Automobile pipe cutting device

A cutting device and pipe technology, applied in the field of mechanical processing, can solve problems such as unevenness and burr cutting on the cutting surface, and achieve the effects of easy cutting, good stability, and increased friction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

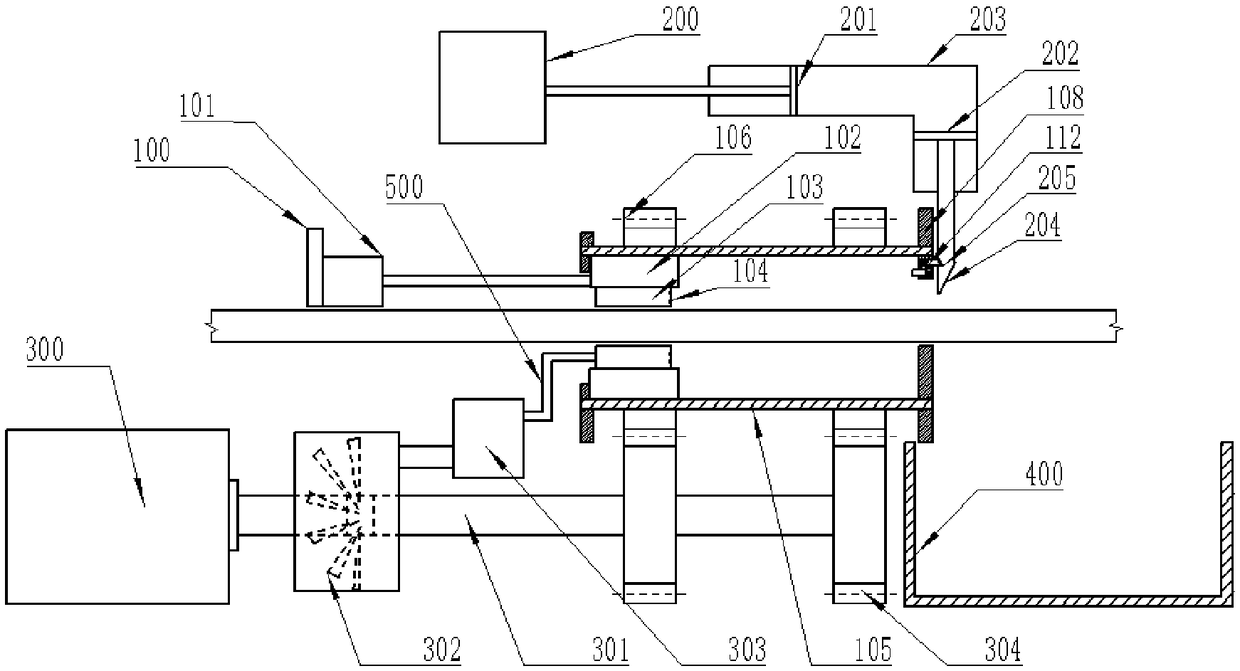

[0022] The reverse is described in further detail below through specific implementation methods:

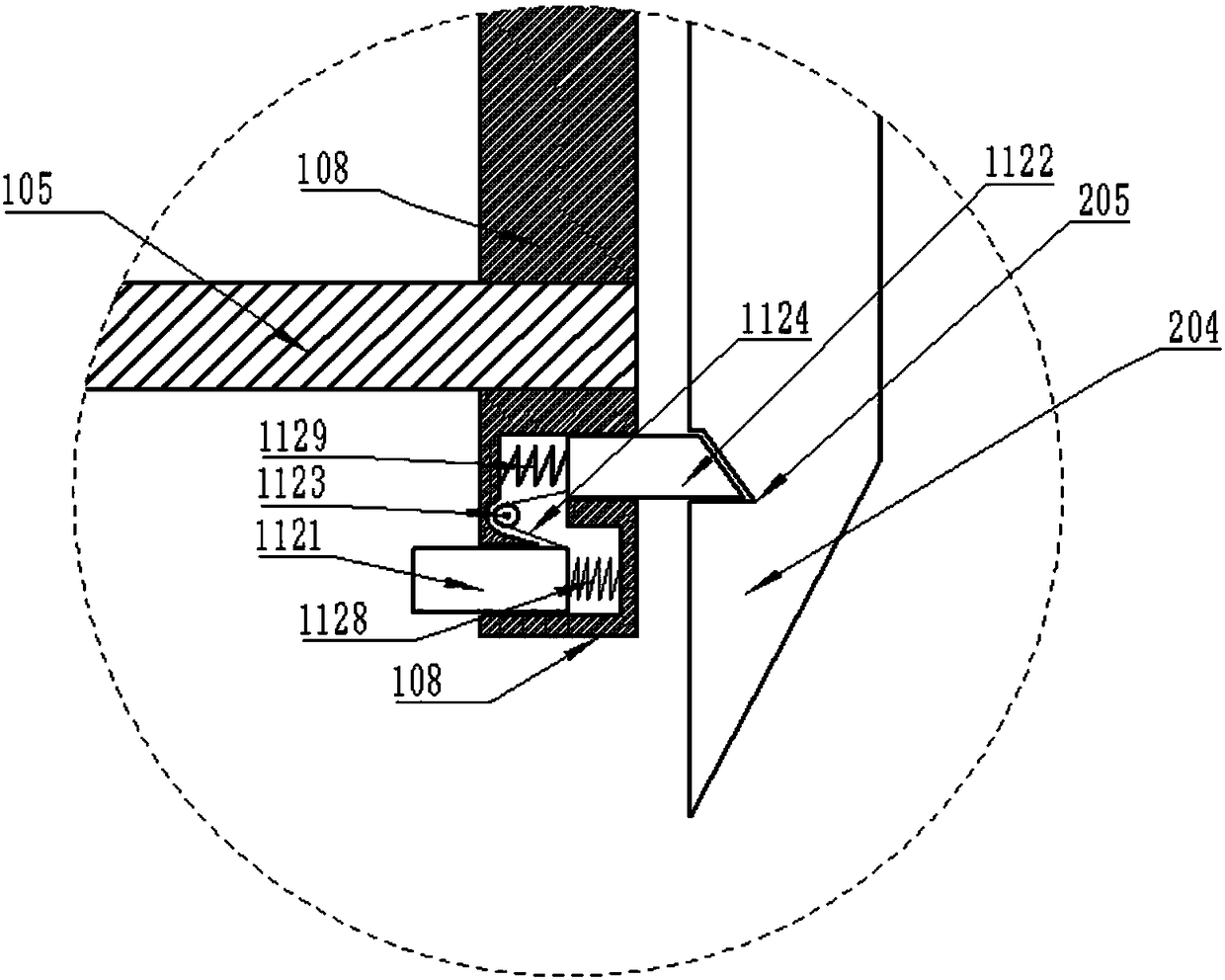

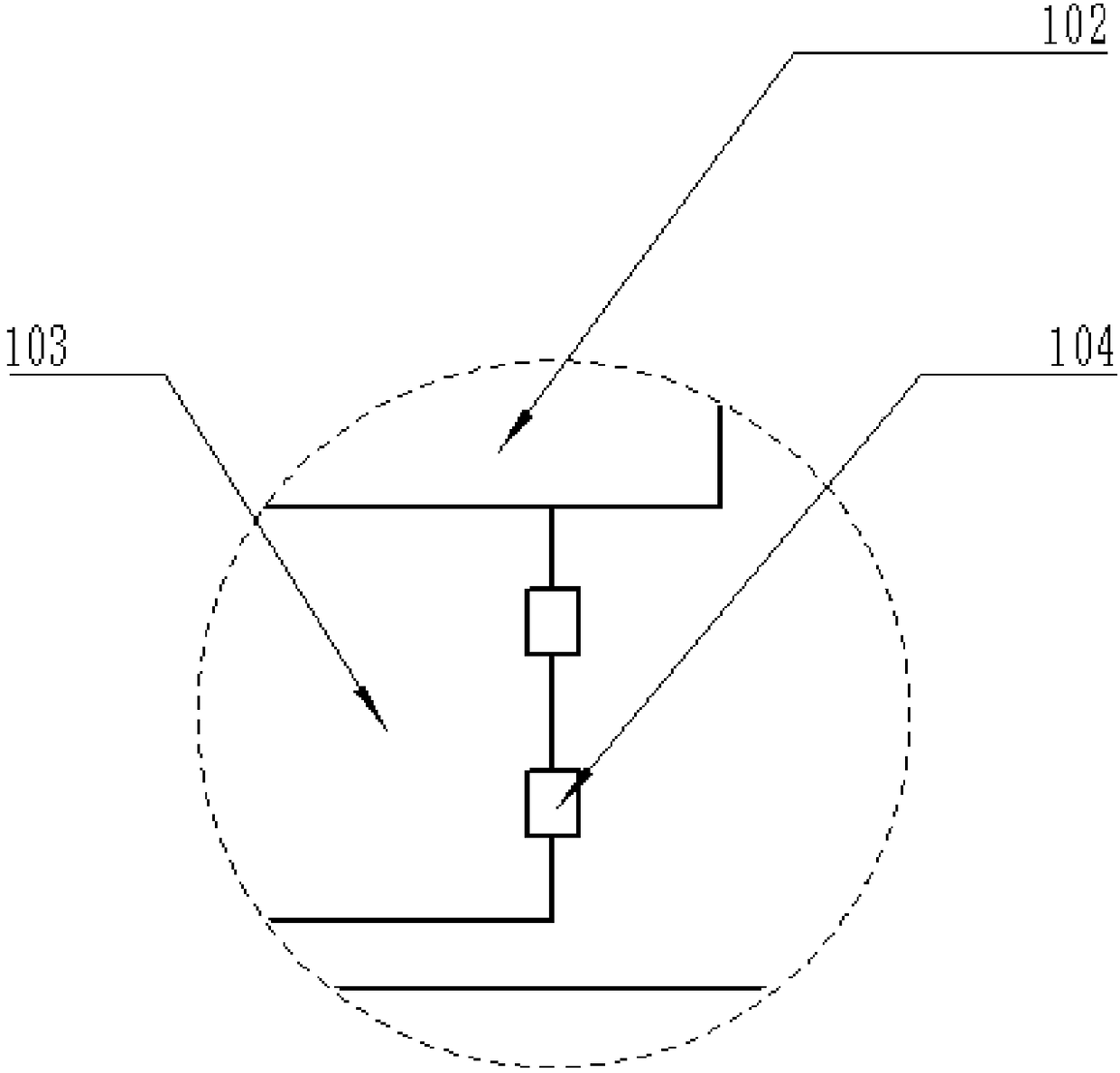

[0023] The reference signs in the accompanying drawings of the description include: frame 100, telescopic rod 101, ring clamp 102, air bag 103, air valve 104, rotating barrel 105, ring gear 106, frame extension 108, cutting control 112, the second One block 1121, second block 1122, runner 1123, connecting belt 1124, first spring 1128, second spring 1129, cylinder telescopic rod 200, first piston 201, second piston 202, piston cylinder 203, cutting knife 204 , card slot 205 , drive motor 300 , rotating shaft 301 , turbocharger 302 , air heater 303 , gear 304 , storage box 400 , hose 500 .

[0024] The forward direction mentioned in the description of this application document is the direction of movement towards the cutting control, and the backward direction mentioned is the direction of movement towards the direction of the cylinder button.

[0025] The embodiment is basically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com