Online controlling method for steam turbine rotator equivalent stress safety margin coefficient

A steam turbine rotor and equivalent stress technology, applied in the field of steam turbines, can solve the problems of large equivalent stress error and affecting the accuracy of the equivalent stress of the steam turbine rotor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

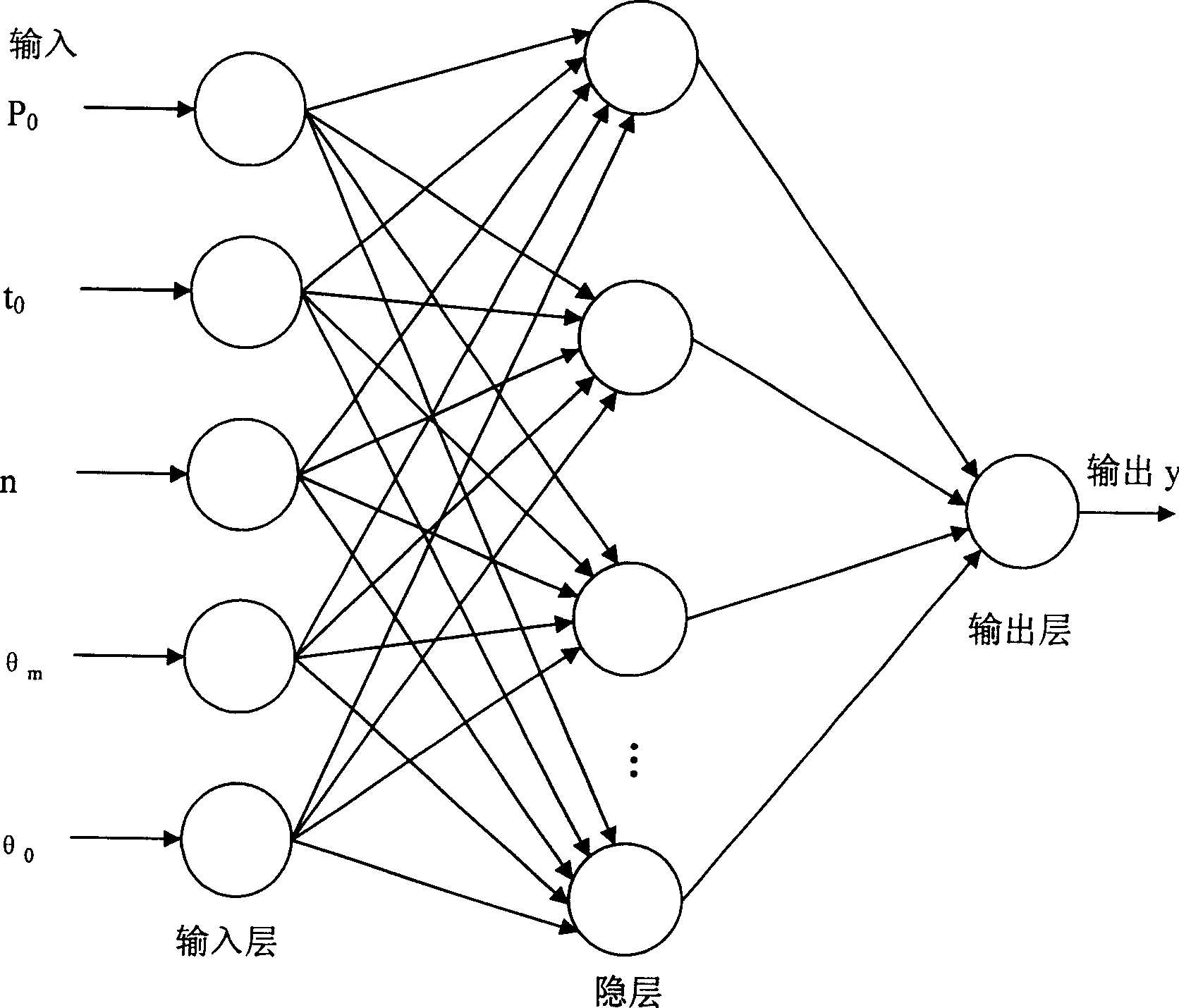

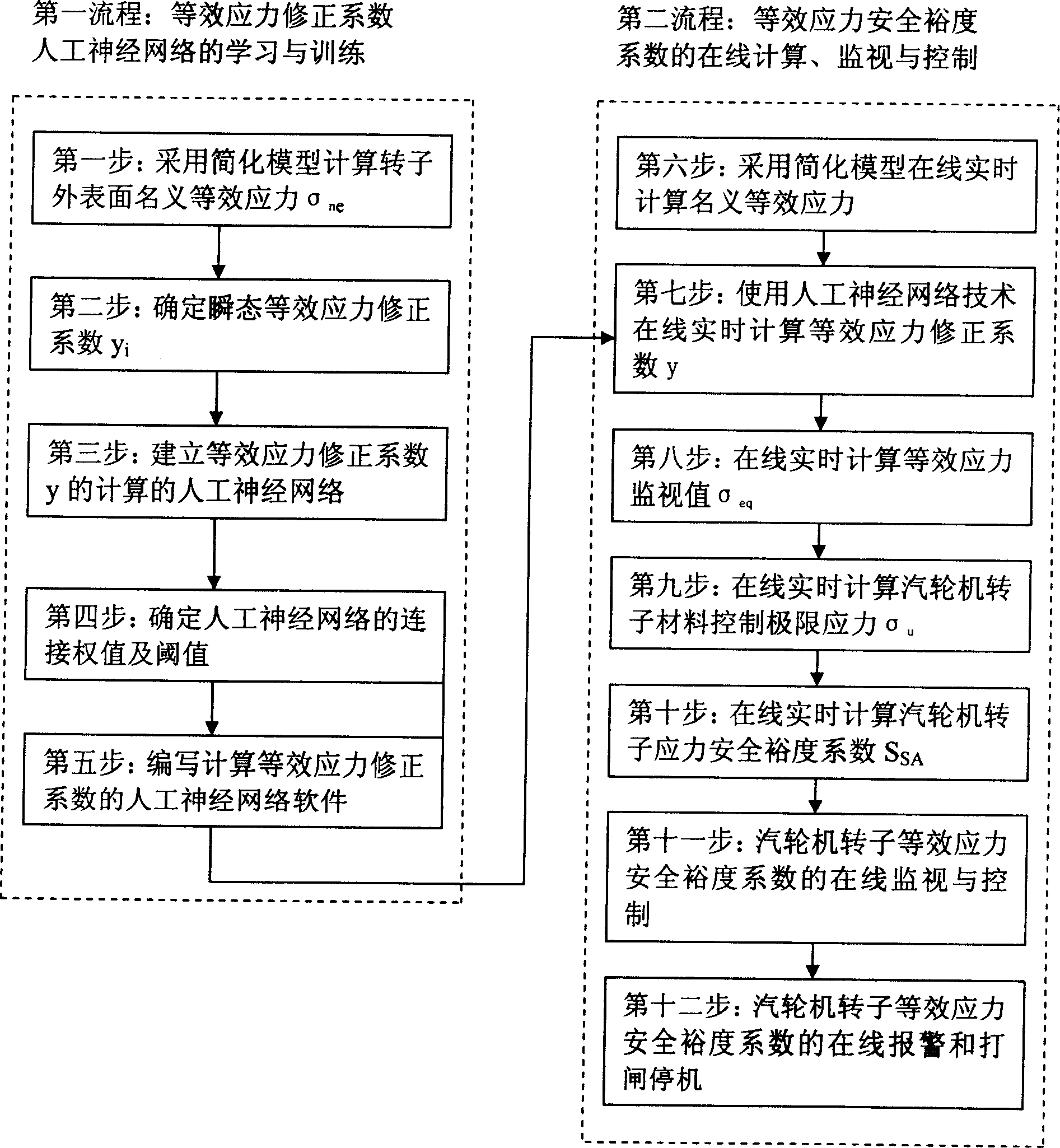

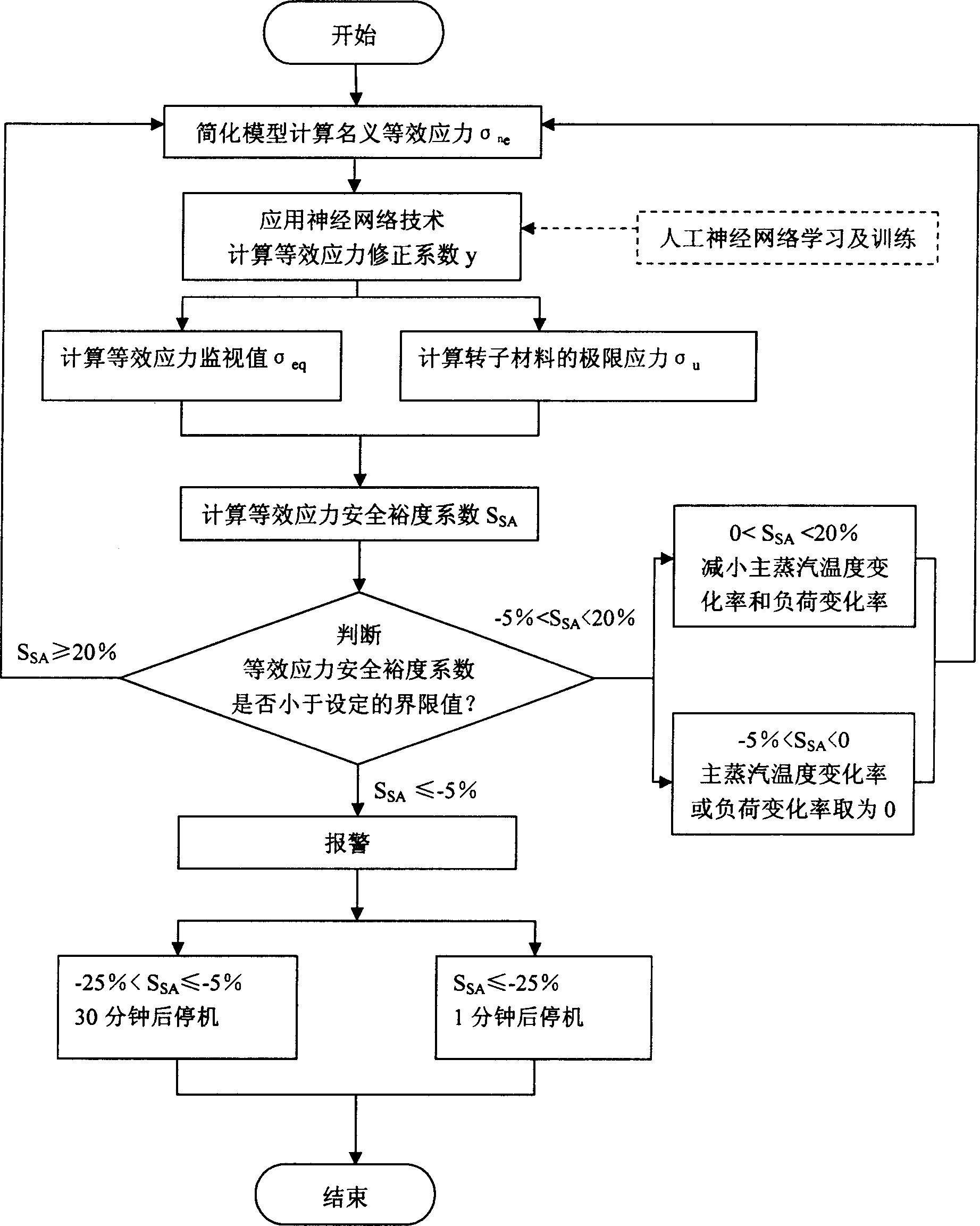

[0053] For a certain type of supercritical 600MW steam turbine high pressure rotor with an inlet steam temperature of 566°C, the figure 1 The artificial neural network model adopted by the present invention shown, figure 2 The flow chart of the method provided by the present invention is shown and image 3 The calculation software block diagram of the method of the present invention is shown, and the calculation results of the equivalent stress of the high-pressure rotor of the steam turbine in different starting processes are listed in Figure 4 to Figure 7 .

[0054] Steps 1 and 6: Using the simplified model of the prior art to calculate on-line, the rounded corners of the outer surface of the impeller of the regulating stage of the high-pressure rotor of the steam turbine are obtained in the cold state start process, the warm state start process, the hot state start process, and the extremely hot state. The nominal equivalent stress σ of the start-up process ne exist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com