Friction generator based on folded conductive film, preparation method thereof, and integrated structure

A technology of triboelectric generator and conductive film, applied in triboelectric generators and other directions, can solve the problems of weak friction effect, low output voltage and output power of device output performance, poor versatility, etc., to improve output voltage and output power, and broaden power generation. method, the effect of large output voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

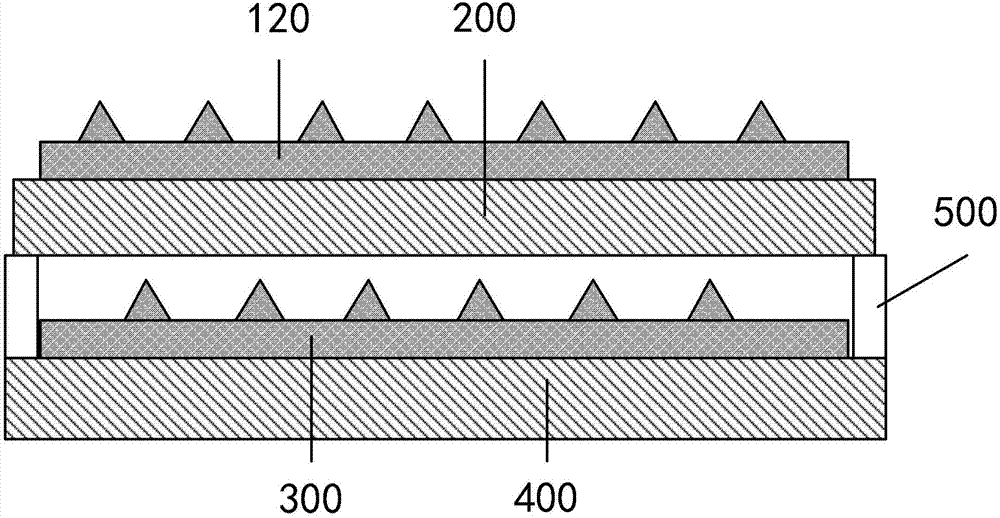

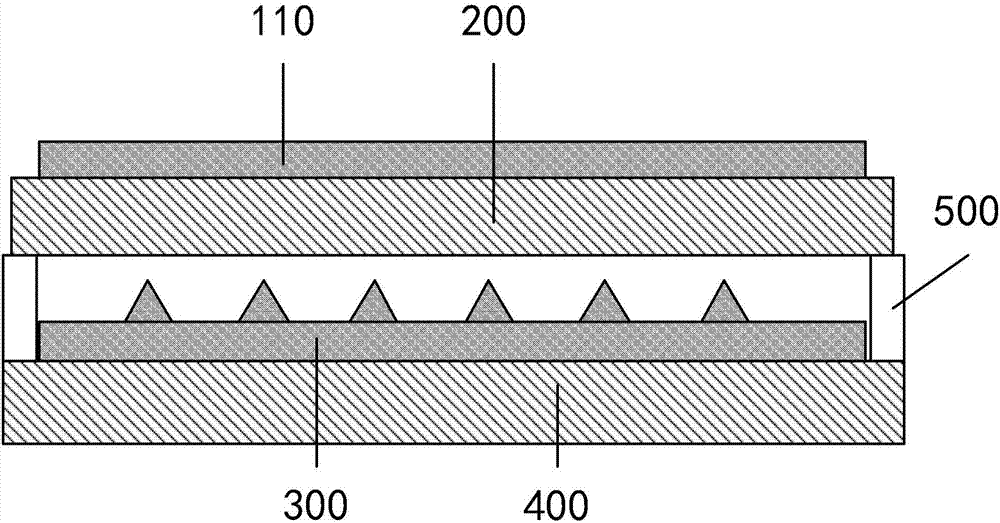

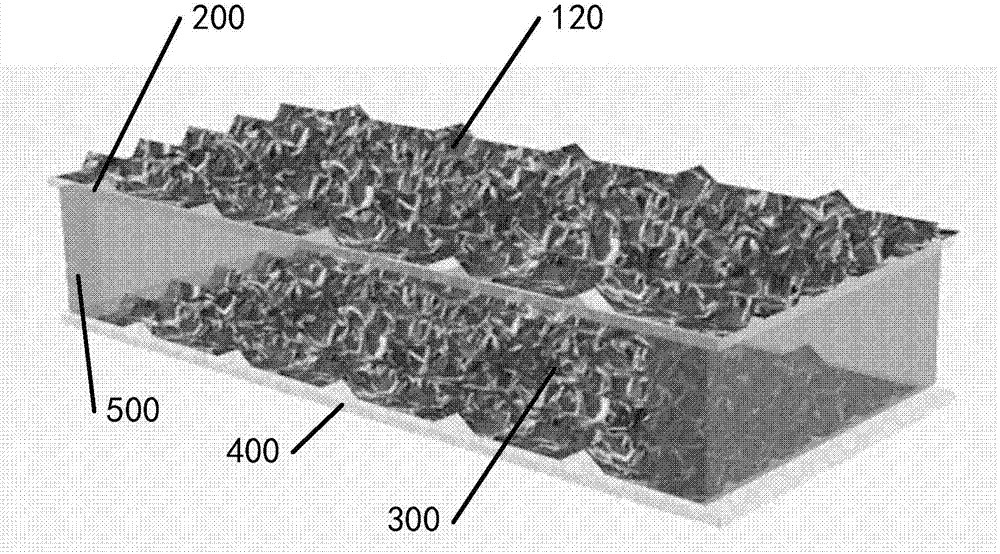

[0050] The invention provides a triboelectric generator based on a wrinkled conductive film and a preparation method thereof. By preparing the conductive thin film material of the electrode part of the triboelectric generator into a wrinkled shape, and cooperating with a flexible substrate as an insulating layer, the friction area is increased and friction effect, and also improved the ductility of the device. On the one hand, the output voltage and output power of the friction generator were effectively improved, and the integration and popularization of the device were improved; on the other hand, the traditional friction generator was expanded. The power generation method can generate electricity through pressure, stretching and bending, which further enhances the versatility of the device and helps to broaden the application of friction generators in complex environments and human-machine interfaces.

[0051] In order to make the object, technical solution and advantages of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com