Controlling method for steam turbine high and medium pressure rotator equivalent stress

A technology of equivalent stress and control method, applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as low accuracy, slow calculation speed of equivalent stress, and inability to apply online monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

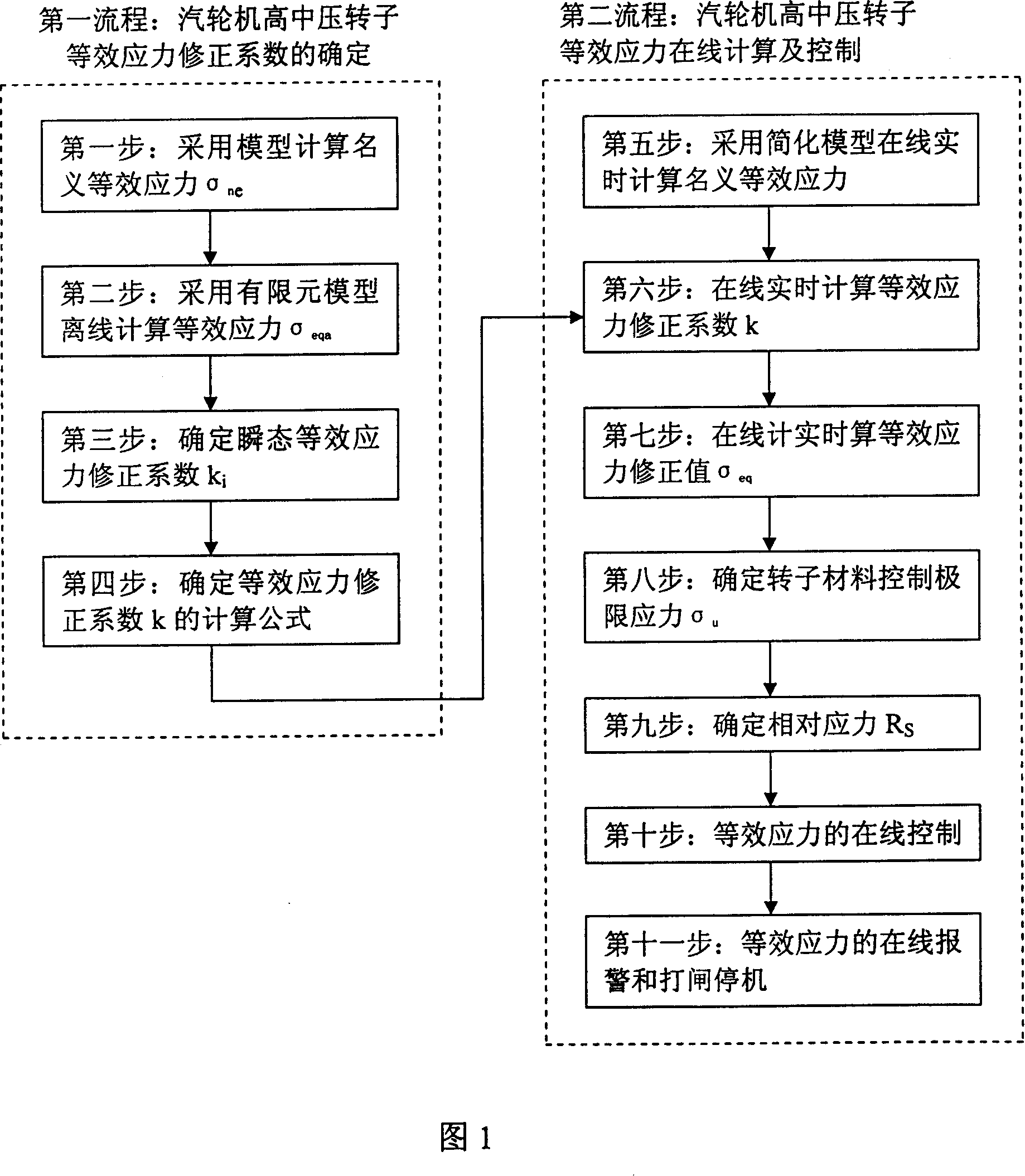

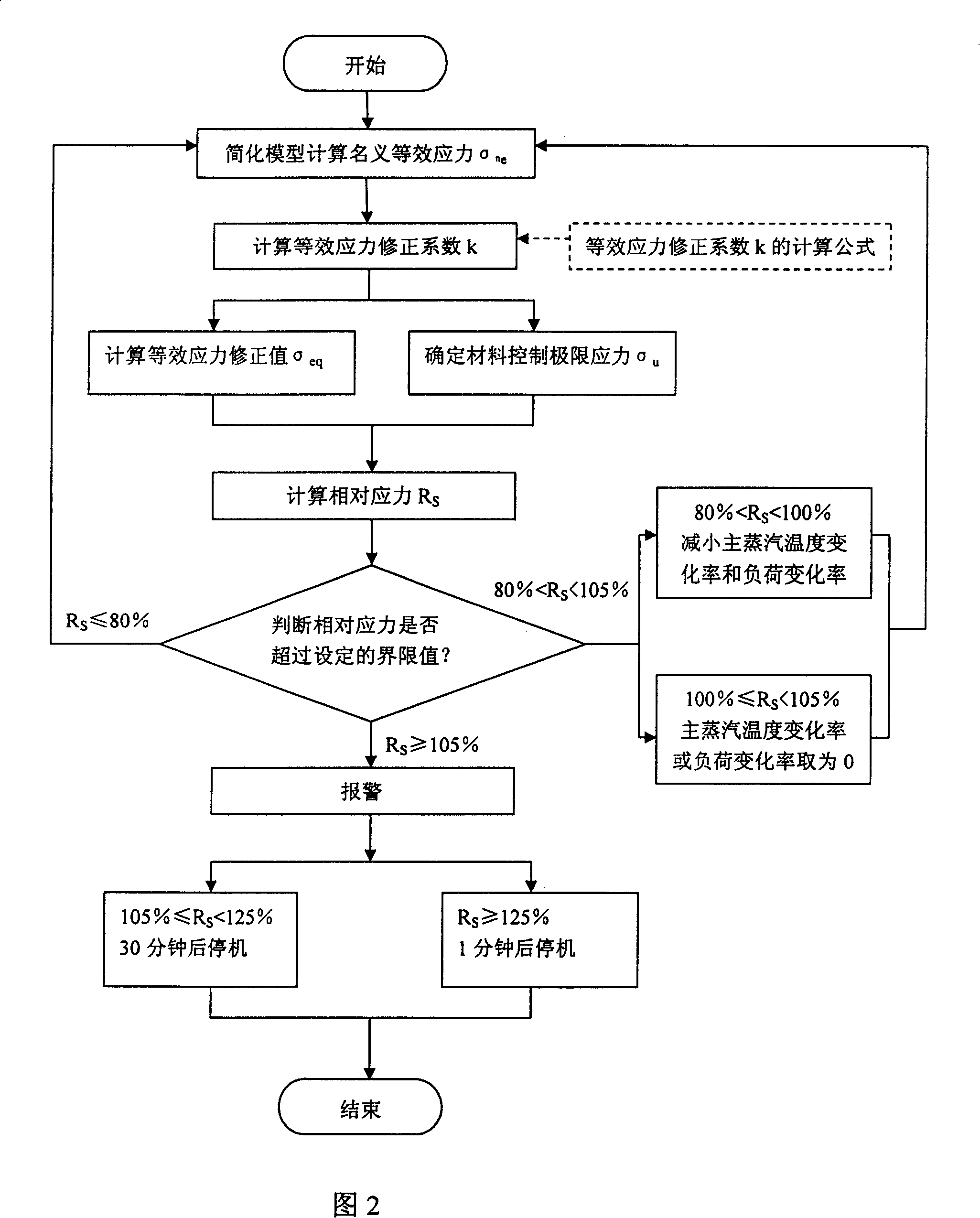

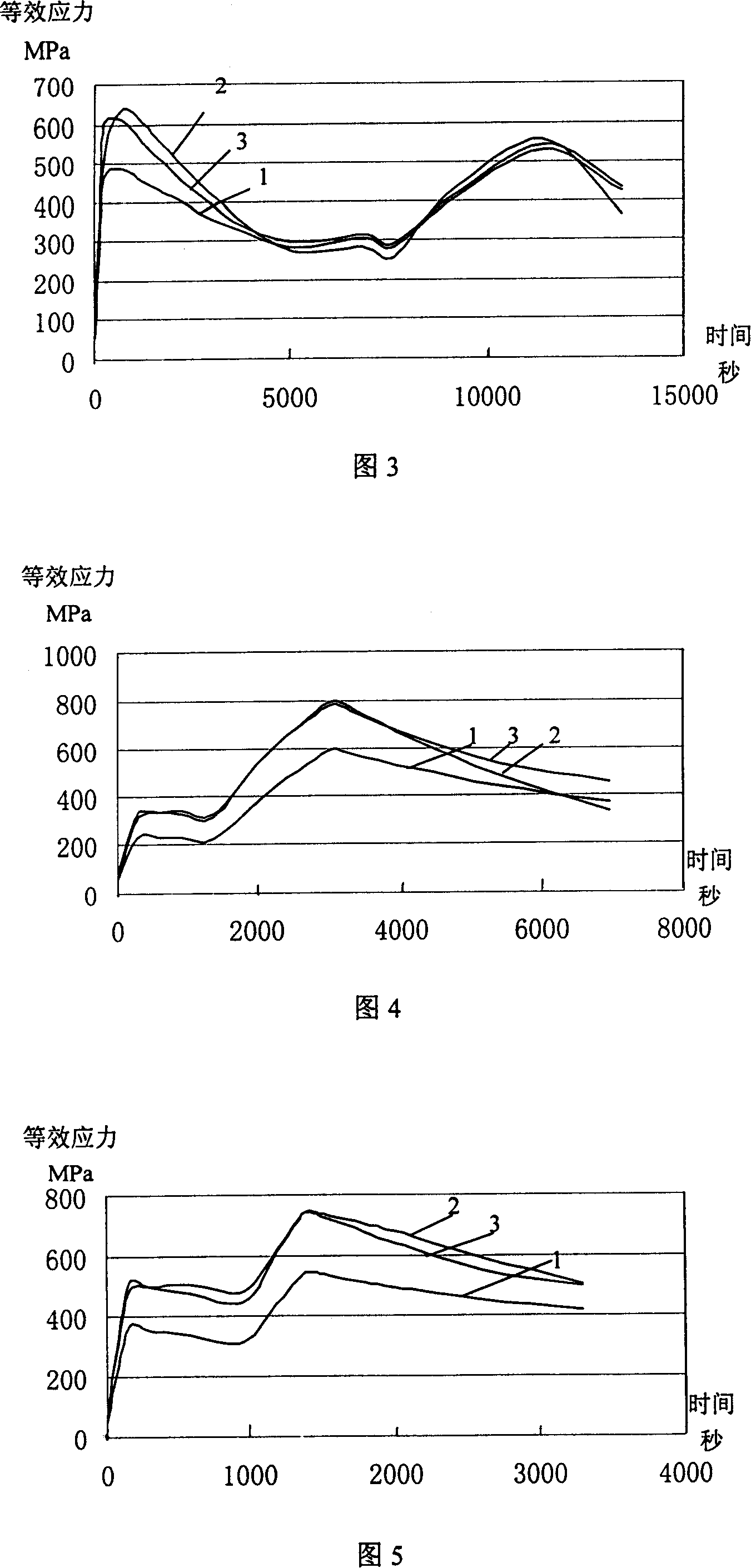

[0058] For the supercritical 600MW steam turbine high-pressure rotor with a certain model inlet steam temperature of 566°C, the flow chart of the method provided by the present invention shown in Fig. 1 is adopted, and the calculation software is written in C language, and runs on the computer of the parameter monitoring and control of the steam turbine, such as Fig. 2 shows a block diagram of the calculation software of the method of the present invention, and the calculated correction value of the high-pressure rotor equivalent stress of the steam turbine is shown in Fig. 3 to Fig. 6 .

[0059] The first and fifth steps: use the simplified model of the existing technology to calculate on-line the outer surface fillet of the high-pressure rotor regulating stage impeller of the steam turbine during the cold start process, warm state start process, hot state start process, and extremely hot state The nominal equivalent stress σ of the start-up process ne This is represented by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com