Crimp tool for strain relief connector and method of forming a strain relief connector

a technology of crimping tool and connector, which is applied in the direction of optics, instruments, optical light guides, etc., can solve the problems of changing the optical characteristics of the optical fiber, affecting the lateral flow the crimping method of conventional crimping methods is short relative to the diameter of the jacket material, so as to achieve a large frictional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

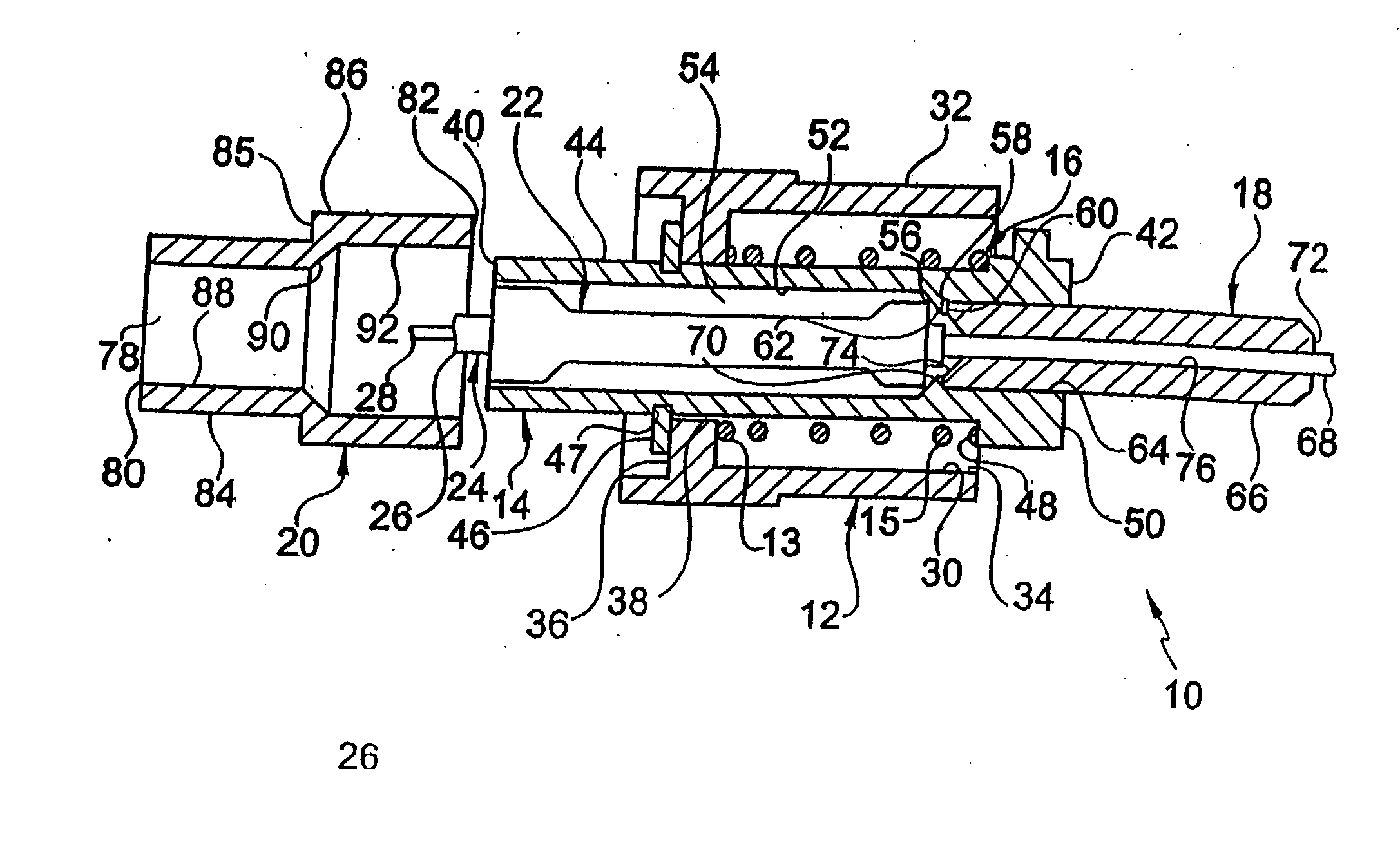

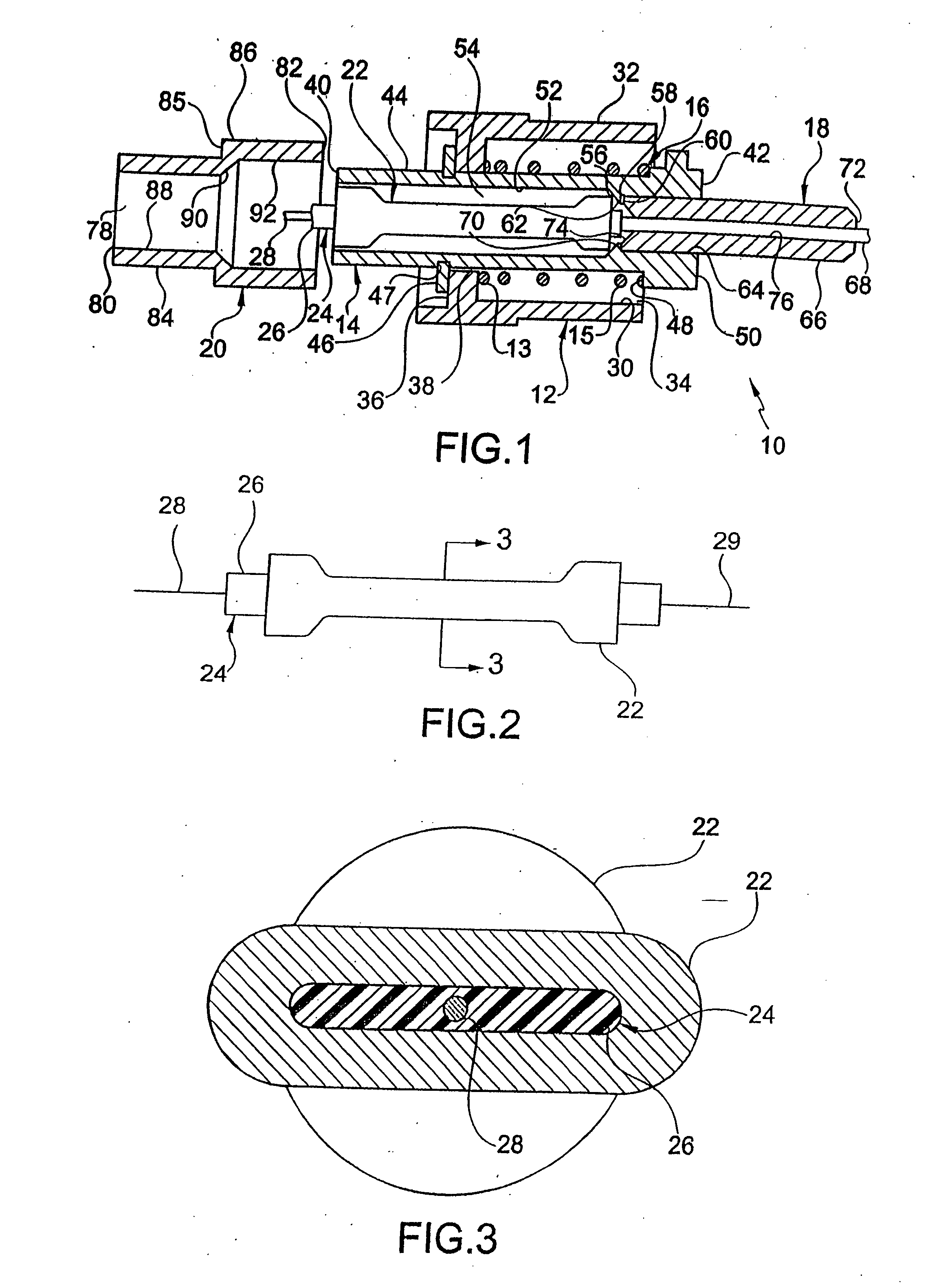

[0047] Referring initially to FIGS. 1-3, a strain relief connector 10 according to the present invention has a securing member or mechanism 12 surrounding a deformable connector body 14. Spring 16 is inserted between the securing member 12 and the connector body 14. The connector body 14 surrounds a portion of an alignment ferrule 18 and is coupled to a crimp ring 20. A deformable crimp tube or sleeve 22 is disposed within the connector body and the deformable crimp tube 22 is coupled to a fiber optic cable 24 having a cover 26 surrounding an optical fiber 28.

[0048] The securing member 12 is preferably a tubular or round metal threaded or bayonet type nut known in the pertinent art, such as an FC or ST type connector or any other suitable connector. The securing member does not necessarily have to be tubular, round, or metal and may be any type of securing device that can be connected to the deformable connector body 14 receiving deformable crimp tube 22.

[0049] Preferably, the secu...

embodiment

of FIG. 8

[0066] As seen in FIG. 8, metal connector body 214 has a plastic or metal alignment ferrule 218, inserted therein, as described above. Ferrule 218 is substantially similar to ferrule 18 and the description of ferrule 18 is applicable to ferrule 218. In the present embodiment, body 214 has an inner cylindrical surface 224 adjacent first open end 226 defining a through passageway 228 therethrough. Surface 224 is adjacent axially facing outwardly extending surface 230 that extends to cylindrical surface 232, which terminates at second open end 234. Surface 232 defining a through passageway 236 that is larger in diameter than through passageway 228.

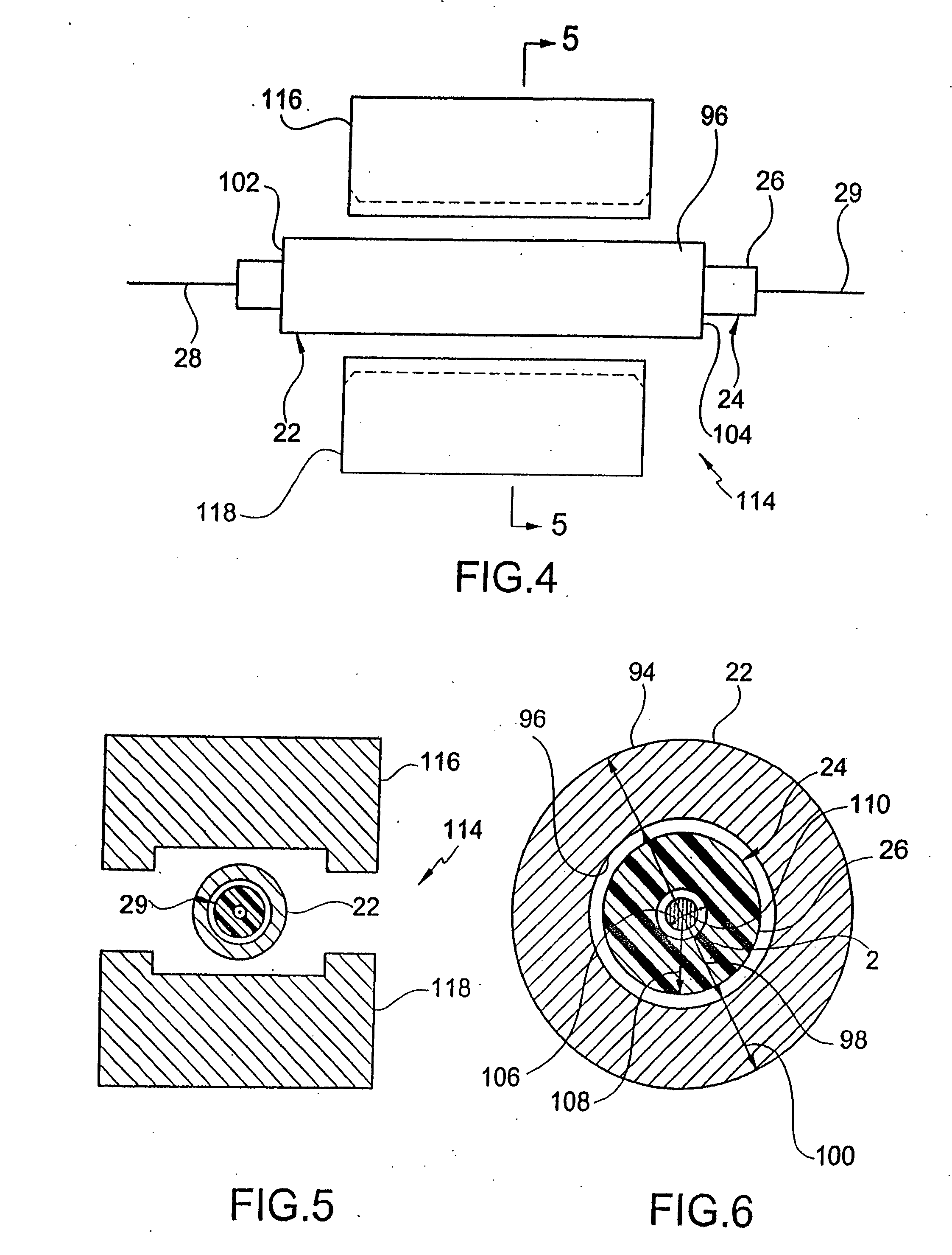

[0067] Ferrule 218 may be inserted though second end 234 and one end of ferrule 218 abutting surface 230. In this configuration, the crimp, using a long flat crimp die similar to die 114 shown in FIGS. 4 and 5, is performed directly onto the connector body 214. Disposed within the connector body prior to crimping may be an fiber opt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| outer diameter | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com