Transport platform

A transport platform and a pair of technology, applied in the field of transport platforms, can solve the problems of inability to transport other containers and low utilization rate of space at the stern, and achieve the effects of reducing transportation costs, facilitating fastening, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

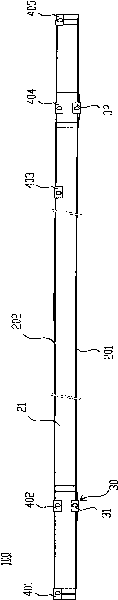

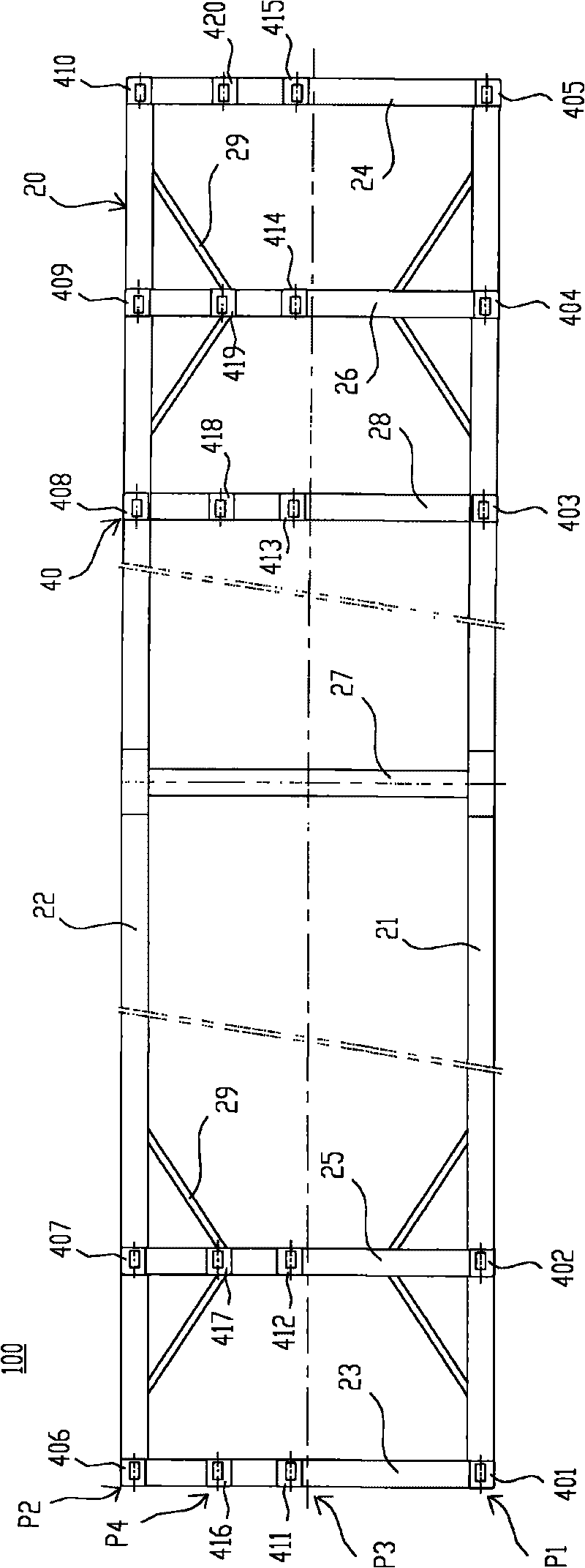

[0030] Such as Figure 2A , 2B As shown, the structure of the transportation platform of the present invention is shown. The transportation platform 100 of the present invention includes a frame 20 , a plurality of standard fixed corner fittings 31 and 32 arranged on the bottom surface 201 of the frame 20 , and a plurality of top corner fittings 401 - 420 arranged on the top surface 202 of the frame 20 .

[0031] The frame 20 of the transport platform of the present invention may consist of a pair of parallel longitudinal beams 21 , 22 . Of course, the frame 20 may also include a fixed beam 27 to connect and fix the pair of longitudinal beams 21, 22; preferably, it may further include a pair of end beams 23, 24 located on the outside and a pair of end beams located on the inside 25 , 26 , the end beams 23 , 24 , 25 , 26 are located between the pair of longitudinal beams 21 , 22 and are connected to the longitudinal beams 21 , 22 at both ends. In the present invention, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com