Fermentation tray for solid organic materials

A technology of organic materials and fermentation trays, applied in the direction of organic fertilizer, organic fertilizer preparation, climate change adaptation, etc., to achieve the effect of no maintenance, reduction of secondary environmental pollution, and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

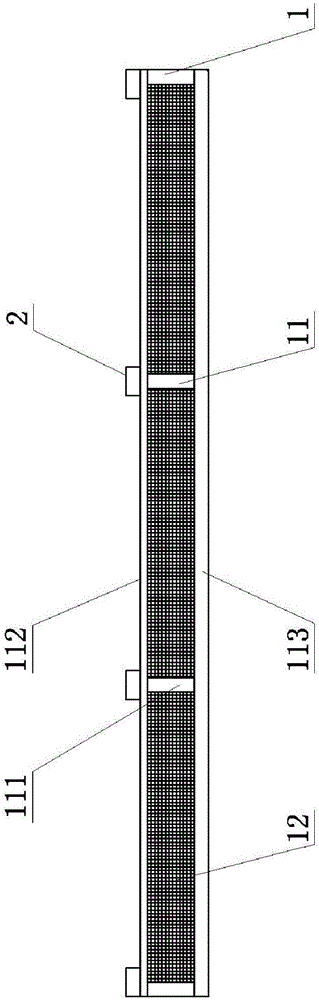

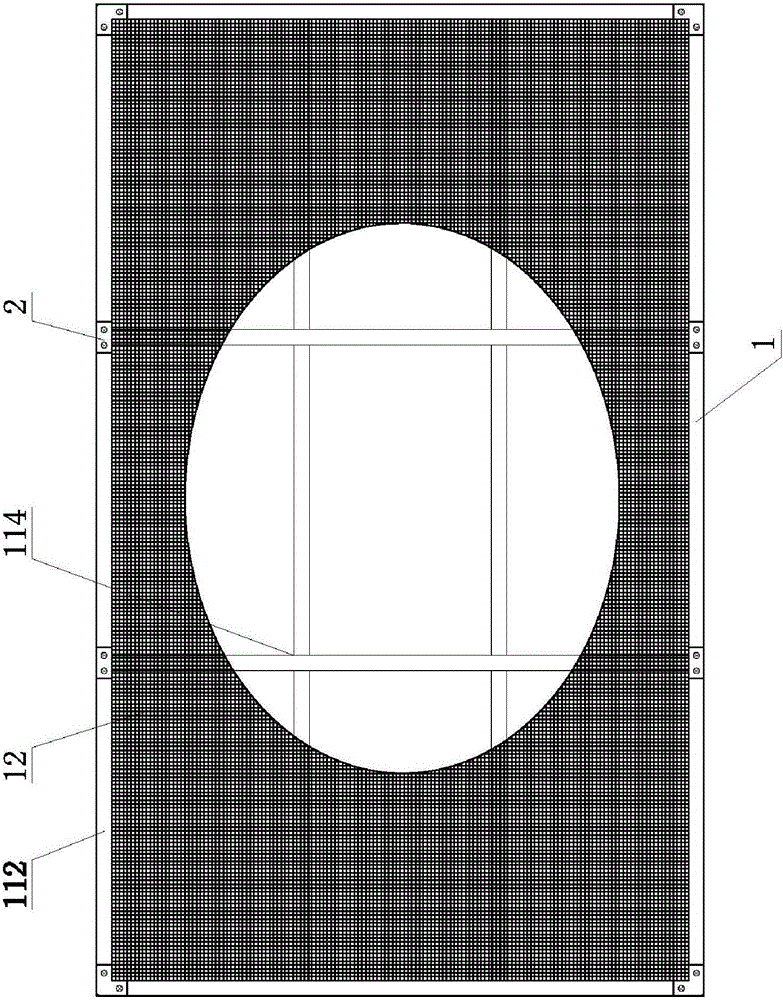

[0041] see figure 1 and figure 2 As shown, the solid organic material fermentation tray in Embodiment 1 of the present invention is mainly composed of a fermentation tray body 1 and a layered support 2, wherein the fermentation tray body 1 is mainly composed of a load-bearing frame 11 and a grid tray 12, and the grid tray 12 is installed on the load-bearing frame within 11. The load-bearing frame 11 is mainly composed of a frame column 111, an upper frame 112, a lower frame 113 and a frame bottom beam 114. The frame column 111 is vertically connected between the upper frame 112 and the lower frame 113, and the frame bottom beam 114 is connected to the inner side of the lower frame 113. .

[0042] In this embodiment, the fermentation tray body 1 is rectangular, with a length of 1000 mm to 3500 mm, a width of 300 mm to 2500 mm, and a height of 100 mm to 400 mm. The upper frame 112 and the lower frame 113 of the load-bearing frame 11 are both rectangular frames. 111 has eight...

Embodiment 2

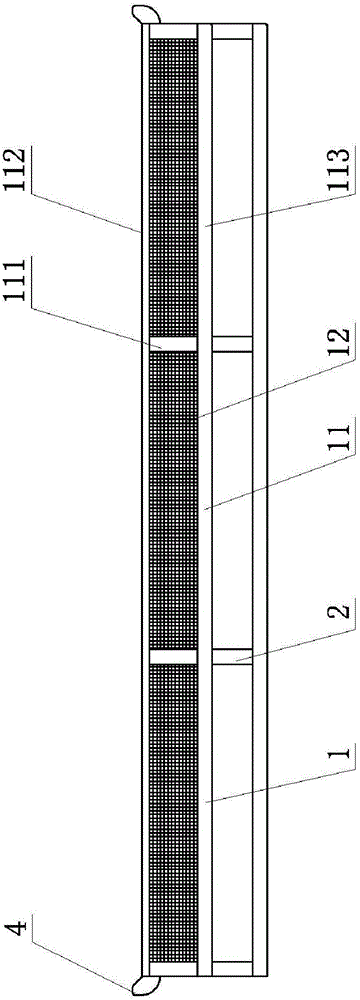

[0047] see image 3 and Figure 4 As shown, the solid organic material fermentation tray of the second embodiment of the present invention is similar to the first embodiment, the only difference is that the layered support 2 is installed under the load-bearing frame 11 of the fermentation tray body 1, and at the same time, in order to avoid the pile of solid organic material fermentation trays After being stacked, relative motion is generated to slide down, and a locking block 4 is installed on the outside of the load-bearing frame 11 .

[0048] In this embodiment, the layered support 2 is made of a rectangular frame welded by stainless steel square tubes with the same size as the upper frame 112 and lower frame 113 of the load-bearing frame 11, and the same number of frame columns as the load-bearing frame 11. , and be installed below the lower frame 113 by these frame columns alignment welding, there are four locking stoppers 4, and two equidistant symmetrical installations...

Embodiment 3

[0050] see Figure 5 and Image 6 As shown, the solid organic material fermentation tray of the third embodiment of the present invention is similar to the first embodiment, the only difference being that the grid tray 12 is punched with a hole diameter of 1 to 20 mm, a hole spacing of 1 to 20 mm, and a thickness of 0.5 to 5 mm. The bottom beam 114 of the load-bearing frame 11 is removed, and at the same time in order to prevent the solid organic material fermentation trays from sliding down due to relative movement after they are piled up, a locking block 4 is installed on the outside of the load-bearing frame 11.

[0051] In this embodiment, the net plate 12 is folded and processed by stainless steel punching mesh. Since the bottom beam 114 of the frame is removed, in order to increase the mechanical strength of the net plate 12, the bottom surface of the net plate 12 is folded along the long side into Trapezoidal and wavy, the four sides of the network disk 12 are welded t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com