Angle-adjustable suction hardware tool

A technology for adjusting angles and fittings, applied in the field of suction fittings, can solve the problems of inability to adapt to product production automation, increased equipment labor costs, and weak suction by suction cups, achieving the effects of light weight, reduced production costs, and firm suction of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

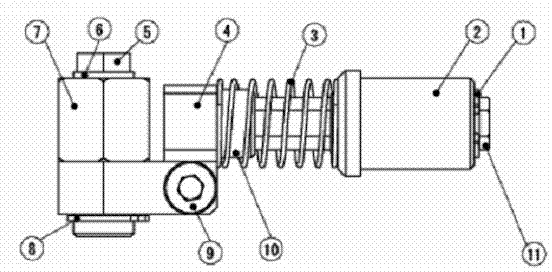

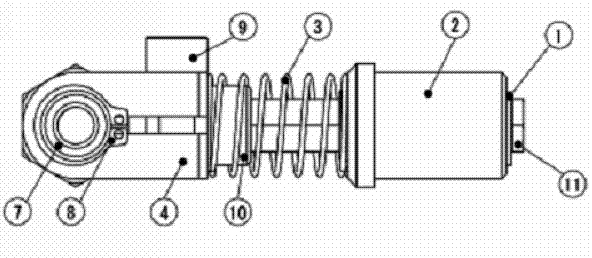

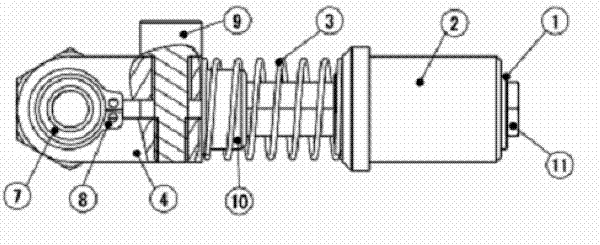

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the suction cup 12 is installed on the suction cup installation head 7, and the supporter 2 is installed on the fixture plate of the manipulator. The supporter 2 is made of cylindrical aluminum bar stock, and its installation position is a cylindrical surface, which is convenient for installation and connection with the manipulator fixture plate. position. The guide rod 11 passes through the supporter 2 and connects with the rotating bracket 4. The tail of the guide rod 11 is fixed by the snap ring 1 to prevent the supporter 2 from detaching from the guide rod 11. The guide rod 11 is made of a hexagonal prism profile and passes through the supporter 2. For guiding and anti-rotation; the spring 3 is set on the guide rod 11, and the two ends are respectively connected with the supporter 2 and the rotating bracket 4. The spring 3 has a buffering effect while transmitting the force to prevent the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com