Cigarette box opening method and cigarette box envelope reclamation method

A smoke box and box skin technology, which is applied in the field of smoke box opening and smoke box skin recycling, can solve the problems of large area occupied by manual operations, dirty working environment, and high labor intensity, and achieves small footprint and low labor costs. The effect of low strength and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The inventive method comprises the following steps:

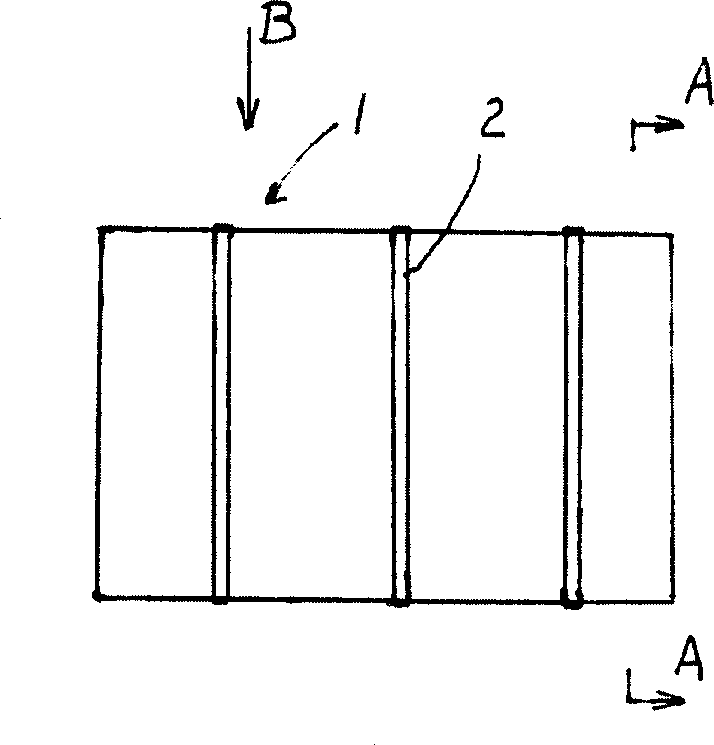

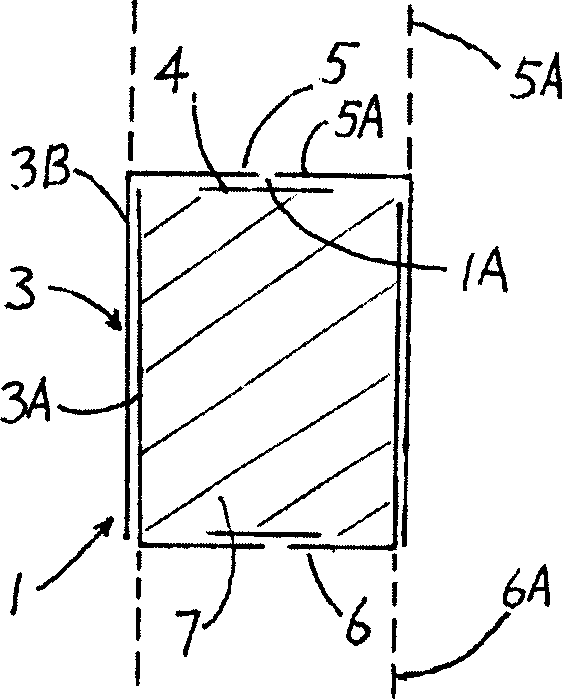

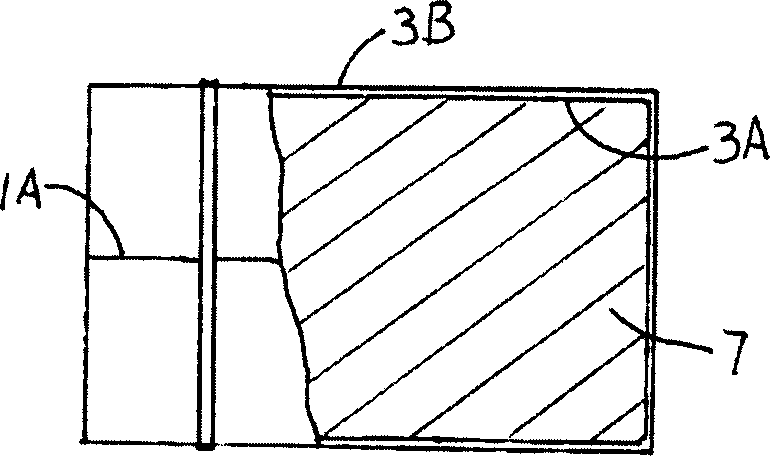

[0076] Such as figure 1 , 2 , 3, cut the packing belt 2 of cigarette case 1, open the sealing 1A of described cigarette case 1 one end ( image 3 ), take out the backing paper 4;

[0077] Turn the cigarette box 180°, open the other end of the cigarette box 1, and take out the pad paper 4;

[0078] Such as Figure 8 , clamping and lifting the box skin 3, so that the box skin 3 is separated from the cigarette block 7 in the cigarette box 1, leaving the cigarette block 7 and sending it to make cigarettes;

[0079] Clamping and removing the case skin 3 to another place;

[0080] Such as Figure 9 , dropping the case skin 3 into the frame bar 30 located at the other place;

[0081] Loosen and reset the clamping frame 20;

[0082] Such as Figure 10 , the frame hurdle 30 that case skin 3 is housed is overturned 90 °; Described case skin 3 is released from frame hurdle 30 (also described case skin 3 can be pushed d...

Embodiment 2

[0085] Such as Figure 4 For the station layout diagram of the present invention, each of the above-mentioned operation steps is completed by the following stations of the production line:

[0086] Station 1, such as Figure 5 , the cigarette box 1 sent by the roller table 8 is manually cut off the packing belt 2 of the cigarette box 1, one end of the cigarette box 1 is opened, and the backing paper 4 is taken out; the opened cigarette box 1 is sent to the station 2 by the roller table 8 . It is also possible to merge station 1 into station 2.

[0087] Station 2, such as Image 6 , use the cylinder 16 in the overturning device 10 to compress the cigarette box 1, and turn it over 180°; open the other end of the cigarette box 1, and take out the pad paper 4; use the belt conveyor 19 to transport the cigarette box 1 opened at both ends to the station 3. The illustrated position is the position of the turning device 10 after the turning operation has been completed. The over...

Embodiment 3

[0100] The following is an improved solution, the operation process is the same as above, but there are some improvements in the following parts:

[0101] When at station 1, the described opening of one end of the cigarette box 1 is to open the inner skin 3A of the cigarette box ( figure 2 ) cover 6;

[0102] When at station 2, the other end of the described opening of the cigarette box 1 is to open the cigarette box outer skin 3B ( figure 2 ) cover 5;

[0103] In station 3-1, such as Figure 7A , 7B , 8, before the above-mentioned clamping and lifting of the box skin 3, the two halves 5A of the cover 5 of the outer skin 3B of the disassembled cigarette box 1 are sucked up with the suction cup 23. This sucker 23 is fixed on the rocking arm 27 of rotating shaft 22, by the rotation of rotating cylinder 26, rotating shaft 22 and rocking arm 27 are swung, and half cover 5A is absorbed and then lifted 90 °, and half cover 5A is vertical, as Figure 8 shown.

[0104] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com