Afterheat recovering device of I.C. engine

A technology of waste heat recovery device and internal combustion engine, which is applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of long time and inefficient recovery of condensation heat, and achieve the effect of avoiding contact and not easy to deteriorate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

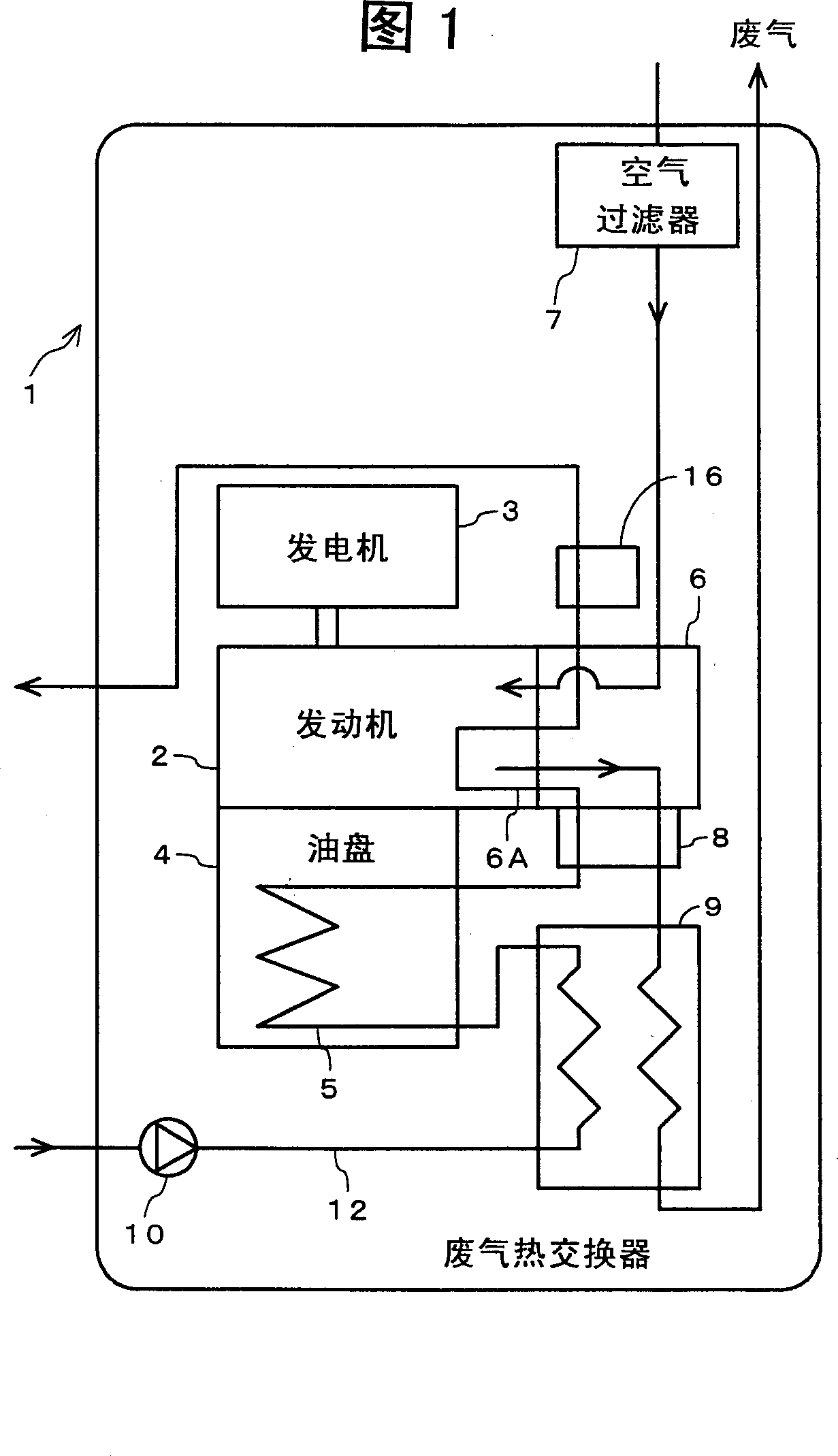

[0025] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings. As shown in FIG. 1 , a waste heat recovery device 1 included in a cogeneration device is configured to recover waste heat from an internal combustion engine portion of an internal combustion engine generator. An internal combustion engine 2 and a generator 3 mechanically connected to the internal combustion engine 2 are provided in the waste heat recovery device 1 . The generator 3 generates alternating current corresponding to the rotational speed of the internal combustion engine. The internal combustion engine 2 is provided with an oil pan 4 storing lubricating oil. An oil cooler (oil heat exchanger) 5 is connected to the oil pan 4, and the oil heat exchanger 5 performs heat exchange between oil in the oil pan 4 and a heat medium (cooling water). The cylinder head 6 of the internal combustion engine 2 takes in air from an air filter 7 . Exhaust gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com