Automatic debugging and testing method and device for transmitting optical power and eye pattern of optical module

A technology of emitting light and optical eye diagram, applied in the field of optical modules, it can solve the problems of low yield, long working hours and increase, and achieve the effect of meeting automation requirements, best performance and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

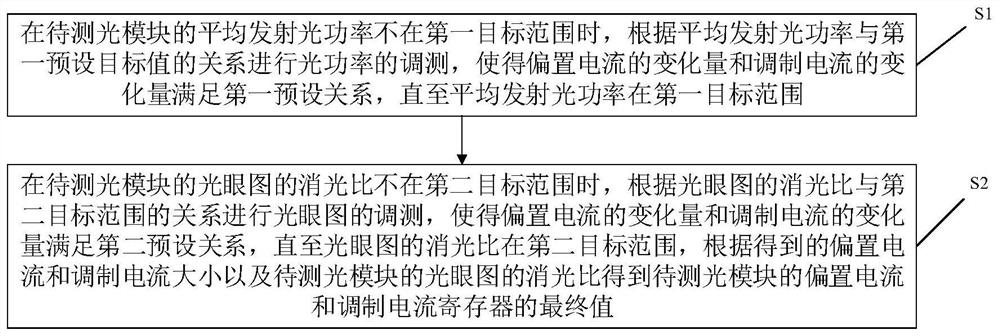

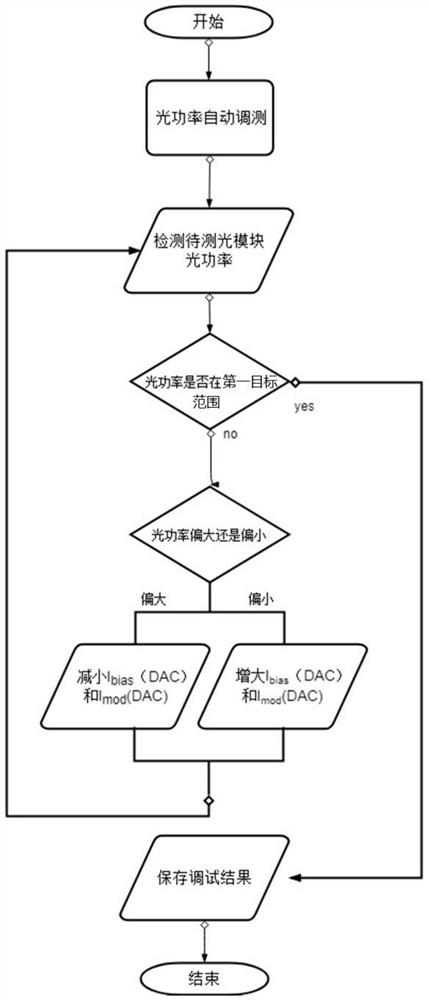

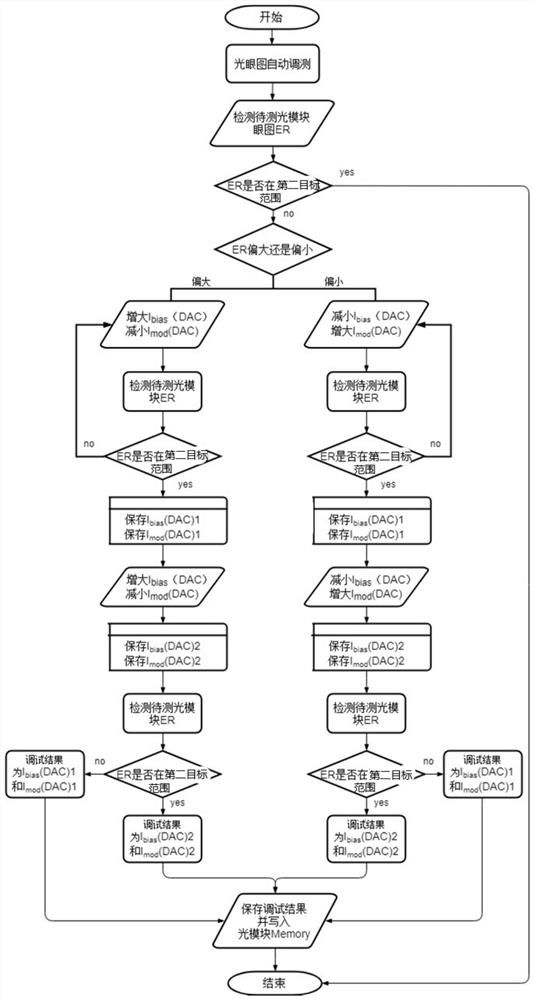

[0038] Such as figure 1 Shown is a schematic flow chart of an automatic commissioning method for transmitting optical power and eye diagram of an optical module provided by an embodiment of the present invention. figure 1 The method shown includes the following steps:

[0039] S1: When the average transmitted optical power of the optical module to be tested is not within the first target range, perform optical power commissioning according to the relationship between the average transmitted optical power and the first target range, so that the variation of the bias current and the change of the modulation current The amount satisfies the first preset relationship until the average emitted optical power is within the first target range;

[0040] In the embodiment of the present invention, the first target range may be determined according to the protocol, standard or specification followed by the optical module to be tested.

[0041] In the embodiment of the present invention...

Embodiment 2

[0072] Such as Figure 4 Shown is a schematic structural diagram of an automatic commissioning device for transmitting optical power and eye diagrams of an optical module provided by an embodiment of the present invention, including:

[0073] The optical power commissioning module 401 is configured to perform commissioning of the optical power according to the relationship between the average transmitted optical power and the first target range when the average transmitted optical power of the optical module to be tested is not within the first target range, so that the bias current The amount of variation and the amount of variation of the modulation current satisfy a first preset relationship until the average emitted optical power is within the first target range;

[0074] The eye diagram commissioning module 402 is configured to perform commissioning of the optical eye diagram according to the relationship between the extinction ratio of the optical eye diagram and the sec...

Embodiment 3

[0083] Figure 5 It is a schematic structural diagram of an automatic commissioning system for optical module optical power and optical eye diagram provided by an embodiment of the present invention, which includes: a sampling oscilloscope / eye diagram instrument, an optical power meter, and a bit error meter for testing the optical module Fixtures, fiber optics and automatic commissioning devices.

[0084] In actual operation, the operator connects the optical module to be tested to the optical fiber, and inserts it into the Figure 5 On the test board shown, the automatic commissioning device can realize the automatic commissioning of the optical power and eye diagram of the transmitting end of the optical module.

[0085] The system realizes the real-time commissioning of the eye diagram of the module to be tested through the real-time program-controlled oscilloscope, bit error detector, optical power meter and optical module to be tested through the automatic commissioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com