Biomass combustible gas tar separation and removal apparatus

A biomass and tar technology, applied in combustible gas purification, combustible gas purification/transformation, separation methods, etc., can solve problems such as large energy consumption, water pollution, secondary pollution, etc., to reduce energy loss and achieve significant economic benefits , the effect of reducing loss and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

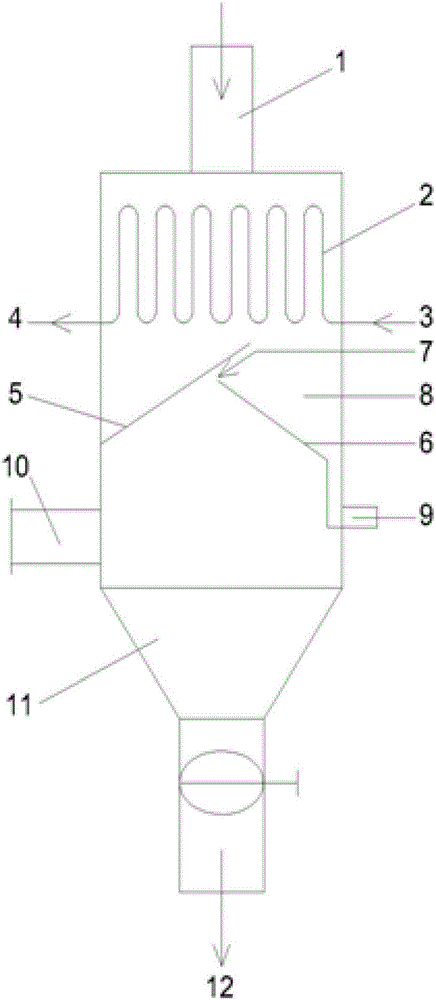

[0024] Referring to the accompanying drawings, a biomass combustible gas tar separation and removal device includes a primary cooling tar separator and a secondary cooling tar separator with the same structure, and the primary cooling tar separator and the secondary cooling tar separator respectively include equipment Cavity condenser 2, tar collection upper side plate 5, tar collection lower side plate 6; the top of the equipment cavity is provided with a delivery pipe interface air inlet 1, the delivery pipe interface air inlet 1 is connected to the delivery pipe, and the upper part of the equipment cavity is equipped with equipment Cavity condenser 2, the two ends of the equipment cavity condenser 2 are the circulating cooling water inlet 3 and the circulating cooling water outlet 4 respectively, and the middle part of the equipment cavity is provided with a cross-stacked tar collecting upper side plate 5 and a tar collecting lower side plate 6, the tar collecting The gap be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com