Pipeline internal corrosion detection device and detection method

A detection device and detection method technology, applied in the direction of material electrochemical variables, etc., can solve the problems of high technical requirements for personnel operation, high detection cost, inconvenient operation, etc., and achieve the effect of reducing interference, simple operation, and non-stop production detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

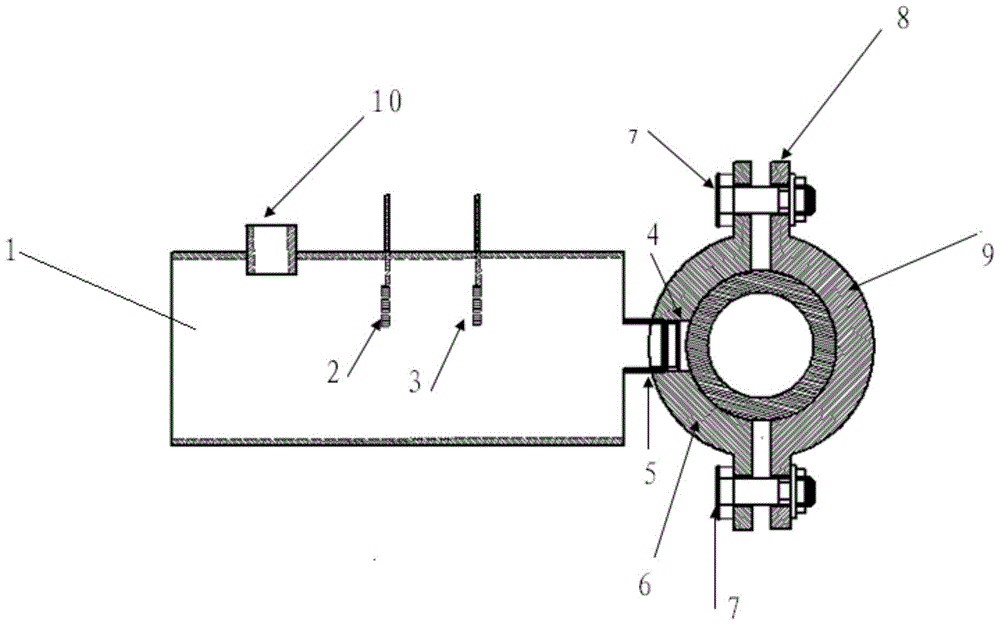

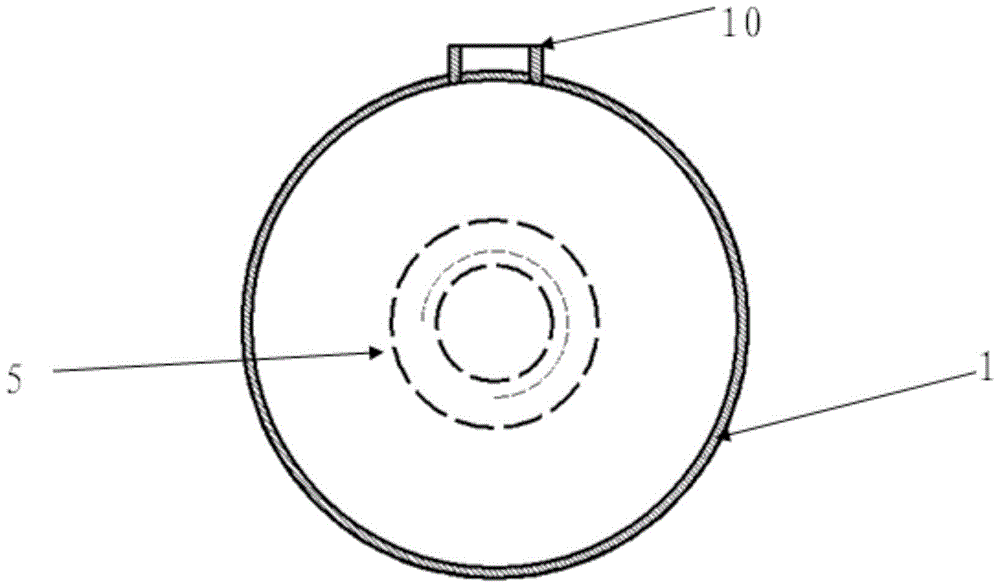

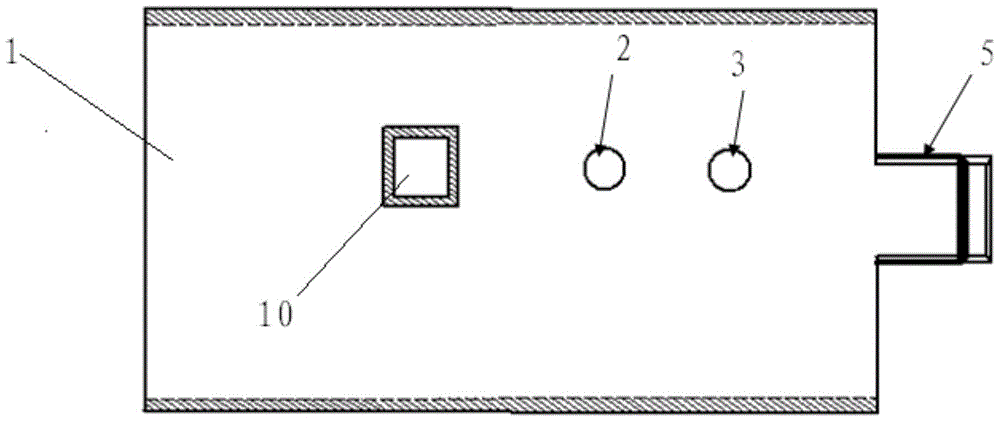

[0029] like Figure 1 to Figure 5 As shown, a pipeline internal corrosion detection device of the present invention includes an anode tube 1 and a first splint 6 connected to the anode tube 1, a first electrode 2 and a second electrode 3 are arranged in the anode tube 1, and the first electrode 2 It is a platinum electrode, the second electrode 3 is an Ir / IrO reference electrode, the first electrode 2, the second electrode 3 and the anode tube 1 are filled with silicon rubber to seal, and the first splint 6 is clamped by the second splint 9 on the measured On the pipeline, the first splint 6 and the second splint 9 are arc-shaped, and the two ends of the first splint 6 and the second splint 9 are provided with a connecting plate 8, and the connecting plate 8 is provided with a through hole, and the bolt 7 is inserted into the through hole to connect with the The nut c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com