Titanium alloy friction stir welding stirring head and welding method thereof

A friction stir welding and titanium alloy technology, which is applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc. It can solve the problem of unclear welding method of stirring head, and achieve excellent mechanical properties, controllable structure, and use. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

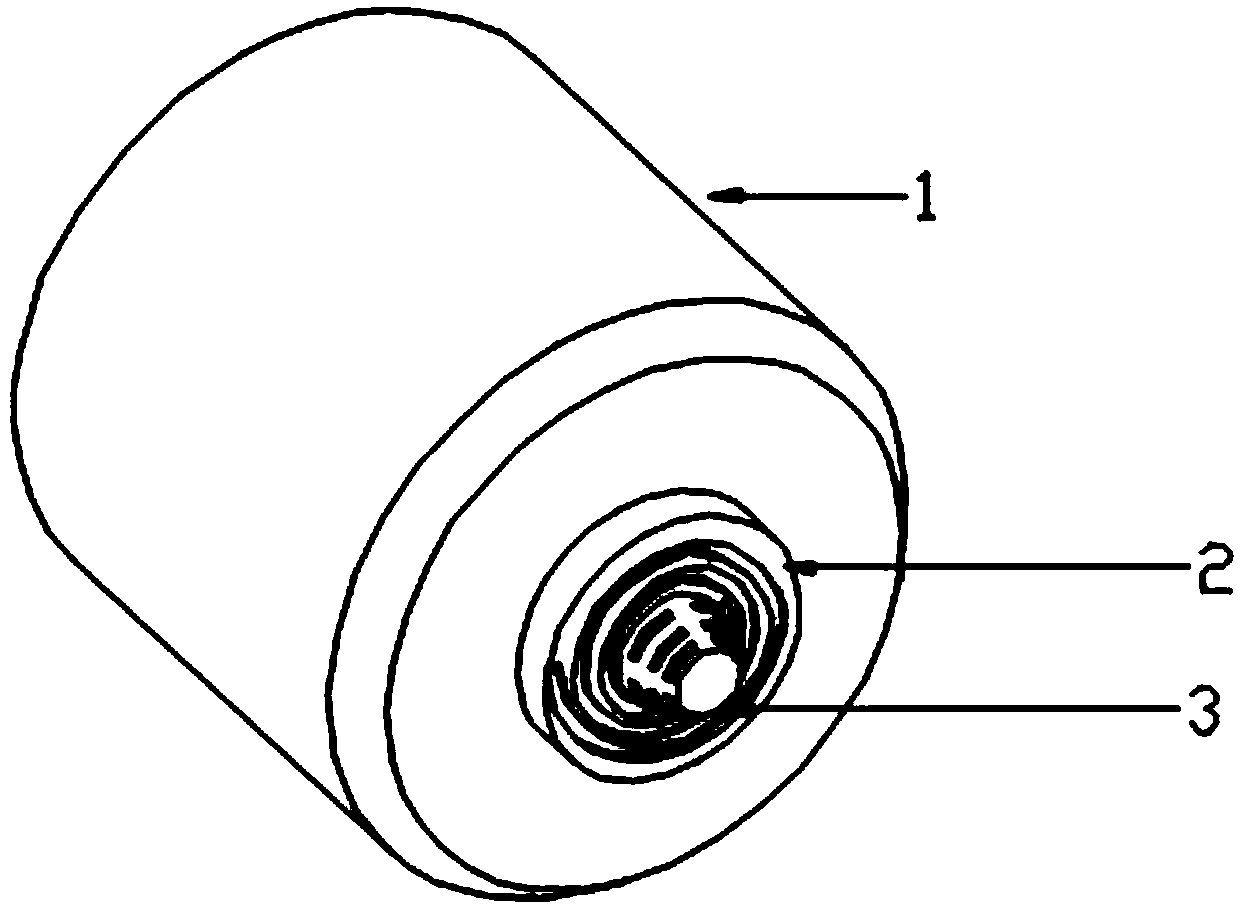

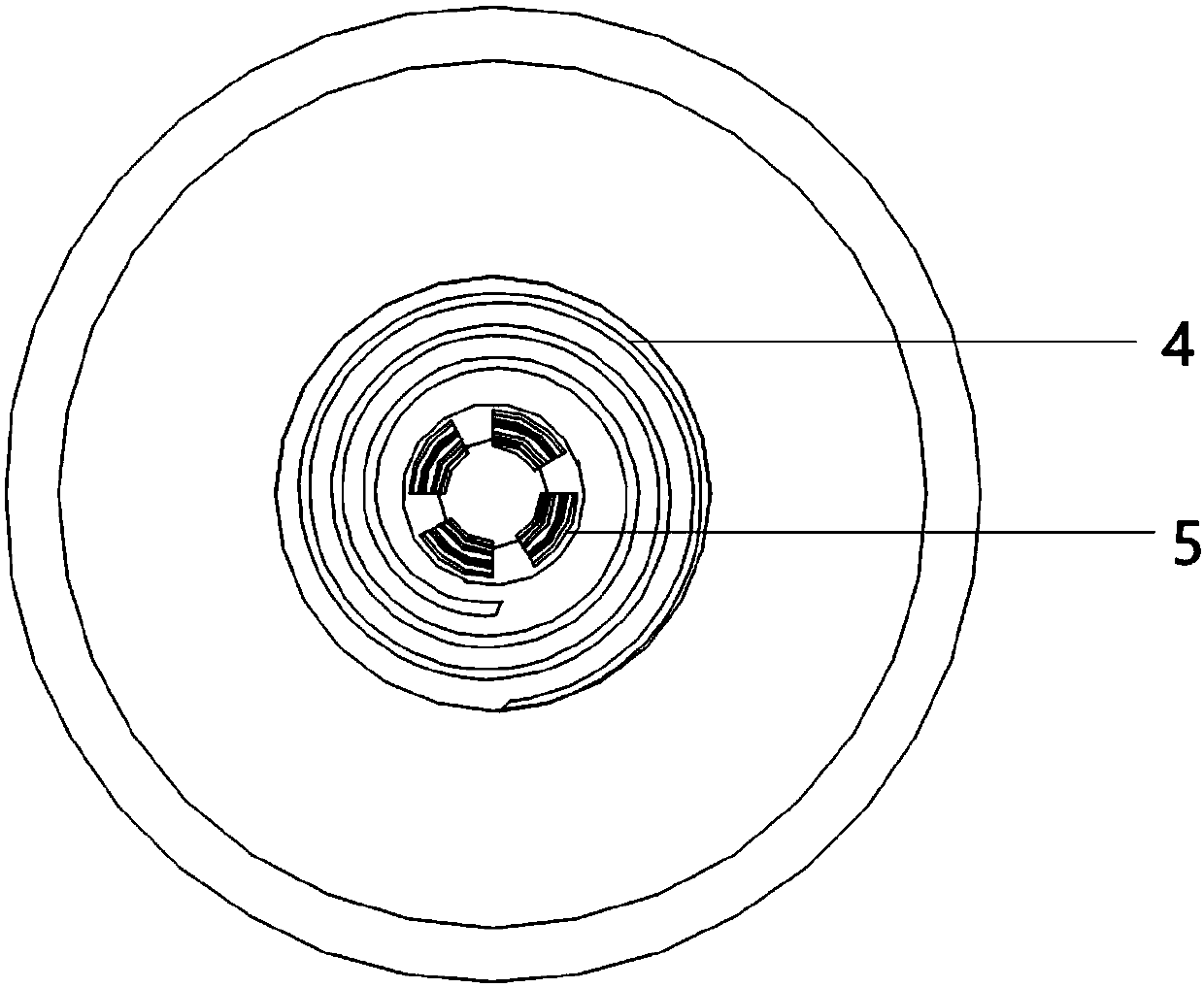

[0038] In this embodiment, the titanium alloy plate 8 is Ti-6Al-4V with a thickness of 4.3 mm. The material of the stirring head 9 is W-Re alloy, the diameter of the shaft shoulder 2 is 25mm, the length of the stirring needle 3 is 4.2mm, the diameter of the root of the stirring needle 3 is 8.5mm, the diameter of the top is 5mm, and the depth of the annular groove 5 is 0.6mm. The width is 0.8 mm; the depth of the spiral groove 4 is 0.8 mm, and the width is 1.5 mm.

[0039] The welding process described in the present embodiment is as follows:

[0040] (1) Drilling a preset hole: before welding, punch a preset hole with a diameter of 7mm and a depth of 3mm on the titanium alloy plate 8, and the preset hole is located at the place where the stirring head 9 is screwed in.

[0041] (2) Fixing the titanium alloy plate: Clean the titanium alloy plate 8 with alcohol to ensure the cleanliness of the titanium alloy plate 8, fix the tungsten alloy backing plate 10 through the pad II12 o...

Embodiment 2

[0047] In this embodiment, the titanium alloy plate 8 is Ti-6Al-4V with a thickness of 5 mm. The material of the stirring head 9 is W-Re alloy, the diameter of the shaft shoulder 2 is 20mm, the length of the stirring needle 3 is 4.7mm, the diameter of the root of the stirring needle 3 is 8.5mm, the diameter of the top is 5mm, and the depth of the annular groove 5 is 0.8mm. The width is 1 mm; the depth of the spiral groove 4 is 1 mm, and the width is 1.5 mm.

[0048] The welding process described in the present embodiment is as follows:

[0049] (1) Drilling a preset hole: punch a preset hole with a diameter of 7 mm and a depth of 4.5 mm on the titanium alloy plate 8 before welding, and the preset hole is located at the place where the stirring head 9 is screwed in.

[0050] (2) Fixing the titanium alloy plate: Clean the titanium alloy plate 8 with alcohol to ensure the cleanliness of the titanium alloy plate 8, fix the tungsten alloy backing plate 10 through the pad II12 on t...

Embodiment 3

[0056] In this embodiment, the titanium alloy plate 8 is Ti-6Al-4V with a thickness of 5 mm. The material of the stirring head 9 is W-Re alloy, the diameter of the shaft shoulder 2 is 20mm, the length of the stirring needle 3 is 4.7mm, the diameter of the root of the stirring needle 3 is 8.5mm, the diameter of the top is 5mm, and the depth of the annular groove 5 is 0.8mm. The width is 1 mm; the depth of the spiral groove 4 is 1 mm, and the width is 1.5 mm.

[0057] The welding process described in the present embodiment is as follows:

[0058] (1) Drilling a preset hole: punch a preset hole with a diameter of 7 mm and a depth of 4.5 mm on the titanium alloy plate 8 before welding, and the preset hole is located at the place where the stirring head 9 is screwed in.

[0059] (2) Fix the plate to be welded: clean the titanium alloy plate 8 with alcohol to ensure the cleanliness of the titanium alloy plate 8, fix the tungsten alloy backing plate 10 through the pad II12 on the wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com