Tractor for magnetic levitation traffic installation routing inspection rescue

A tractor and transportation technology, applied in the field of tractors, can solve problems such as wheel strength wear, difficulty in driving vehicles, difficulty in traction, etc., and achieve the effect of improving friction, large traction, and increasing friction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

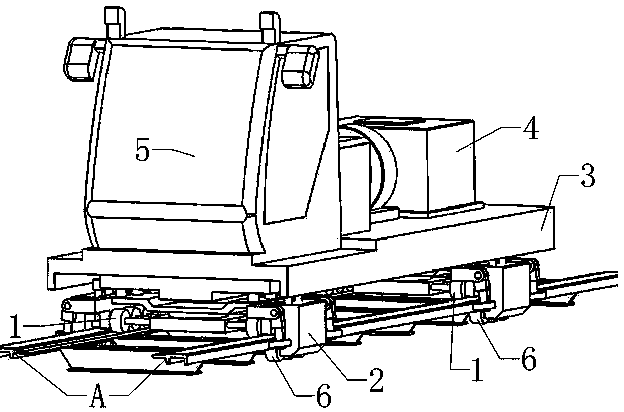

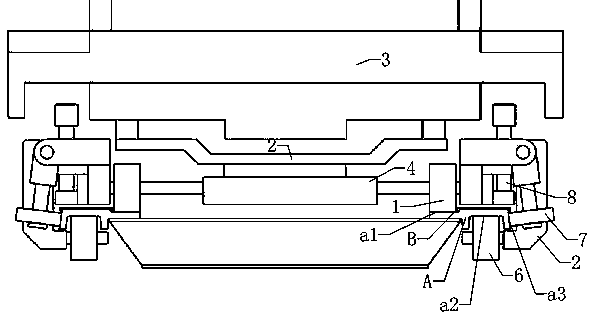

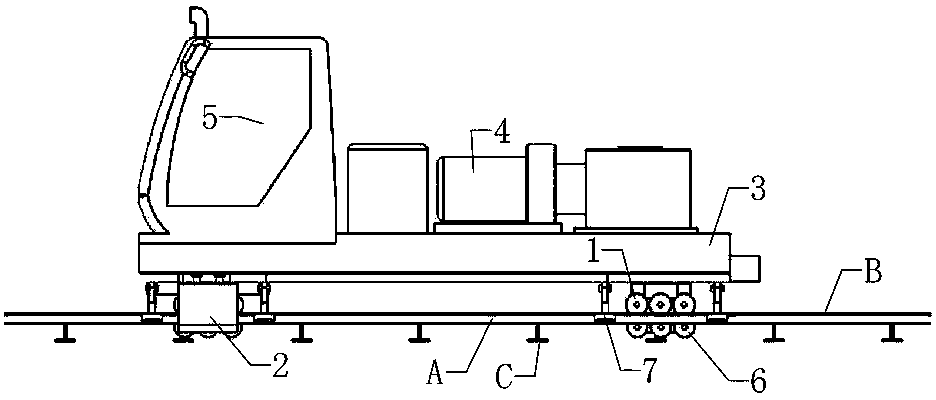

[0021] Such as figure 1 , figure 2 , image 3 , the tractor runs on the rail row composed of F rail (A), aluminum induction plate (B) and sleeper (C) on the maglev track line;

[0022] The tractor travels on the sliding surface (a1) of the F rail (A) by carrying the driving wheel (1), and then supports the car body (3) through the bogie (2), and the car body (3) is equipped with a power transmission system ( 4) and driving braking system (5);

[0023] Add the loading driving wheel (6) connected to the bogie (2) in the groove surface (a2) formed by the two magnetic pole legs on the opposite side under the F rail (A), and the loading is realized through the hydraulic cylinder (8) to increase The friction area and positive pressure of the wheel are generally not affected in the groove surface on the opposite side of the F rail under rain, snow and freezing weather, so it can still provide stable and large traction;

[0024] The moment formed by loading the load driving wheel...

Embodiment 2

[0031] Embodiment 1 is usually used when a large traction force is to be obtained, such as pulling heavy objects, climbing a slope, etc. When the tractor is required to drive fast and does not require a large traction force, it is different from Embodiment 1, and the driving wheel (6) is loaded Separated from the F rail (A) surface, the guide wheel is also guided by gap control or elastic guide.

[0032] It can be seen from the diagram and the above installation steps that the tractor for inspection and rescue of maglev traffic installation of the present invention can provide reliable and large traction effect.

[0033] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com