Intelligent control system for weld seam tracking and fusion penetration in spiral pipes

An intelligent control system, spiral tube technology, applied in general control system, control/regulation system, computer control, etc., can solve the problem of not having a good extraction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

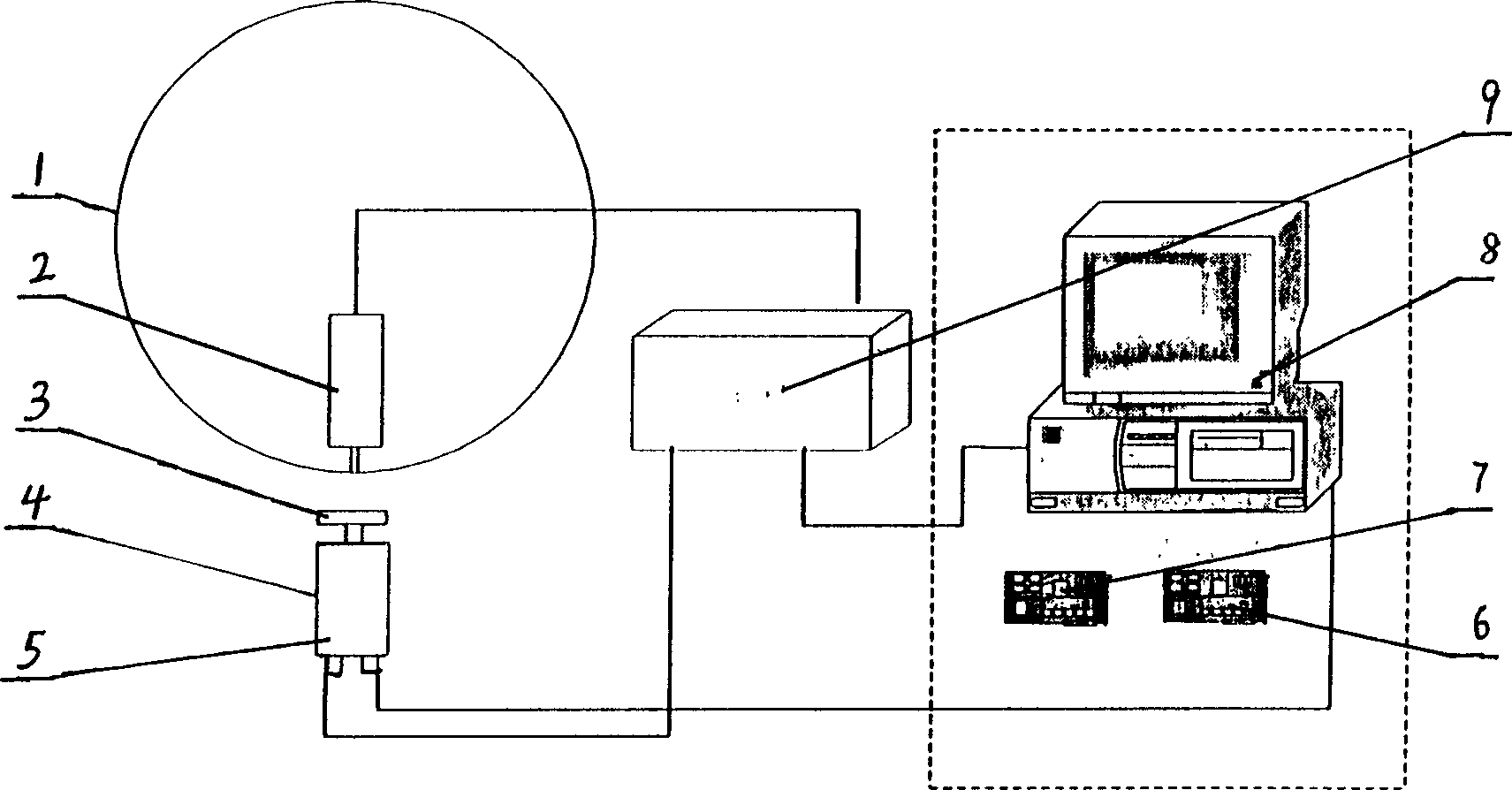

[0022] Below in conjunction with embodiment and with reference to accompanying drawing, the utility model is described in further detail.

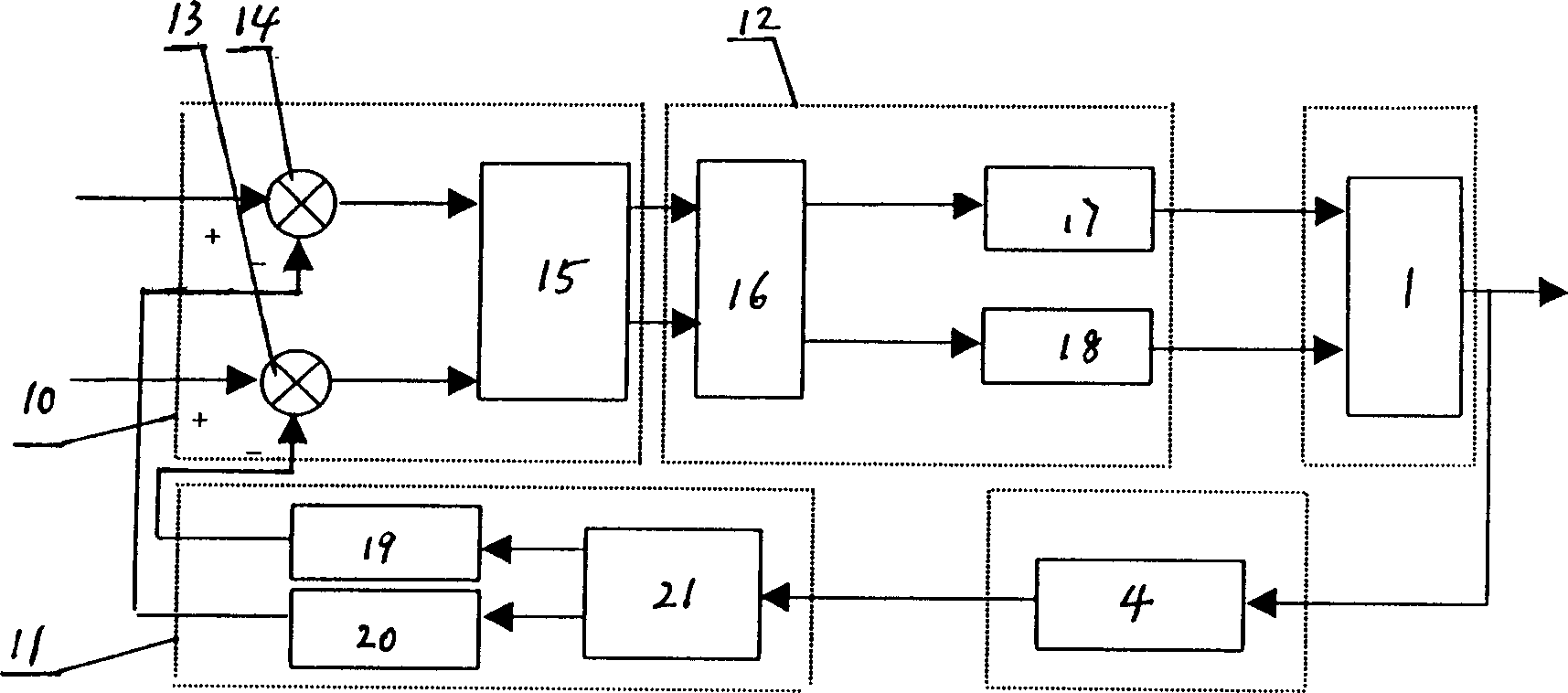

[0023] The present invention consists of a spiral tube submerged arc welding machine 2 placed in a spiral tube 1, a temperature field sensor 4, a control box 9 and an industrial control computer 8. The temperature field sensor 4 installed on the back of the weld in the spiral tube 1 is controlled by an infrared filter. Composed of light sheet 3 and image charge coupled device 5, weld seam tracking and penetration integrated intelligent control module 10 and interface drive circuit 12 are installed in control box 9, image acquisition card 7 and The input / output card 6 is designed with a temperature field welding seam and penetration feature identification information processing module 11 in the industrial control computer 8 .

[0024] The temperature field weld seam and penetration feature recognition information processing module 11 is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com