Jetting, expansion and extrusion combined pile, construction method thereof and spiral jetting, expansion and extrusion drilling rig used in method

A construction method and technology of combined piles, which are used in earth-moving drilling, drilling equipment and methods, and drilling with mechanical conveying devices, etc. problems, to achieve the effect of saving concrete consumption, saving concrete consumption, and improving the bearing capacity of single piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

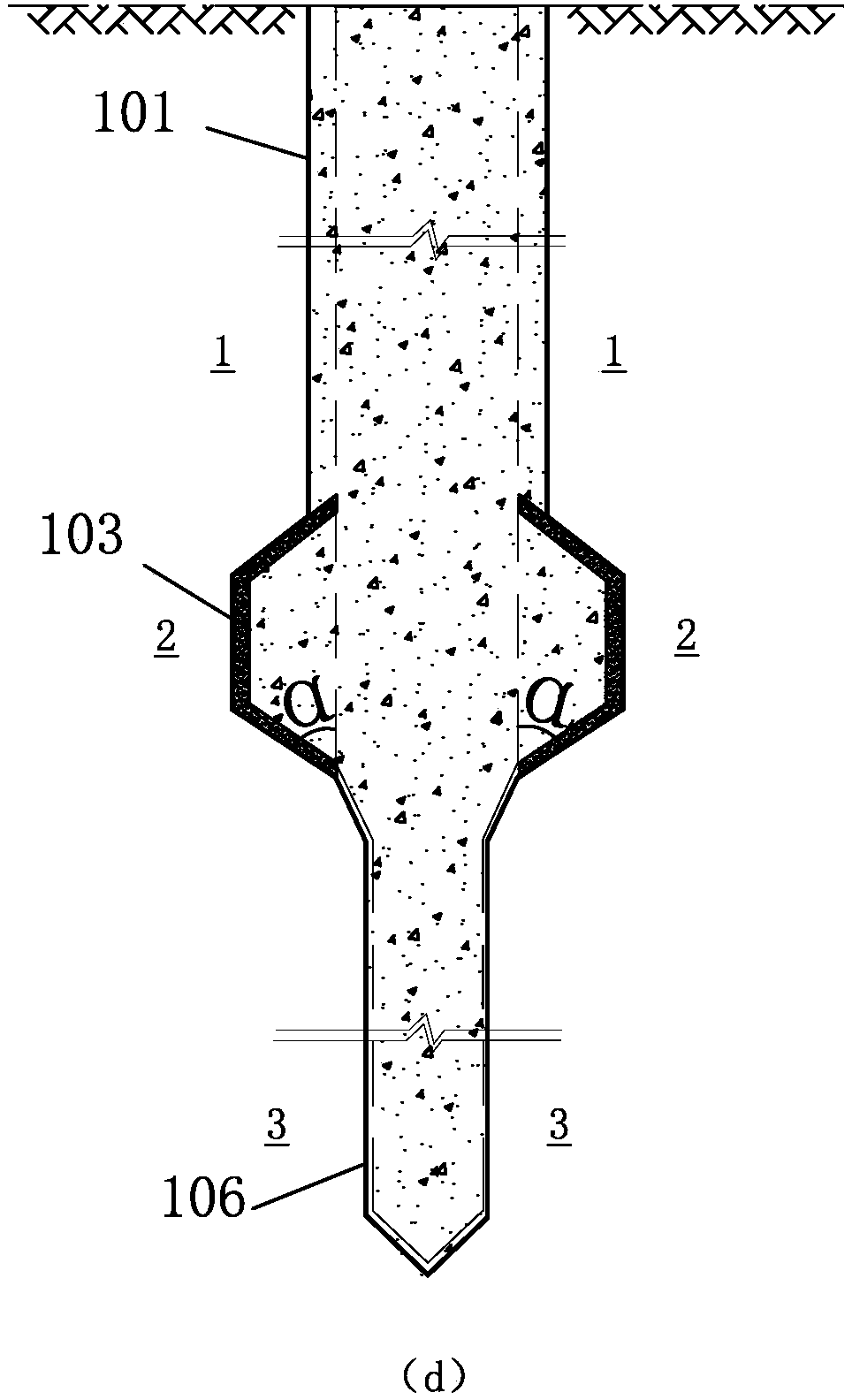

[0047] to combine Figure 1-2 As shown, a spiral spraying extrusion drilling rig includes a spiral hollow drill rod 1, a power head 2, and a high-pressure grouting pipe 5 is installed on one side of the outer wall of the core tube of the spiral hollow drill rod 1 from top to bottom, and the spiral hollow drill rod 1 It includes an upper drill rod 3 and a lower drill rod 4, wherein the upper drill rod 3 and the lower drill rod 4 are connected into one body through a flange, and the radius of the helical blade of the upper drill rod 3 is greater than the radius of the helical blade of the lower drill rod 4, so The lower end of the high-pressure grouting pipe 5 is provided with a multi-layer grouting nozzle 6, and each layer of the grouting nozzle 6 is located below the outer edge of the helical blade at the bottom of the upper drill pipe 3.

[0048] The length of the upper drill pipe 3 l 1 is 6m, and the length of the drill pipe 4 in the lower section is l 2 is 8m, the diamete...

Embodiment 2

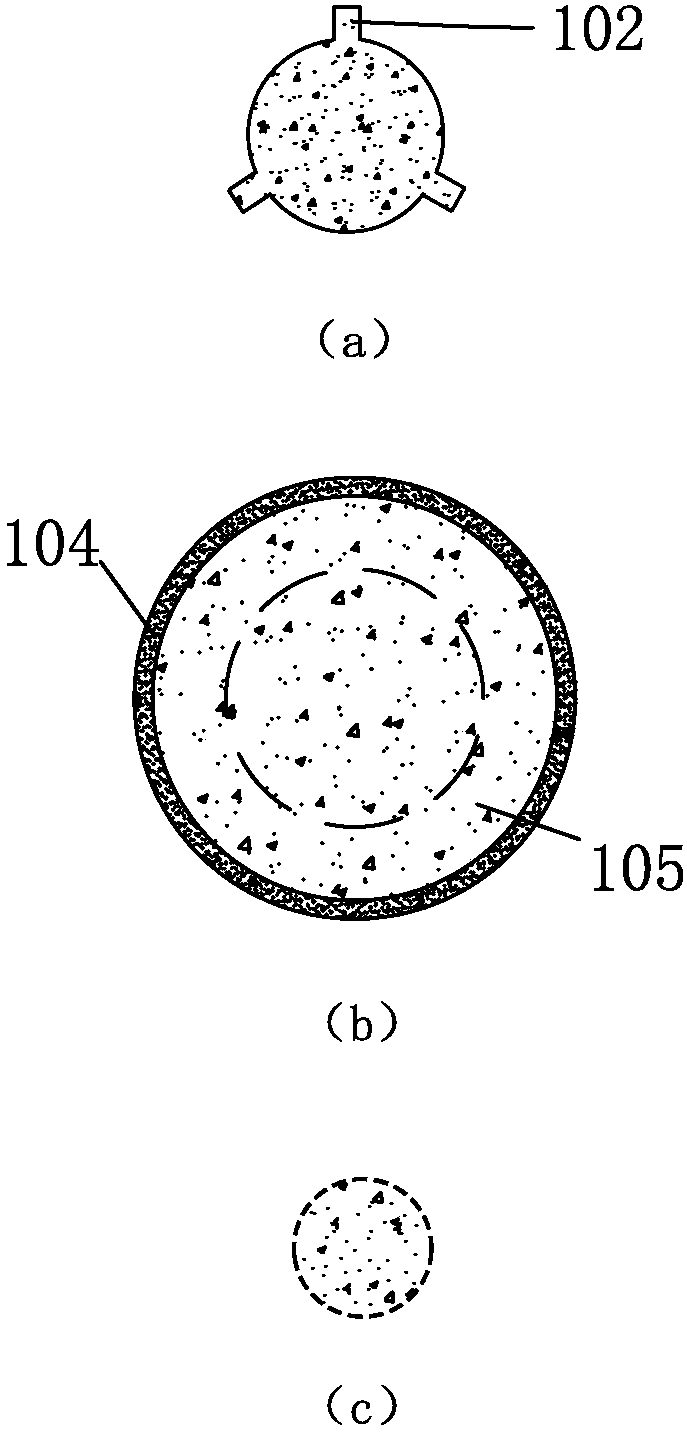

[0053] As shown in Figure 3, a spray-expanded extrusion composite pile with high bearing capacity has a pile body consisting of a pile body 101, a diameter-expanding body 103 and a pile end 106. The pile body 101 is provided with a The expanding diameter body 103 of biconical frustum. A reinforcement cage is arranged in the pile body. The biconical frustum is a structure that is large in the middle and gradually becomes smaller up and down.

[0054] The diameter-expanding body 103 is located in the sand layer where the pile body 101 is located. The pile body 101 is provided with a layer of wing plates 102 that are substantially perpendicular to the axis of the pile body. Each layer of wing plates 102 has three pieces and is evenly distributed along the circumference. The width of the wing plate 102 is 5-25 cm, and the thickness is 2-12 cm.

[0055] The diameter of the pile body above the diameter expanding body 103 is greater than the diameter of the pile body below the diam...

Embodiment 3

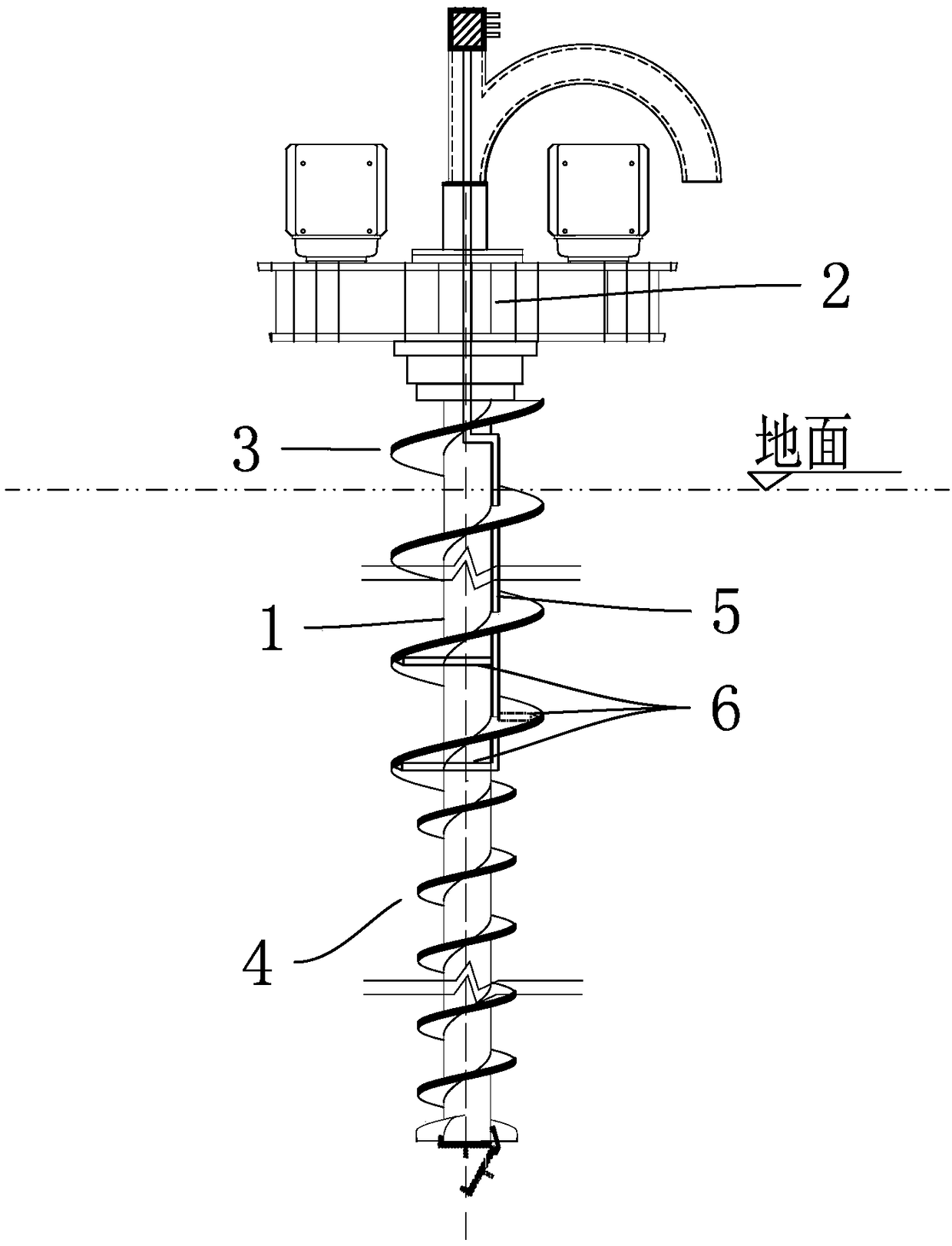

[0065] Such as Figure 5 As shown, a spray-expanded extrusion composite pile with high bearing capacity is composed of a pile body 201, an expanding diameter body 203, a pile body 206, an expanding diameter body 208 and a pile end 211. The expanding diameter body 203 and the expanding diameter body The diameter body 208 is double-conical truncated, and is integrally formed with the pile body. A reinforcement cage is arranged in the pile body. The biconical frustum is a structure that is large in the middle and gradually becomes smaller up and down.

[0066] The diameter-expanding body 203 and the diameter-expanding body 208 are located at the position of the bearing layer with relatively high shear strength in the vertical direction of the pile body. The pile body 201 and the pile body 206 are respectively provided with a layer of wing plates (202, 207) substantially perpendicular to the axis of the pile body, and each layer of wing plates has three pieces, which are evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com