Two-for-one twister control system and method based on intelligent network

An intelligent network and control system technology, applied in the field of textile and intelligent control of two-for-one twisters, can solve the problem that feedback control cannot be realized for twisting product quality and twisting efficiency, the drive cannot be adjusted according to actual needs, and the control of two-for-one twisters cannot be obtained. Effectiveness and other issues, to achieve the effect of saving manpower calibration costs, improving use efficiency and product quality, and varieties are fast and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

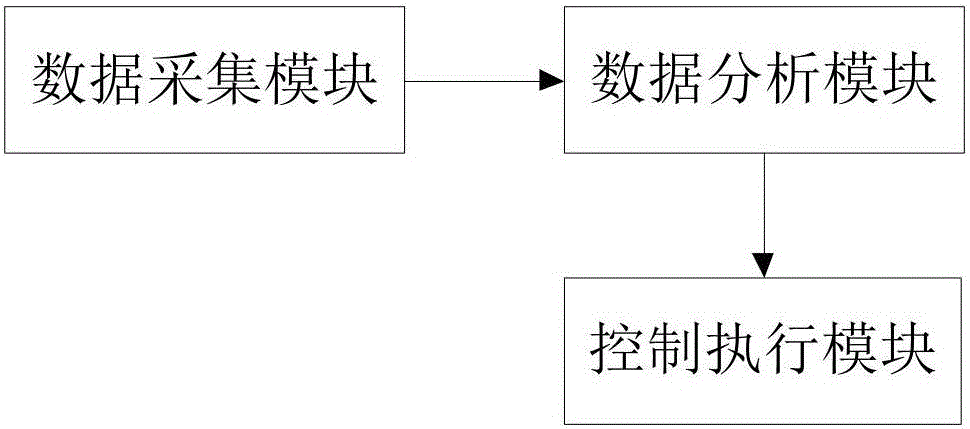

[0050] Such as figure 1 Shown is the structure diagram of the two-for-one twister control system based on the intelligent network of the present invention. The system includes:

[0051] The data acquisition module is used to collect the operating parameters of each two-for-one twister in real time;

[0052] The data analysis module is used to analyze and obtain the control strategy of the two-for-one twister according to the operating parameters of the two-for-one twister shown;

[0053] The control execution module is used for controlling the running state of the two-for-one twister according to the control strategy of the two-for-one twister.

[0054]Specifically, the data analysis module can evaluate the operation status and spinning quality of each two-for-one twister through the real-time operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com