Method for judging polymerization reaction condition at initial production stage of polyethylene process

A technology of polymerization reaction and polyethylene, applied in the direction of material separation, instrumentation, analysis of materials, etc., can solve problems such as economic loss, long induction period, polymerization accidents, etc., and achieve the effect of preventing polymerization accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

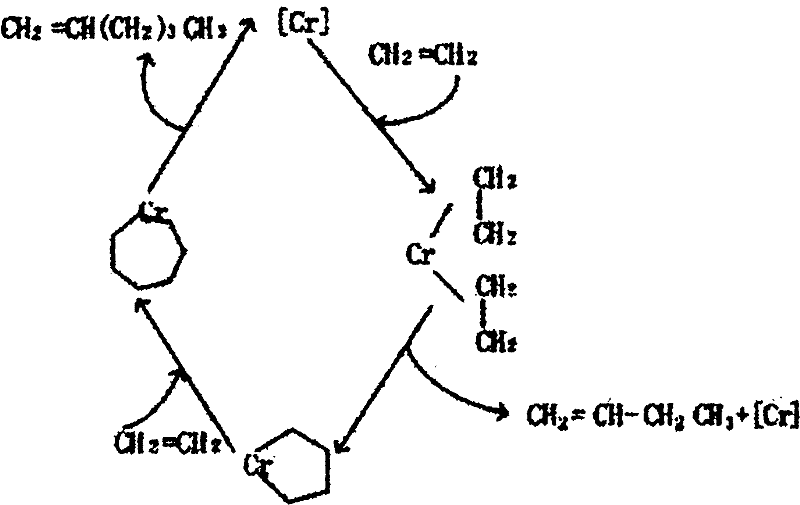

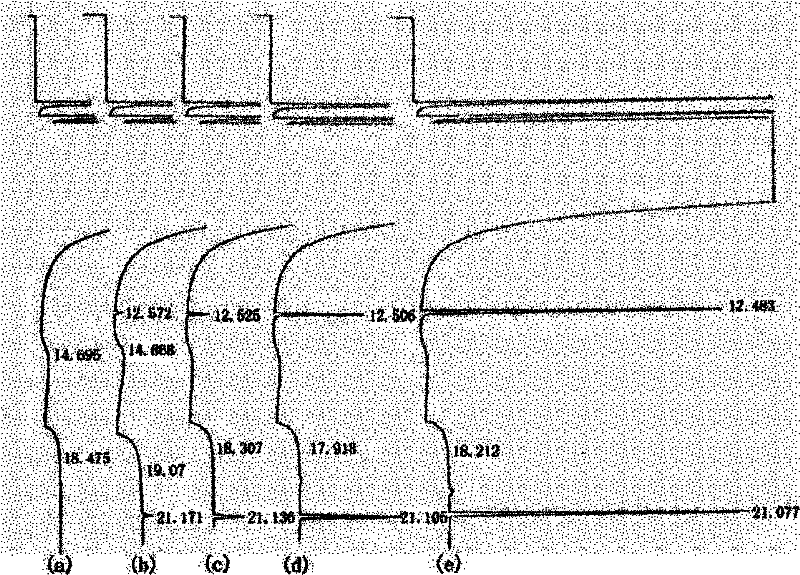

[0020] Example 1: figure 2 It is the result of analyzing the circulating gas in the reactor by gas chromatography during the successful start-up of the unit. The catalyst used during start-up is S-2 type chromium catalyst, that is, bis(triphenylsilyl)chromate is used as the main catalyst and diethylaluminum oxide is used as the reducing agent. Before judging that the polymerization reaction initiated by the catalyst is successful, only ethylene monomer is added to the reactor, and no comonomer is added, so the olefins other than ethylene appearing in the recycle gas at this time should be produced by ethylene oligomerization.

[0021] figure 2 Among them, the spectrogram (a) is the circulating gas chromatogram when the oxygen value of the water in the reactor is qualified and no catalyst is put in. It can be seen from the figure that the circulating gas before the catalyst is actually refined ethylene without other impurities. The spectrum of chromatographic analysis is th...

Embodiment 2

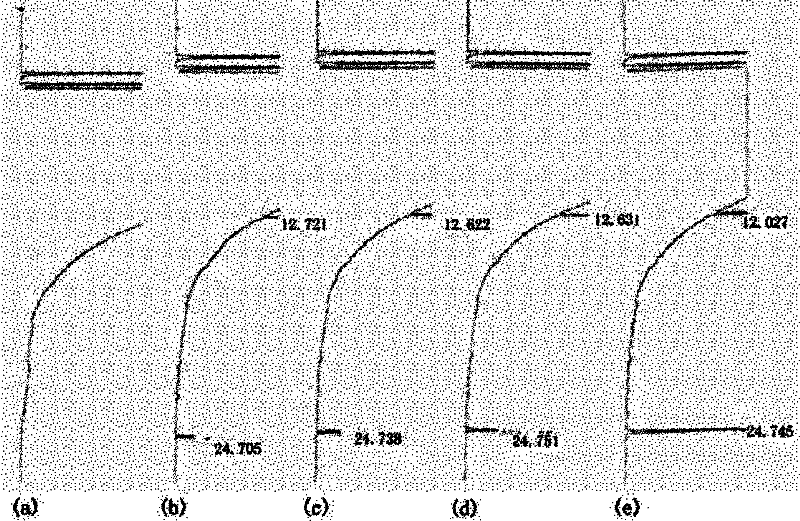

[0023] Example 2: image 3 It is the result of analyzing the circulating gas in the reactor by gas chromatography during the successful start-up of the unit. The catalyst used during start-up and the reaction conditions of only adding ethylene monomer in the reactor are the same as in Example 1.

[0024] image 3 Among them, the meanings of spectrograms (a)-(e) are the same as in Example 1.

[0025] according to image 3 The gas chromatographic analysis results show that: spectrogram (a), when no catalyst is added, no 1-butene and 1-hexene are detected in the recycle gas, indicating that ethylene has not yet undergone polymerization; After 1 hour of the catalyst, traces of 1-butene and 1-hexene can be detected from the recycle gas. According to the theory that chromium-based catalysts can simultaneously catalyze ethylene oligomerization and polymerization, it is preliminarily judged that the catalyst has begun to initiate the polymerization of ethylene. ; Spectrogram (c)-(...

Embodiment 3

[0026] Example 3: Figure 4 It is the result of analyzing the circulating gas in the reactor by gas chromatography during the successful start-up of the unit. The catalyst used during start-up and the reaction conditions of only adding ethylene monomer in the reactor are the same as in Example 1.

[0027] Figure 4 Among them, the meanings of spectrograms (a)-(e) are the same as in Example 1.

[0028] according to Figure 4The gas chromatographic analysis results show that: spectrogram (a), when no catalyst is added, no 1-butene and 1-hexene are detected in the recycle gas, indicating that ethylene has not yet undergone polymerization; After 1 hour of catalyst, traces of 1-butene and 1-hexene can be detected from the recycle gas. According to the theory that chromium-based catalysts can simultaneously catalyze ethylene oligomerization and polymerization, it is preliminarily judged that the catalyst has begun to initiate the polymerization of ethylene. ; Spectrogram (c)-(e)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com