Screw sorting device

A sorting device and screw technology, applied in sorting and other directions, can solve the problems of low efficiency, time-consuming and labor-intensive, high error rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

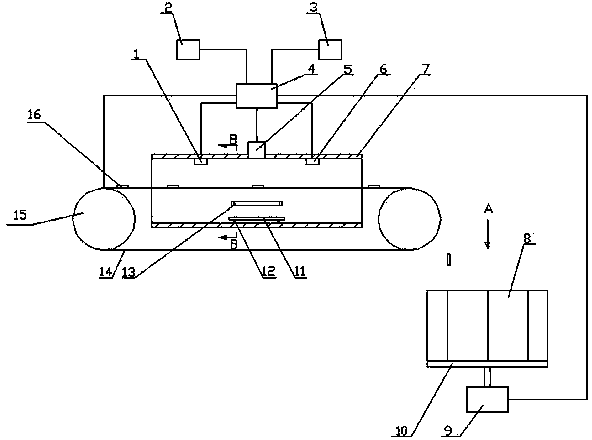

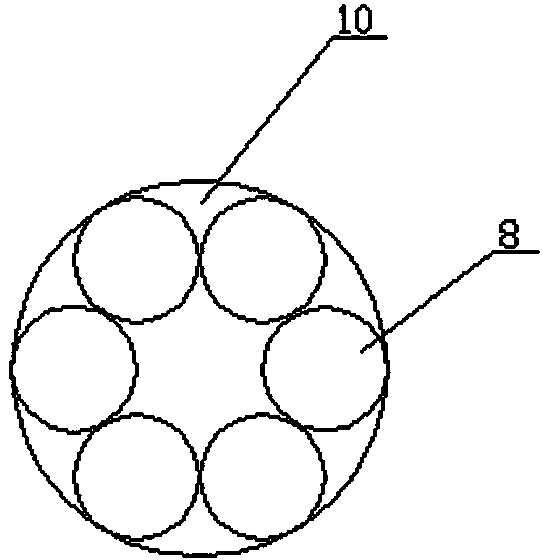

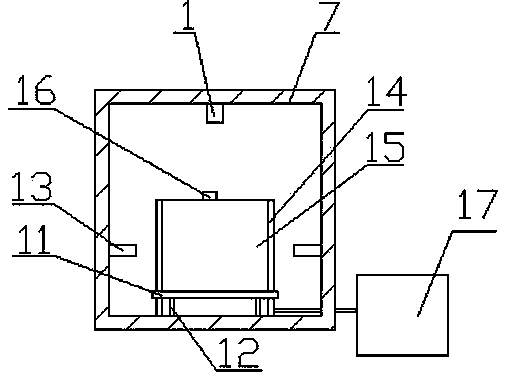

[0014] Such as figure 1 and image 3 As shown, the screw sorting device of the present invention includes a pipe 7, a belt conveyor, a material receiving mechanism, a touch screen 3, and a controller 4. The touch screen 3 is connected with the controller 4 by wires. The cross section of the pipe 7 is square. Described belt conveyor contains two belt rollers 15, conveyer belt 14 and second power mechanism 17, and described conveyer belt 14 is enclosed within on the belt roller 15, and the output shaft of described second power mechanism 17 is connected with a The roller shafts of the belt rollers 15 are connected. The conveyor belt 14 is a hollowed-out conveyor belt, which passes through one end of the pipeline 7 and exits from the other end of the pipeline 7 . The first photoelectric switch 1 and the second photoelectric switch 6 are arranged in the rear end and the front end of the pipeline 7 respectively, and the first photoelectric switch and the second photoelectric sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com