An impeller feeder

A technology of feeding machine and feeding mechanism, which is applied in the directions of packaging, loading/unloading, and large containers, etc. It can solve the problems of incomplete unloading, increase the distance between the impeller and the discharge port, and blockage, so as to reduce the distance and prevent winding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

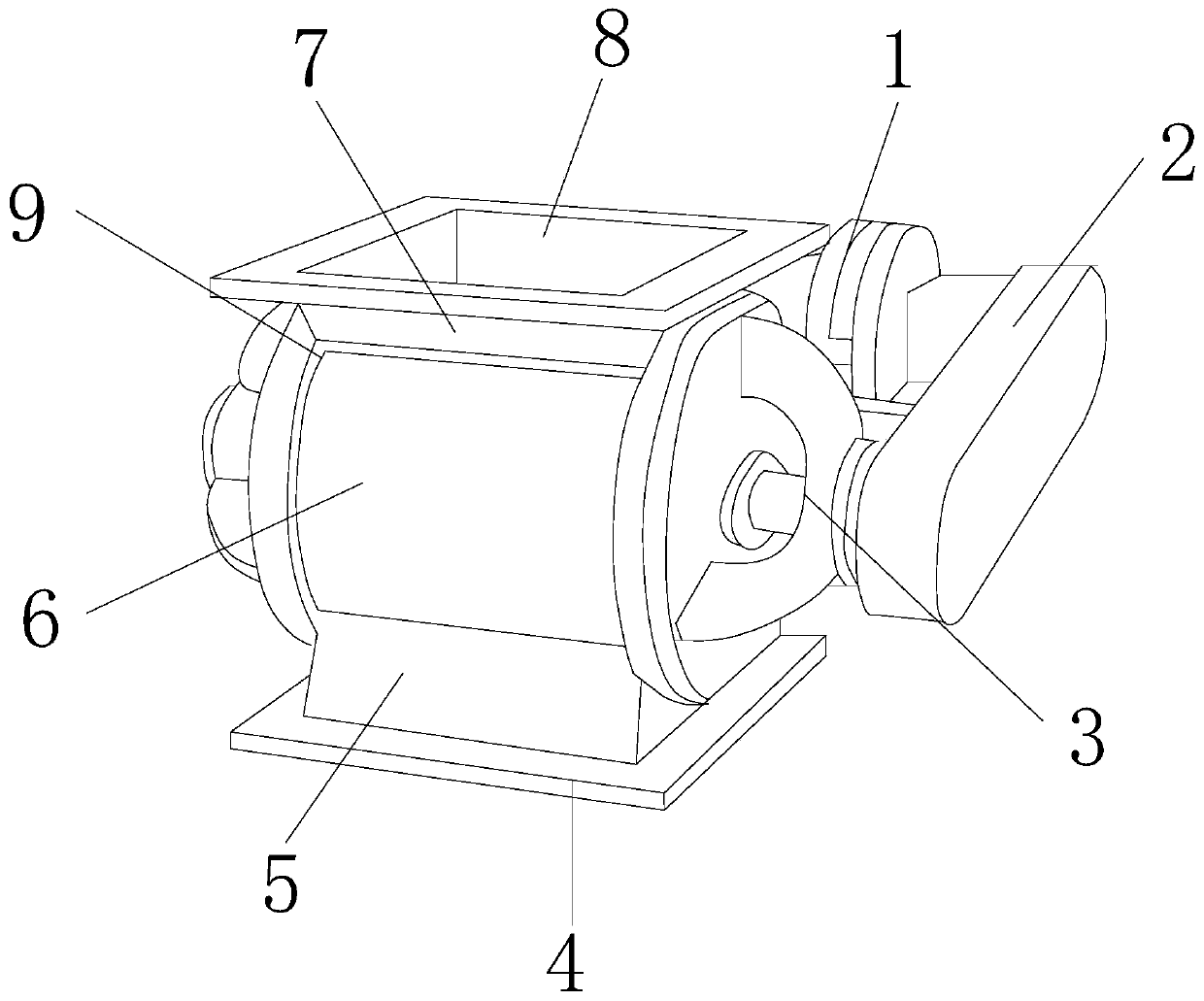

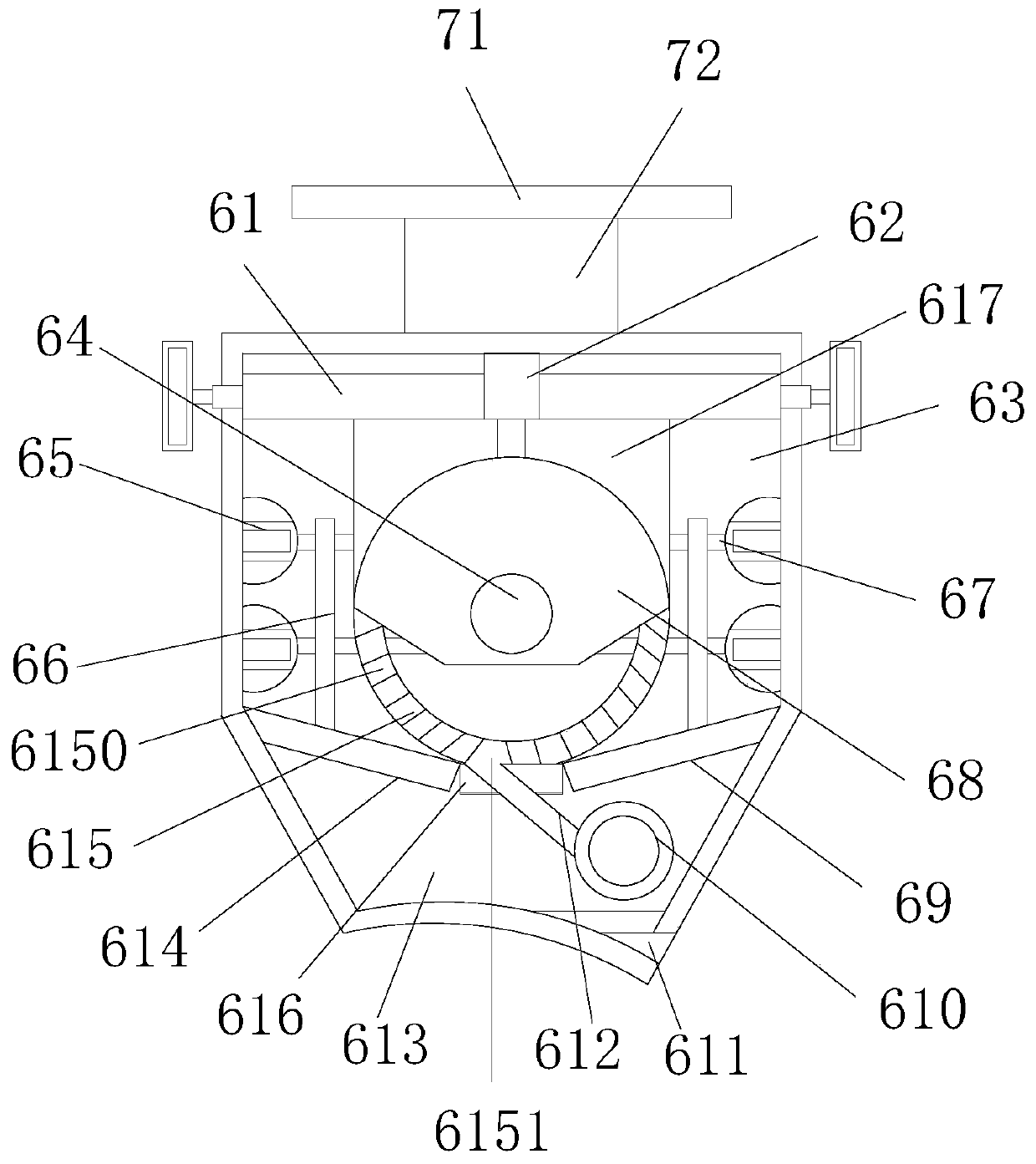

[0023] see Figure 1 to Figure 4 , the present invention provides a kind of impeller feeder, its structure comprises motor 1, transmission cover wheel 2, transmission shaft 3, support bottom plate 4, middle plate 5, feeding mechanism 6, feeding hopper 7, feeding port 8, shell 9 , the bottom of the shell 9 and the middle plate 5 are an integrated structure, the middle plate 5 is welded to the support base 4 and is perpendicular to the support base 4, the top of the shell 9 is welded to the feed hopper 7 and is perpendicular to each other, the The feeding port 8 is located above the feeding hopper 7 and is an integrated structure with the feeding hopper 7. The feeding mechanism 6 is installed inside the casing 9, and the rear of the casing 9 is provided with a motor 1, and the motor 1 passes through the transmission The cover wheel 2 is connected to the transmission shaft 3, and the transmission shaft 3 penetrates through the shell 9 through a through hole and is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com