Marine high-strength steel plate double-wire submerged-arc welding process

A high-strength steel plate and welding process technology, applied in the field of steel material welding, can solve the problems of container ship hull structure fracture, phase transformation cooling rate slowing down, high temperature residence time prolonging, etc., to achieve excellent joint comprehensive performance, reduce heat ratio, welding The effect of thermal cycling improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) EH47 high-strength anti-crack steel plate is used, which is combined with EH47 high-strength anti-crack steel plate of the same plate thickness, and the plate thickness combination is 50mm+50mm. The size of the test plate is 1000mm×400mm×50mm; the carbon content of the steel plate is less than 0.10%, and the cold crack sensitivity index Pcm≤0.21%;

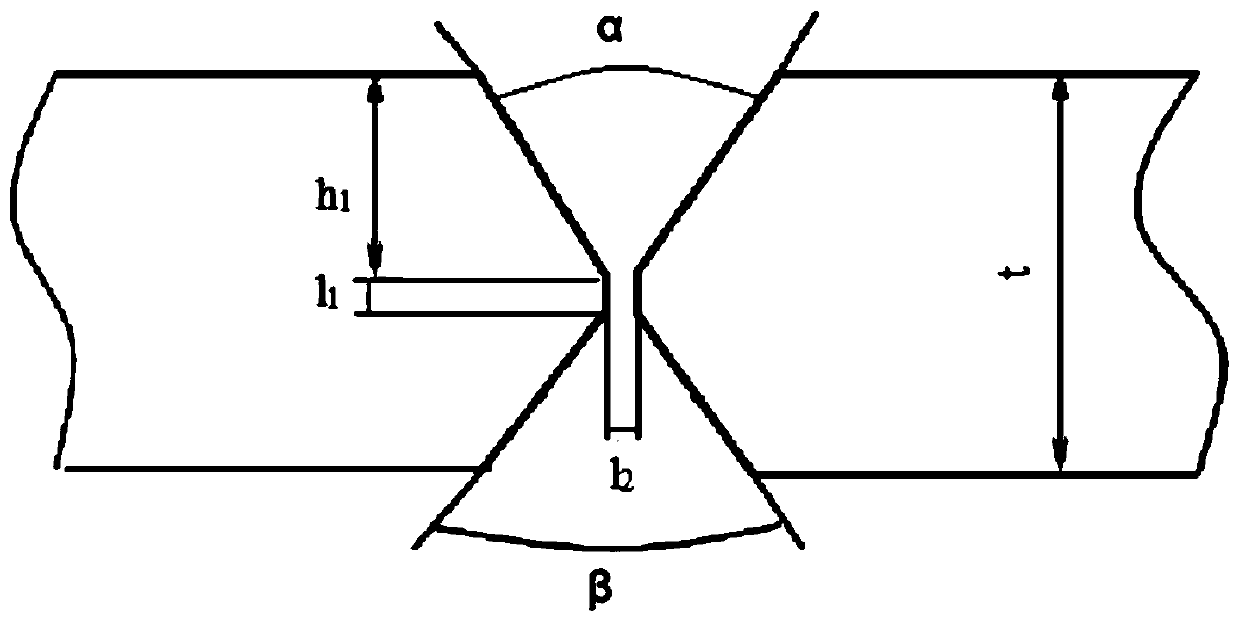

[0022] (2) The groove adopts X-shaped groove, as attached figure 1 As shown, the up-groove angle α is 50°, the down-groove angle β is 60°, and the up-groove depth h 1 20mm, the blunt edge of the groove l 1 3-4mm, groove gap l 2 3mm;

[0023] (3) The front wire adopts DC reverse connection, the wire diameter is Ф2.4mm, and is perpendicular to the surface of the test plate; the rear wire adopts AC, the wire diameter is Ф4.0mm, the angle with the front wire is 10°, and the welding wire spacing is 25mm;

[0024] (4) The chemical composition and weight percentage of the submerged arc welding wire used are: C: 0.05-0.10%, ...

Embodiment 2

[0028] (1) EH47 high-strength anti-crack steel plate is used, which is combined with EH47 high-strength anti-crack steel plate of the same plate thickness, and the plate thickness combination is 100mm+100mm. The size of the test plate is 1000mm×400mm×100mm; the carbon content of the steel plate is less than 0.10%, and the cold crack sensitivity index Pcm≤0.21%.

[0029] (2) The groove adopts X-shaped groove, as attached figure 1 As shown, the up-groove angle α is 60°, the down-groove angle β is 70°, and the up-groove depth h 1 60mm, blunt edge l 1 4-6mm, groove clearance l 2 is 0mm;

[0030] (3) The double-wire submerged arc welding process is adopted, the front wire adopts DC reverse connection, the wire diameter is Ф2.4mm, and is perpendicular to the surface of the test plate; the rear wire adopts AC, the wire diameter is Ф4.0mm, and the included angle with the front wire is 15°, welding wire spacing is 35mm;

[0031] (4) Submerged arc welding wire and flux used. The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com