Glass ring sensor packaging structure

A technology of packaging structure and glass ring, which is applied in the direction of instruments, measuring devices, measuring fluid pressure, etc., can solve the problems of internal stress release and achieve the effect of state stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

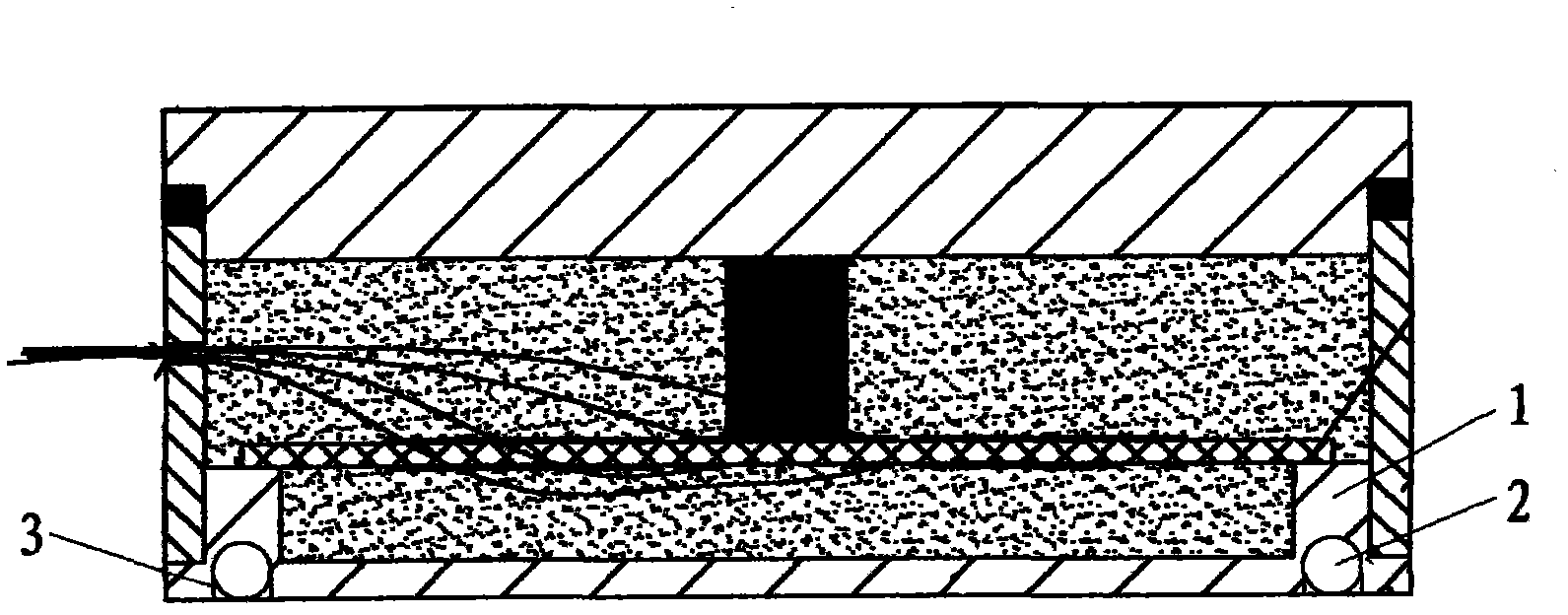

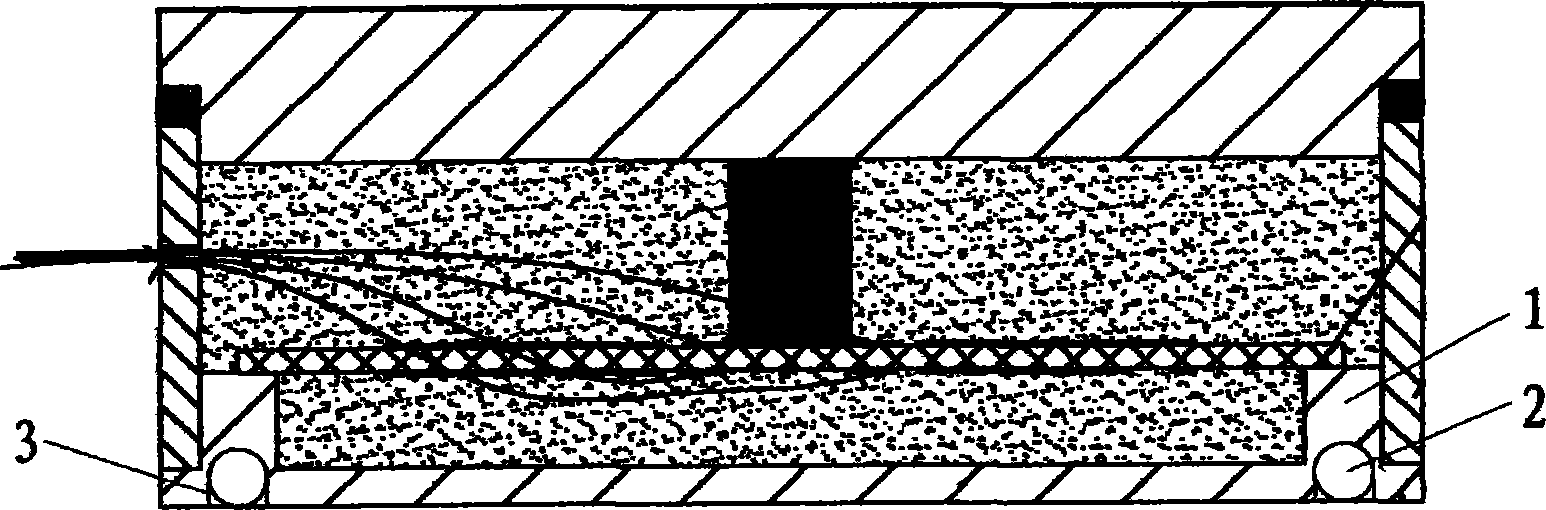

[0008] Such as figure 1 As shown, the glass ring sensor packaging structure of the present invention includes a base 1 for packaging the sensor body, a circular groove 3 is arranged on the outer surface of the sensor base 1, and a circular groove 3 is arranged in the circular groove 3. Glass ring 2, the glass ring 2 is embedded in the ring cutting groove 3, and the whole of the glass ring 2 is buried in the lower part of the outer surface of the base 1, so that the glass ring 2 can be guaranteed to be in the normal use state It can ensure that the glass ring 2 only plays the role of stress evacuation or support for the base itself; the ring cutting groove 3 and the glass ring 2 are interference Cooperate so that the glass ring 2 can evenly evacuate the stress of the base 1 itself, so that the base 1 will not shrink or expand excessively during the process of being cold or heated, and ensure that the sensor body inside the base 1 is in a stable state and will not be affected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com