Rotary friction type replaceable energy dissipation connecting beam

A friction energy-consuming and rotating technology, applied in joists, girders, trusses, etc., can solve the problems of poor deformation capacity, stability and durability of replaceable energy-consuming coupling beams, so as to easily control the damage position and reduce costs. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

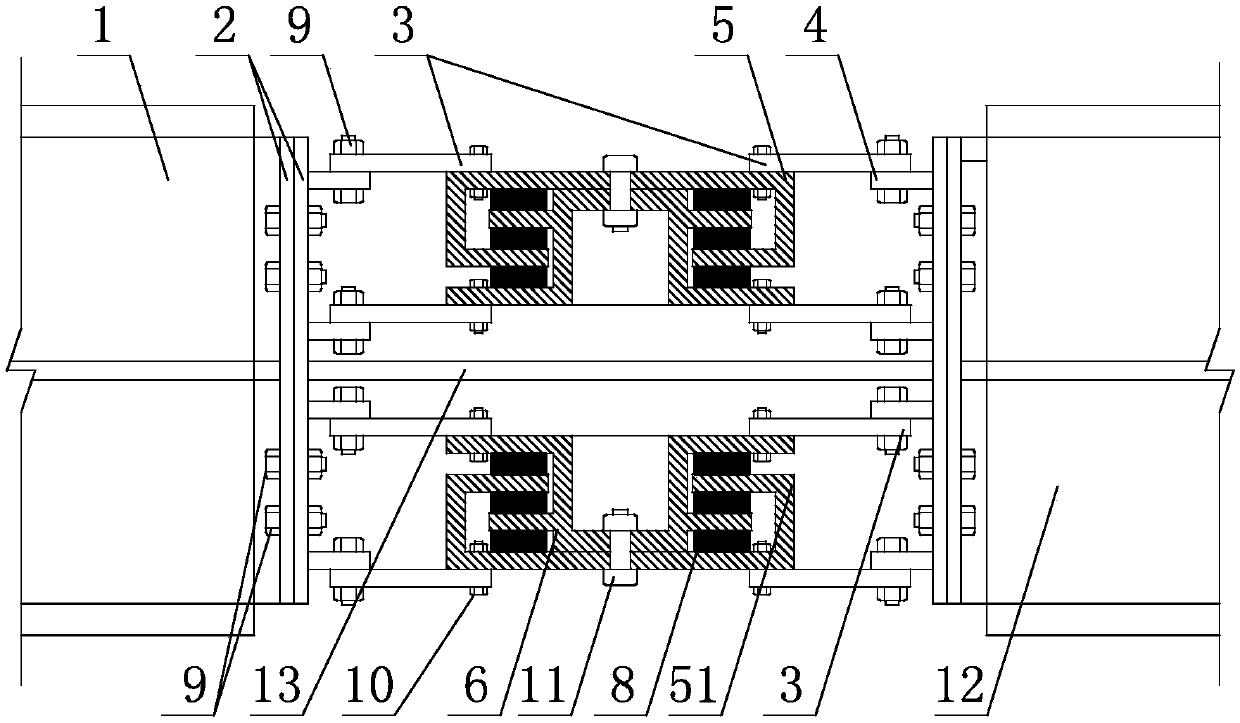

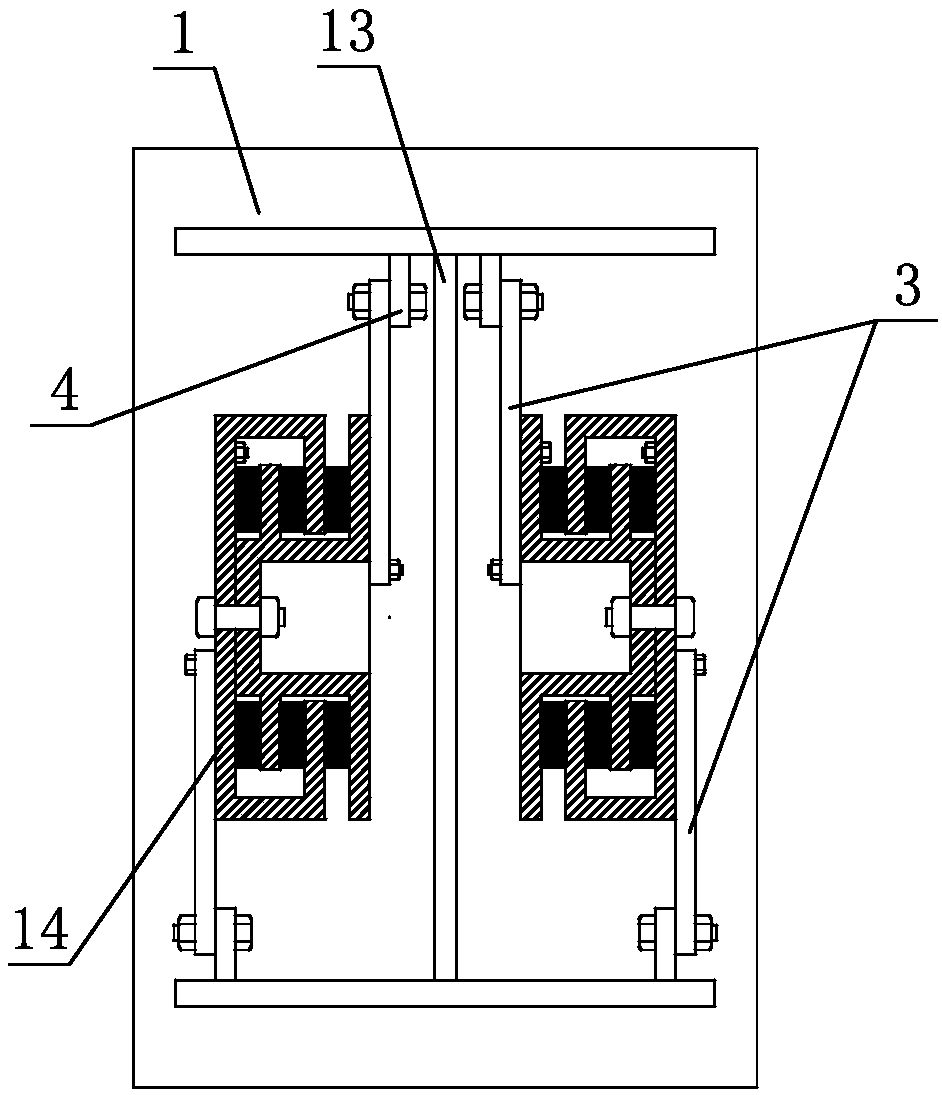

[0025] The invention provides a rotary friction type replaceable energy-dissipating coupling beam, wherein the principle of the rotary frictional energy-dissipating damper is to convert the motion state of the shear wall into the outer casing and the inner The relative rotation of the embedded tubes dissipates energy through friction through the multi-layer high-damping rubber cores between the tube walls, which plays the role of energy dissipation and vibration reduction, thereby achieving the purpose of reducing the seismic response of the structure.

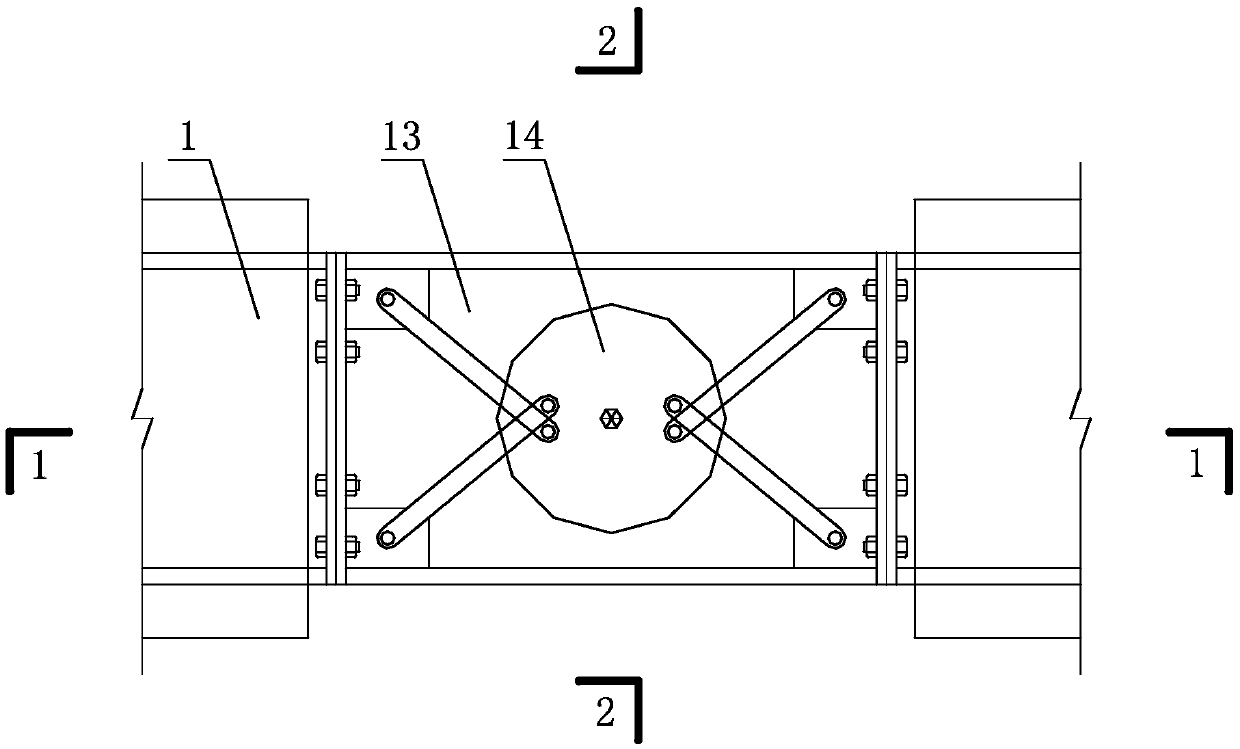

[0026] In a specific embodiment of the present invention, such as Figure 1 to Figure 5 As shown, the rotary friction type replaceable energy-dissipating connecting beam includes a replaceable section located in the center of the connecting beam and two non-energy-dissipating sections 1 arranged at the shear wall limbs on both sides of the replaceable section, which can be replaced The two ends of the section are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com