Internal contact conical ring type continuously-variable transmission

A continuously variable transmission and internal contact technology, which is applied to transmission parts, friction transmission devices, components with teeth, etc., can solve the problems of reduced reliability, high processing requirements, complex systems, etc., and achieve low manufacturing costs and improved The effect of long service life and convenient speed change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

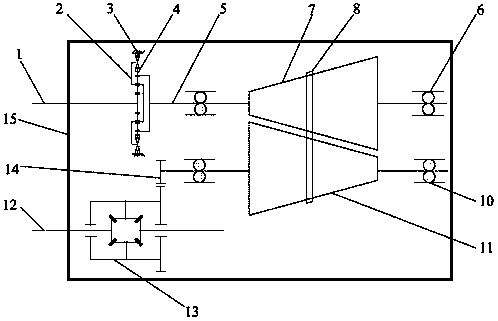

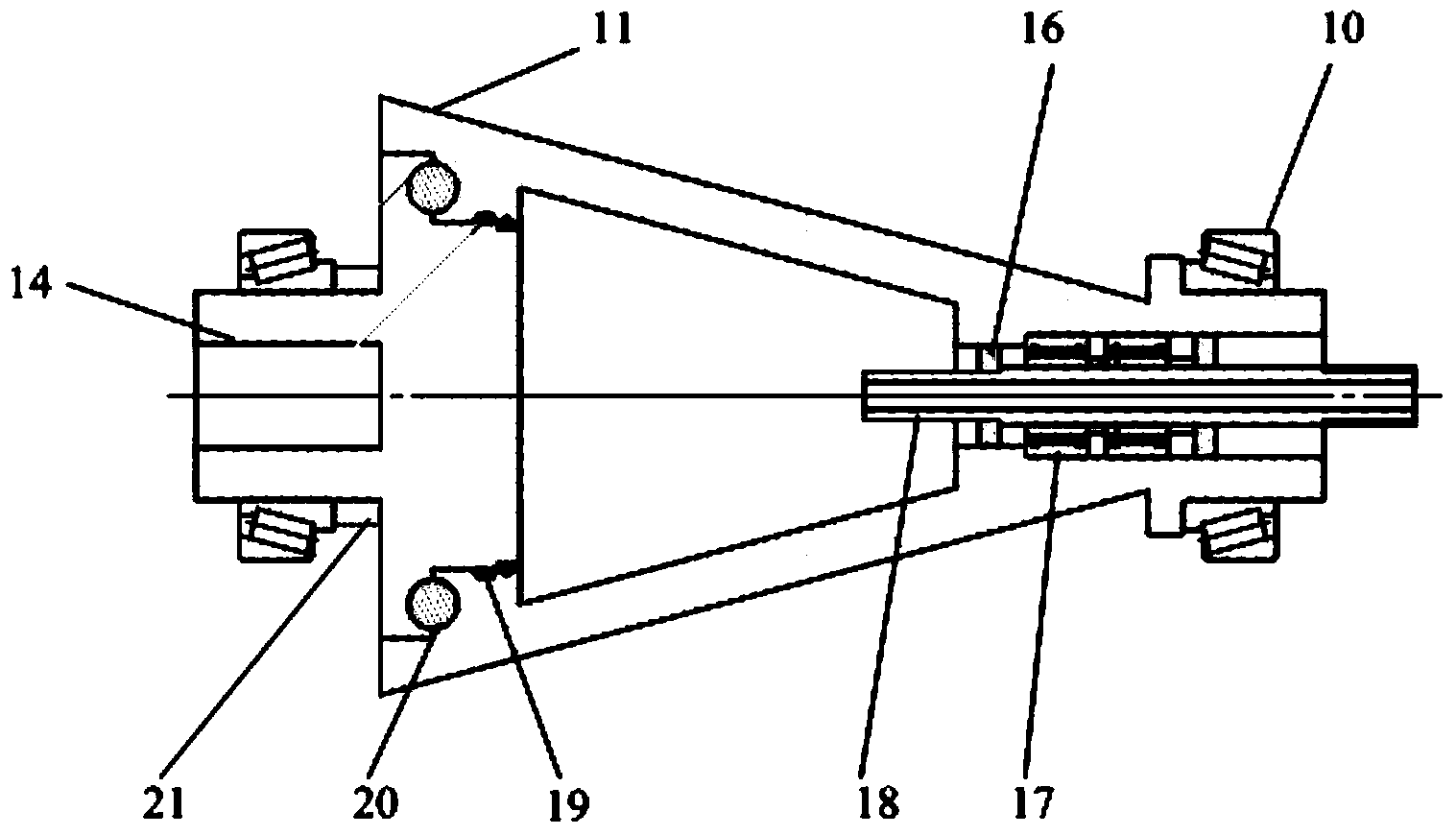

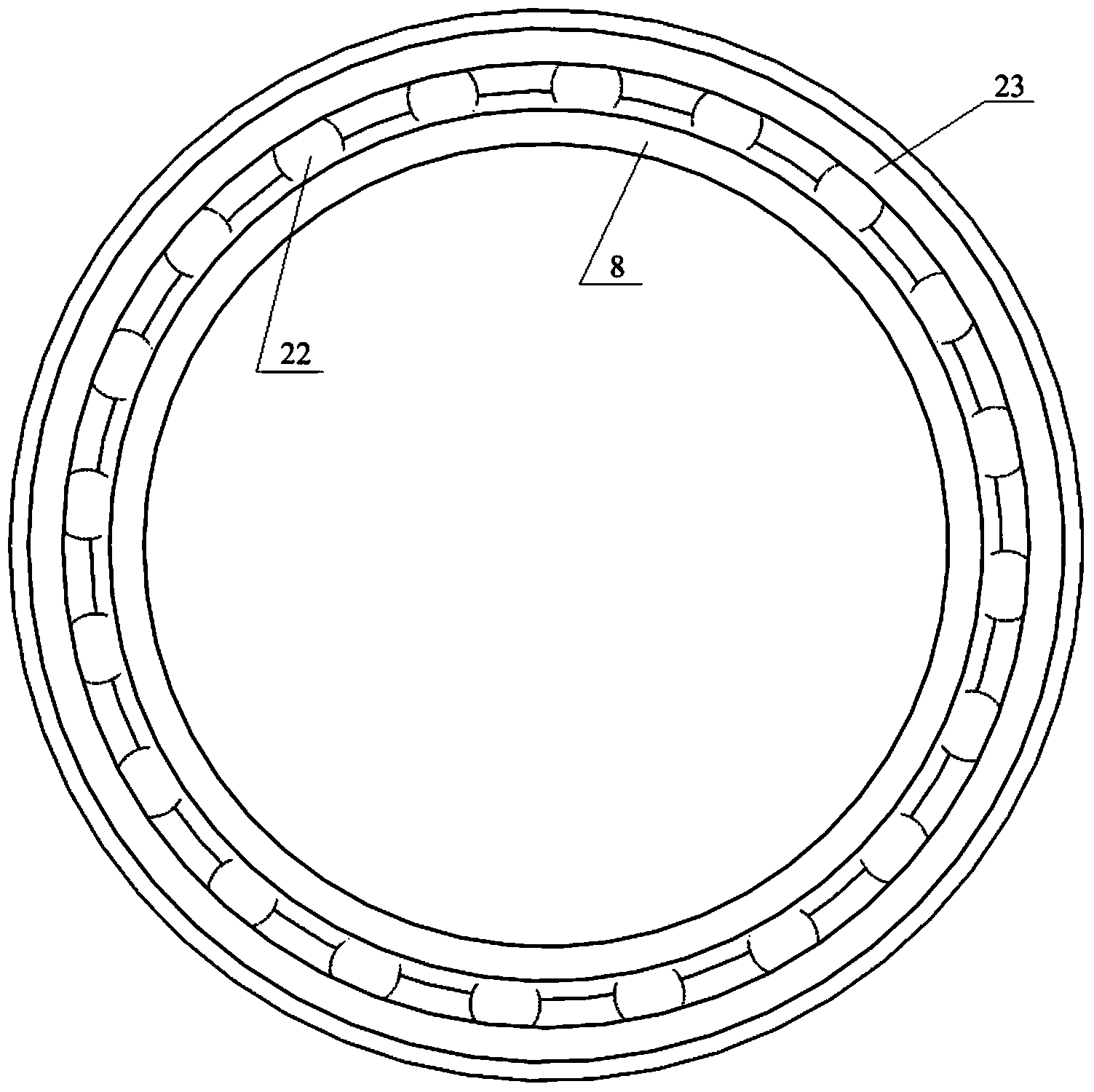

[0023] This embodiment provides an inner contact cone ring type continuously variable transmission suitable for a vehicle with a transverse engine and front-wheel drive. The specific structure of the continuously variable transmission is as follows: figure 1 As shown, it includes the housing 15 and the input shaft 1 inside the housing 15, the planetary row 2, the input cone wheel 7, the cone ring 8, the output cone wheel 11, the output shaft 12, the differential 13, the output gear 14, the loading Mechanisms and gears. The loading mechanism adopts a hydraulic-mechanical loading mechanism formed by coupling a hydraulic part and a mechanical part.

[0024] The connection relationship is as follows: one end of the input shaft 1 protrudes from the casing 15 and is connected to the engine, the other end is connected to the sun gear of the planeta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com