Titanium alloy pipe grinding device

A titanium alloy tube and grinding wheel technology, used in grinding/polishing safety devices, grinding machines, grinding heads, etc., can solve problems such as large tube material jitter, and achieve the effects of small tube material jitter, low heat generation, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

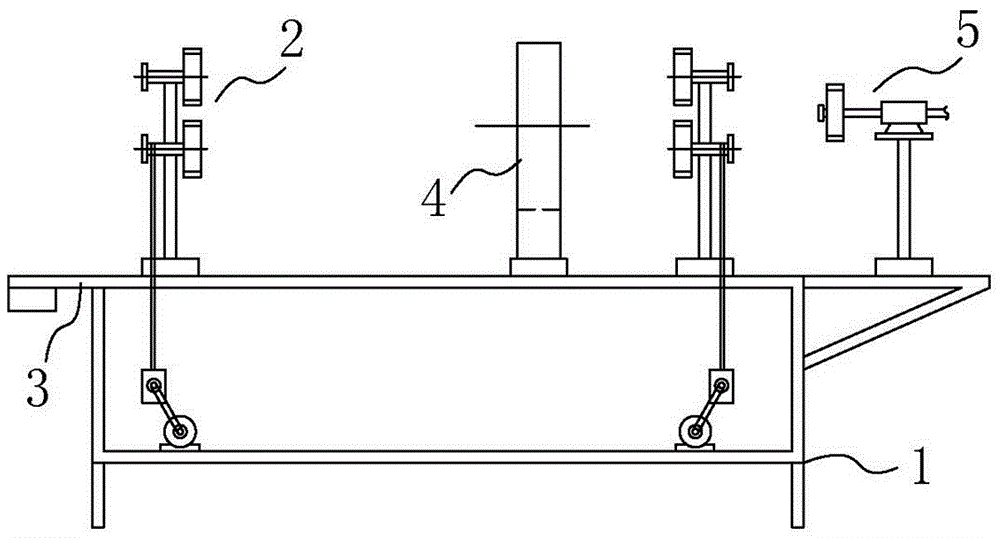

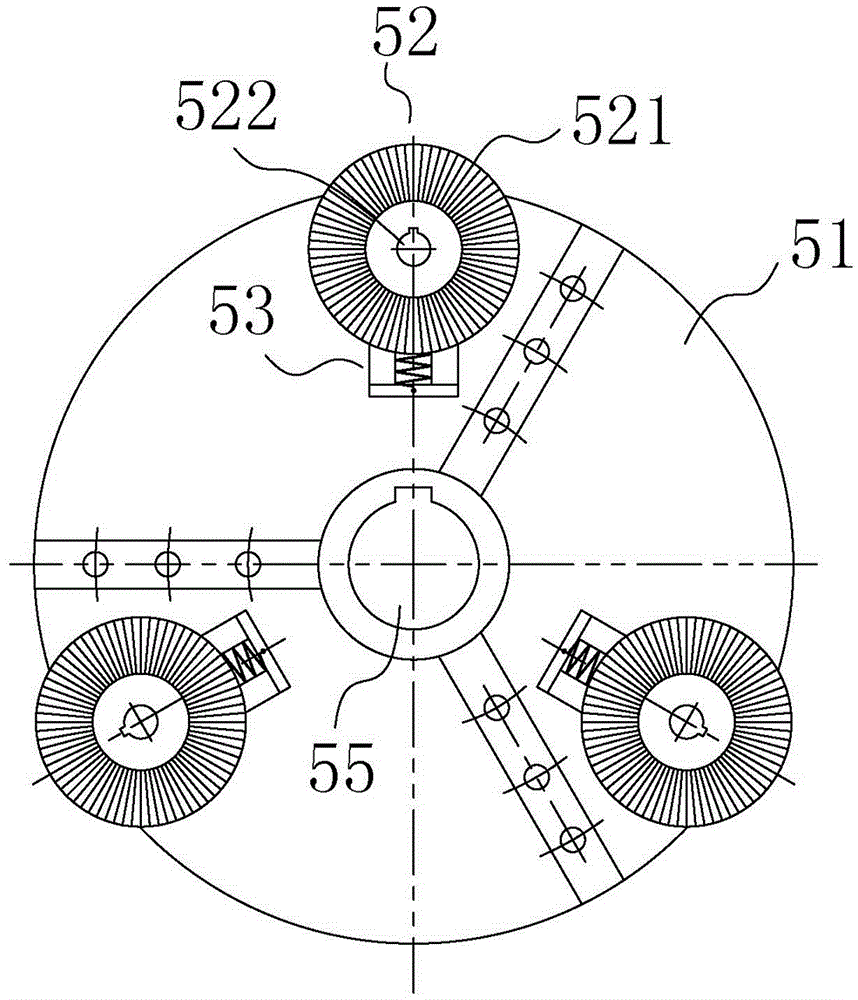

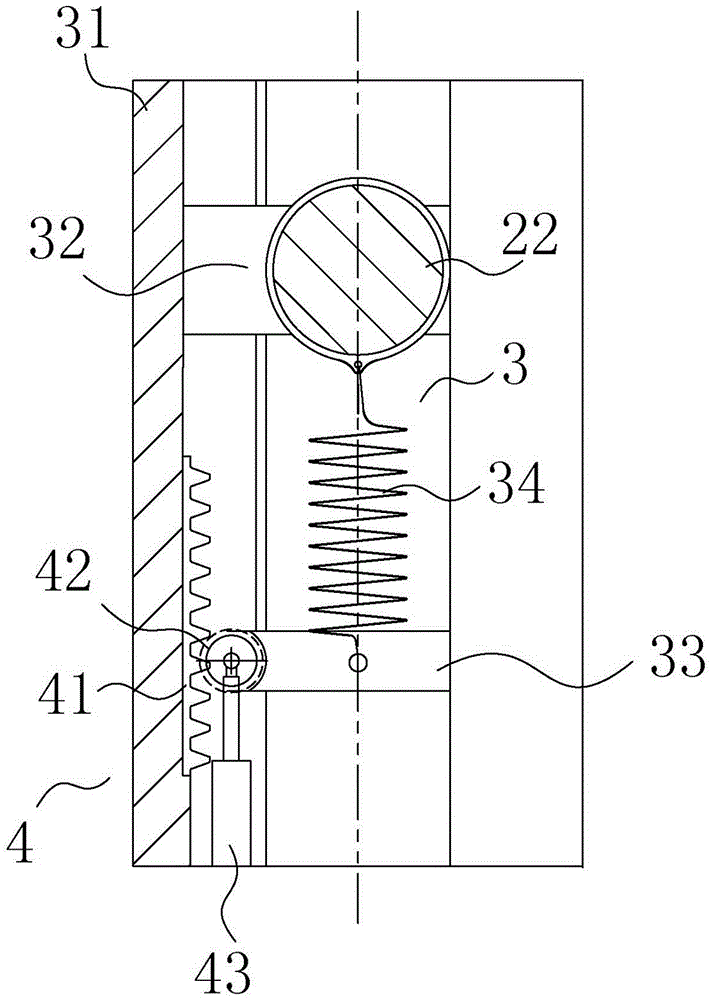

[0031] Embodiment: a kind of titanium alloy tube grinding device, such as figure 1As shown, a track 3 is provided along the length direction of the frame 1, and a grinding assembly 5 is provided at one end of the frame 1; A rotates on its own axis to cooperate with the grinding assembly 5 to complete the grinding on the inner wall of the tube; The assembly 4 is used to carry the rotating assembly 2 along the track 3 to advance or retreat toward the grinding assembly 5, so as to cooperate with the grinding assembly 5 to complete the grinding in the length direction of the inner wall of the pipe; the cooling assembly 6 is arranged on the working position of the grinding assembly 5, and is The grinding heat generated when reducing the grinding assembly 5 works.

[0032] Such as Figure 9 As shown, the rotating support assembly 2 of this embodiment includes a pair of clamping groups arranged opposite to each other, and a pair of clamping groups are respectively screwed or welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com