Wear-resistant and corrosion-resistant rope pressing equipment for mining steel wire rope

A wire rope and rope pressing technology, which is applied in the direction of mechanical equipment, cleaning methods and appliances, cleaning methods using tools, etc., can solve problems such as affecting normal transportation, vibration of the wire rope, and insufficient stability, so as to achieve the stability of the wire rope, reduce friction, and prevent The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

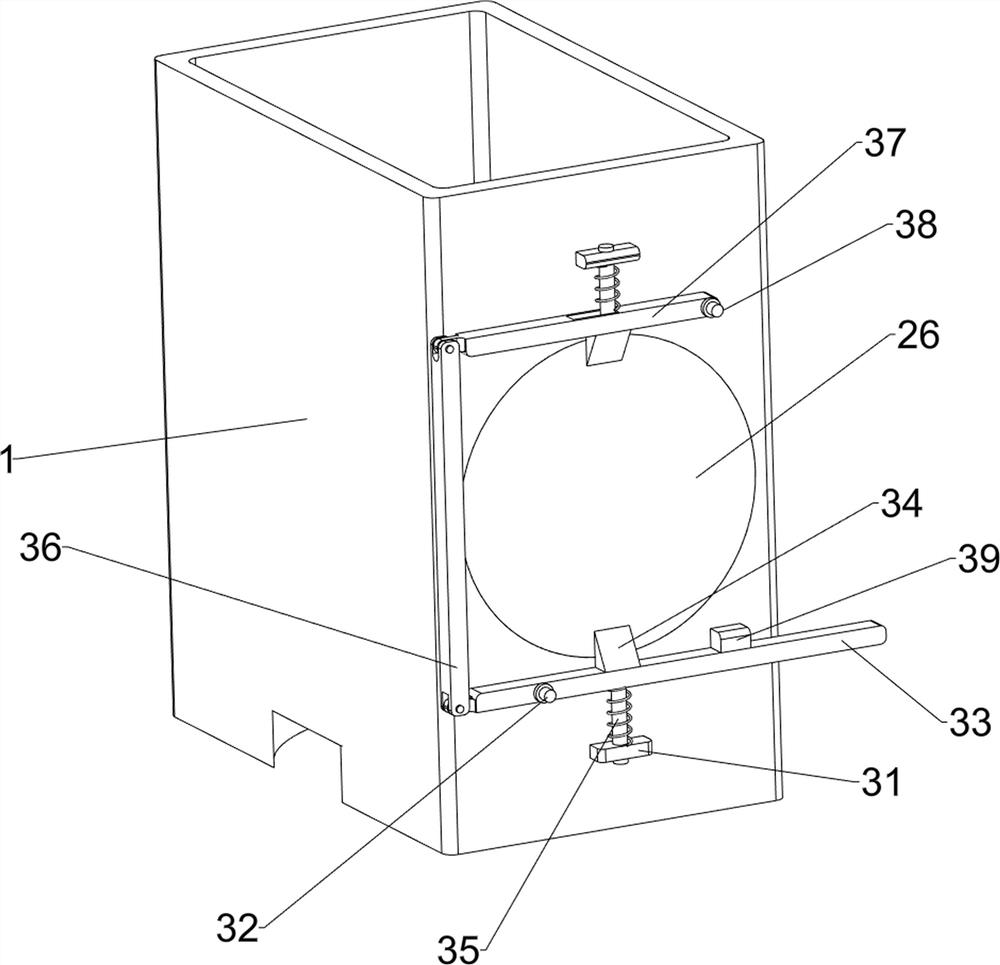

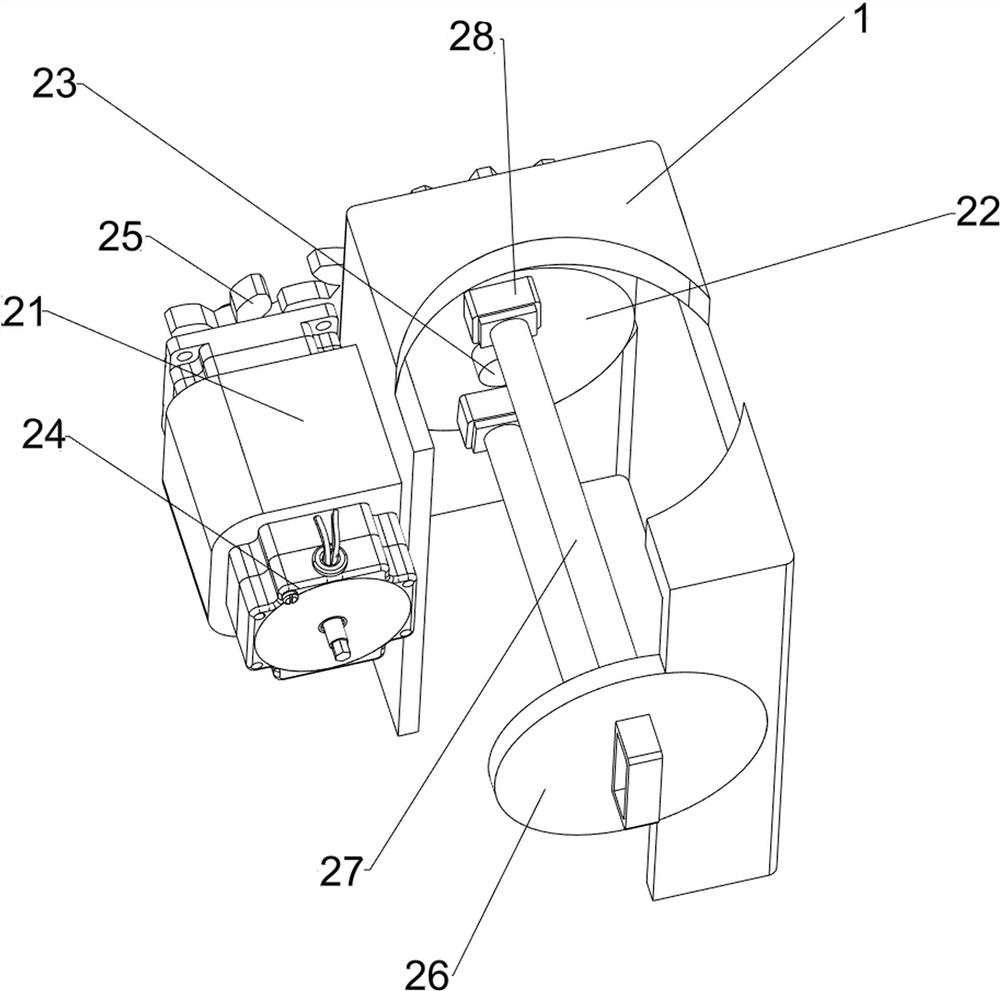

[0031] A mining steel wire rope wear-resistant anti-corrosion rope pressing equipment, such as Figure 1-4 As shown, a frame 1, a voltage stabilizing mechanism 2 and a locking mechanism 3 are included, and the voltage stabilizing mechanism 2 and the locking mechanism 3 are installed on the frame 1.

[0032] People pass the steel wire rope through the voltage stabilizing mechanism 2, and then control the voltage stabilizing mechanism 2 to work. The voltage stabilizing mechanism 2 tightens the steel wire rope to make the steel wire rope more stable, thereby not affecting normal transportation. After the steel wire rope is tightened, people close the voltage stabilizing mechanism 2 . After the work is over, people control the voltage stabilizing mechanism 2 to release the steel wire rope, and then close the voltage stabilizing mechanism 2. If there is a steel wire rope remaining on the voltage stabilizing mechanism 2, people can control the locking mechanism 3 to release the volt...

Embodiment 2

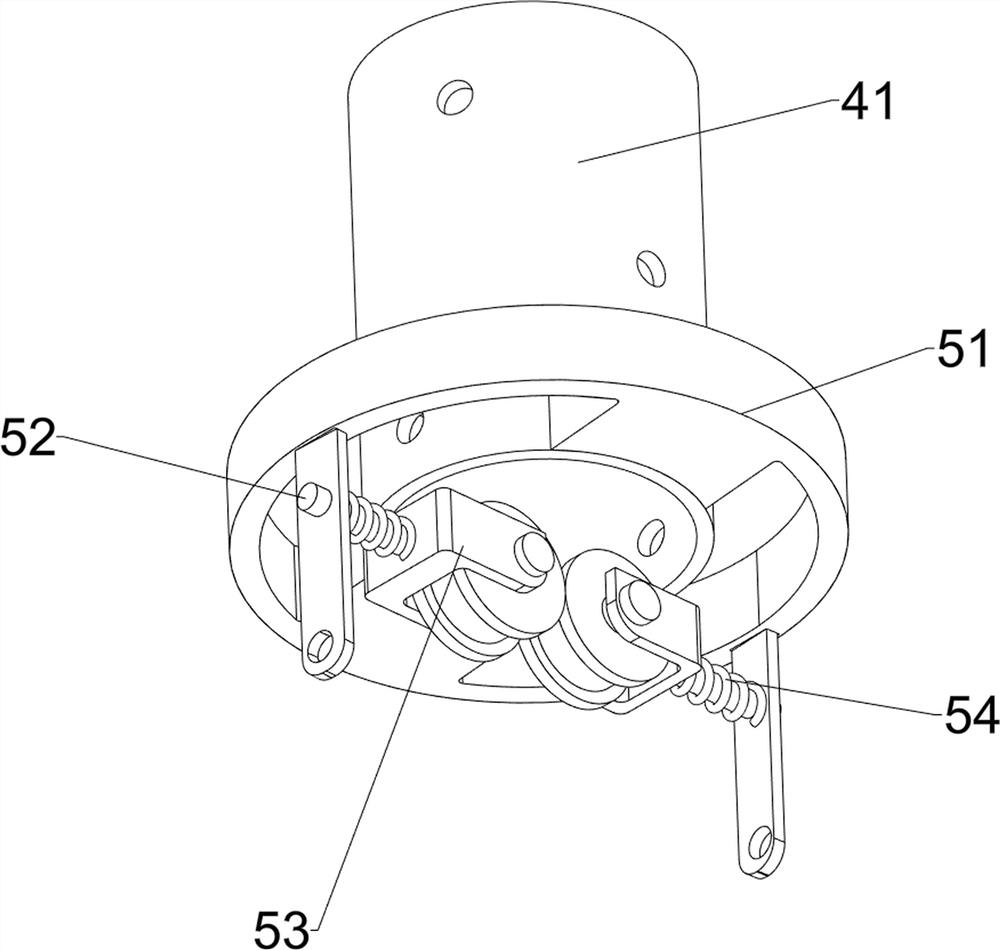

[0038] On the basis of Example 1, such as Figure 5-8 As shown, a shock absorbing mechanism 4 is also included, and the shock absorbing mechanism 4 includes a first fixed sleeve 41, a first telescopic rod 42, an arc clamp block 43 and a first spring 44, and the bottom of the frame 1 is connected with a first fixed sleeve 41 , the front and rear sides of the first fixed sleeve 41 are embedded with two first telescopic rods 42, the inner ends of the first telescopic rods 42 are connected with arc-shaped clamping blocks 43, and the four first telescopic rods 42 are all covered with the first telescopic rods 42. A spring 44 , the two ends of the first spring 44 are respectively connected with the first fixing sleeve 41 and the arc clamping block 43 .

[0039] People pass the steel wire rope between the two first fixed rods 27, and then the steel wire rope passes between the arc clips 43, and through the effects of the first telescopic rod 42, the arc clip 43 and the first spring 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com