Winch brake device

A technology of a braking device and a winch, applied in the field of the braking device of the winch, can solve the problems of unsatisfactory service life and braking reliability, short service life of the coil expansion winch, insufficient safety of the mechanical handbrake, etc. Improved braking response, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

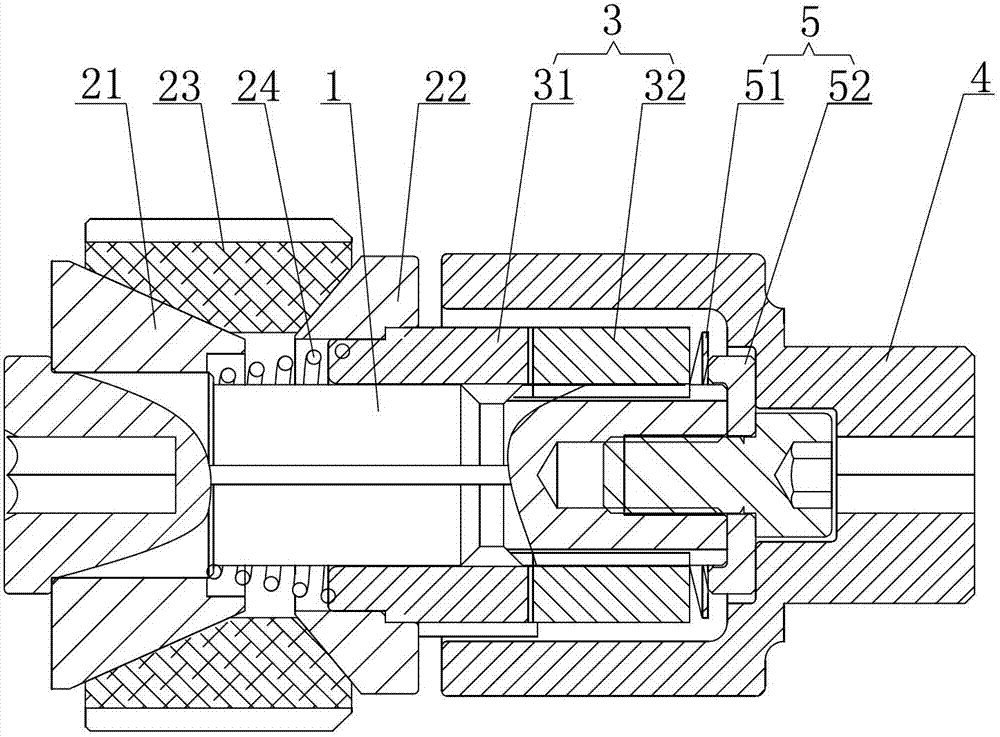

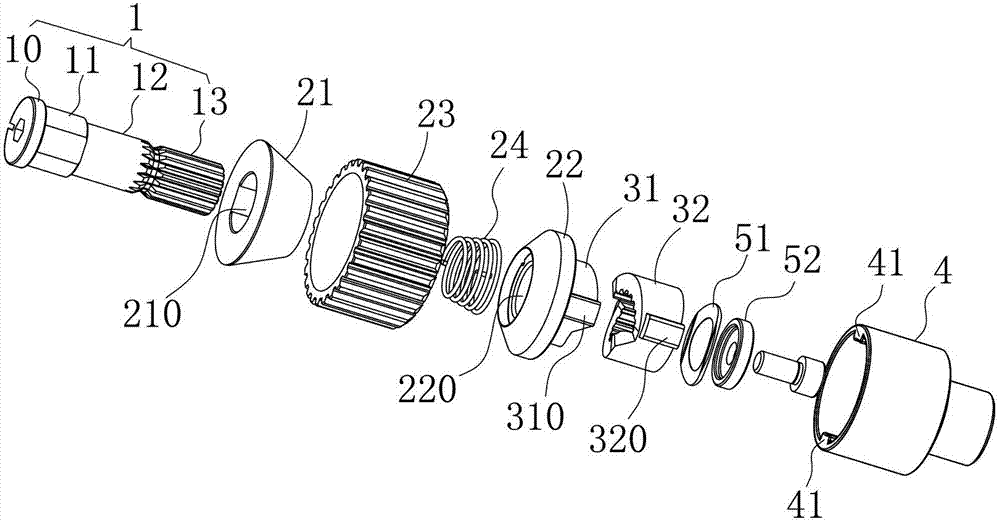

[0027] refer to figure 1 , 2 , a winch braking device, including a brake shaft 1, the brake shaft 1 is installed in turn from left to right with an outer brake cone 21, a brake hub 23, an inner brake cone 22, a screw clutch mechanism 3 and a brake coupling sleeve 4.

[0028] Outer brake cone 21: it is a hollow conical body, and the hollow part is an approximately oblate through hole 210;

[0029] Inner brake cone 22: it is also a hollow conical body, and the hollow part is a stepped hole 220;

[0030] Brake hub 23: it is a gear part, and its axial two sides are provided with inclined surfaces that cooperate with the outer brake cone 21 and the inner brake cone 22, and the outer ring of the brake hub 23 is provided with key teeth;

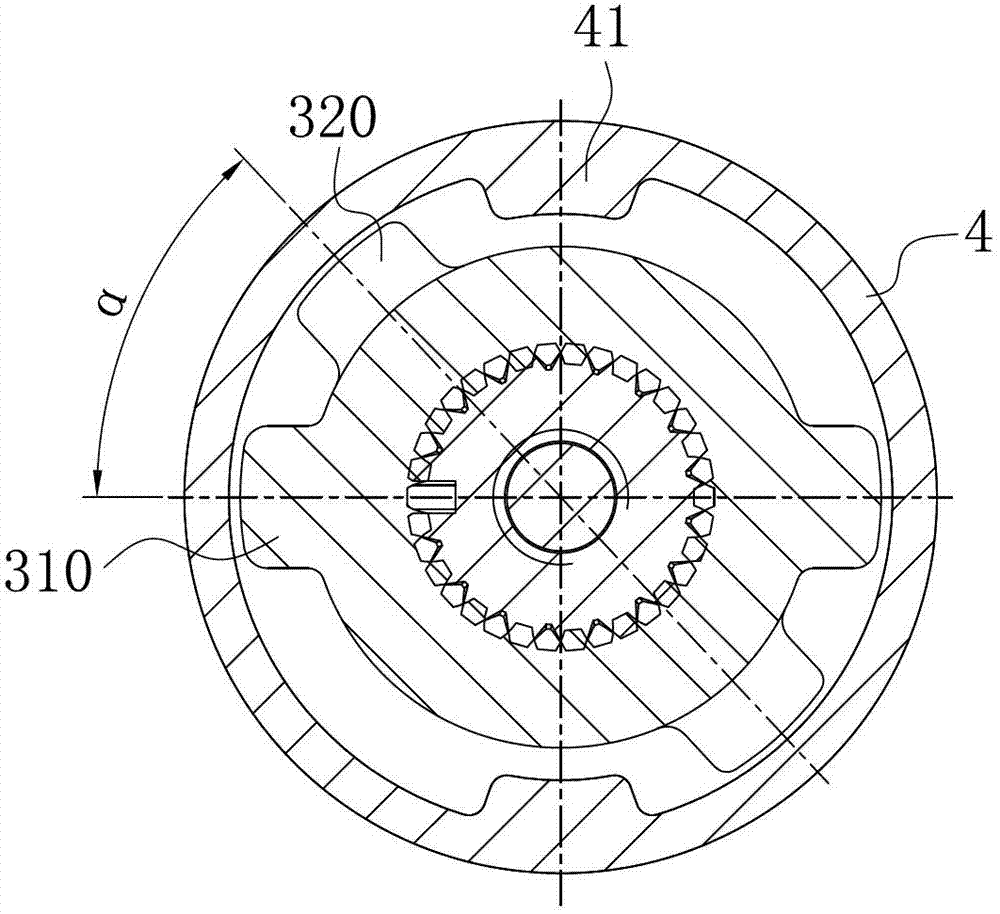

[0031] combine image 3 , Spiral clutch mechanism 3: composed of a first twist sleeve 31 and a second twist sleeve 32, one end of the first twist sleeve 31 is provided with an axial protrusion to form a helical surface, and the second twist sleev...

Embodiment 2

[0045] refer to Figure 5 , the structure of this embodiment is roughly the same as that of Embodiment 1, and the similarities will not be described in detail again. The difference is that the winch brake device also includes an outer friction plate 26 arranged between the end of the brake shaft 1 and the outer brake cone 21. And inner friction plate 25. With reference to the working principle of Embodiment 1, in the winch braking process of this embodiment, under the action of the screw clutch mechanism 3, the outer friction plate 26, the inner friction plate 25, the outer brake cone 21, the brake hub 23, and the inner brake cone The pressure between 22 becomes tighter and tighter, and the brake hub 23 brakes. Since the brake hub 23 engages with the key teeth of the reel 6, the reel 6 is also effectively braked; in addition, the outer ring of the inner friction plate 25 is provided with key teeth , The inner friction plate 25 meshes with the key teeth of the reel 6 to play t...

Embodiment 3

[0047] refer to Figure 6 , The capstan braking device of the present invention can also be simply transformed as follows: the inner brake cone 22 is changed into a disc shape, and the first torsion sleeve 31 and the inner brake cone 22 are integrally formed. For the rest of the structure and working principle of the winch braking device in this embodiment, reference may be made to Embodiment 1 or Embodiment 2, and no further details will be given.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com