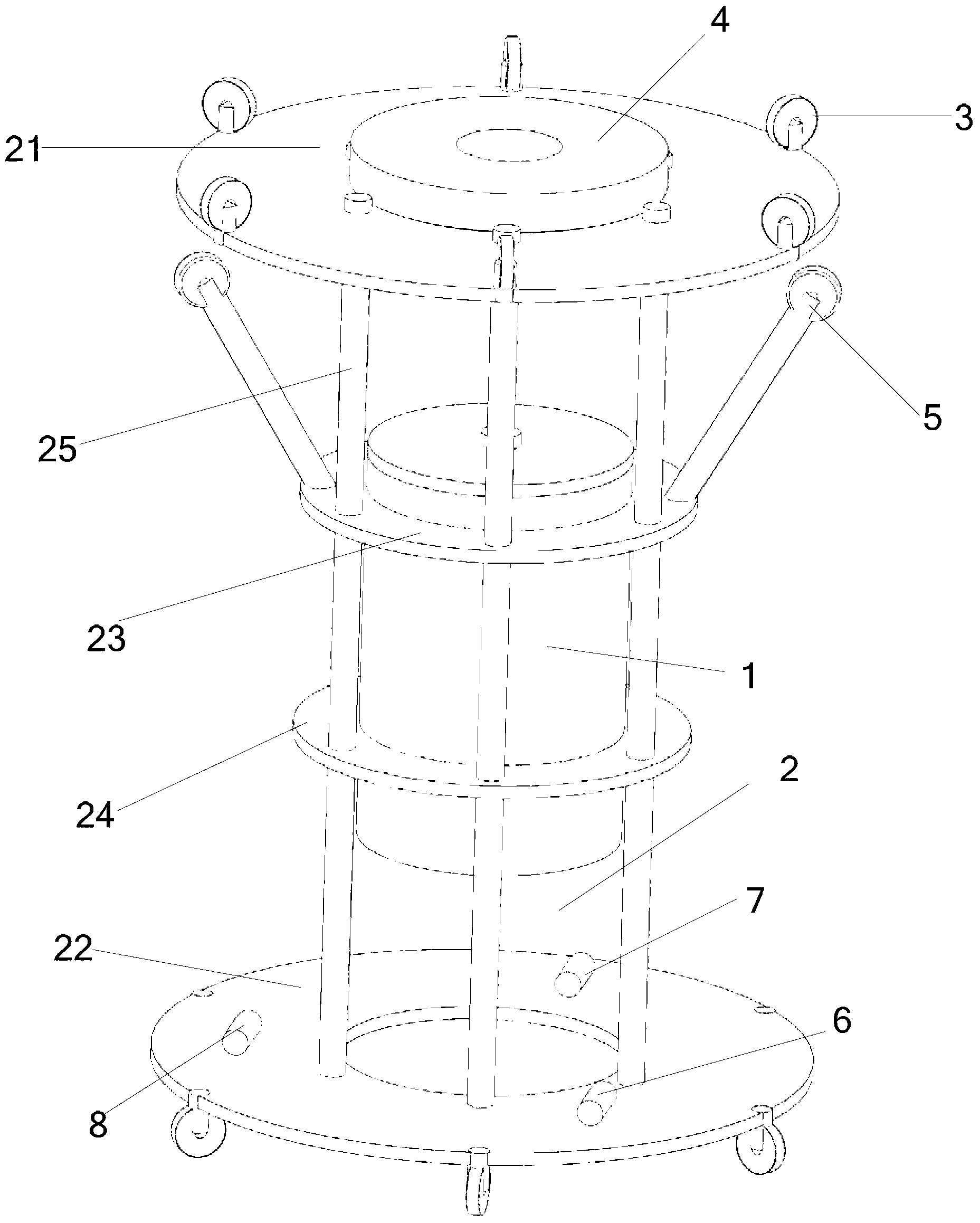

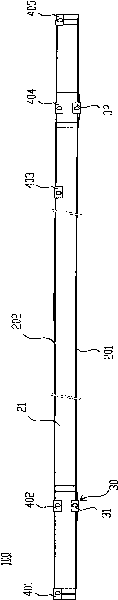

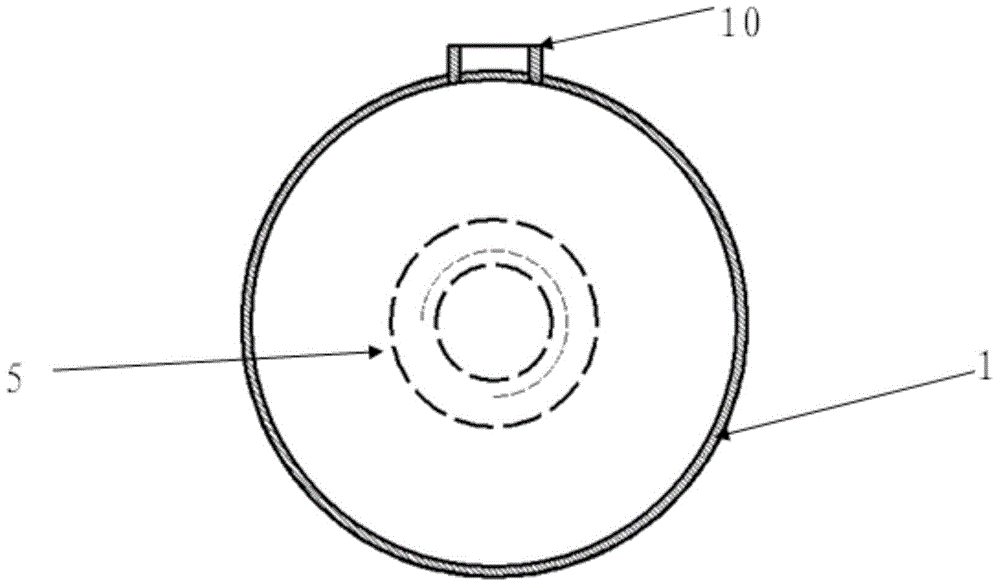

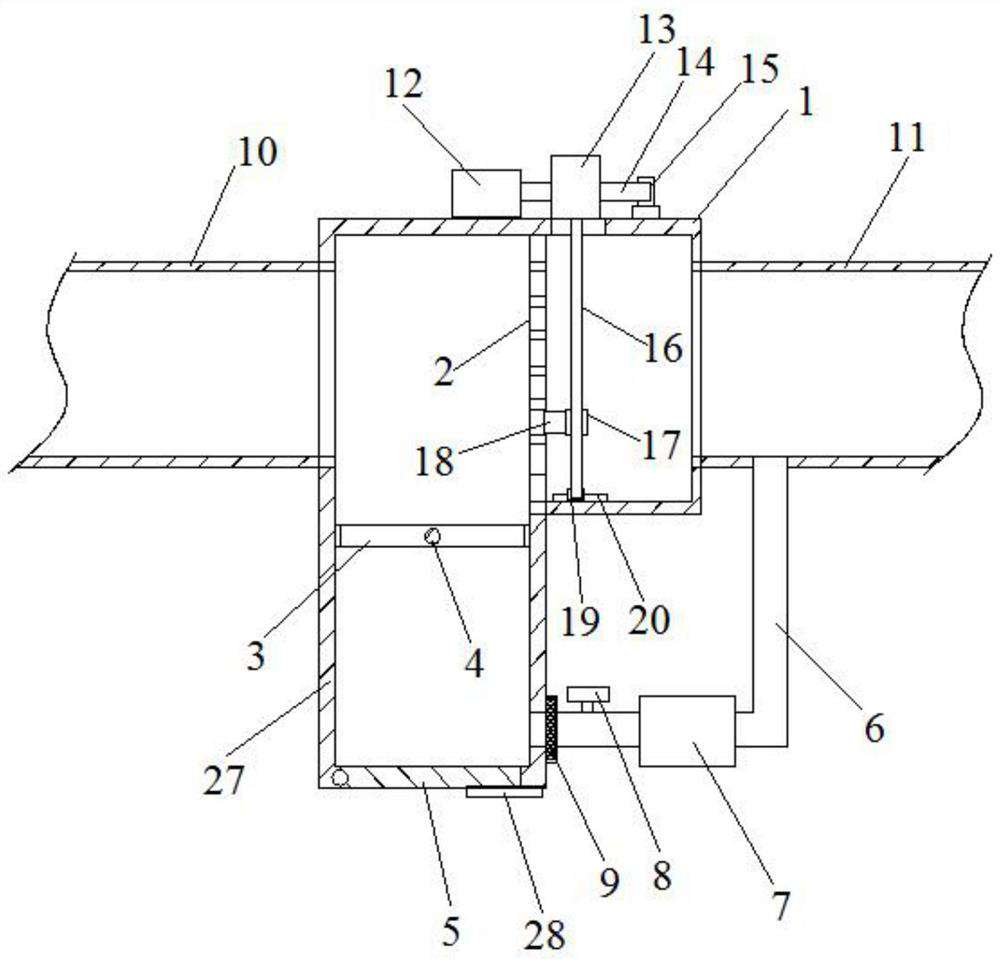

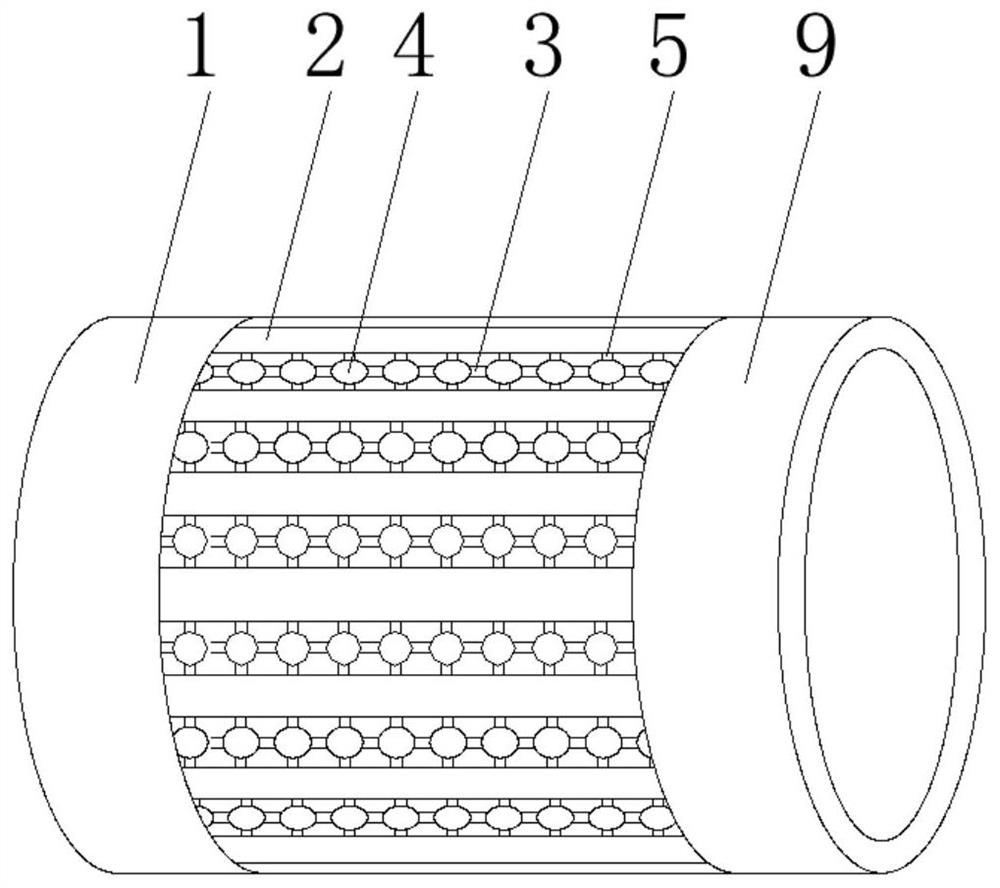

Inner detection system for submarine pipelines and detection method thereof

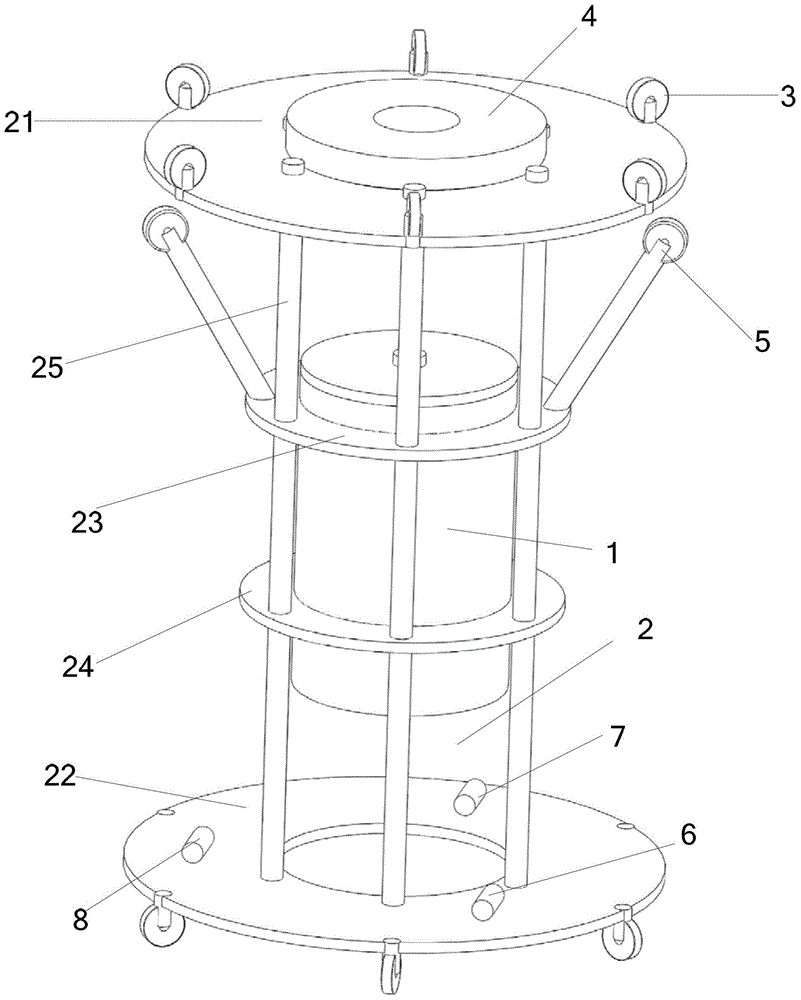

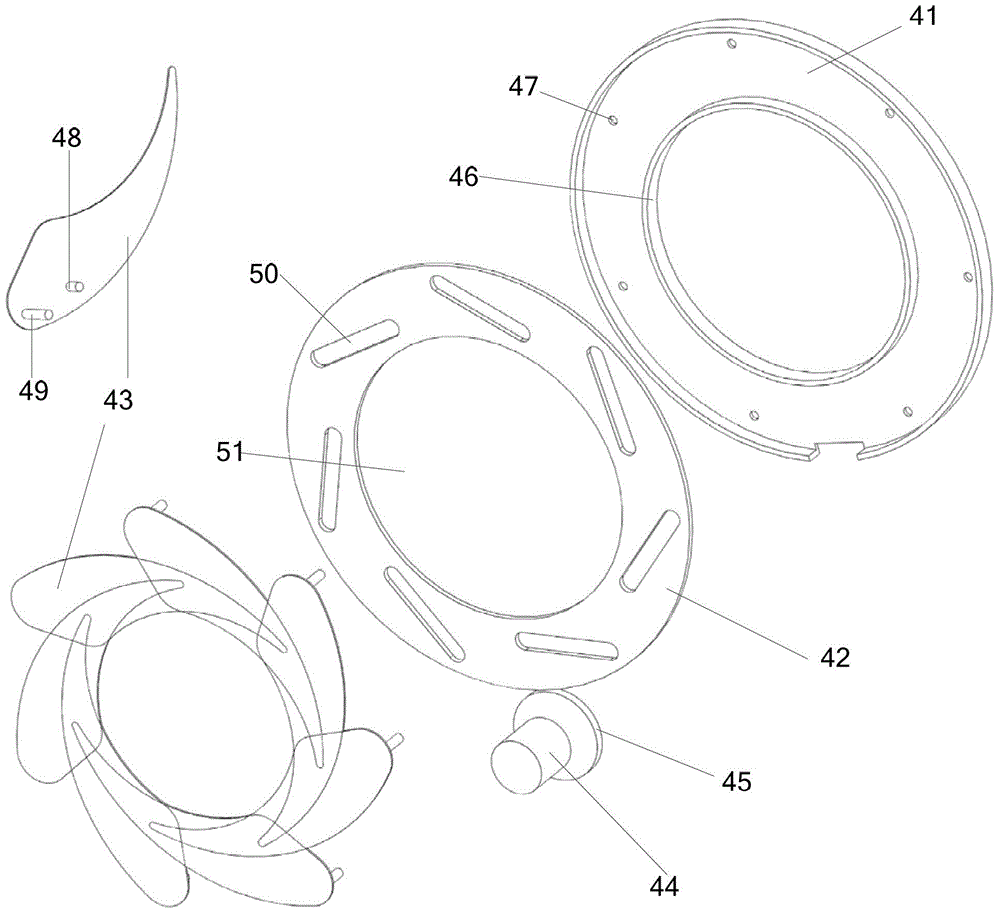

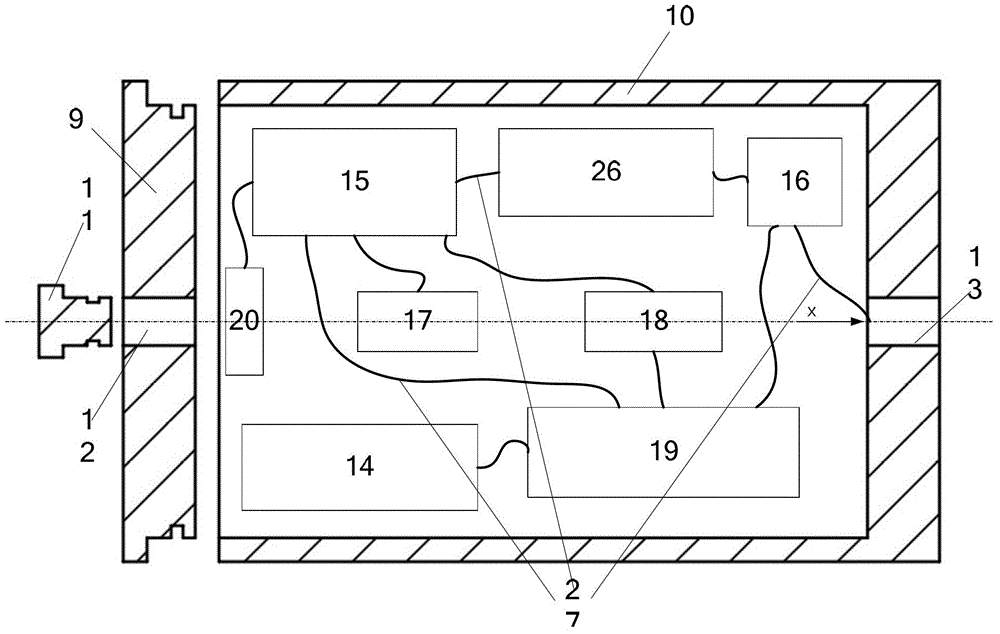

The invention discloses an inner detection system for submarine pipelines and a detection method thereof. The inner detection system comprises an electronic sealed cabin arranged in a supporting frame. The supporting frame is provided with a supporting roller array, an odometer wheel, a pressure sensor, a temperature sensor and a sound sensor, wherein the supporting roller array, the odometer wheel, the pressure sensor, the temperature sensor and the sound sensor are distributed in an annular mode. The detection method includes: the inner detection system is connected to an upper computer to download signals collected by the sensors, and filtering and noise reduction processing is performed on the signals; traveling mileage of the inner detection system and included angles of the axis of the inner detection system and a local geomagnetic field and local gravitational acceleration are calculated at any time t, and a direction vector of the axis of the inner detection system is obtained through the included angles; the position of the inner detection system at any time is obtained; and whether leakage exists is judged through comparison of processed sound signals, pressure signals and temperature signals, and leakage rate is estimated. The inner detection system for submarine pipelines and the detection method of the inner detection system achieve detection of little leakage, improve detection accuracy, reduce detection difficulty and cost, and shorten detection period.

Owner:TIANJIN UNIV

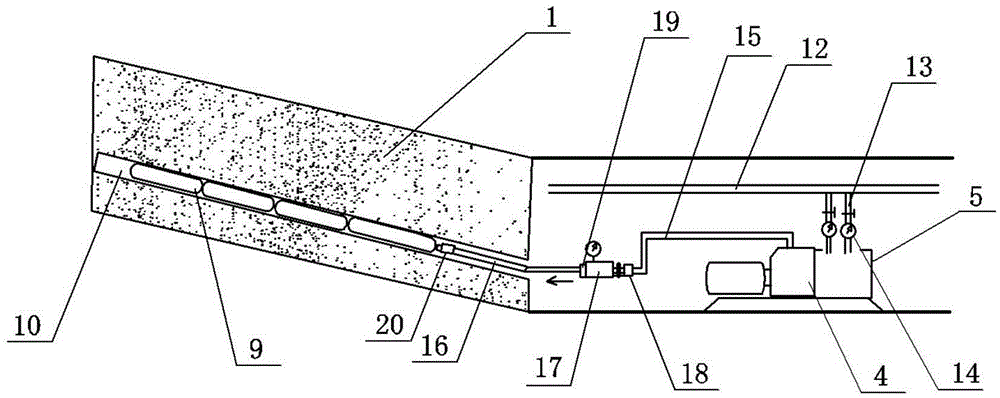

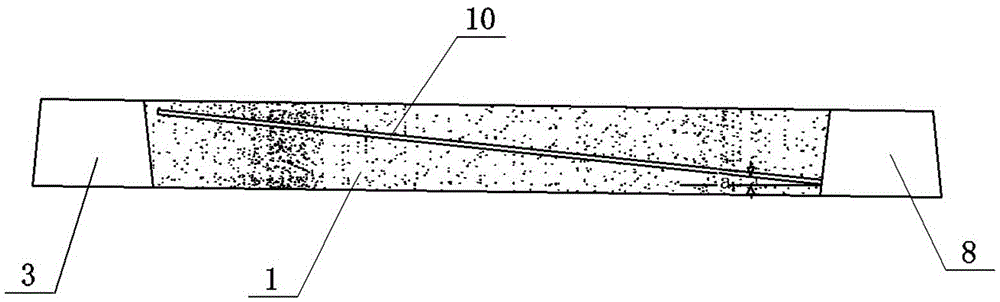

Efficient water injection method and device of hydraulic fracture permeability increase auxiliary coal seam

InactiveCN105422164AGood water permeabilityHigh densityDust removalFire preventionHydraulic fracturingHigh pressure water

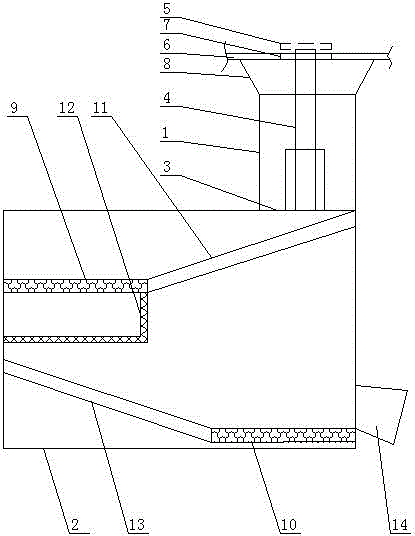

The invention discloses an efficient water injection method and device of a hydraulic fracture permeability increase auxiliary coal seam. Before coal seam static pressure water injection, high pressure water generated by an emulsion pump is injected into a drilled static pressure water injection drilled hole through a high pressure pipeline, high pressure water is injected into a coal body fracture by means of the cutting and fracturing effect of a water wedge generated by the high pressure water on the coal seam on the periphery of the drilled hole to overcome the minimum principal stress and the anti-fracture pressure of the coal body, so that fractures are broadened, extended and communicated; in the fracturing process, quartz sand is added into the high pressure water, the quartz sand enters the fractures along with the high pressure water, the effect of a supporting agent is achieved, and the water injection drilled hole is connected to a static pressure pipeline to perform static pressure water injection on the coal seam after hydraulic fracturing is finished. Before static pressure water injection is performed, the breathability of a water pre-injection coal seam is increased, so that the coal seam water injection speed is increased, and the water injection efficiency and effect are improved. According to the method, no special emulsion pump is needed, the running time of the emulsion pump is short, the drilling construction work amount can be decreased, and the water injection working efficiency is improved.

Owner:HENAN POLYTECHNIC UNIV

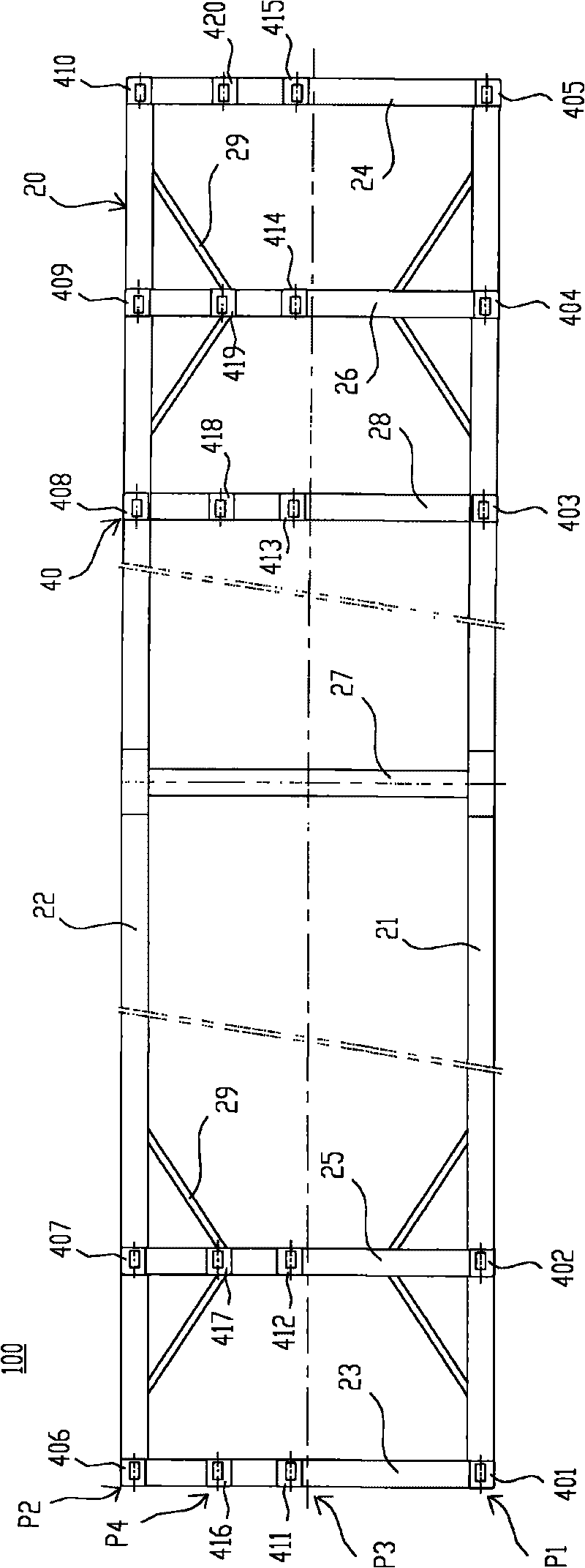

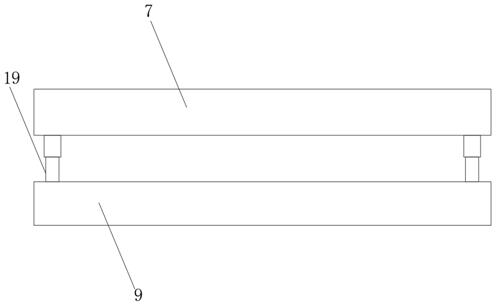

Transport platform

InactiveCN101746486AEasy to fastenReduce shipping costsPreventing unwanted cargo movementEngineeringIso standards

The invention relates to a transport platform, which is applied to the stern shipping spaces of a container transport ship to transport containers. The inner part of each stern shipping space is provided with at least one corner piece base group which is composed of a plurality of corner piece bases and has a first standard length and a first standard width corresponding to the standard size of an ISO standard container. The transport platform comprises a frame, at least one standard fixed corner piece group and a plurality of top corner pieces, wherein the frame has a frame width corresponding to the standard width of the ISO standard container; the standard fixed corner piece group is arranged on the bottom surface of the frame, and each standard fixed corner piece group is composed of a plurality of standard fixed corner pieces and has a second standard length and a second standard width corresponding to the standard size of the ISO standard container; and the top corner pieces are arranged on the top surface of the frame and can be combined into at least one stacking corner piece group. Each stacking corner piece group has a predetermined length corresponding to the length of a container or the length of a header, and the header is formed by connecting a plurality of containers.

Owner:NANTONG CIMC SPECIAL TRANSPORTATION EQUIP MFR +1

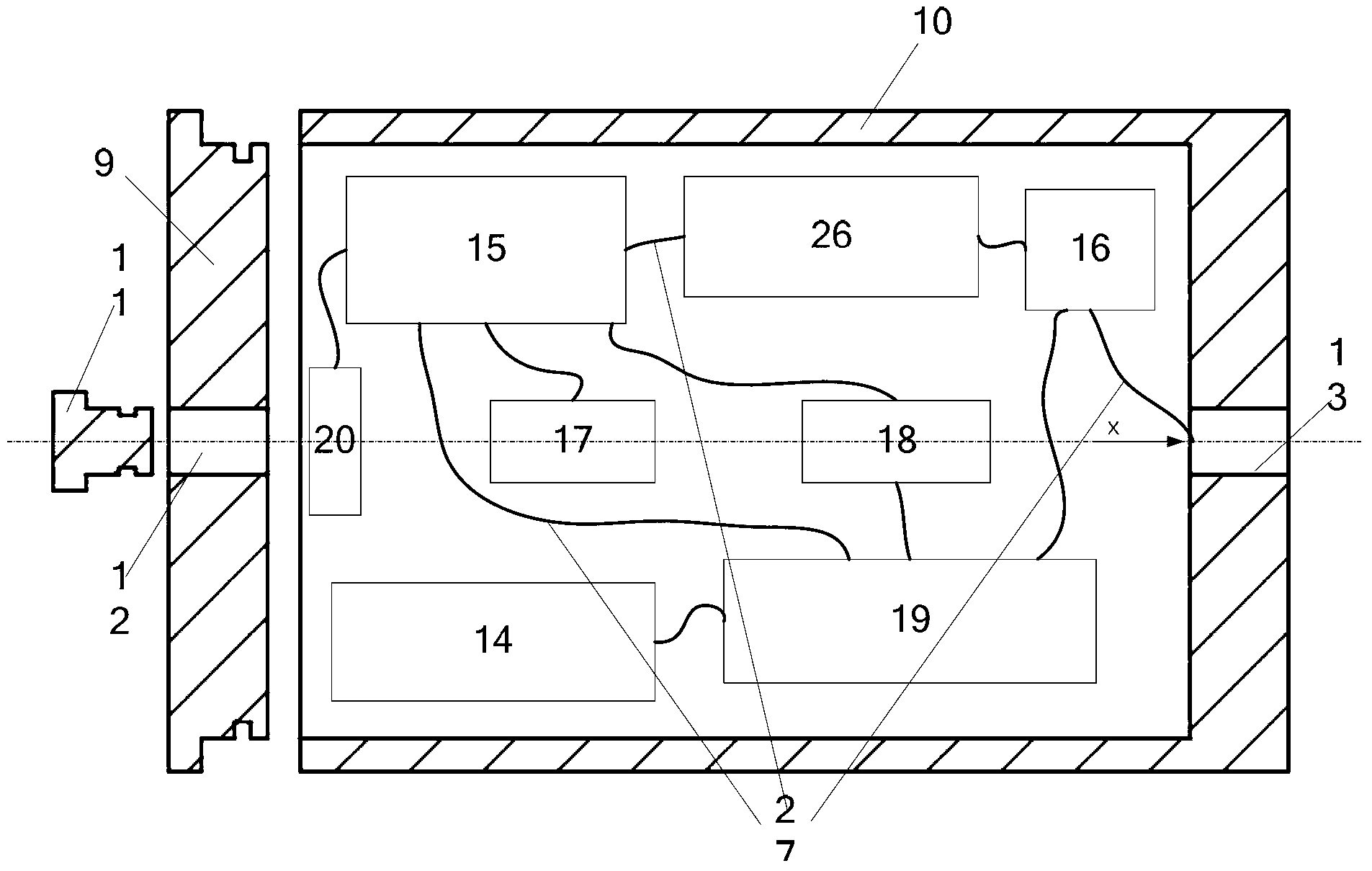

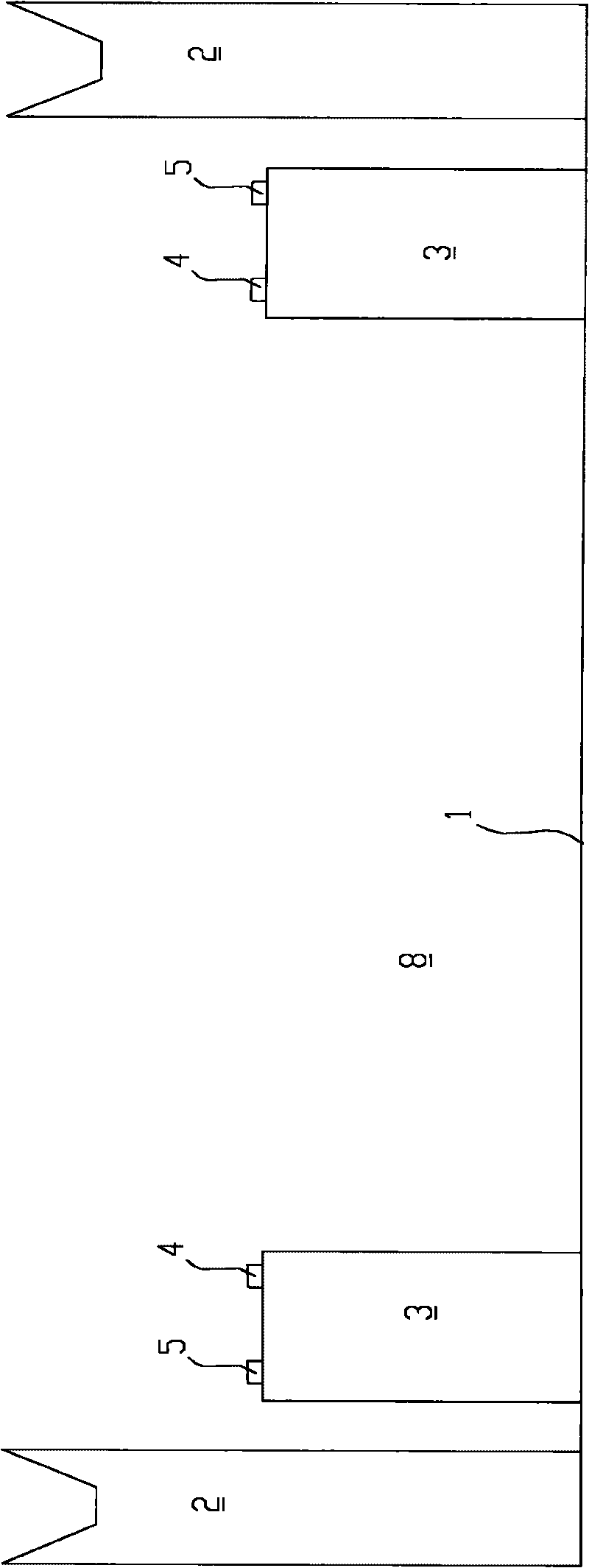

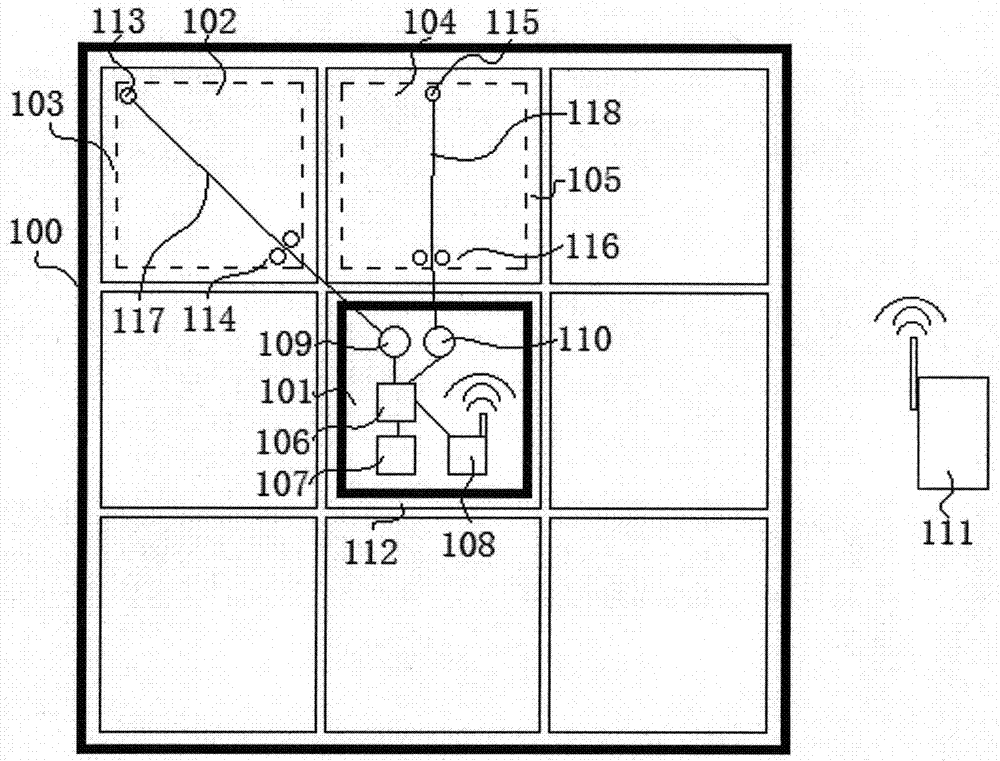

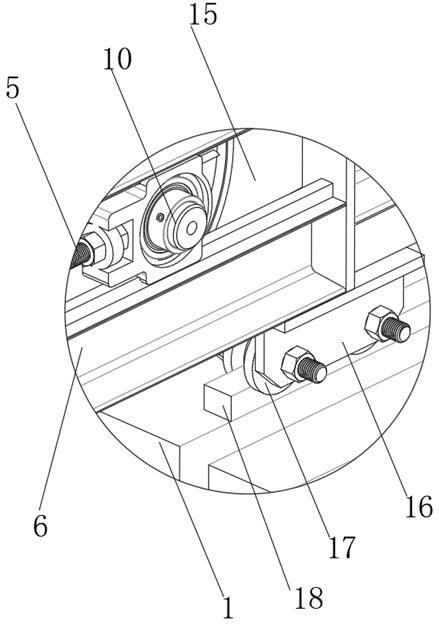

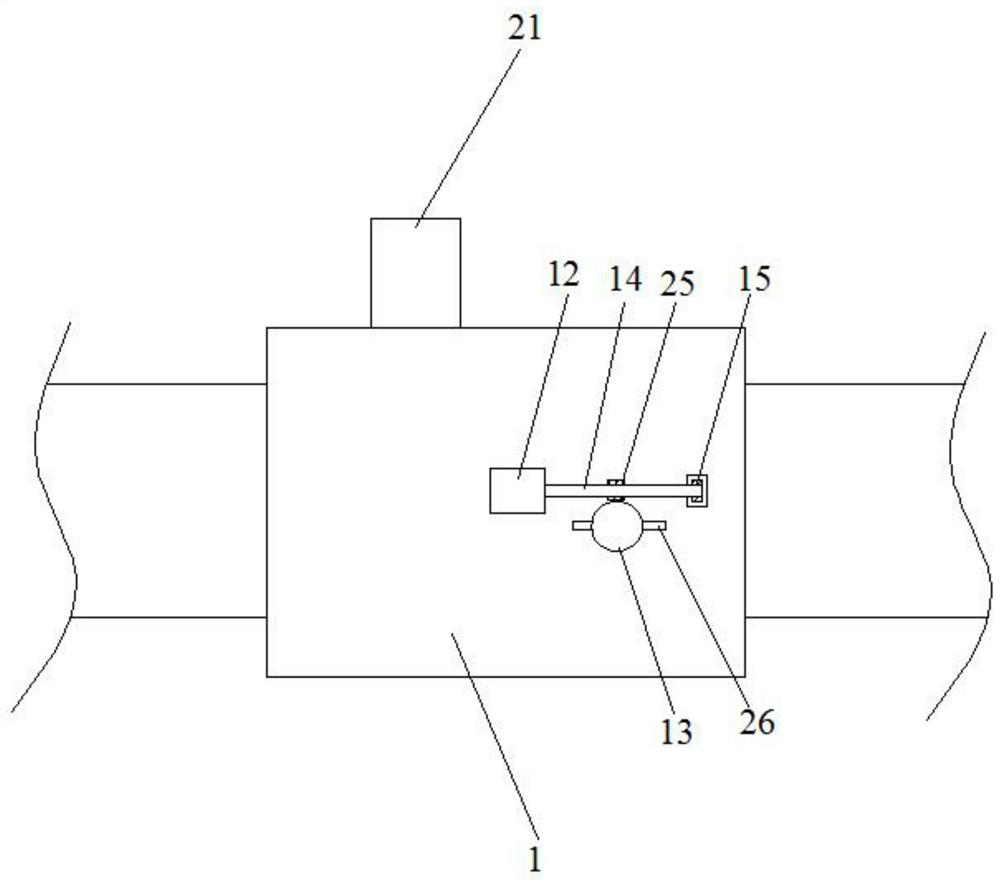

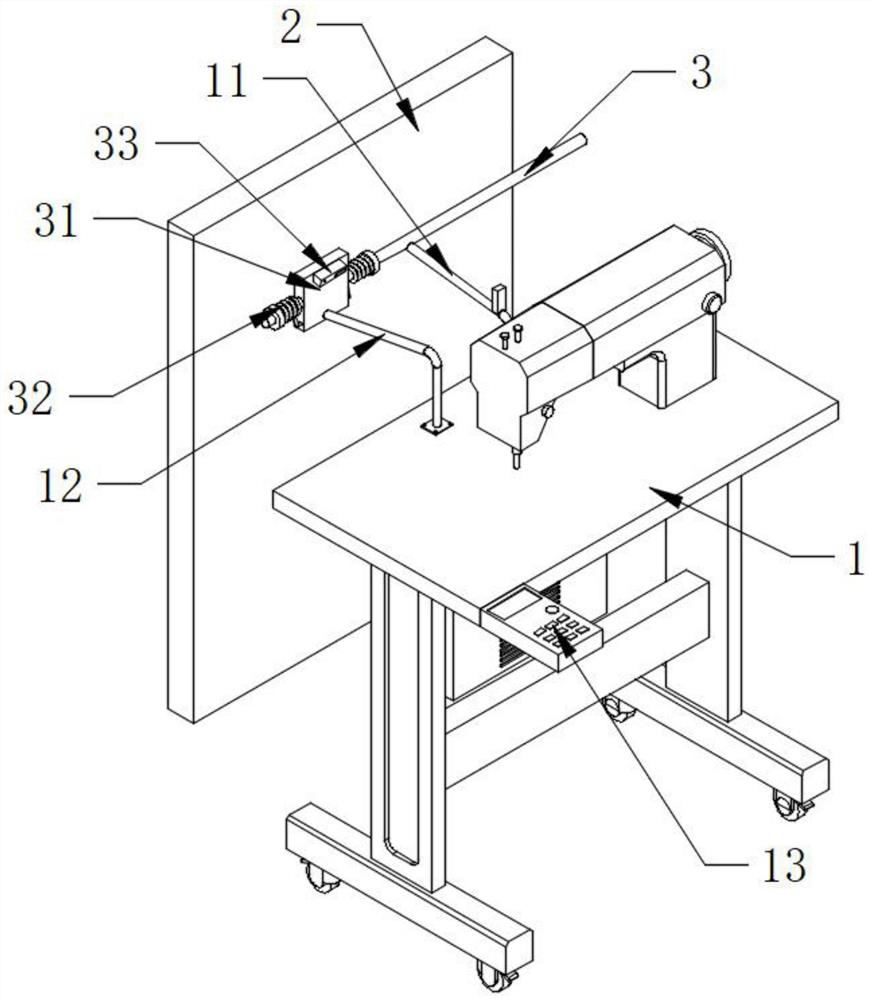

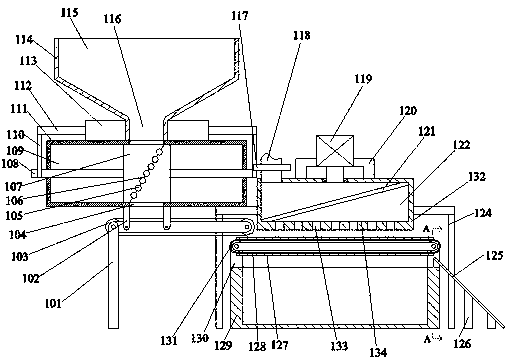

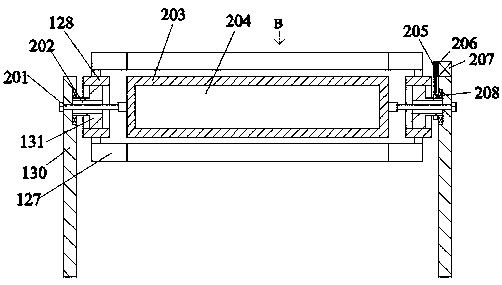

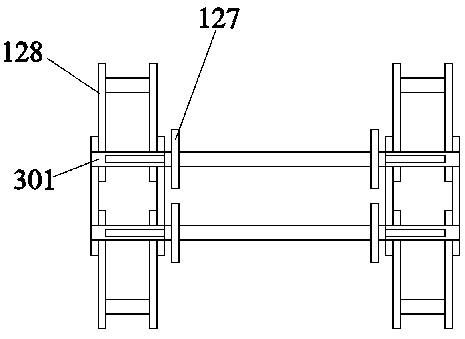

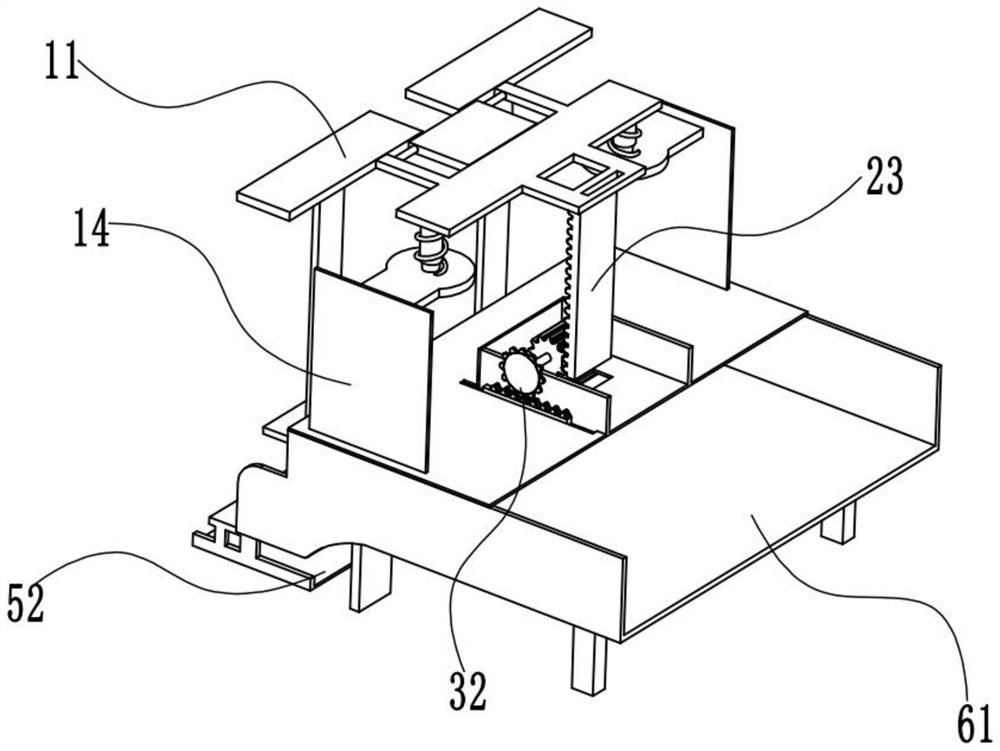

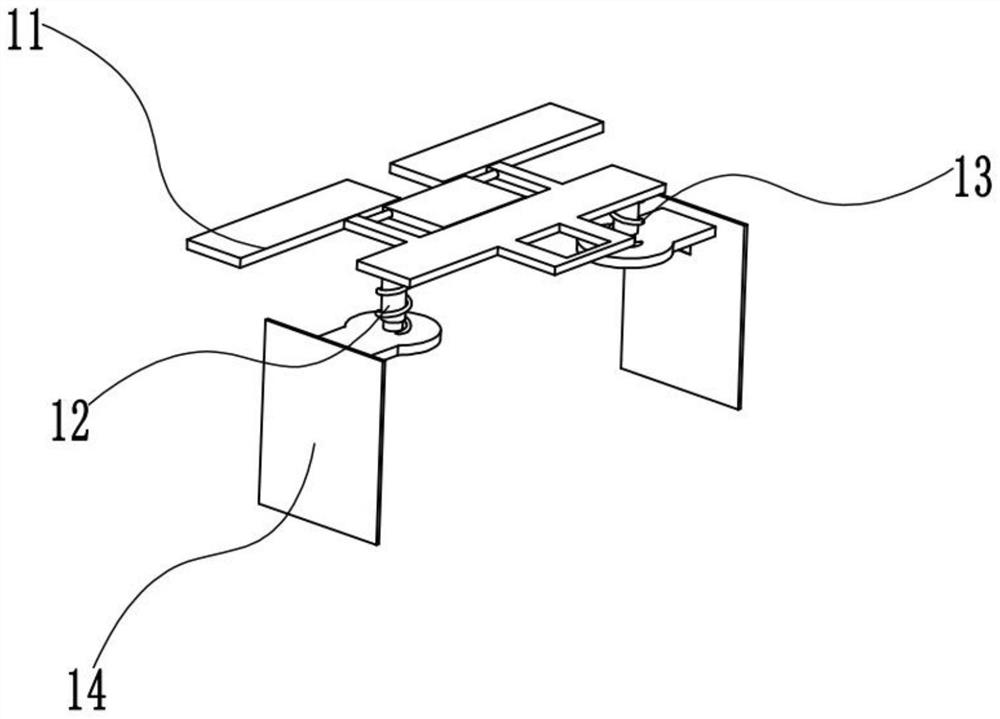

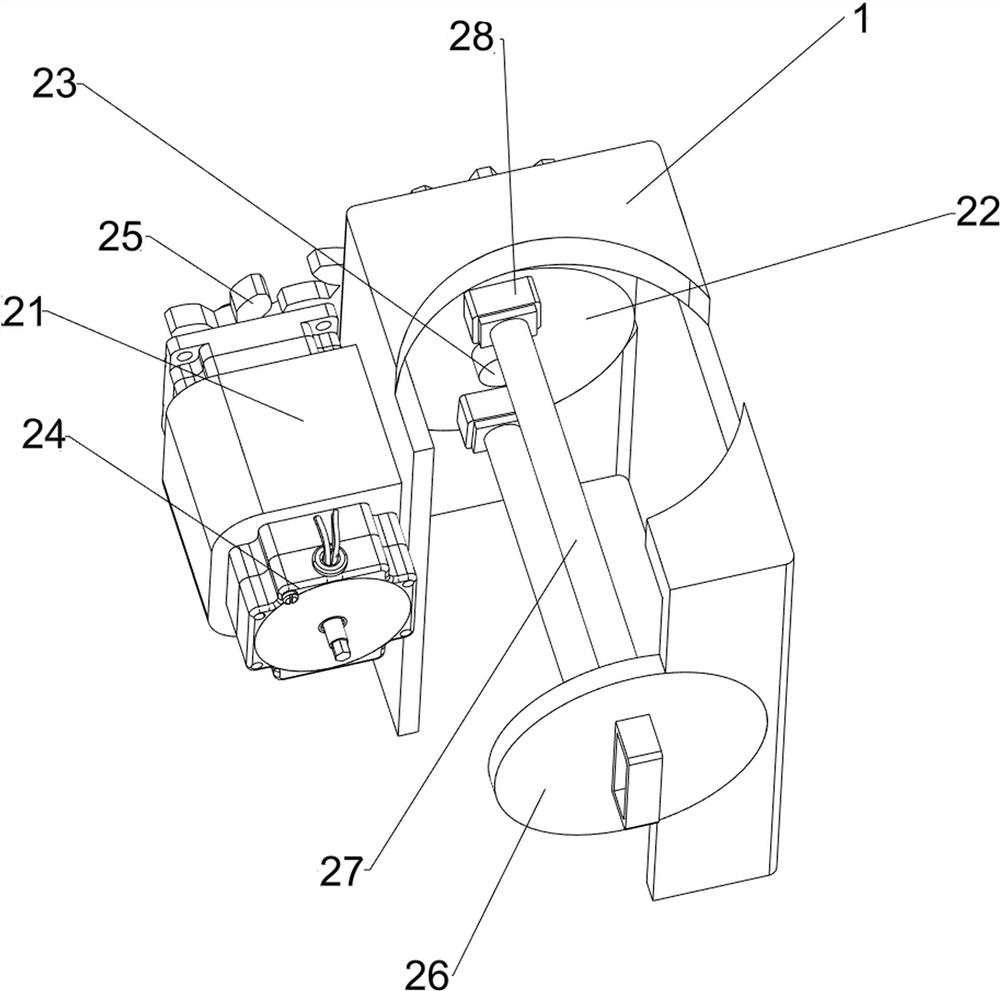

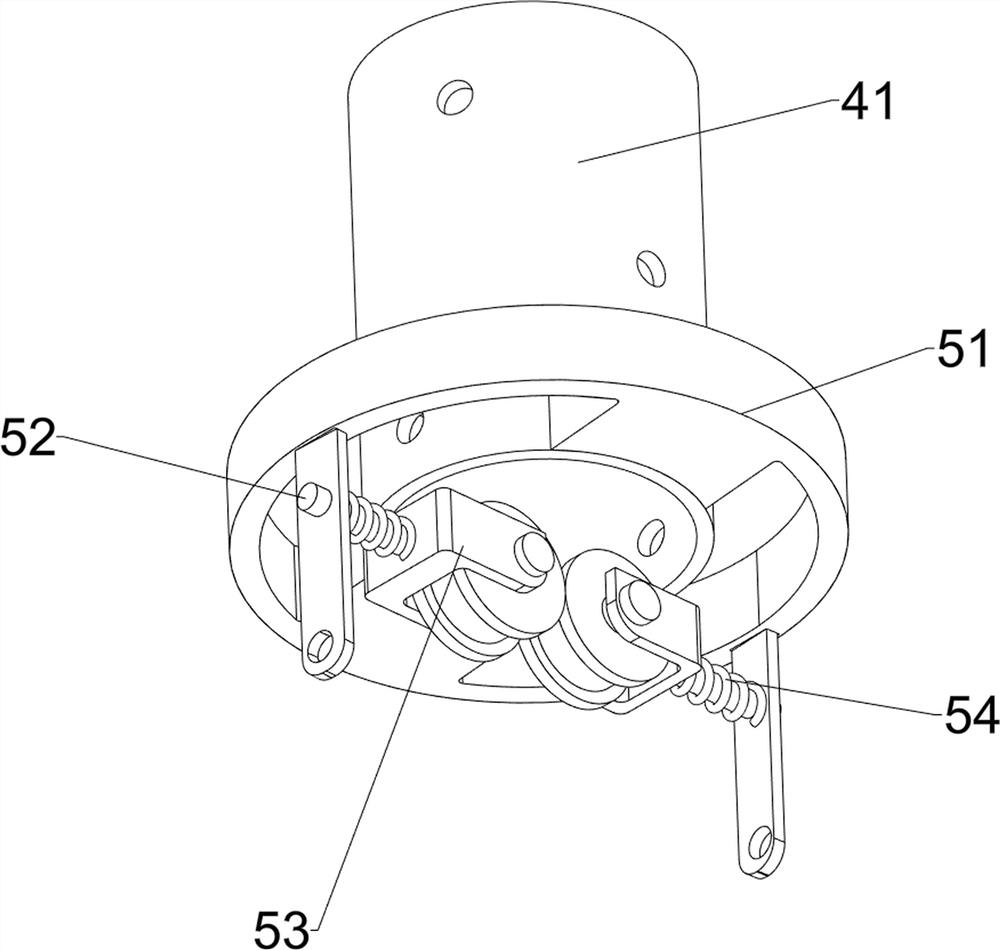

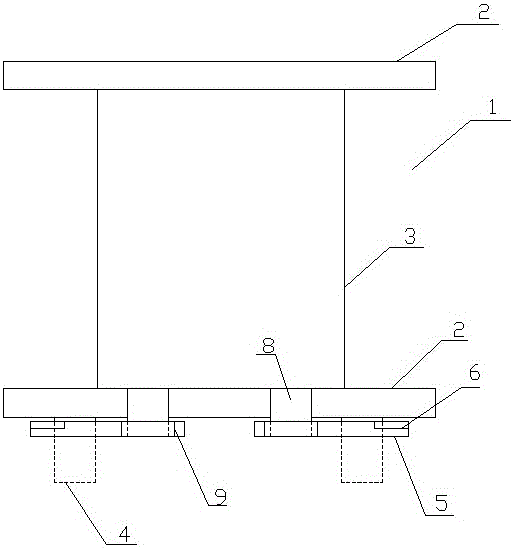

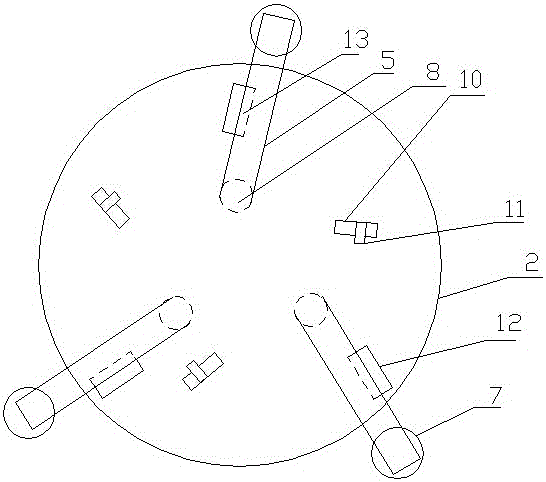

A real-time detection device for the displacement of goods transported on an intercity expressway

ActiveCN105043326BSave detection spaceDoes not affect normal transportationMeasurement devicesRelative displacementEconomic benefits

The invention discloses a device for detecting the displacement of cargo transported in an intercity highway in real time. The device detects the relative displacement of the cargo by means of a linear displacement sensor and is composed of a detecting bracket and a plurality of detected brackets. In each logistic pallet, the middle cargo stack is provided with a detecting bracket and the other cargo stacks are provided with the detected brackets respectively. Before the cargo is transported every time, each cargo stack displacement sensor on the logistic pallet is installed and acquires displacement data to be used as initial displacement values of the cargo stacks. In transit, displacement values of the cargo stacks are detected regularly and are used as transported cargo vibrated indexes in transit. The detecting bracket and the detected brackets are separated so that the device is suitable for different types of pallet stacking requirements. A cargo stack top fixing technical scheme decreases detection space and does not influence normal transport. The device is easy to install, low in cost, and high in reliability, can be repeatedly used, and has good economic benefit and market promotion prospect.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

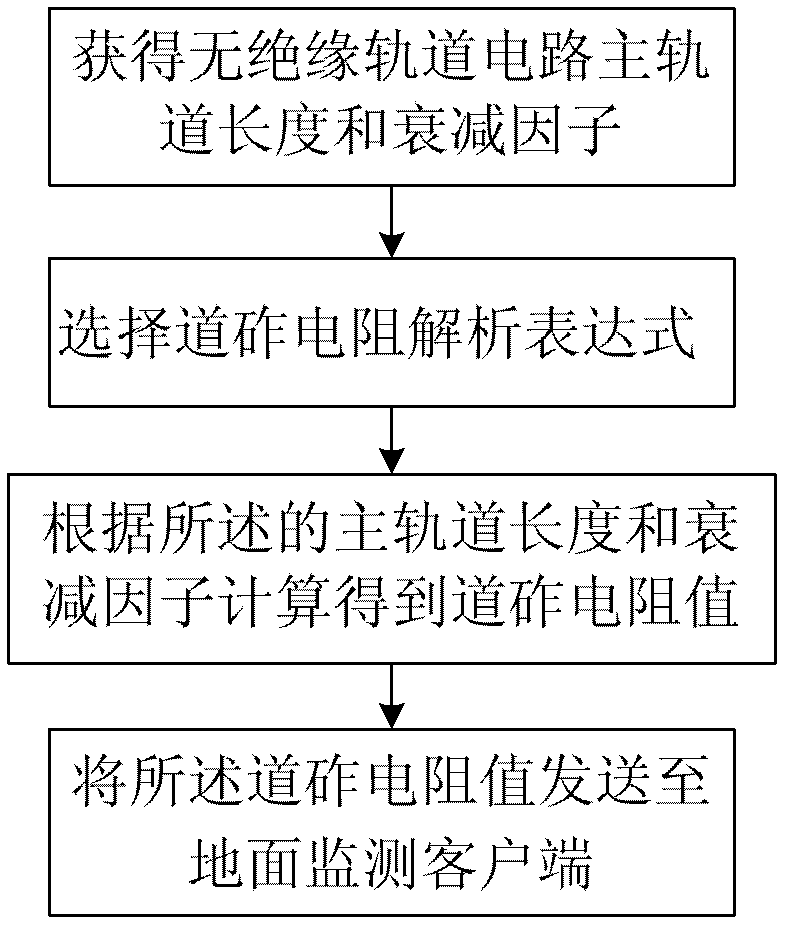

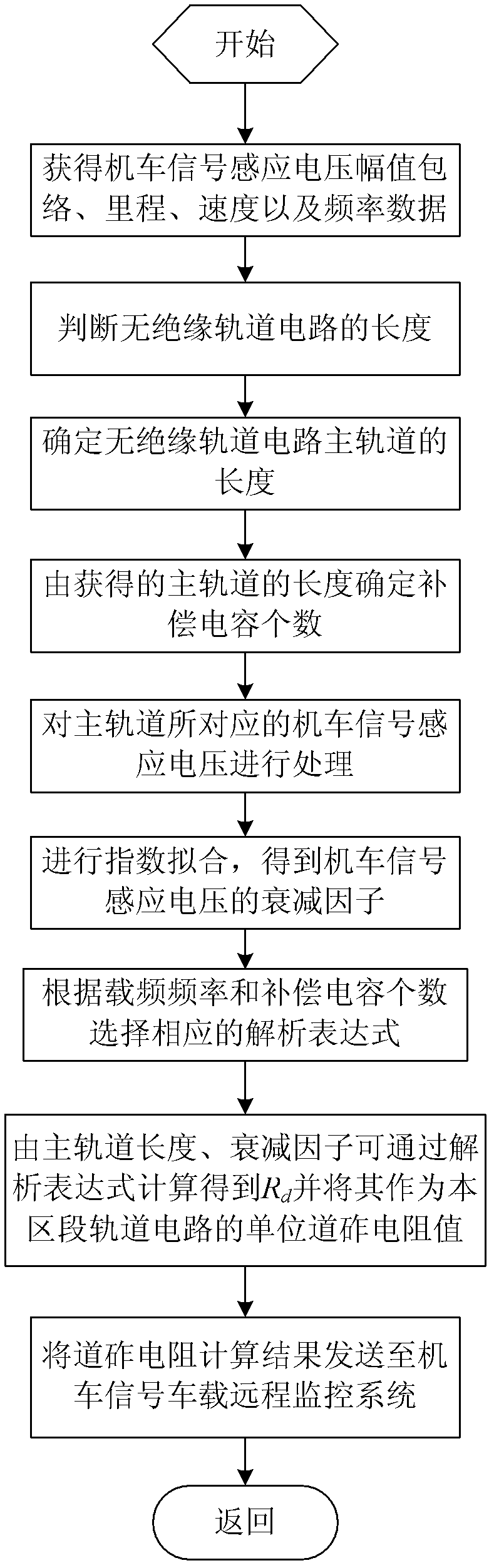

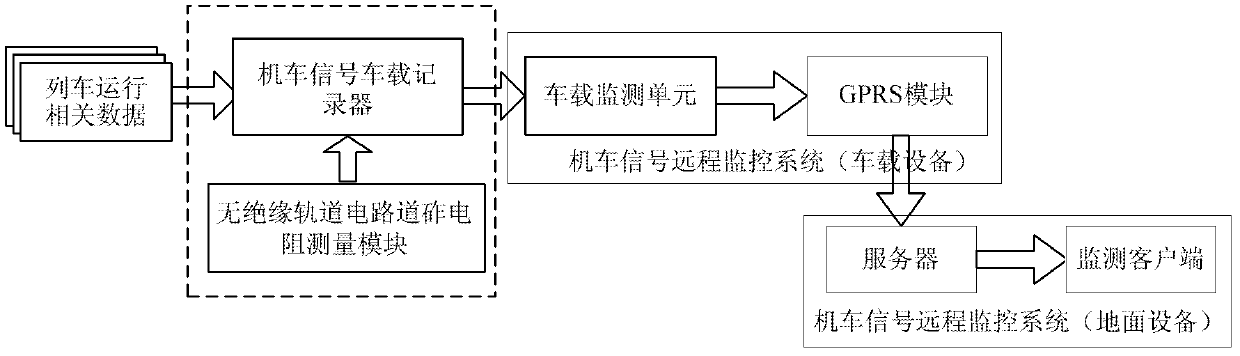

Ballast resistance online monitoring method of jointless track circuit

InactiveCN102565536ADoes not affect normal workDoes not affect normal transportationResistance/reactance/impedenceElectrical resistance and conductanceEngineering

The invention relates to a ballast resistance online monitoring method of a jointless track circuit. The method comprises the following steps: getting the length of a main track and an attenuation factor of the jointless track circuit; selecting a ballast resistance resolution expression; calculating a ballast resistance value according to the length of the main track and the attenuation factor; and sending the ballast resistance value to a ground monitoring client, wherein the calculation of ballast resistance is realized in a locomotive signal vehicle-mounted system. According to the ballast resistance online monitoring method, the ballast resistance value of the jointless track circuit can be simply and quickly calculated, the measurement accuracy is high, and the anti-noise performance is better; and furthermore, the ballast resistance online monitoring method only relies on an existing locomotive signal system, any hardware equipment does not need to be increased, the monitoring cost is low, and the ballast resistance online monitoring method is conductive to whole-line popularization and use of a railway.

Owner:BEIJING JIAOTONG UNIV

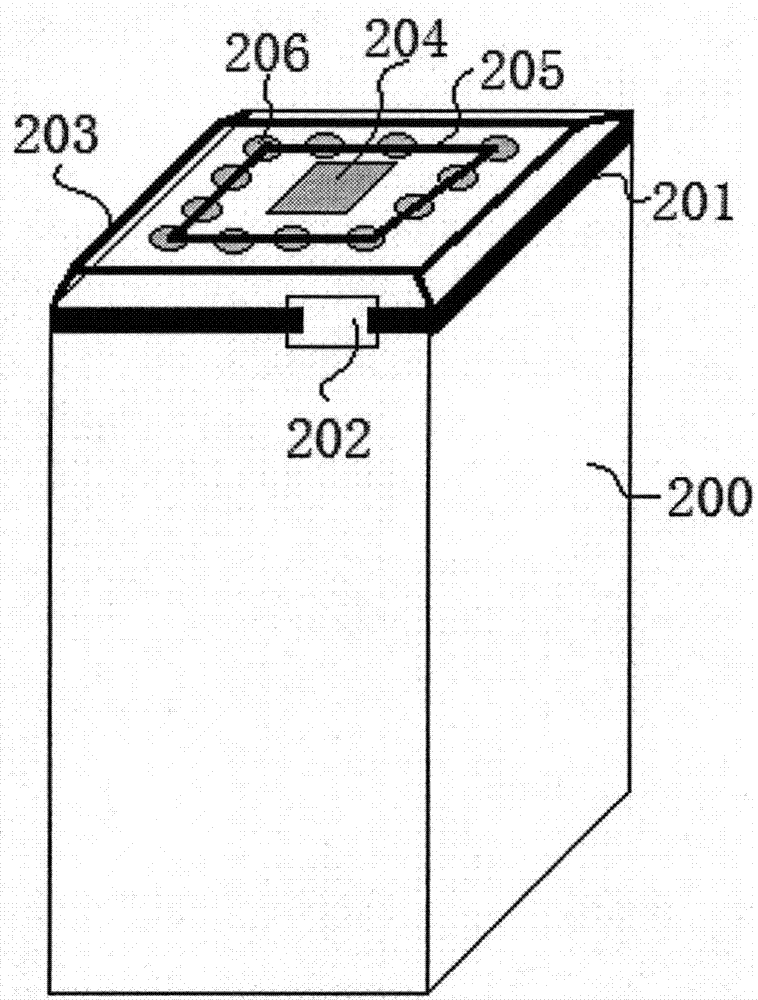

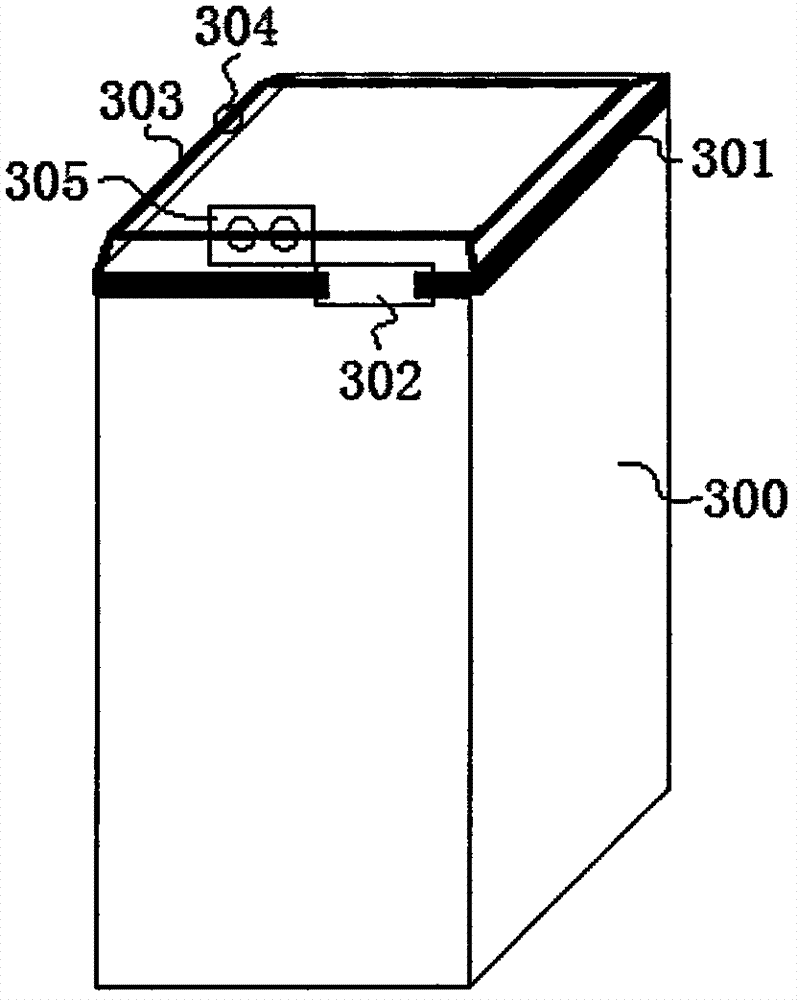

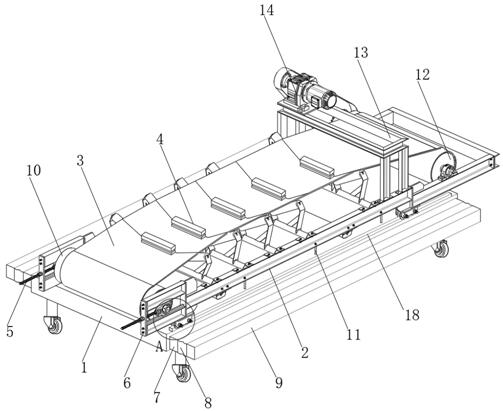

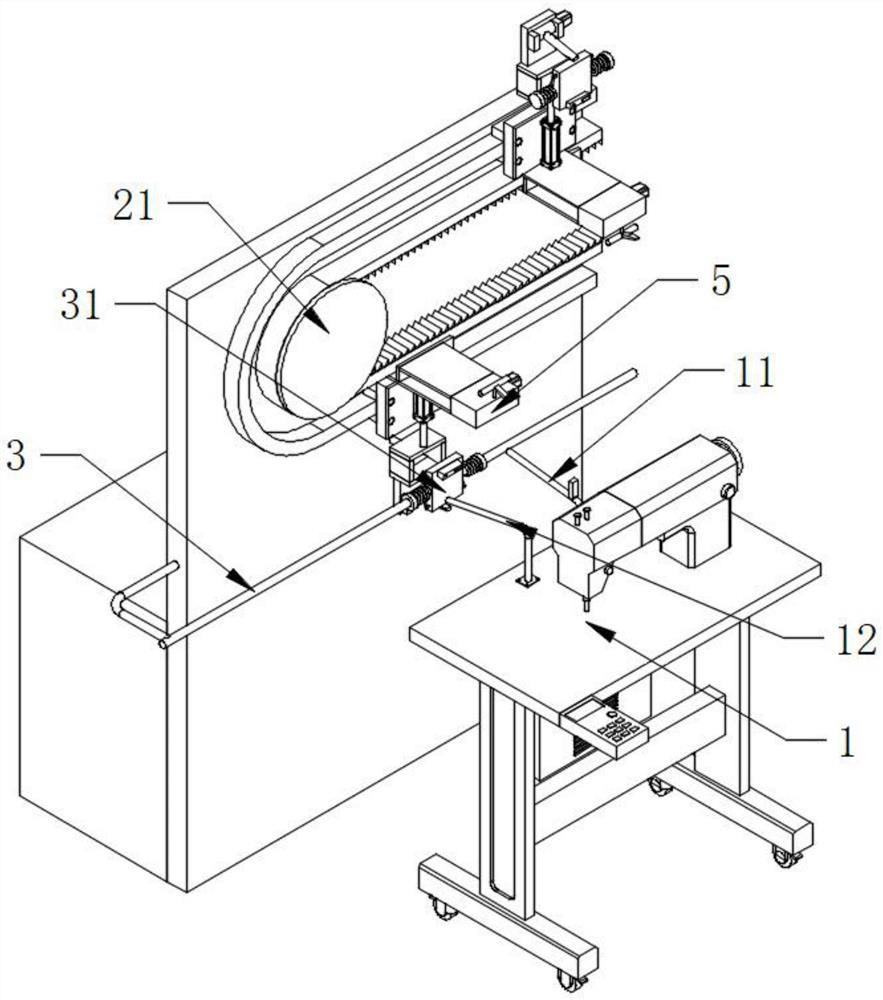

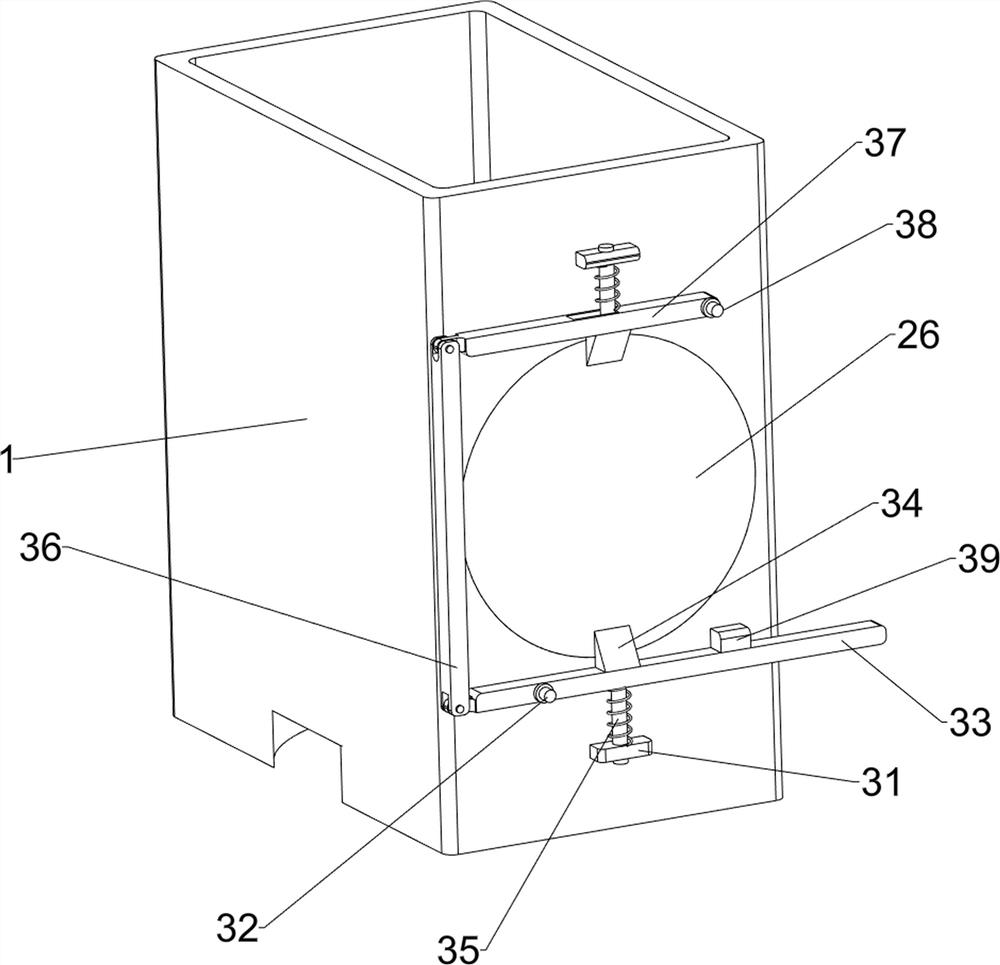

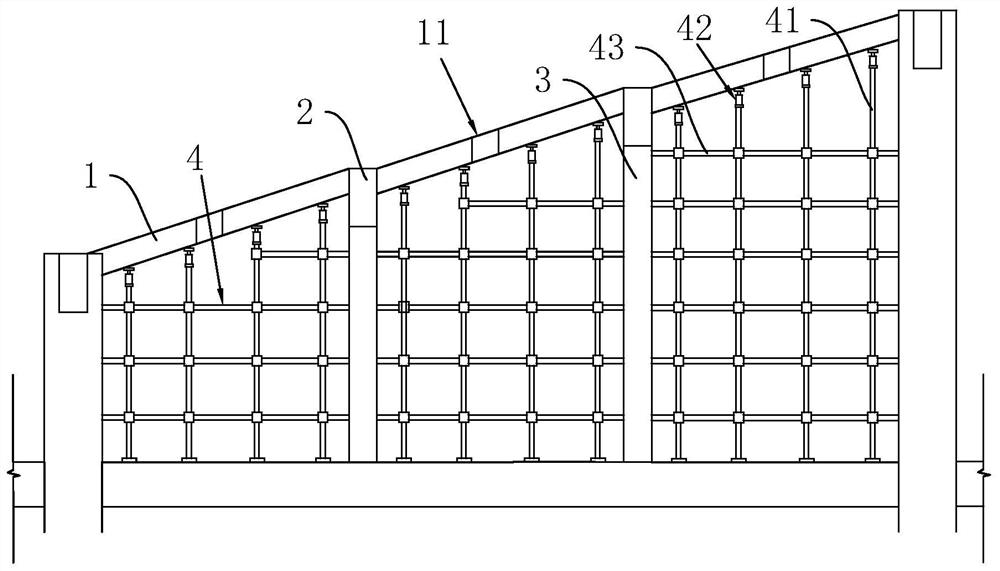

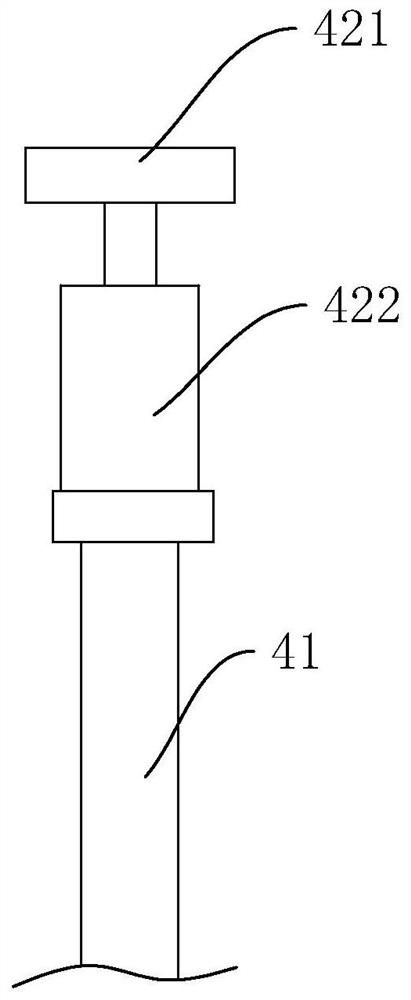

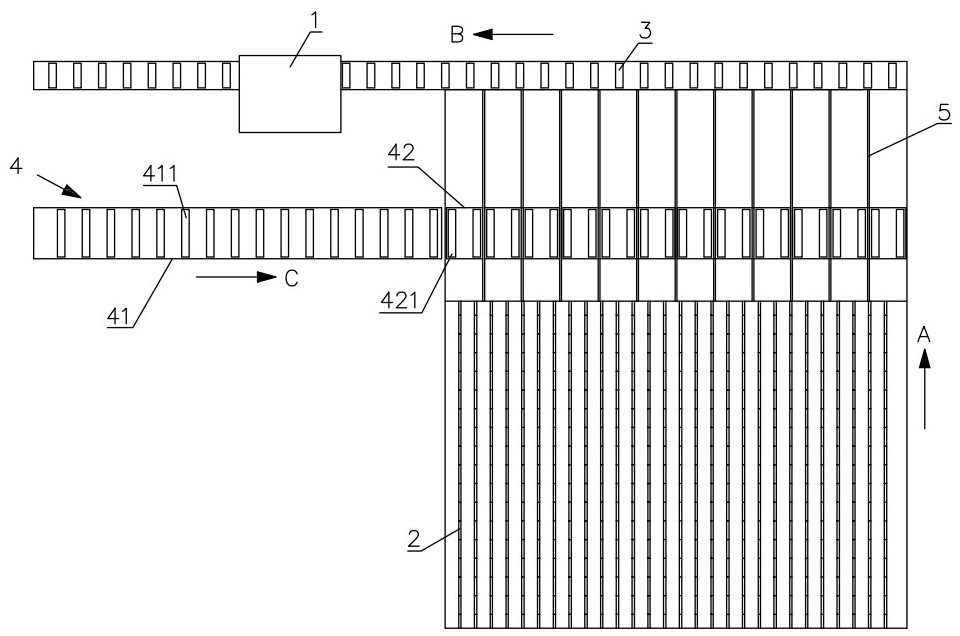

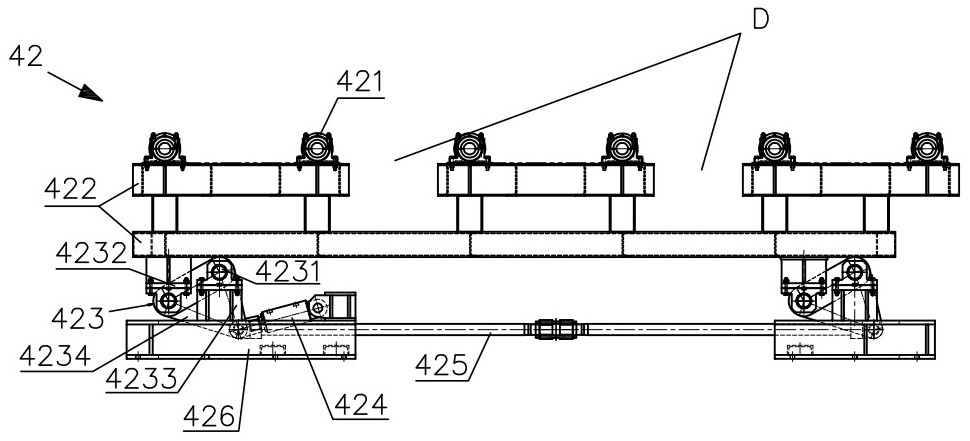

Novel conveyor

ActiveCN111874528AImprove securityInstalled and disassembledConveyorsSupporting framesTransmission beltBatten

The invention discloses a novel conveyor which comprises a mounting frame. The mounting frame is detachably mounted on the upper portion of a bottom plate, fixing battens are horizontally mounted on the two sides of the bottom plate in the length direction, end plates are mounted on the sides, away from the bottom plate, of the fixing battens, and storage plates are mounted between the end platesand the fixing battens; and a plurality of first electric telescopic columns are further mounted below the storage plates and between the end plates and the fixed battens. A cushion plate, an angle adjusting mechanism and the storage plates are used in cooperation so that the safety of object transportation can be greatly improved, and different work requirements can be met; when the three parts are used independently, different protection effects are achieved, and objects on the conveying belt can be protected from different directions; or any two of the three parts can be used in cooperationto protect different objects. Due to various protection instruments, the conveying belt is safe and efficient when used for conveying the objects and is more diversified in the conveying process.

Owner:山东中煤工矿物资集团有限公司

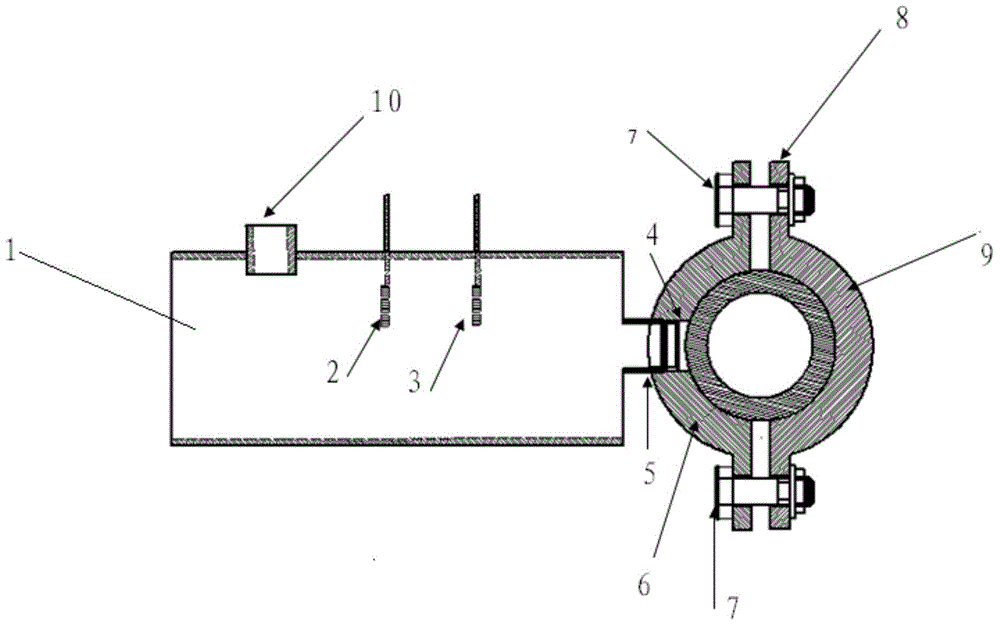

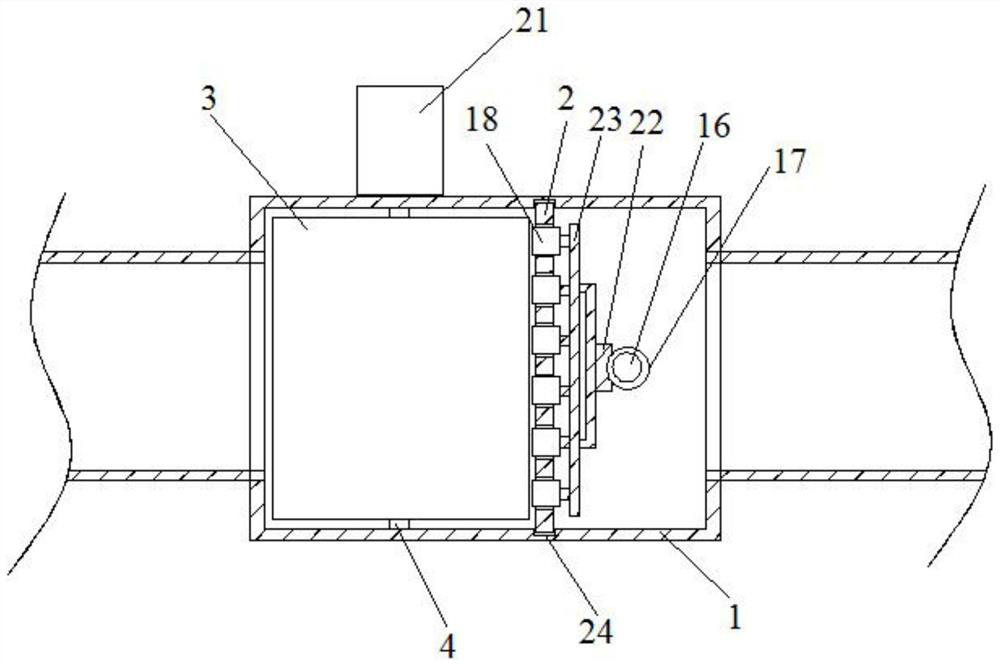

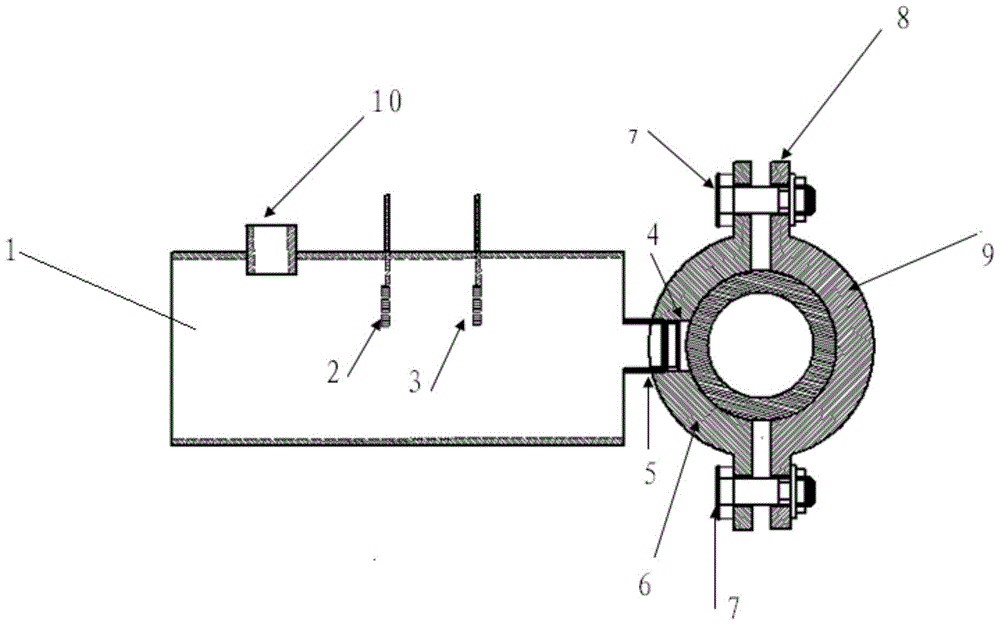

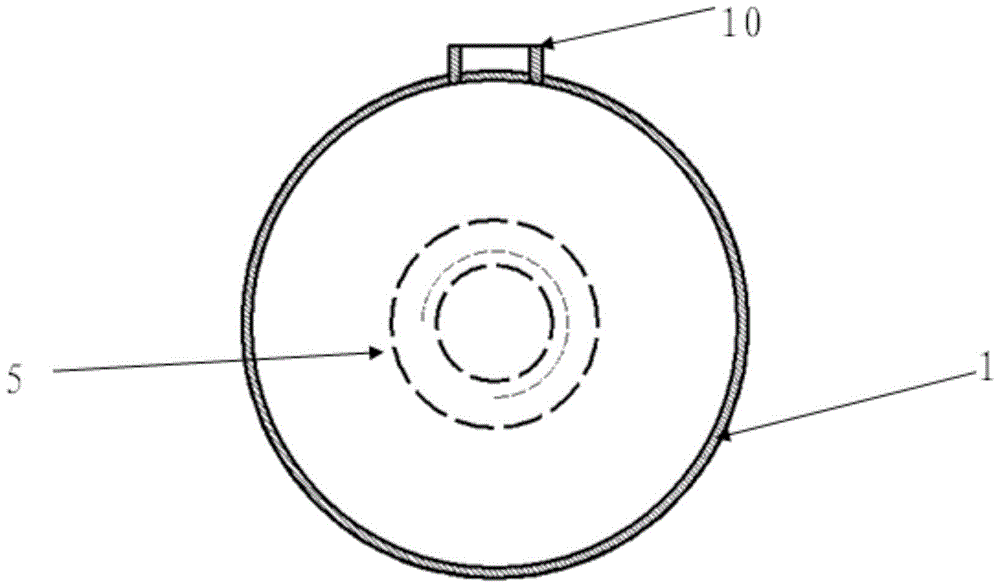

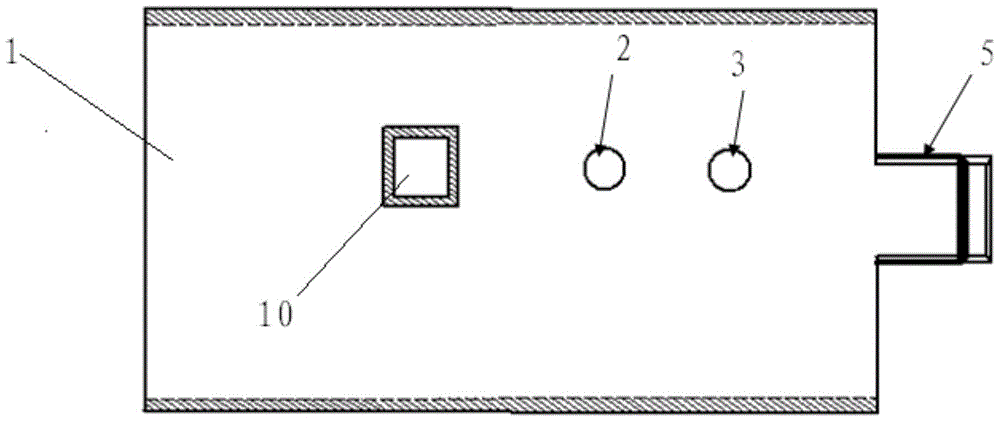

Pipeline internal corrosion detection device and detection method thereof

InactiveCN103983674ARealistic response to corrosion conditionsReactive Corrosion ConditionMaterial electrochemical variablesPower flowEngineering

The invention discloses a pipeline internal corrosion detection device and a detection method thereof. The pipeline internal corrosion detection device comprises an anode tube and a first clamping plate connected with the anode tube, wherein a first electrode and a second electrode are arranged in the anode tube, the first clamping plate is clamped on a pipeline to be detected by a second clamping plate, the first clamping plate and the second clamping plate are clamped by a clamping device, the anode tube is provided with a boss and a liquid inlet used for filling anode solution, the boss is provided with an external thread, and the first clamping plate is provided with a threaded hole matched with the external thread; the detection method of the pipeline internal corrosion detection device comprises the steps of preparation, installation, electroplating and monitoring, and the corrosion condition of the pipeline is reflected by electric current size. The pipeline internal corrosion detection device has skillful structure, low cost and convenience in use, and the detection method of the pipeline internal corrosion detection device is convenient to operate and can accurately and intuitively detect the pipeline internal corrosion condition.

Owner:JIANGSU UNIV OF SCI & TECH

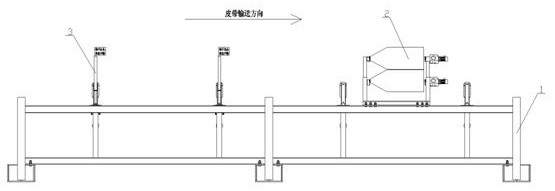

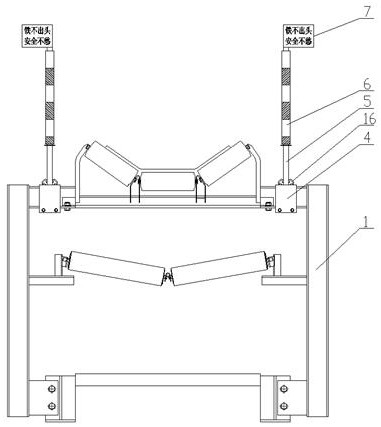

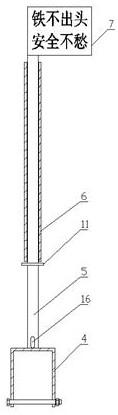

Belt conveyor capable of preventing foreign matter from extending outwards

PendingCN113213070AAvoid injuryPlay the role of double insuranceConveyorsControl devices for conveyorsForeign matterEngineering

The invention belongs to the technical field of belt conveyors, and particularly relates to a belt conveyor capable of preventing foreign matter from extending outwards. The belt conveyor comprises a belt conveyor body, a rod piece limiting rod and a rolling and pulling roller set are arranged on a machine tail frame of the belt conveyor body, and the rod piece limiting rod comprises a base connected with the machine tail frame and a vertical rod fixed to the base; and the rolling and pulling roller set comprises a roller frame and rollers arranged on the roller frame in parallel up and down, the roller frame is installed on the machine tail frame, rotating shafts of the rollers are parallel to the conveying direction of a belt, the rollers are wrapped with rubber roller skin, each roller comprises a cylindrical roller body and a conical roller tip integrally connected with the cylindrical roller body, the roller tips point to the flowing-in direction of the belt, the roller bodies of the upper roller and the lower roller are closed up, and the upper roller and the lower roller are both connected with a torque input element. The belt conveyor capable of preventing the foreign matter from extending outwards is high in safety, avoids wounding accidents caused by the fact that the foreign matter exceeds the outer side of the belt too long, can well protect constructors in a belt roadway, and is worthy of being used and popularized in the whole mine range.

Owner:晋城乾泰安全技术有限责任公司

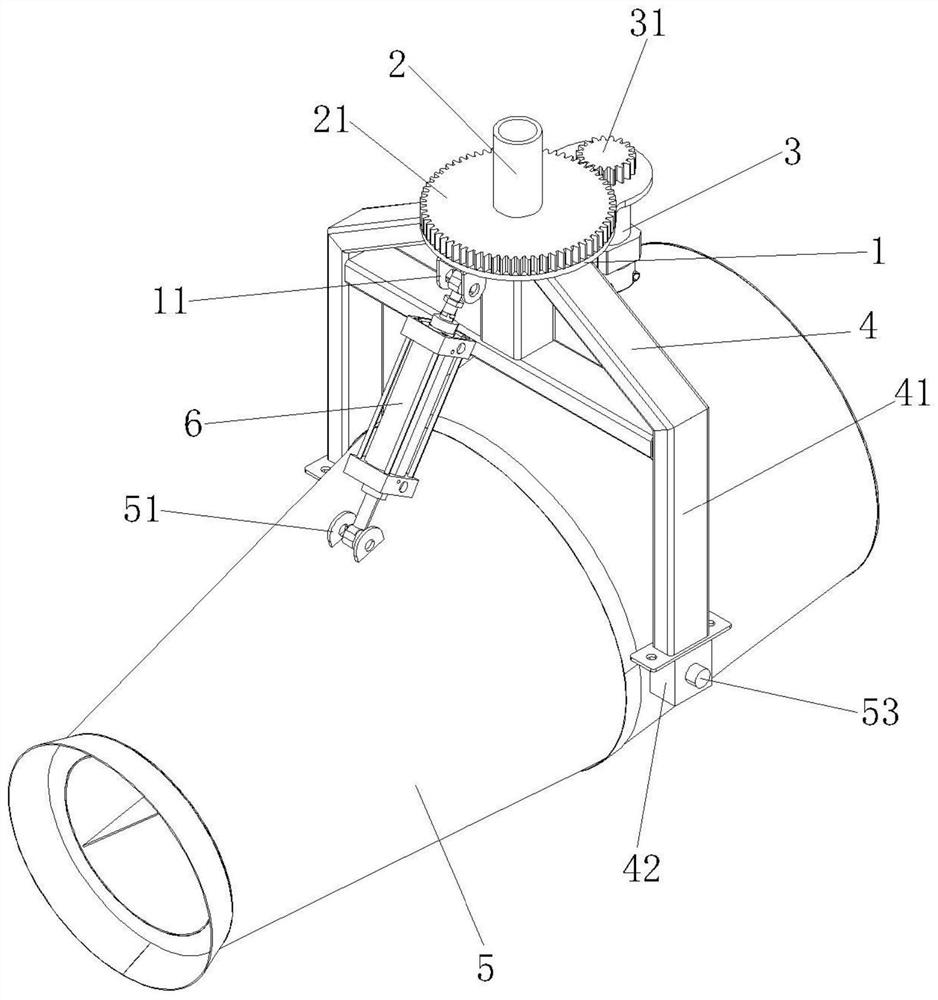

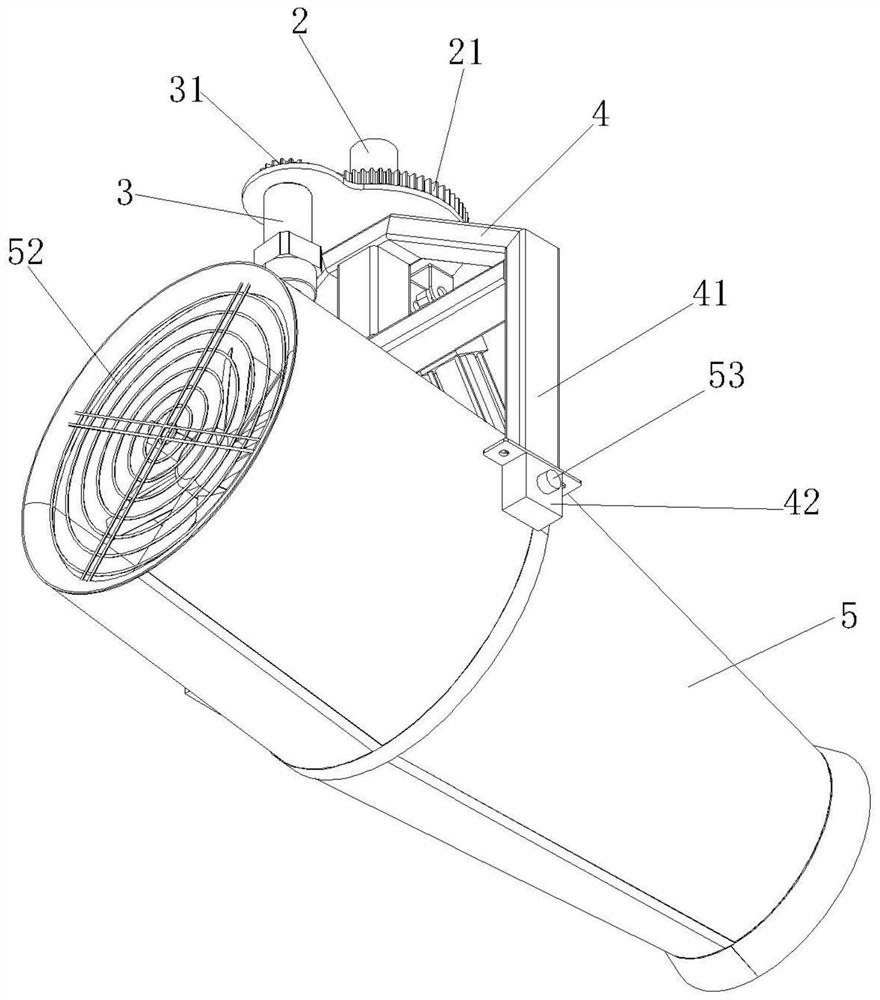

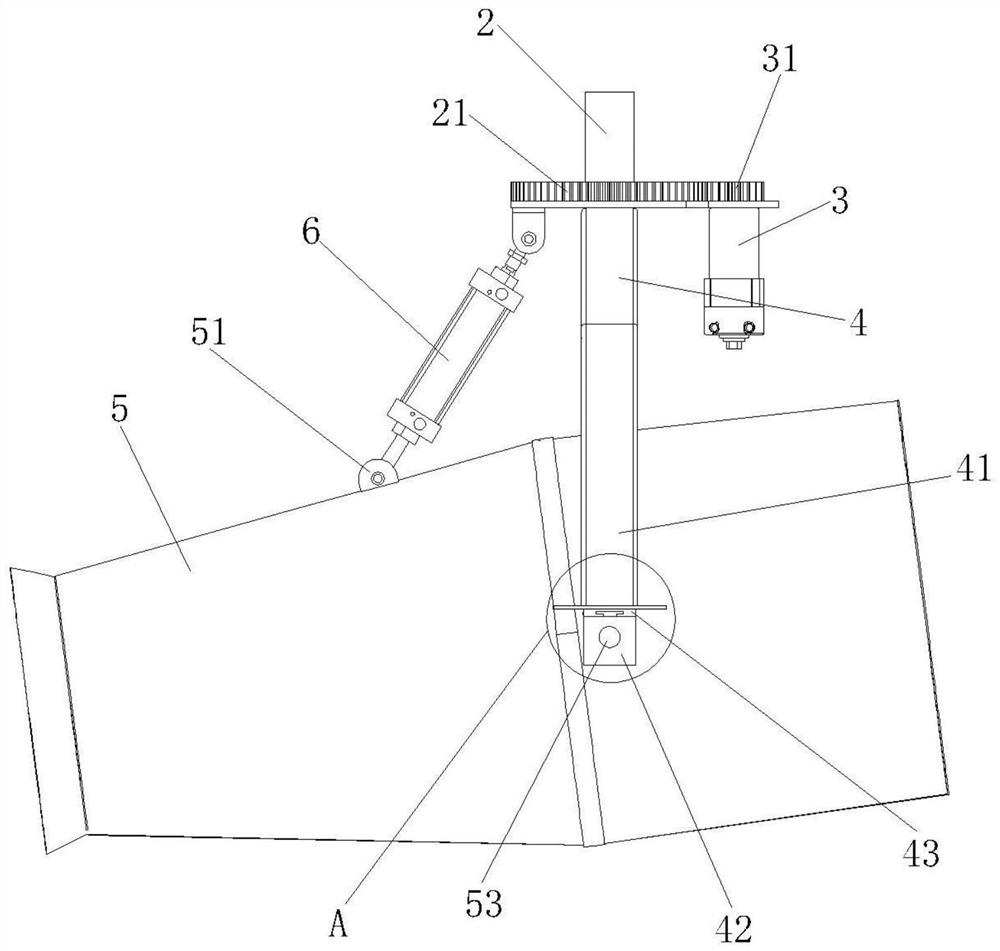

Underground fog gun dust settling method and device

PendingCN111608719AIncrease rangeWide coverageDust removalFire preventionEnvironmental engineeringMechanical engineering

The invention discloses an underground fog gun dust settling method and device. The dust settling method comprises steps as follows: 1), a fog gun dust settling device is mounted and fixed at the topof a mine, an atomizing system and a multilayer annular spray ring are arranged in the fog gun dust settling device, the fog gun dust settling device atomizes a normal-state solution into water mist particles with size of 10-150 micrometers, the water mist particles are diffused in a large area after being accelerated by a pneumatic high-speed fan, and a large number of tiny water mist particles are gathered and float in air to form white cloud and fog; and 2), by controlling for the atomizing system, an air duct of a fog gun is controlled to rotate left and right and move in a pitching mannerto spray mist to the mine in a large range. According to the underground fog gun dust settling method and device, the dust settling effect is better; and the fog gun is hoisted at the top of an underground roadway, and normal transporation and construction of the roadway are not affected.

Owner:合肥合安智为科技有限公司

Anti-blocking gravel filtering device for petroleum exploitation

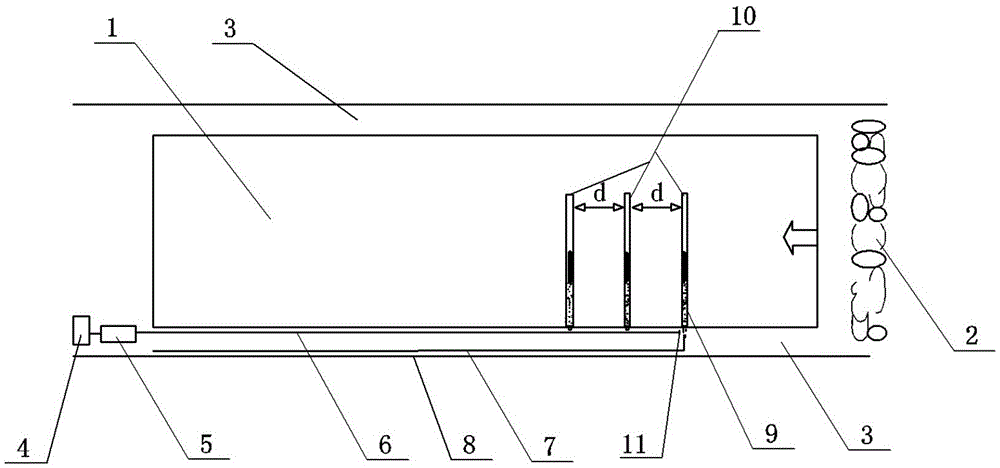

InactiveCN113144749AAvoid cloggingDoes not affect transportationRefining by filtrationFiltration circuitsPetroleum oilMechanical engineering

The invention relates to the technical field of petroleum sand removal, and discloses an anti-blocking gravel filtering device for petroleum exploitation, which comprises: a box body, wherein the left side of the box body is communicated with a petroleum inlet pipeline, the right side of the box body is communicated with a petroleum outlet pipeline, and the vertical filter screen plate is arranged in the box body and divides the box body into a left part and a right part; a cleaning device which is used for regularly cleaning gravels on the vertical filter screen plate; a gravel storage box which is fixedly arranged below the box body and communicates with the bottom, located on the left side of the vertical filter screen plate, of the box body, wherein a door plate is arranged at the bottom in a sealed mode, and the gravel storage box is used for cleaning gravel in the gravel storage box; a baffle device, wherein when the gravel is collected, the gravel storage box is communicated with the box body through the baffle device, and after the gravel is collected, the gravel storage box is sealed and isolated from the box body; and a petroleum return device which is arranged between the lower part of the gravel storage box and the petroleum outlet pipeline. The gravel filtering device can prevent blockage, does not influence petroleum transportation, is convenient to operate, and saves time and labor.

Owner:QIANNAN NORMAL UNIV FOR NATTIES

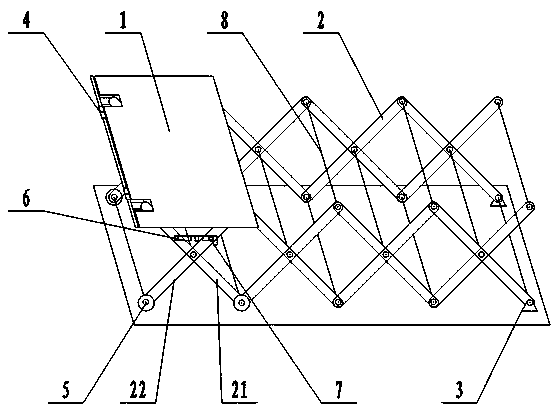

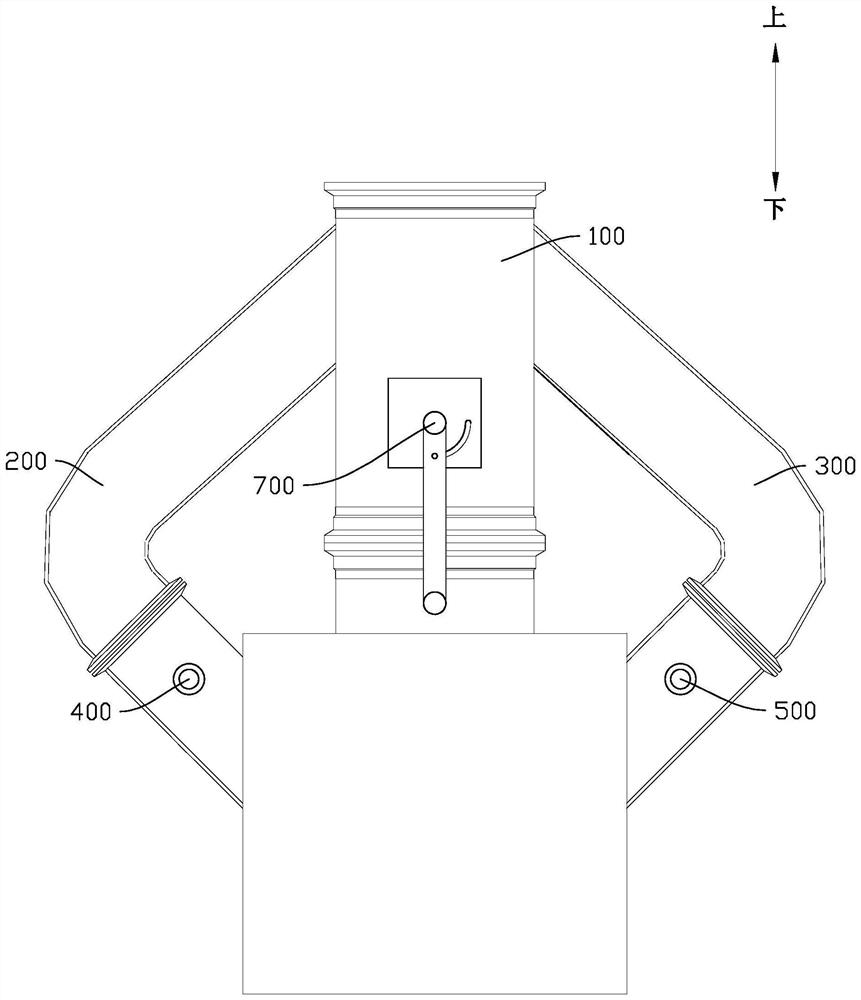

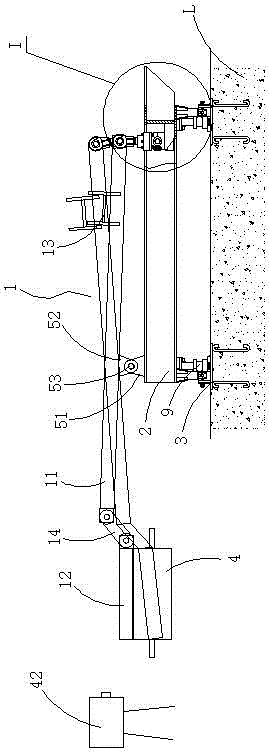

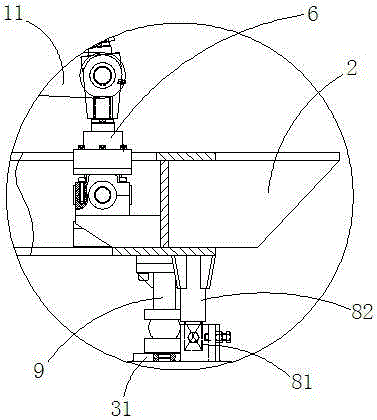

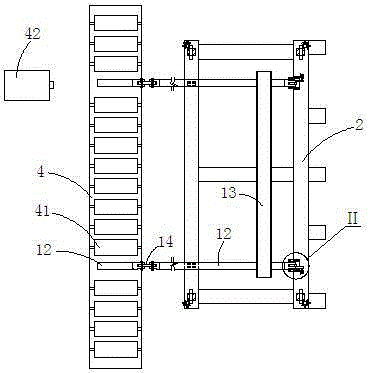

Foldable movable cable car passenger platform

InactiveCN110979355ADoes not affect normal transportationReduce laborRope railwaysGondola liftMechanical engineering

The invention discloses a foldable movable cable car passenger platform, which comprises a passenger platform and a telescopic device connected with the passenger platform, and is characterized in that the telescopic device comprises two sets of telescopic mechanisms which are symmetrically arranged, each telescopic mechanism comprises connecting rods with the same length, and the middle points ofthe connecting rods are hinged through pin shafts, the two ends of the connecting rods are hinged in pairs through pin shafts to form a prismatic grid telescopic mechanism, a fixing base is arrangedat one end of the telescopic device, and the other end of the telescopic device is connected with the passenger platform through a hinge, so that passengers can normally take the cable car, the laboramount of field operators is reduced, and good popularization and application value is achieved.

Owner:TIANCHEN COAL MINE OF ZAOZHUANG MINING GRP

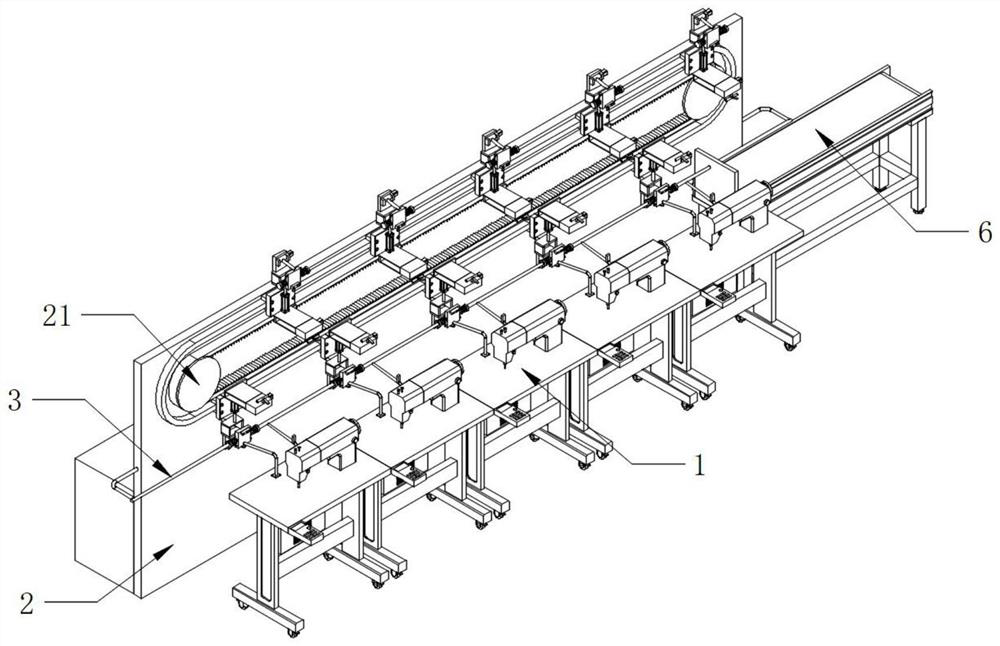

Automatic cloth conveying device and automatic cloth conveying line

PendingCN114541046ALabor savingEasy access for sewingSewing-machine elementsManufacturing computing systemsElectric machineryEngineering

Owner:安徽红爱实业股份有限公司

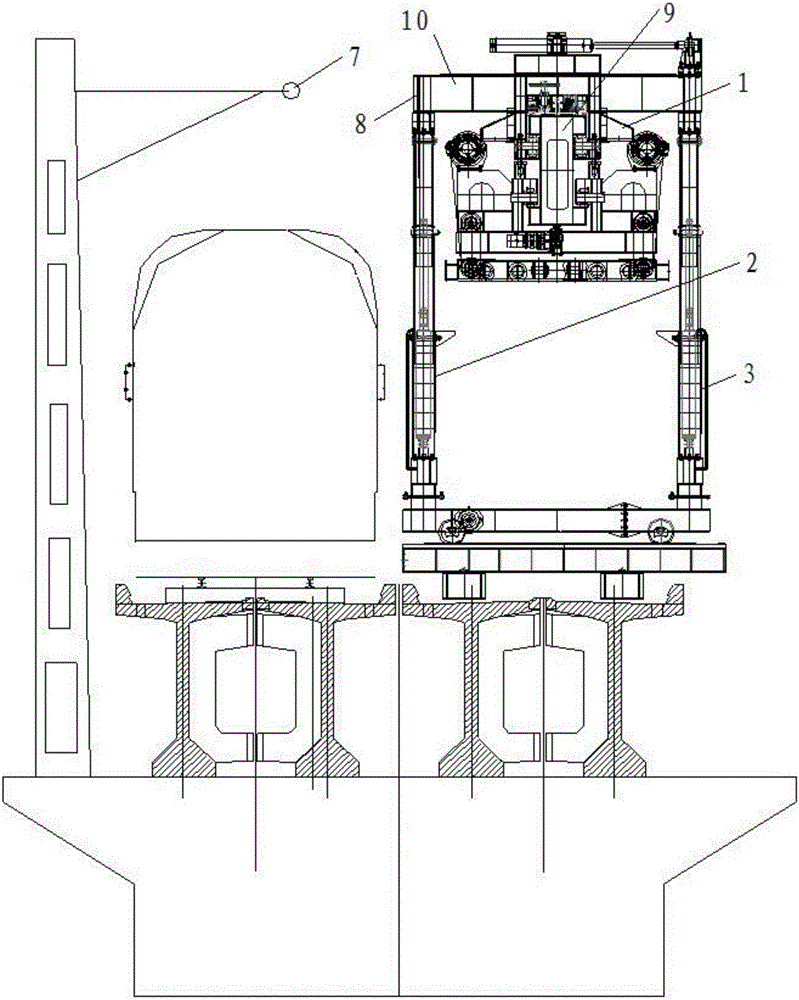

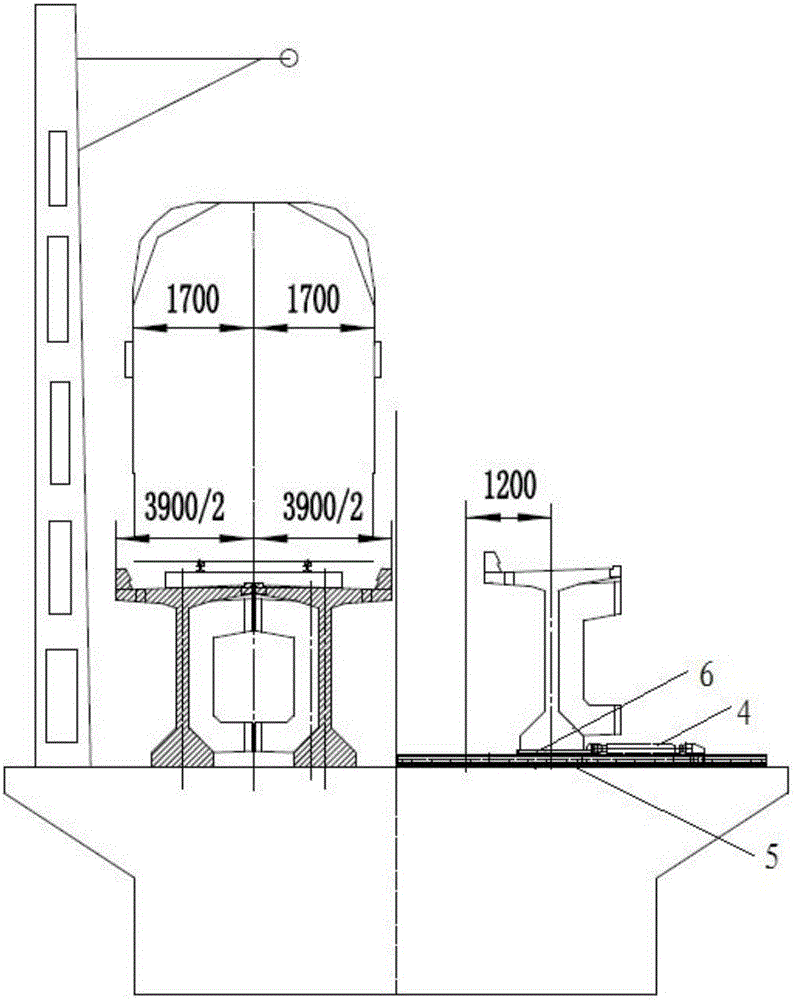

Small-spacing existing line added second line bridge erecting machine girder erecting method

InactiveCN105926451ADoes not affect normal transportationBridge erection/assemblySlide plateIndustrial engineering

Owner:THE 2ND ENG CO LTD OF CHINA RAILWAY 16TH BUREAU GRP

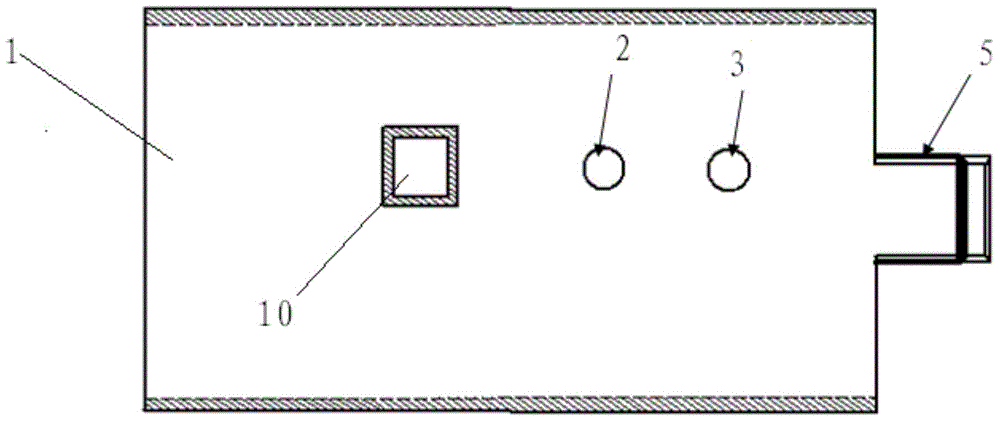

Particle material detection device

InactiveCN106153396ADoes not affect normal transportationReduced sampling timeWithdrawing sample devicesSolid particleEngineering

The invention relates to a particle material detection device. The device comprises a material taking barrel and a detection barrel, wherein the material taking barrel is arranged on one side of the top of the detection barrel, a material inlet is formed between contact positions on the detection barrel and the material taking barrel, a cylinder is arranged in the material taking barrel, a top plate is arranged at the top of the cylinder and arranged between falling ports in a running platform, a primary weighing rod and a secondary weighing rod are arranged in the detection barrel, the primary weighing rod is arranged on the upper side of the secondary weighing rod, the primary weighing rod and a material inlet are connected through a primary guide plate, a screen net is arranged on the lower side of the primary weighing rod, the screen net and the secondary weighing rod are connected through a secondary guide plate, and the secondary weighing rod is connected with a discharge port. Compared with the prior art, the particle material detection device has the advantages as follows: solid particles are sampled and detected, normal transportation of a conveying platform is not affected, the sampling time is shortened, the detection efficiency is also improved, the overall structure is simple, and the operation is convenient.

Owner:沈蓉蓉

Quantitative sampling method of composite plastic

PendingCN113916333ADoes not affect normal transportationEasy to sampleWeighing apparatus with automatic feed/dischargeProcess engineeringParticle transport

Owner:ZHUHAI SUMIKA POLYMER COMPOUNDS CO LTD

Profile steel production line with back straightening function

ActiveCN113083946ADoes not affect normal transportationMetal-working feeding devicesPositioning devicesStructural engineeringManufacturing line

The invention relates to a profile steel production line with a back straightening function. The profile steel production line comprises a straightening machine, a cooling bed, a straightening conveying roller and a back straightening roller way, wherein a steel moving chain is arranged at the tail end of the cooling bed; the straightening conveying roller is arranged between the tail end of the steel moving chain and the straightening machine; the back straightening roller way extends to the steel moving chain from a far position and comprises a back conveying roller mechanism and a lifting roller mechanism; the back conveying roller mechanism comprises a back conveying roller wheel; the lifting roller mechanism comprises a lifting roller wheel; the back conveying roller mechanism extends to the outer side of the steel moving chain from the far position; the lifting roller mechanism is arranged in the steel moving chain in a lifting manner; the lifting roller mechanism at least has a lifting state and a lowering state; in the lifting state, the upper surface of the lifting roller wheel is higher than the upper surface of the steel moving chain; and in the lowering state, the upper surface of the lifting roller wheel is lower than the upper surface of the steel moving chain. The back conveying roller mechanism conveys profile steel needing to be straightened for the second time to the outer side of the steel moving chain, then the profile steel is conveyed to the steel moving chain through the lifting roller mechanism, and the profile steel is conveyed into the straightening machine again through the steel moving chain and the straightening conveying roller to be straightened.

Owner:CHANGSHU LONGTENG SPECIAL STEEL

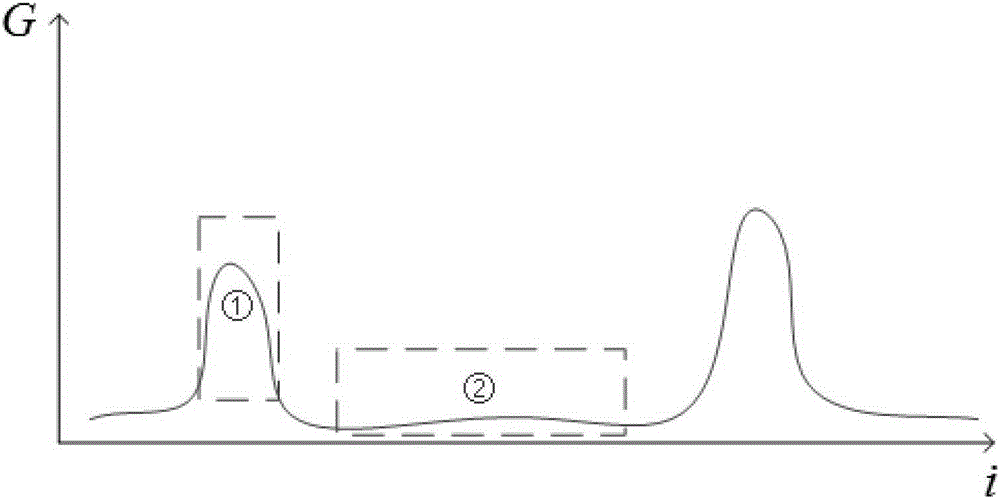

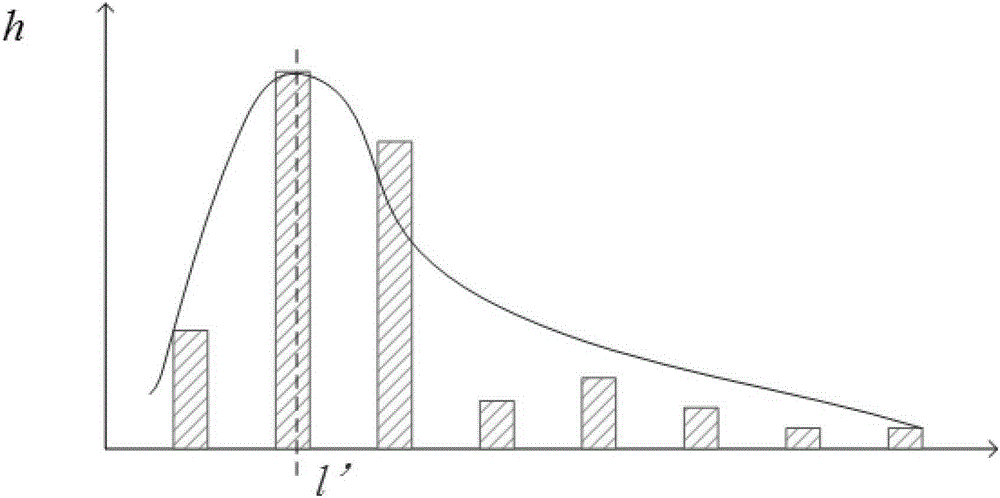

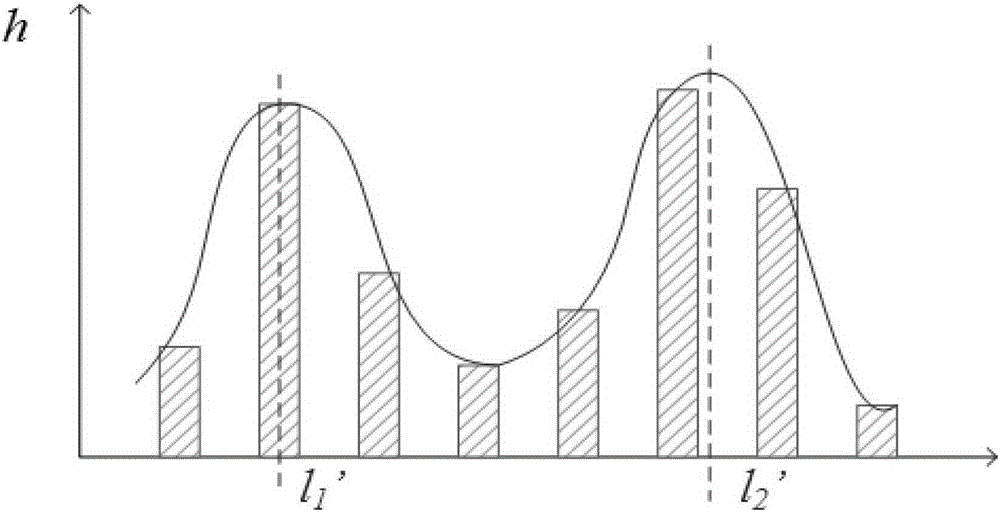

A method for detecting the burial status of submarine pipelines

InactiveCN103278851BDoes not affect normal transportationTimely detection of naked leaksSeismic signal processingOcean bottomFrequency spectrum

Owner:TIANJIN UNIV

Construction waste cleaning device

InactiveCN110523463AImprove cleaning effectEasy to cleanConstruction waste recoverySolid waste disposalBuilding materialConstruction waste

The invention discloses a construction waste cleaning device. The device includes a support, a conveyor driven by a motor to operate is arranged in the support, and the crushing devices for preliminarily crushing the building materials are arranged at the front side and the rear side of the conveyor. A supporting vertical rod is arranged at the right side of the support, a water liquid spraying device for periodically spraying the water liquid is arranged in the supporting vertical rod, and a cleaning device for transporting the construction waste for the efficient cleaning is arranged at thelower side of the water liquid spraying device. The device is simple in structure, and by adopting the crushing devices, the water liquid spraying device and the cleaning device, the construction waste can be preliminarily crushed through the device to improve the cleaning effect, on the premise that the normal transportation of the construction waste is not affected, the construction waste is fully cleaned in a mode of spraying and washing with the water directly from top to bottom, and a cleaned solution can be collected so as to be recycled conveniently.

Owner:齐嘉蕾

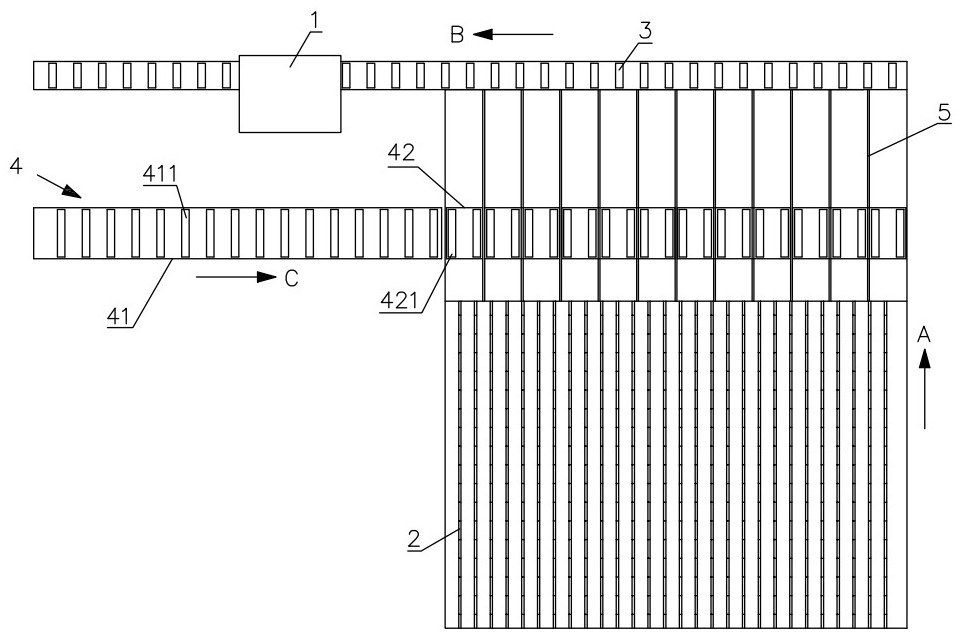

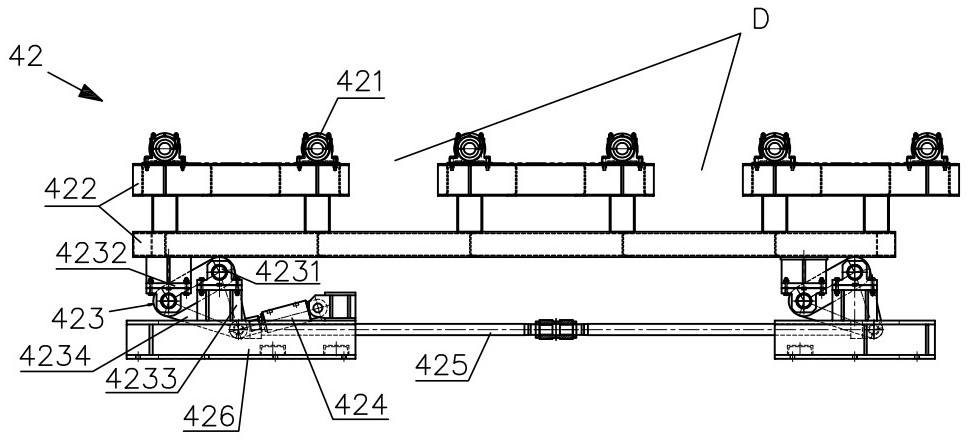

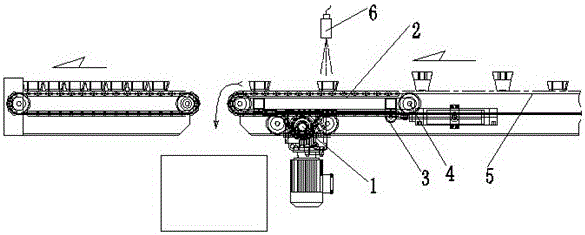

an online feeder

ActiveCN103112709BGuarantee same speed and same directionDoes not affect normal transportationConveyor partsDevice WheelEngineering

The invention relates to an on-line discharging device. A discharging device wheel set and a main conveyor share the same driving power set. A discharging outlet is formed in the main conveyor. The discharging device wheel set is installed on a wheel carrier. A movable auxiliary driving device is assembled on the lower portion of the wheel carrier. The movable auxiliary driving device controls and drives the discharging device wheel set and the wheel carrier. A sensor is arranged above the discharging outlet, and the sensor controls the movable auxiliary driving device. According to the structure, dynamic combination of the discharging device and a main conveying line is achieved, cost is reduced, structure is simplified, only one power source is used, and energy consumption of the equipment is reduced.

Owner:SUZHOU JONO RECYCLING RESOURCES EQUIP

A lever type roller scale

ActiveCN103994807BSimple structureGood foundationWeighing apparatus detailsWeighing apparatus for materials with special property/formClassical mechanicsStructural engineering

Owner:YUYAO TONGYONG METER

a conveyor

ActiveCN111874528BImprove securityInstalled and disassembledConveyorsSupporting framesStructural engineeringConveyor belt

The invention discloses a new type of conveyor, which includes a mounting frame, which is detachably installed on the upper part of the bottom plate, fixed strips are horizontally installed on both sides of the bottom plate along the length direction, and the side of the fixed strip is far away from the bottom plate An end plate is installed, a storage plate is installed between the end plate and the fixed strip, and a plurality of first electric telescopic columns are also installed under the storage plate between the end plate and the fixed strip. The backing plate is used in conjunction with the angle adjustment mechanism and the storage plate, which can greatly improve the safety of object transportation, and can adapt to different work requirements. The three are used alone, each has a different protective effect, and can protect objects on the conveyor belt from different directions, or any two can be used together to protect different objects. A variety of protective equipment makes the conveyor belt safe and efficient when transporting objects, and the transportation is more diverse.

Owner:山东中煤工矿物资集团有限公司

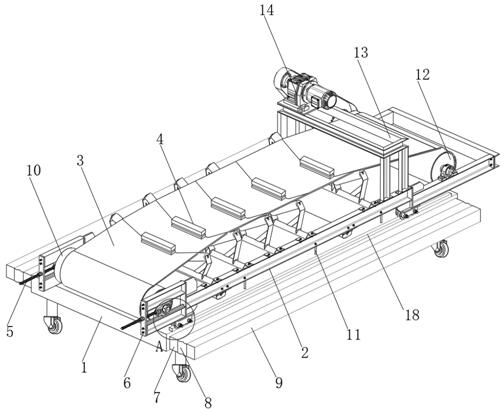

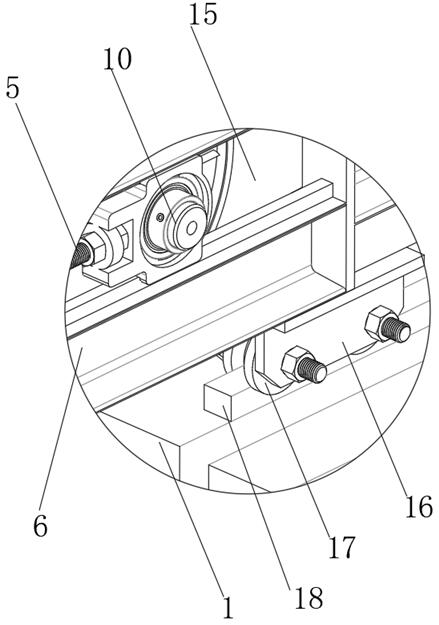

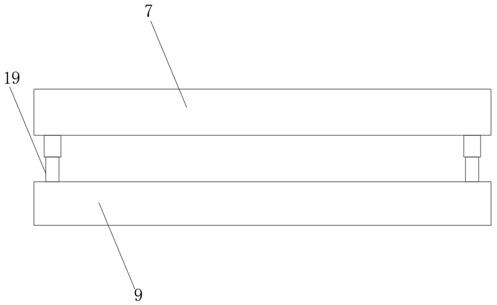

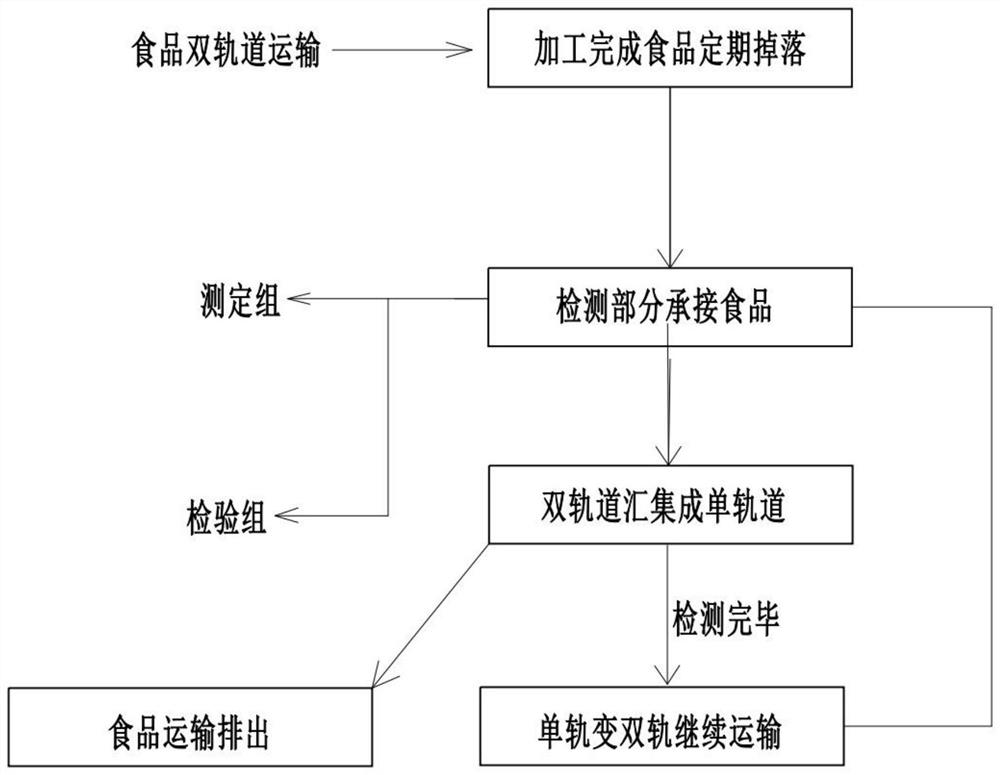

Food detection system and detection method thereof

PendingCN114354966ADoes not affect normal transportationWithdrawing sample devicesMechanical conveyorsProcess engineeringMonorail

The invention relates to the technical field of food production, in particular to a food detection system and a detection method thereof. The method comprises the following steps that firstly, after food processing is completed, double-track parallel transportation is conducted; 2, sampling is conducted when food is discharged regularly in the transportation process; 3, sampling the food, determining the water content, and transporting the food in a monorail manner in the determination process; and 4, changing monorail transportation into double-gauge transportation after the determination is finished, and circulating. Furthermore, the measured water content in the step 3 is divided into a measurement group and a test group. And further, heating the food with the water content measured in the step 3 for 15 minutes at the temperature of 85 DEG C, wherein the food enters into the measurement group. The food sampling device has the advantage of regularly sampling and detecting food under the condition of not influencing the normal transportation of the food.

Owner:刘素华

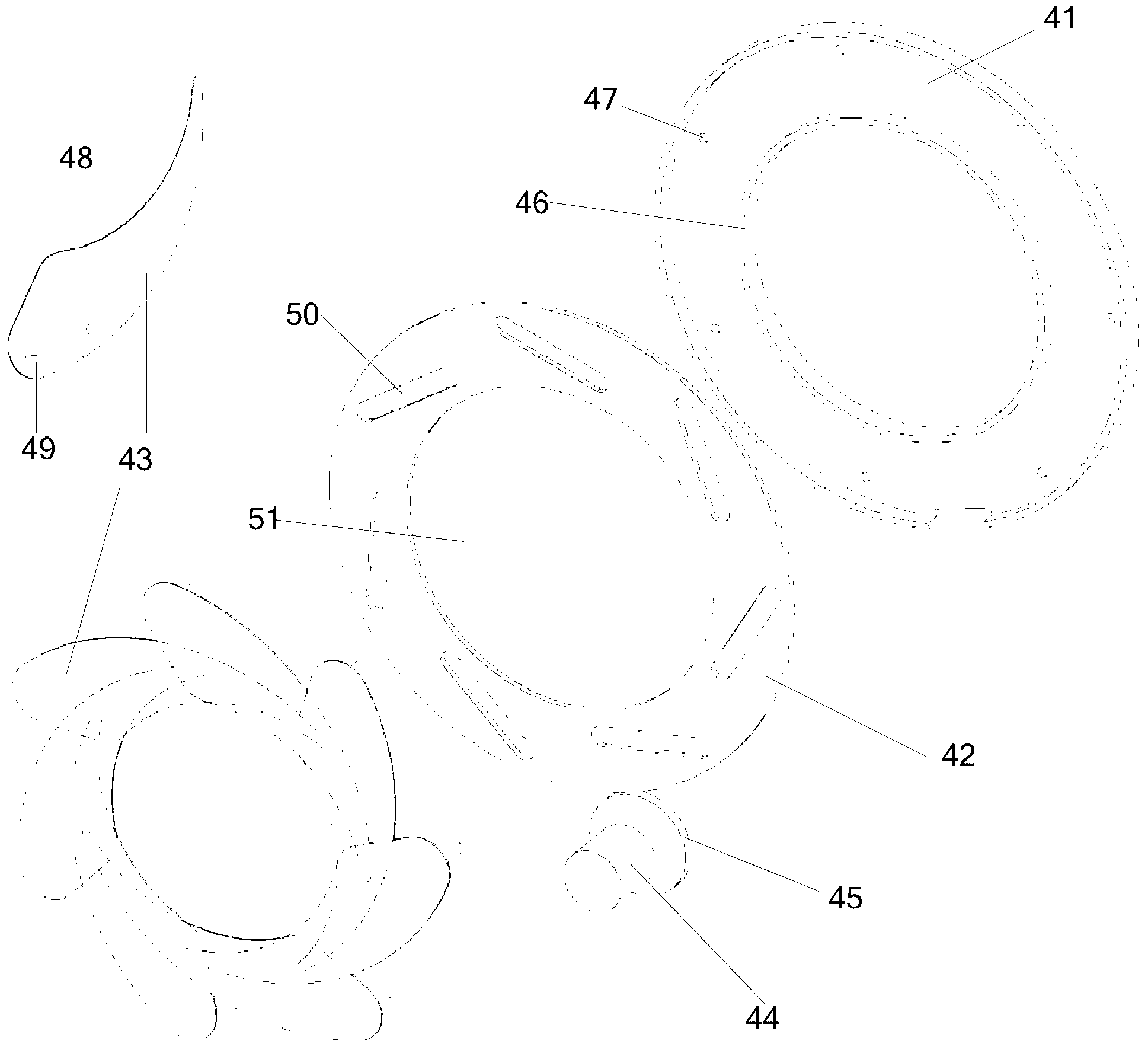

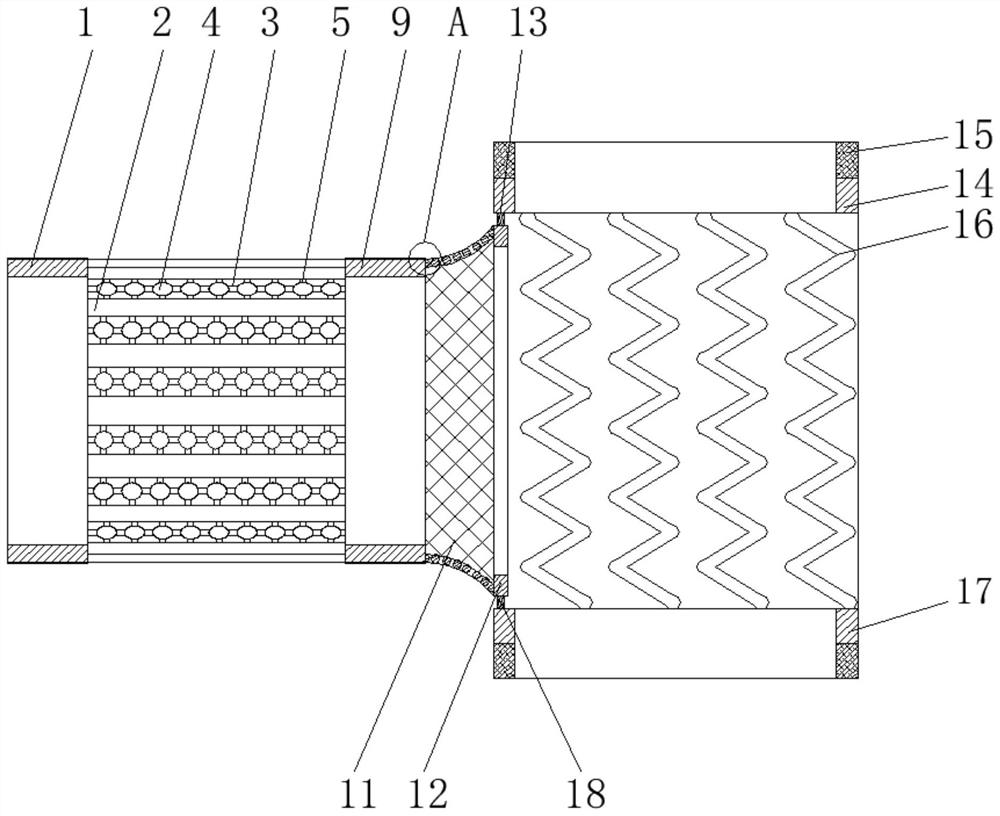

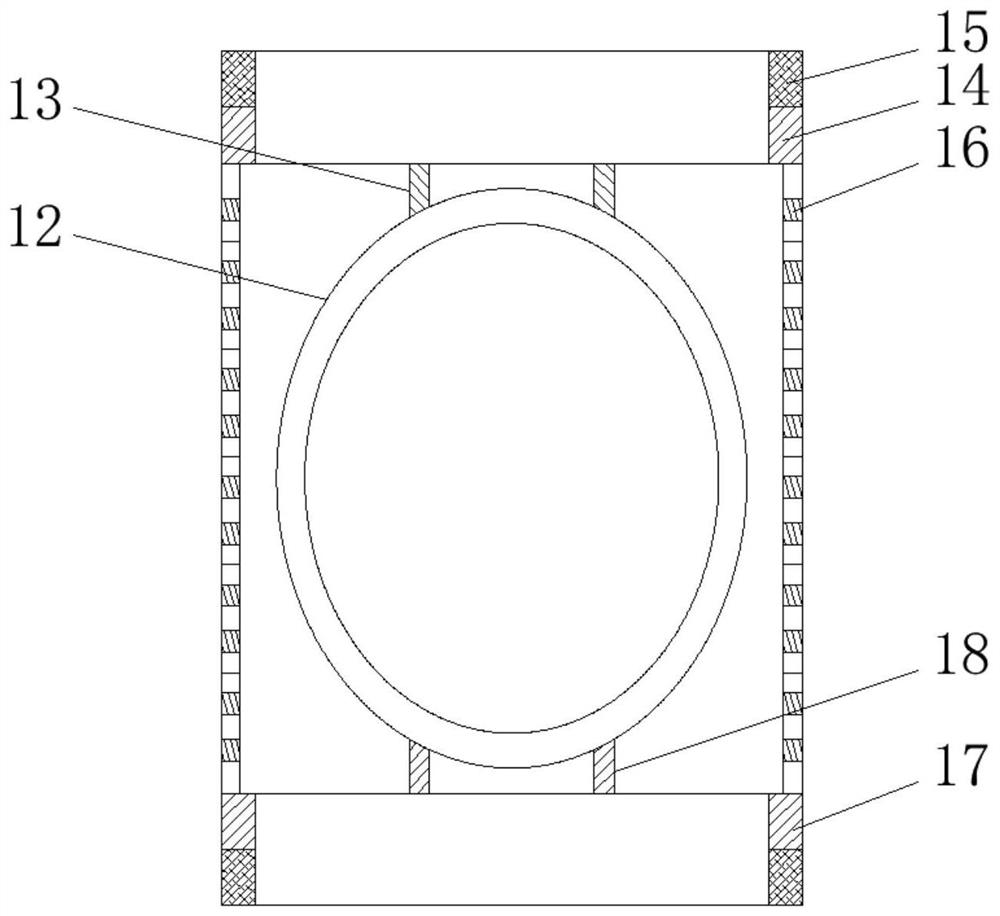

Magnesium alloy renal artery stent

The invention discloses a magnesium alloy renal artery stent, which relates to the technical field of medical devices, comprising a first support ring frame and a second support ring frame, a support piece is embedded on an axial fixing bar, the first support ring frame and the second support ring The outer surfaces of the frame are all provided with protruding belts, and one side of the second supporting ring frame is fixedly connected with a flexible net. In the present invention, by setting the first support ring frame and the second support ring frame made of magnesium alloy, the renal artery stent can be degraded in the blood vessel, which can effectively reduce the possibility of occurrence of problems such as vascular intimal hyperplasia, restenosis, and late thrombus. By setting the flexible net, the junction of the renal artery and the aorta can be avoided to be narrowed again. The first support ring frame and the second support ring frame do not need to protrude into the aorta, thus not affecting the normal transport of blood by the aorta. The protruding belt plays a role of preventing the first supporting ring frame and the second supporting ring frame from shifting to a certain extent.

Owner:郑州美港高科生物科技有限公司

Pipeline internal corrosion detection device and detection method

InactiveCN103983674BRealistic response to corrosion conditionsReactive Corrosion ConditionMaterial electrochemical variablesEngineeringElectroplating

The invention discloses a pipeline internal corrosion detection device and a detection method thereof. The pipeline internal corrosion detection device comprises an anode tube and a first clamping plate connected with the anode tube, wherein a first electrode and a second electrode are arranged in the anode tube, the first clamping plate is clamped on a pipeline to be detected by a second clamping plate, the first clamping plate and the second clamping plate are clamped by a clamping device, the anode tube is provided with a boss and a liquid inlet used for filling anode solution, the boss is provided with an external thread, and the first clamping plate is provided with a threaded hole matched with the external thread; the detection method of the pipeline internal corrosion detection device comprises the steps of preparation, installation, electroplating and monitoring, and the corrosion condition of the pipeline is reflected by electric current size. The pipeline internal corrosion detection device has skillful structure, low cost and convenience in use, and the detection method of the pipeline internal corrosion detection device is convenient to operate and can accurately and intuitively detect the pipeline internal corrosion condition.

Owner:JIANGSU UNIV OF SCI & TECH

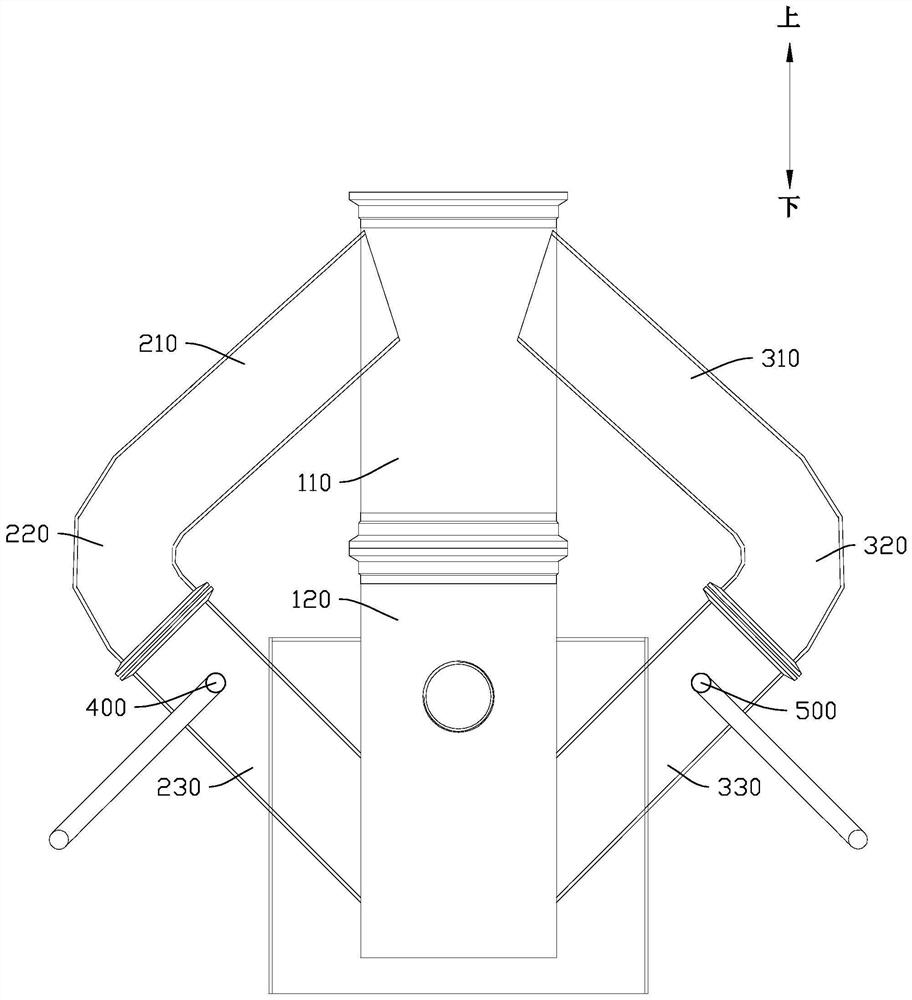

An internal detection system and detection method for submarine pipelines

The invention discloses an inner detection system for submarine pipelines and a detection method thereof. The inner detection system comprises an electronic sealed cabin arranged in a supporting frame. The supporting frame is provided with a supporting roller array, an odometer wheel, a pressure sensor, a temperature sensor and a sound sensor, wherein the supporting roller array, the odometer wheel, the pressure sensor, the temperature sensor and the sound sensor are distributed in an annular mode. The detection method includes: the inner detection system is connected to an upper computer to download signals collected by the sensors, and filtering and noise reduction processing is performed on the signals; traveling mileage of the inner detection system and included angles of the axis of the inner detection system and a local geomagnetic field and local gravitational acceleration are calculated at any time t, and a direction vector of the axis of the inner detection system is obtained through the included angles; the position of the inner detection system at any time is obtained; and whether leakage exists is judged through comparison of processed sound signals, pressure signals and temperature signals, and leakage rate is estimated. The inner detection system for submarine pipelines and the detection method of the inner detection system achieve detection of little leakage, improve detection accuracy, reduce detection difficulty and cost, and shorten detection period.

Owner:TIANJIN UNIV

Wear-resistant and corrosion-resistant rope pressing equipment for mining steel wire rope

ActiveCN112374405ADoes not affect normal transportationReduce swingCleaning using toolsWinding mechanismsCorrosion preventionManufacturing engineering

The invention relates to rope pressing equipment, in particular to wear-resistant and corrosion-resistant rope pressing equipment for a mining steel wire rope. The wear-resisting and corrosion-resisting rope pressing equipment can tension the steel wire rope. According to the technical scheme, the wear-resisting and corrosion-resisting rope pressing equipment for the mining steel wire rope comprises a frame and a pressure stabilizing mechanism, and the pressure stabilizing mechanism is installed on the frame and used for tensioning the steel wire rope. According to the wear-resistant and corrosion-resistant rope pressing equipment for the mining steel wire rope, through the arrangement of the pressure stabilizing mechanism, the steel wire rope can be tensioned, the steel wire rope is morestable, and therefore normal transportation is not affected; the swing amplitude of the steel wire rope can be reduced through a damping mechanism, so that the steel wire rope is more stable; and lubricating oil can be sprayed to the steel wire rope and guide wheels through a lubricating mechanism, so that friction between the steel wire rope and the guide wheels is reduced, and the steel wire rope is prevented from being abraded and corroded.

Owner:江苏锐金钢丝绳索具有限公司

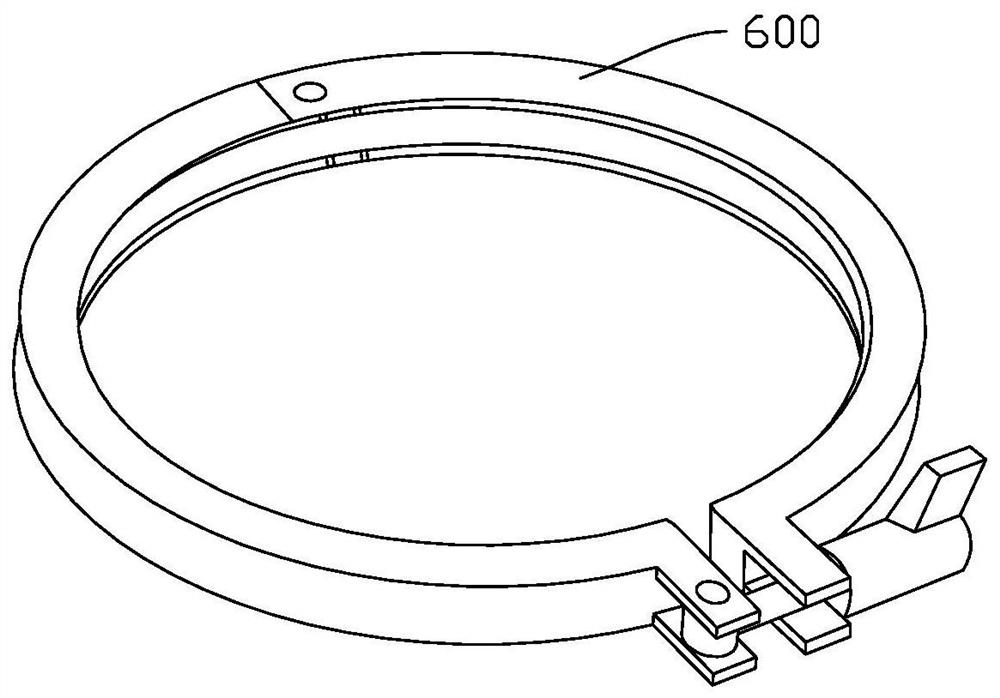

An outdoor cable transport tray with a warning function

The invention provides an outdoor cable transportation disc with a warning function. The outdoor cable transportation disc comprises a disc body, wherein the disc body is composed of press plates at the two ends and a stranded wire column located between the press plates, a support leg fixed on the ground is arranged on the press plate located at the bottom end, rotary arms are arranged below the press plate, each rotary arm is connected with the press plate through a rotation mechanism, an installation head is arranged at the other end of each rotary arm, and a warning plate can be arranged on each installation head; and during working, only the rotary arms need to be manually rotated into location grooves of location blocks to be fixed, and a warning effect can be acted on passage vehicles by arranging the triangular warning plates on the installation heads. The outdoor cable transportation disc provided by the invention is simple in structure, convenient to operate, and capable of greatly increasing a safety coefficient during an operation of workers.

Owner:WUHU SHUNCHENG ELECTRONICS

A wear-resistant and anti-corrosion rope pressing equipment for mining steel wire rope

ActiveCN112374405BDoes not affect normal transportationReduce swingCleaning using toolsWinding mechanismsEngineeringCorrosion

The invention relates to a rope pressing device, in particular to a wear-resistant and anti-corrosion rope pressing device for mine steel wire ropes. The technical problem of the present invention is to provide a mining steel wire rope wear-resistant and anti-corrosion rope pressing equipment that can tighten the steel wire rope. The technical embodiment of the present invention is: a wear-resistant and anti-corrosion rope pressing equipment for mining steel wire ropes, including a frame and a voltage stabilizing mechanism. The voltage stabilizing mechanism is installed on the frame, and the voltage stabilizing mechanism is used to tighten the steel wire rope. The present invention can tighten the steel wire rope through the setting of the voltage stabilizing mechanism, so that the steel wire rope is more stable, thereby not affecting normal transportation; the vibration amplitude of the steel wire rope can be reduced through the shock absorbing mechanism, so that the steel wire rope can be more stable; The lubricating oil is sprayed on the wire rope and the guide wheel to reduce the friction between the wire rope and the guide wheel, avoid the wear of the wire rope, and prevent the corrosion of the wire rope.

Owner:江苏锐金钢丝绳索具有限公司

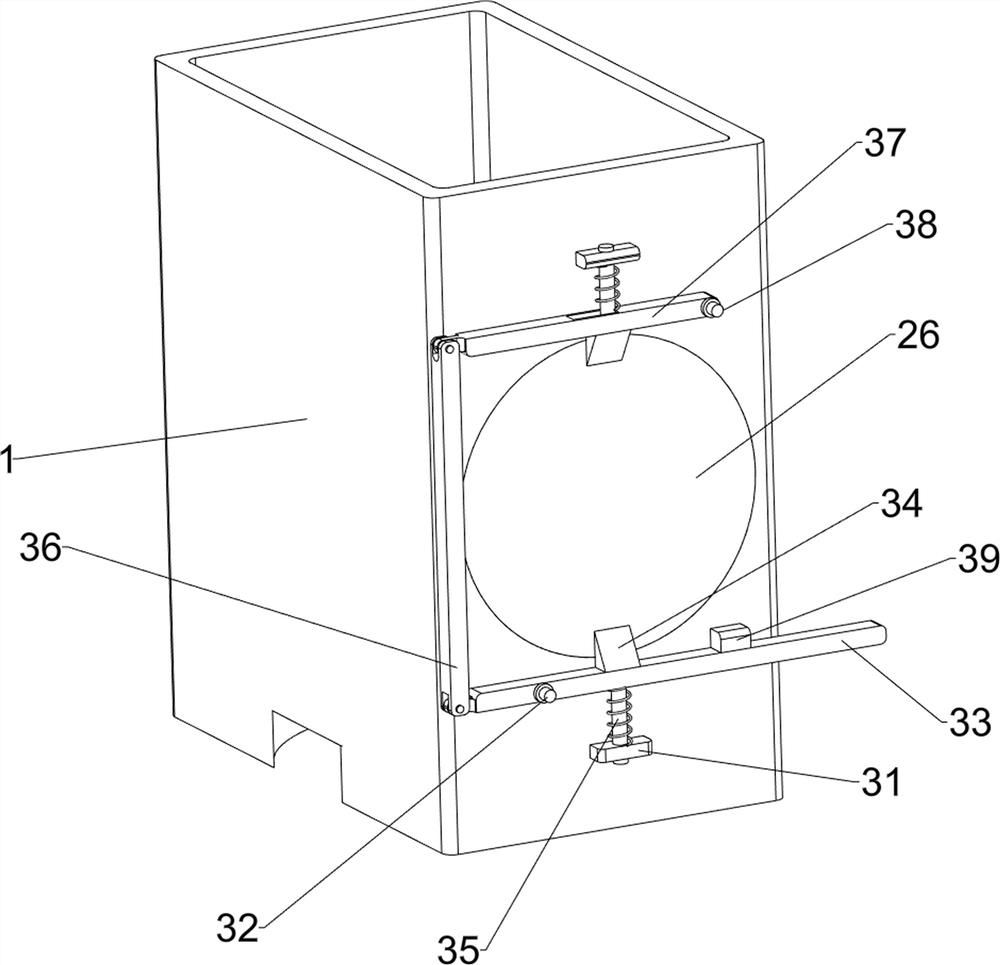

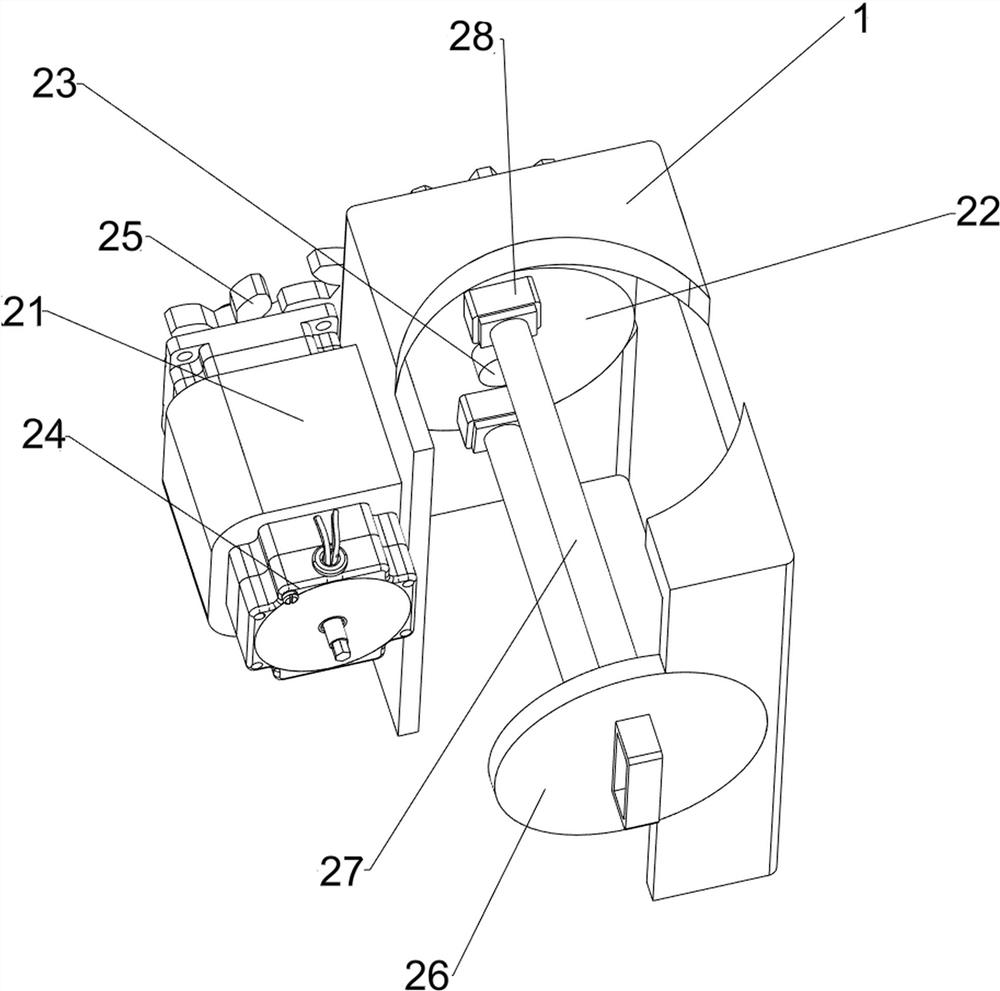

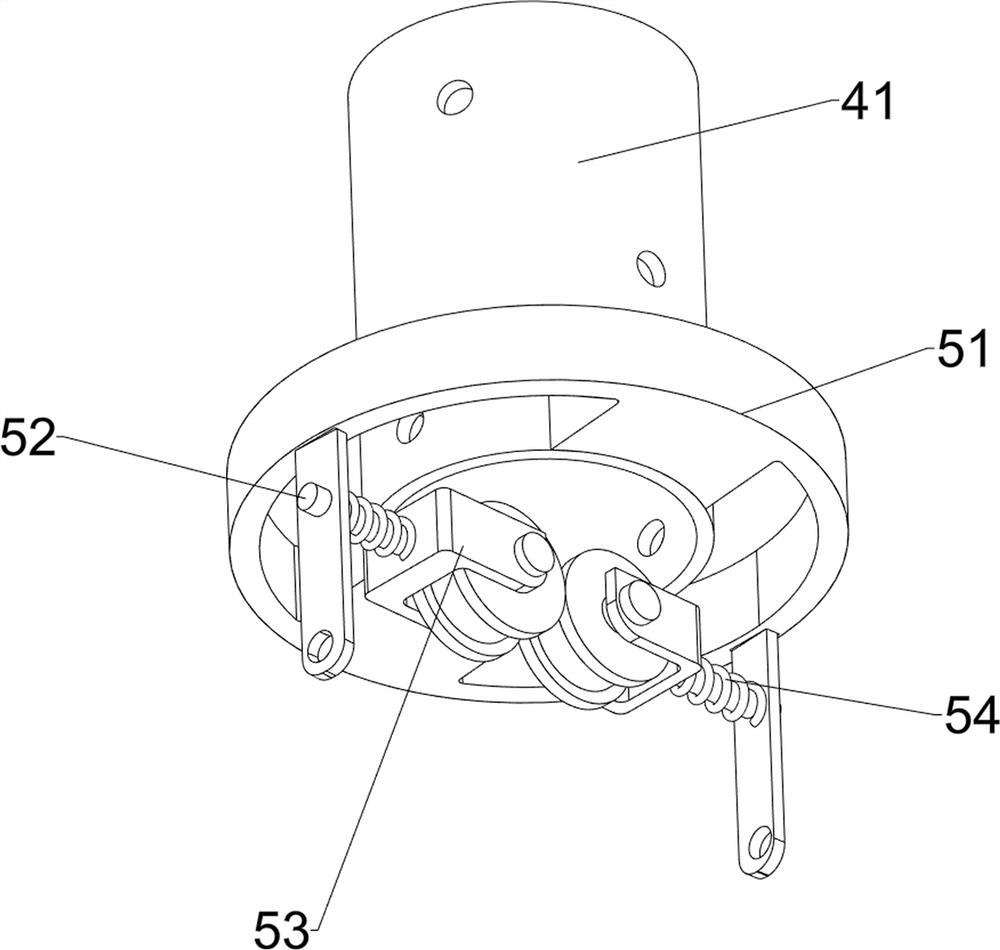

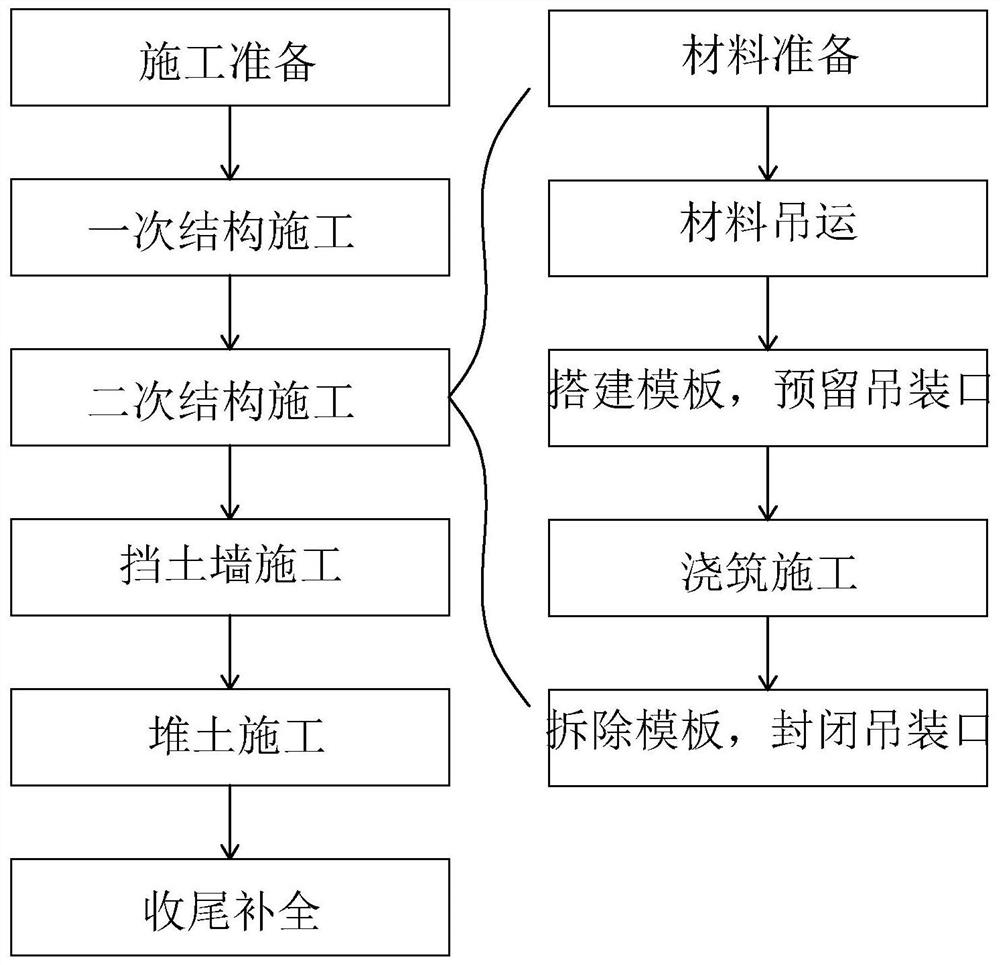

Top soil-piled mountain-shaped structure construction method

InactiveCN113818566AReduce loss and wasteReduce wasteExtraordinary structuresBuilding material handlingArchitectural engineeringRetaining wall

The invention relates to a top soil-piled mountain-shaped structure construction method. The construction method comprises the following steps of a, construction preparation; b, primary structure construction; c, secondary structure construction: firstly building a bracket on a primary structure, then building a tapered plane beam, a tapered plane roof and a conversion column structure template of a secondary structure according to the design scheme, reserving a hoisting opening in the tapered plane roof template, then pouring concrete, removing the template and the bracket after the strength of a concrete structure meets the requirement, transferring the f template and the bracket out of the construction area from the reserved hoisting opening, and then closing the hoisting opening; d, constructing a retaining wall; e, soil piling construction; and f, ending and complementing. When the secondary structure construction is carried out, the template and the bracket are convenient to dismantle by reserving the hoisting opening, the dismantled template and the dismantled bracket can be hoisted out of the hoisting opening, construction tools such as the template and the bracket can be repeatedly used, loss and waste of the construction tools are reduced, and the requirement for sustainable development is met.

Owner:SHANGHAI CONSTR NO 1 GRP

A profiled steel production line with rectification function

ActiveCN113083946BDoes not affect normal transportationMetal-working feeding devicesPositioning devicesEngineeringManufacturing line

The invention relates to a profiled steel production line with back-leveling function, which comprises: a straightening machine; a cooling bed, a steel shifting chain is arranged at the end of the cooling bed; Between machines; back-leveling roller table, back-leveling roller table extends from a distance to the moving steel chain, back-leveling roller table includes return roller mechanism and lifting roller mechanism, return roller mechanism includes return roller, lifting roller mechanism Including the lifting roller, the return roller mechanism extends from a distance to the outside of the moving steel chain, and the lifting roller mechanism is arranged in the moving steel chain in a liftable manner. The lifting roller mechanism has at least a raised state and a lowered state. The upper surface of the wheel is higher than the upper surface of the moving steel chain, and the upper surface of the lifting roller is lower than the upper surface of the moving steel chain when it is lowered. The return roller mechanism transports the section steel that needs secondary straightening to the outside of the steel transfer chain, and then transports the section steel to the transfer steel chain through the lifting roller mechanism, and transports the section steel to the straightening machine again through the transfer steel chain and straightening transfer roller Inner straightening.

Owner:CHANGSHU LONGTENG SPECIAL STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com