Novel clutch for tricycle

A clutch and tricycle technology, applied in the field of clutches, can solve the problems of easy slippage, easy wear, and not easy slippage of the clutch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

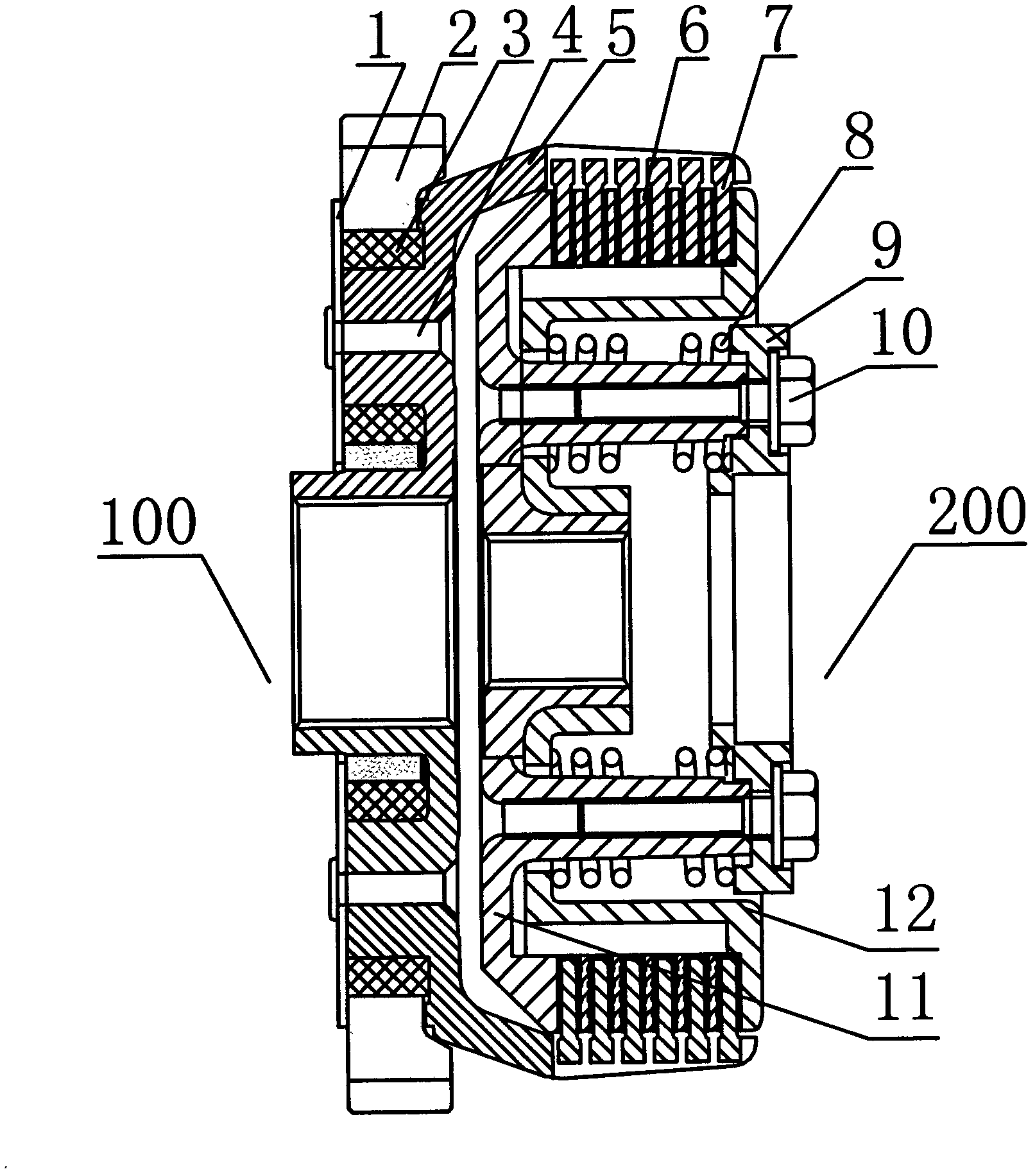

[0030] see Figure 1 to Figure 9 , the novel clutch suitable for tricycles includes a driving disc assembly 100 and a driven disc assembly 200, wherein,

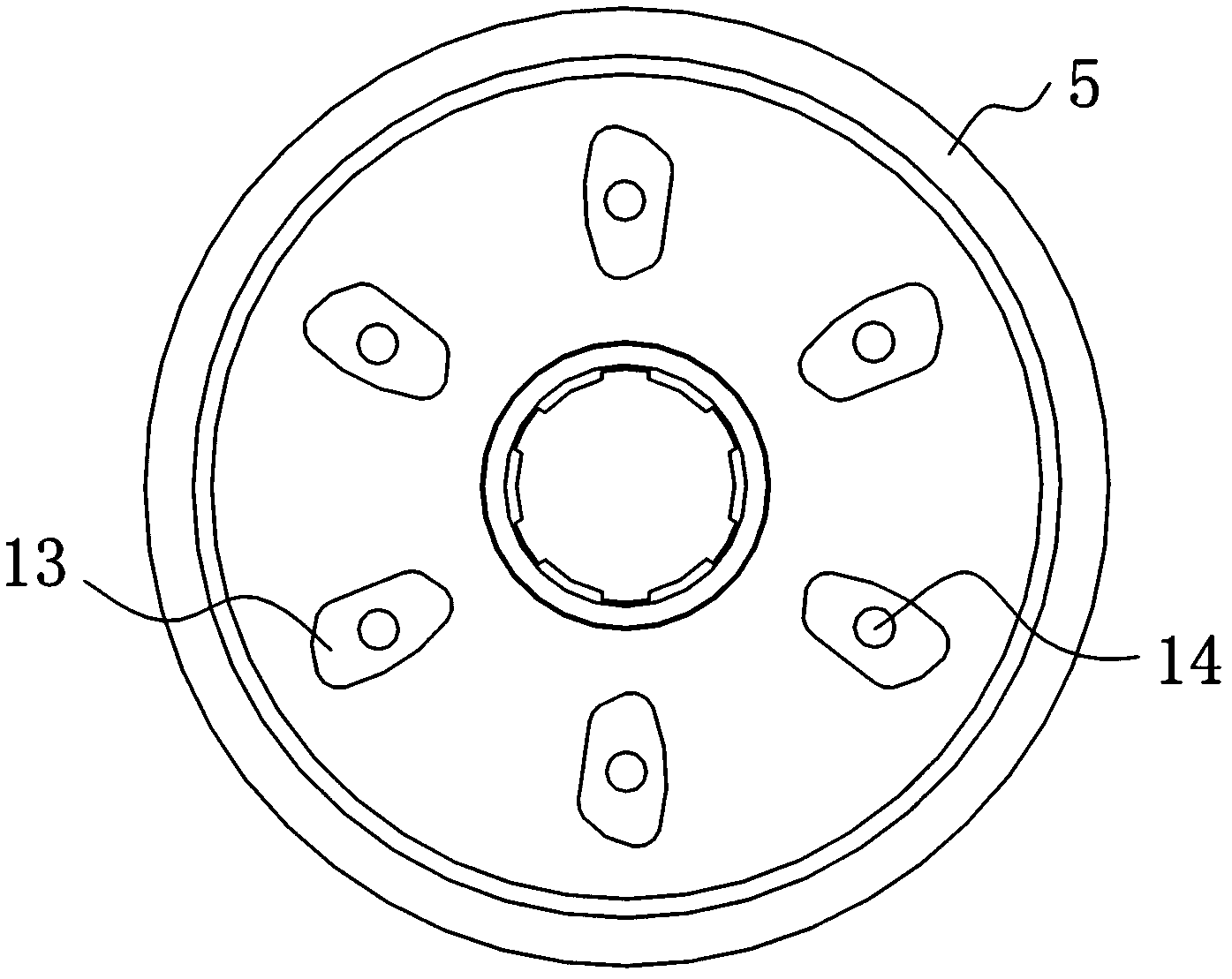

[0031] The driving disc assembly 100 includes a housing 5 on which a driven wheel 2 is arranged;

[0032] The driven disc assembly 200 includes a center sleeve 12, on which several pieces of active friction discs 7 slidingly fit with the axial inner groove of the outer cover 5 are sleeved on the center sleeve 12, and on the outer periphery of the center sleeve 12 there are also There are several pieces of driven steel sheets 6 arranged in sliding fit, and the driven steel sheets 6 and the active friction sheets 7 are sequentially superimposed to form a friction pair;

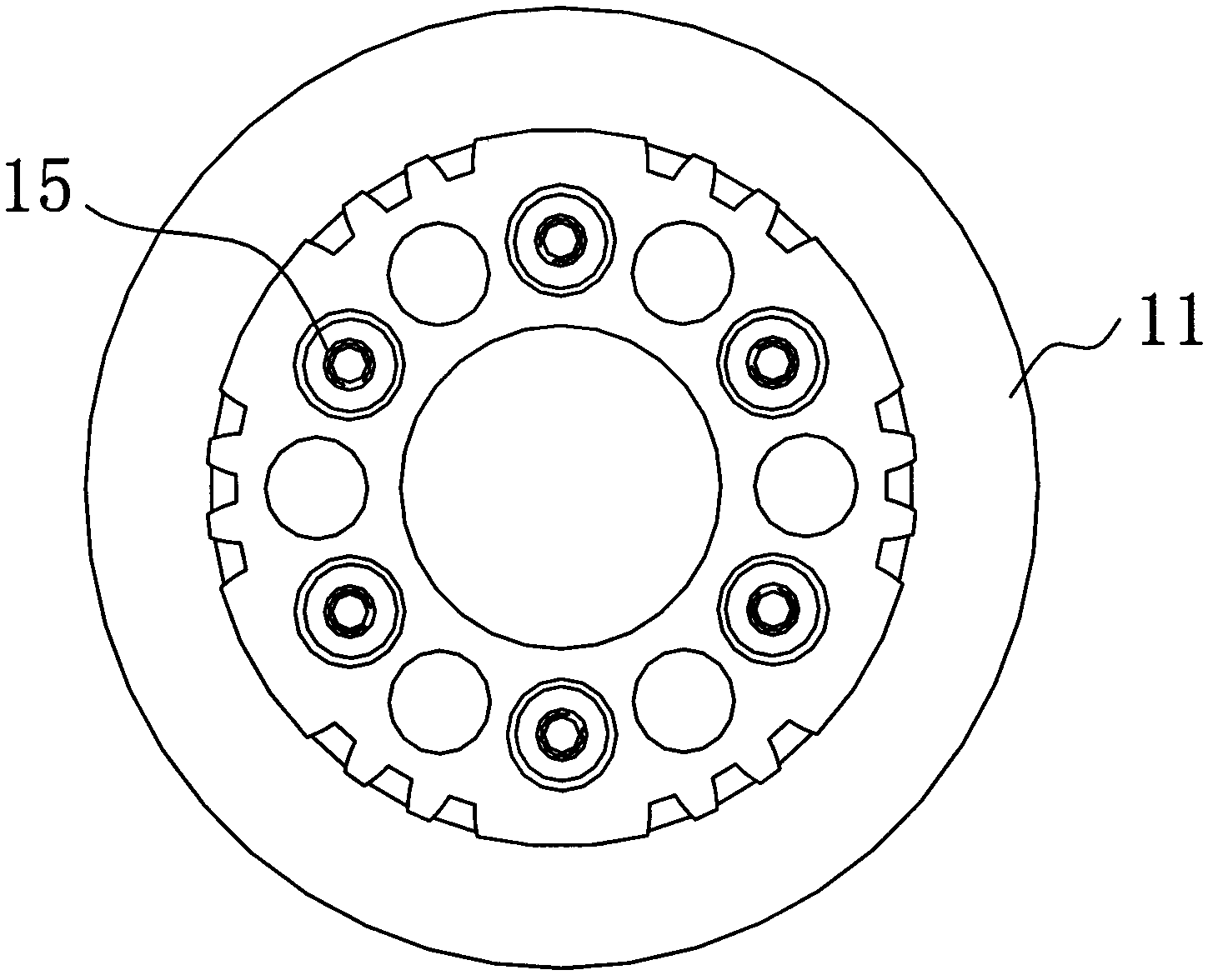

[0033] The two ends of the friction pair are positioned by the center sleeve 12 and a pressure plate 11, and the spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com