Energy-saving and environment-friendly synthesis technology for 1,2,4-1H triazole

An energy-saving, environmental-friendly, synthetic process technology, applied in the direction of organic chemistry, can solve the problems of high by-product treatment costs, high equipment maintenance costs, complex production processes, etc., achieve low production costs, solve corrosion problems, and simple production processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

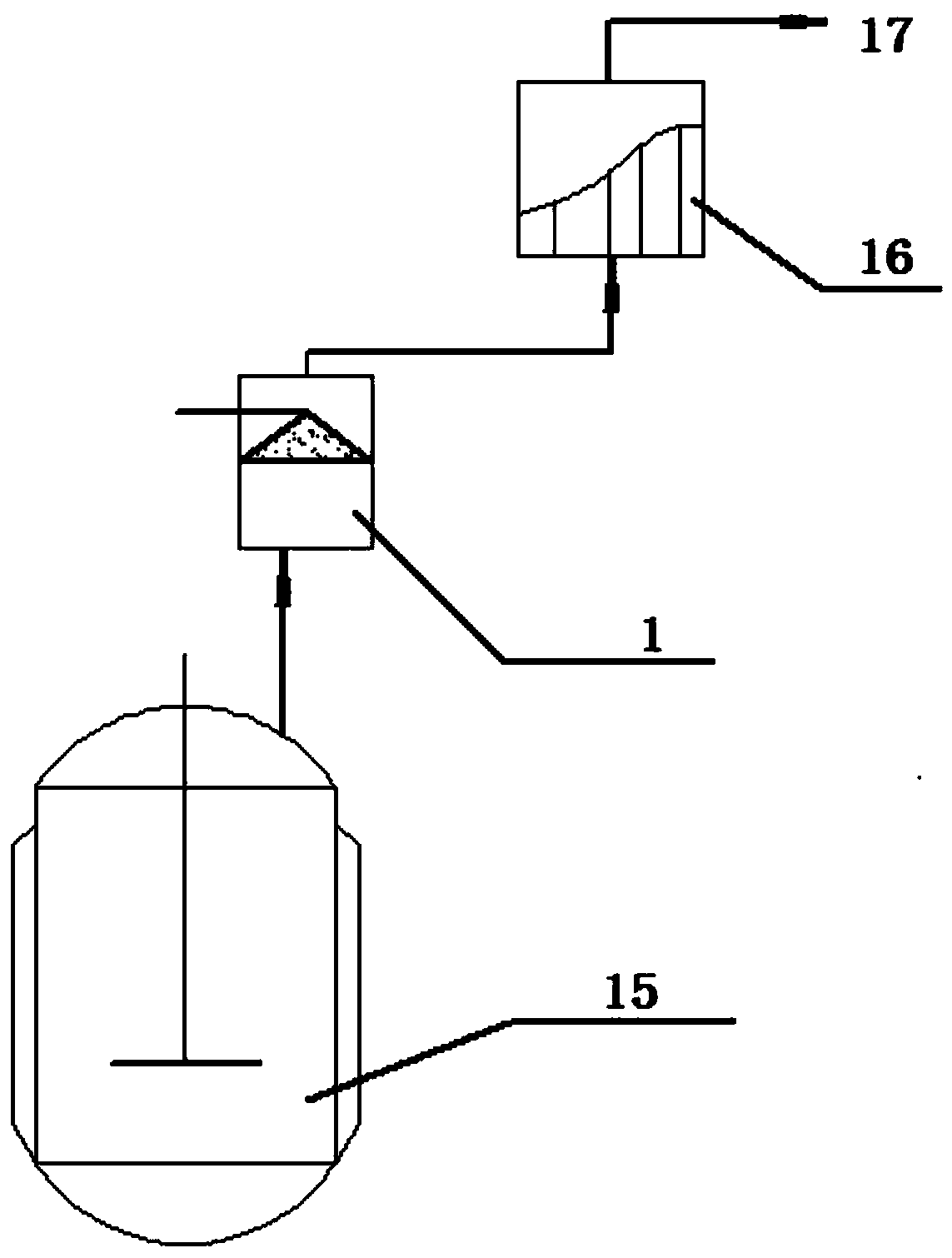

[0040] Step S1, put all the formamide raw materials into the reaction kettle in advance, slowly add hydrazine hydrate into the formamide from the elevated tank, and react to form the main product 1,2,4-1H triazole;

[0041] The ammonia produced in step S2 and step S1 enters the acid shower device through the gas phase inlet, and the formic acid enters the acid shower device through the acid input port, and the cooled ammonia reacts with the formic acid sprayed to generate ammonium formate;

[0042] The ammonium formate generated in step S3 and step S2 is cooled and refluxed into the reactor in the leaching device, and reacts with hydrazine hydrate to generate the main product 1,2,4-1H triazole.

[0043] In steps S1 and S2, the reaction temperature is controlled at 150-160°C.

[0044] In order to make the reactants fully react and discharge waste gas as little as possible, preferably, the mass ratio of formamide, hydrazine hydrate, and formic acid is (1.3-1.7):(0.7-1.1):(0.1-0....

Embodiment 2

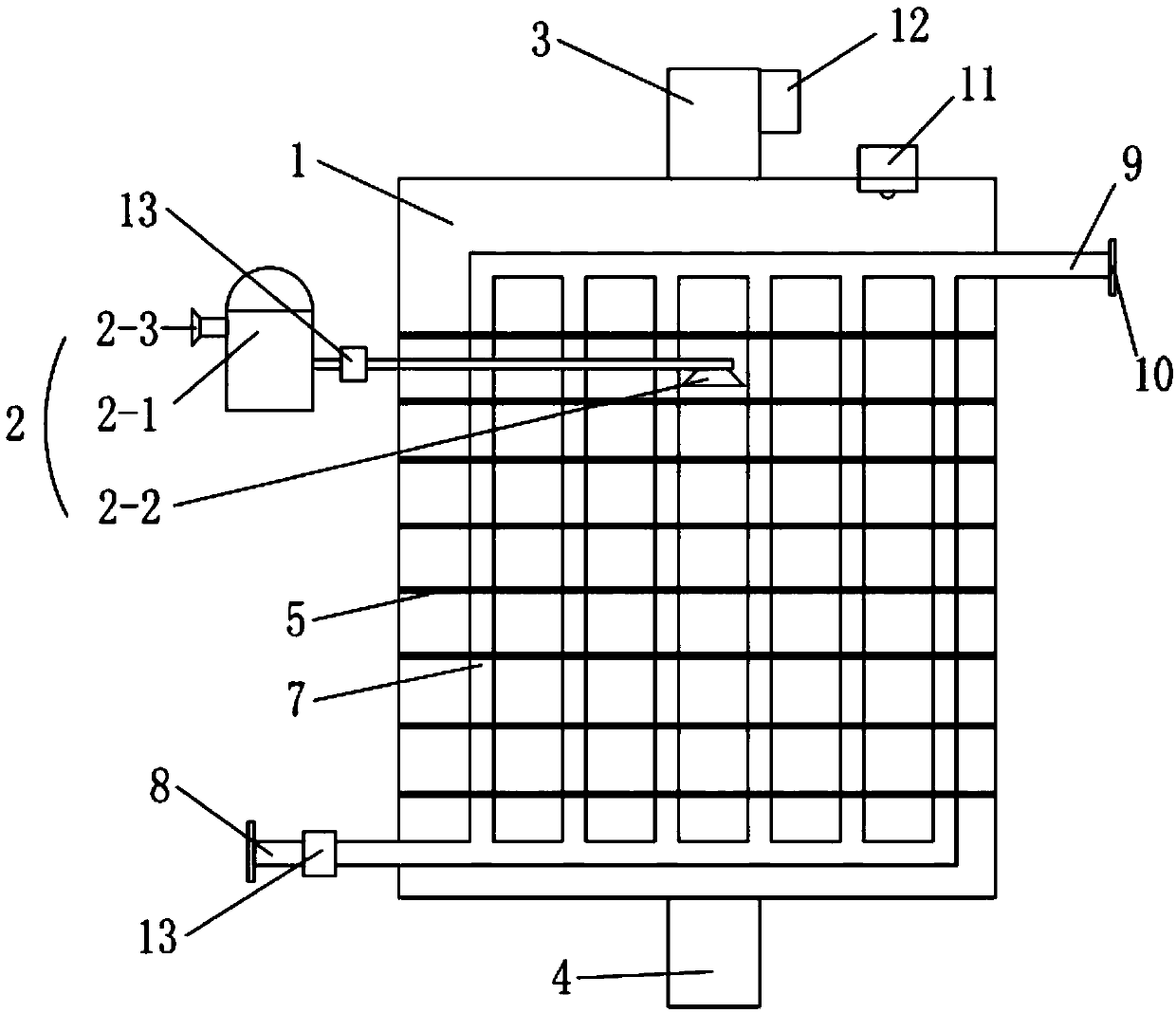

[0053] On the basis of Embodiment 1, the applicant has also made the following design, see figure 1 , in order to be able to monitor the temperature in the acid shower in real time, the top of the container body 1 is provided with a temperature sensor 11, and the temperature sensor 11 is inserted into the container body 1.

Embodiment 3

[0055] On the basis of Embodiment 1, the applicant has also made the following design, see figure 1 , in order to be able to monitor the pH value at the outlet of the gas phase in real time, an ammonia content detector 12 is provided at the outlet of the gas phase at 3 places, and a condenser 16 is set at the outlet of the gas phase at the same time. Exhaust gas absorption device 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com