Top soil-piled mountain-shaped structure construction method

A construction method and secondary structure technology, applied in special structures, building components, building structures, etc., can solve the problems of loss and waste of building appliances, formwork and brackets that cannot be transported out, and stay inside the secondary structure, etc., to achieve lateral movement Short distance, easy to recycle, reduce damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

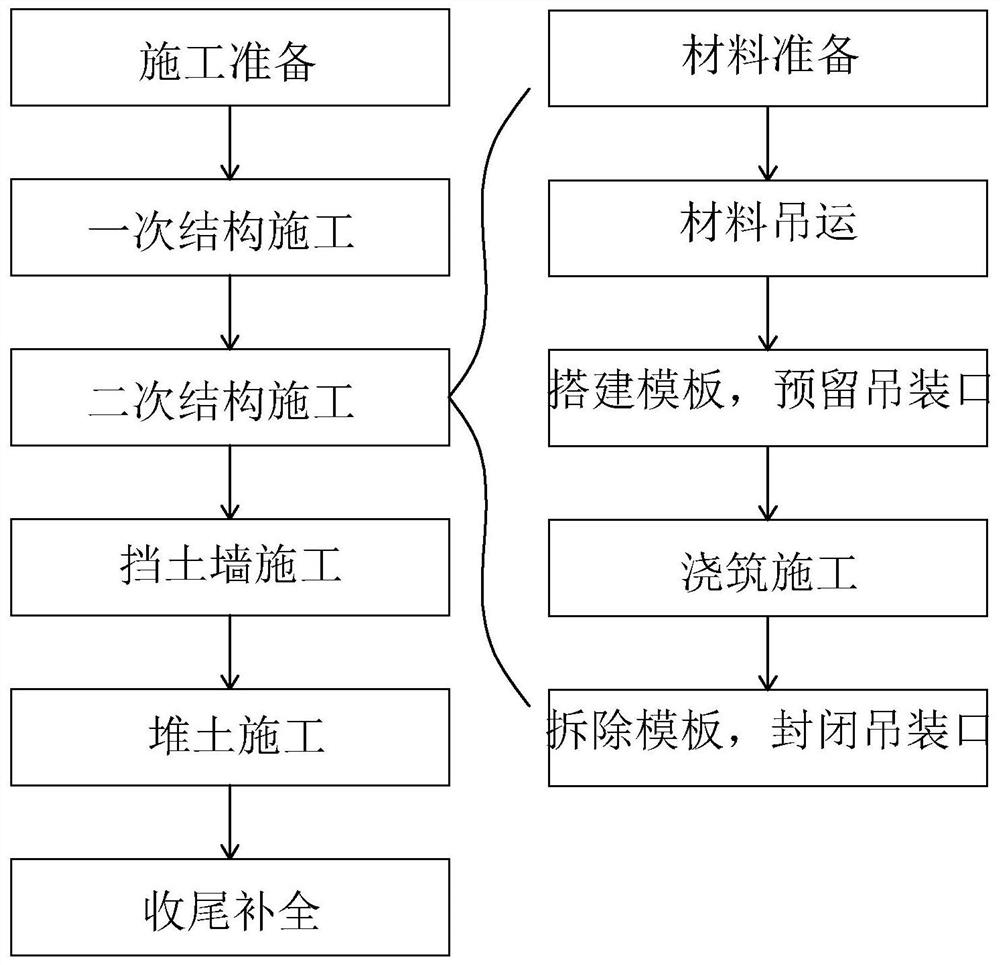

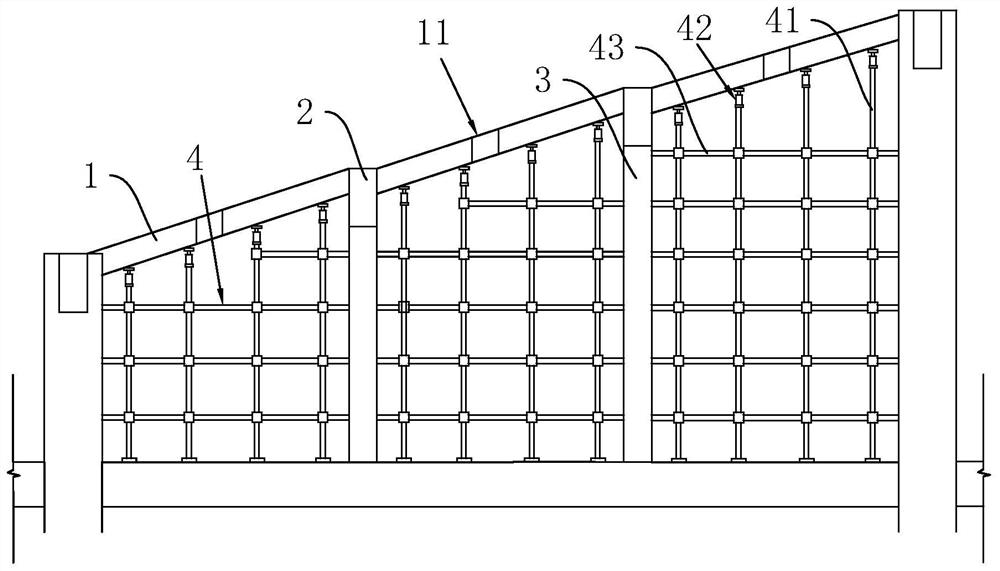

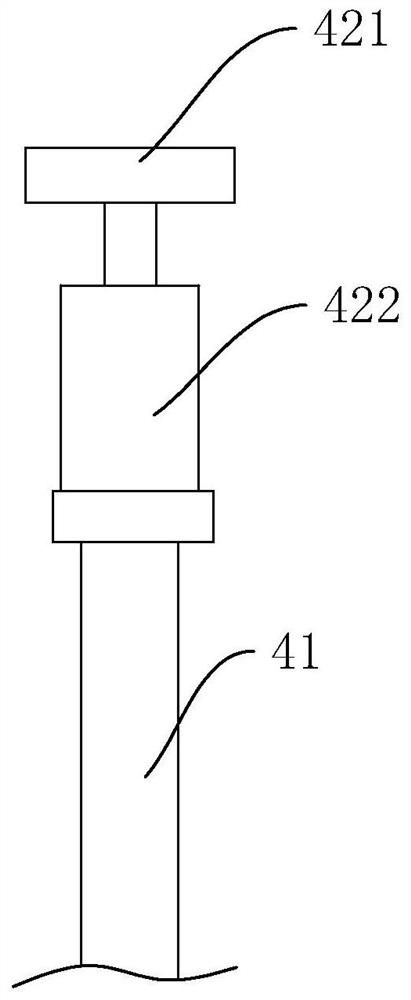

[0043] The following combination figure 1 The application is described in further detail.

[0044] refer to figure 1 , the embodiment of the present application discloses the construction method of the mountain-shaped structure of the top mound, including the following steps:

[0045] a. Construction preparation: According to the design requirements, the mountain-shaped earth mound building is layered from bottom to top and partitioned in the plane.

[0046] Establish the overall BIM model of the mountain-shaped earthen building, use the BIM model to determine the overall engineering volume distribution of the mountain-shaped building, and make the engineering volume of each partition roughly the same according to the structural form of the mountain-shaped building and the overall engineering volume distribution.

[0047] b. Construction of a primary structure: construct the primary structure layer by layer from bottom to top, and set a ring-shaped horizontal roof on the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com