Particle material detection device

A technology for detection devices and granular materials, applied in the direction of sampling devices, etc., can solve the problems of increased workload and inconvenient operation for the same sample, and achieve the effects of shortening sampling time, convenient operation, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

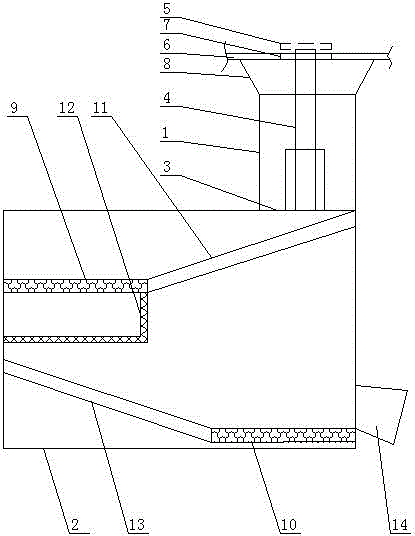

[0017] like figure 1 As shown in the figure, a particle material detection device of the present invention includes a reclaiming cylinder 1 and a detection cylinder 2, the reclaiming cylinder 1 is arranged on one side of the top of the detection cylinder 2, and the detection cylinder 2 and the reclaiming cylinder There is a material inlet 3 between the contact points of the body 1, a cylinder 4 is arranged inside the reclaiming cylinder 1, a top plate 5 is arranged on the top of the cylinder 4, and the top plate 5 is arranged between the blanking ports 7 on the running platform 6. The top plate 5 and the There is no gap between the blanking ports 7, the top of the reclaiming cylinder 1 and the running platform 6 are provided with a guide hood 8, and the inside of the detection cylinder 2 is provided with a first-level weighing rod 9 and a second-level weighing rod 10. The weighing rod 9 is arranged on the upper side of the secondary weighing rod 10. The primary weighing rod 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com