Patents

Literature

55 results about "Transverse engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A transverse engine is an engine mounted in a vehicle so that the engine's crankshaft axis is perpendicular to the direction of travel. Many modern front wheel drive vehicles use this engine mounting configuration. Most rear wheel drive vehicles use a longitudinal engine configuration, where the engine's crankshaft axis is parallel with the direction of travel, except for some rear-mid engine vehicles, which use a transverse engine and transaxle mounted in the rear instead of the front. Despite typically being used in light vehicles, it is not restricted to light vehicles and has also been used on armored vehicles to save interior space.

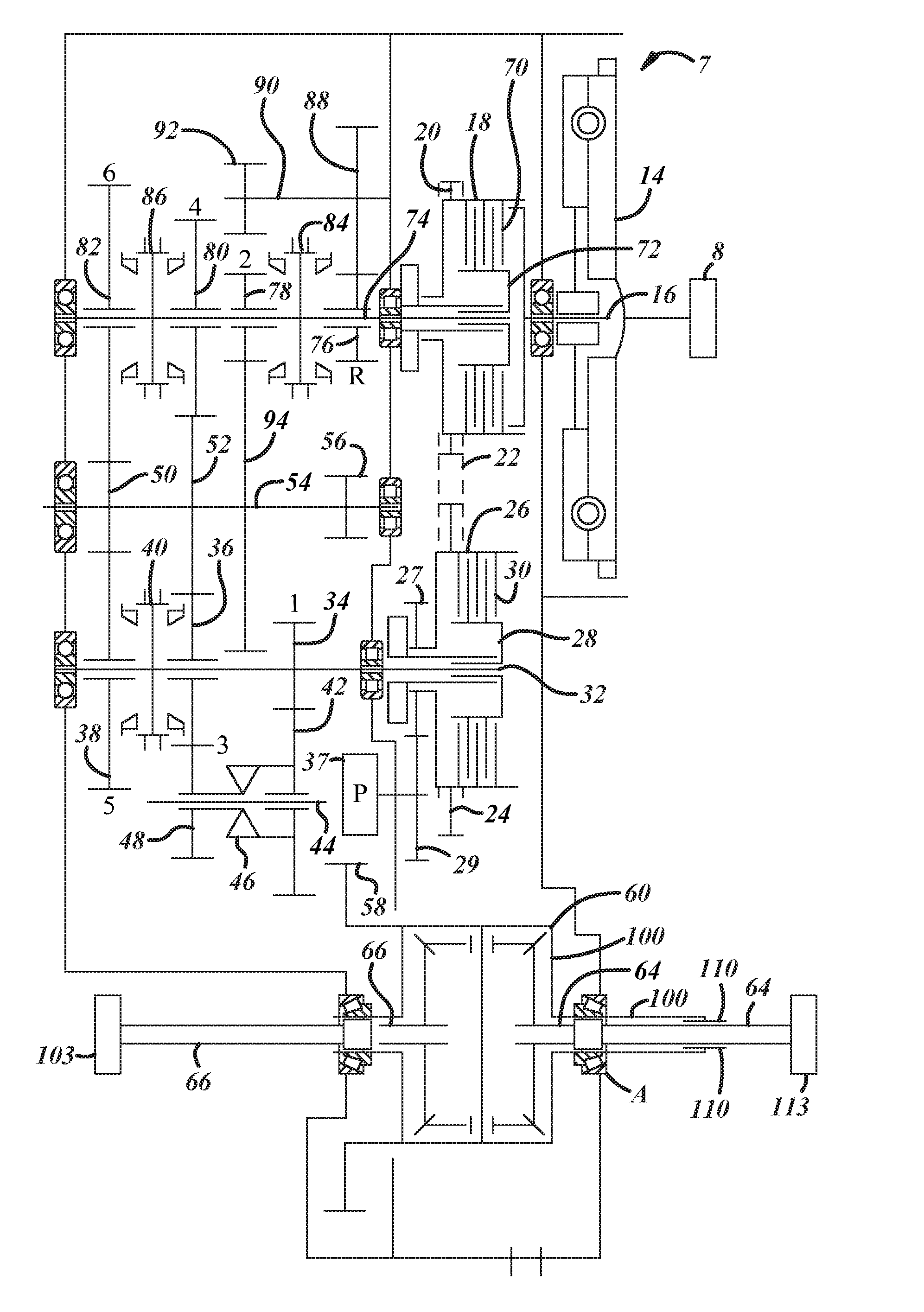

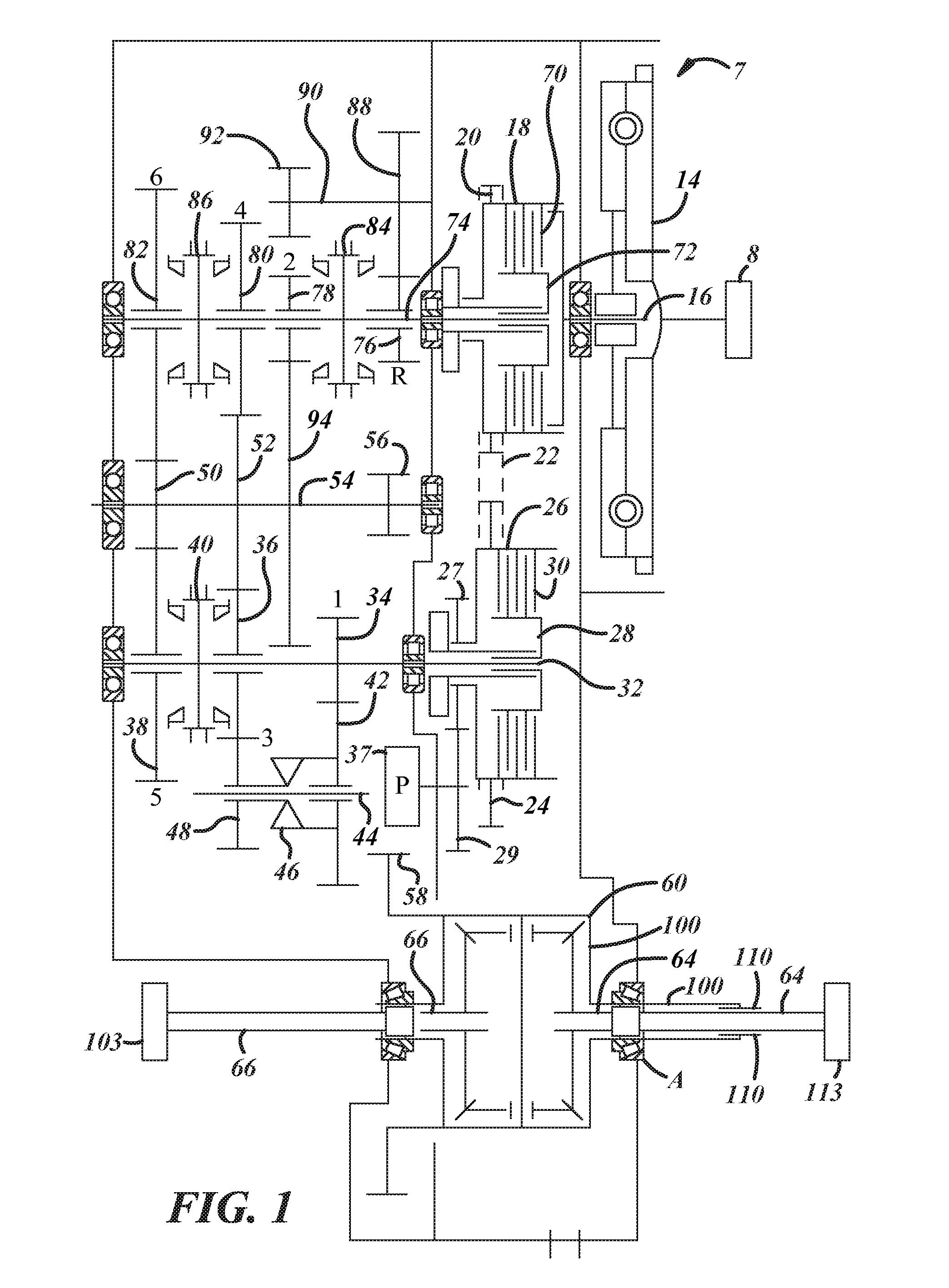

Double clutch transmission

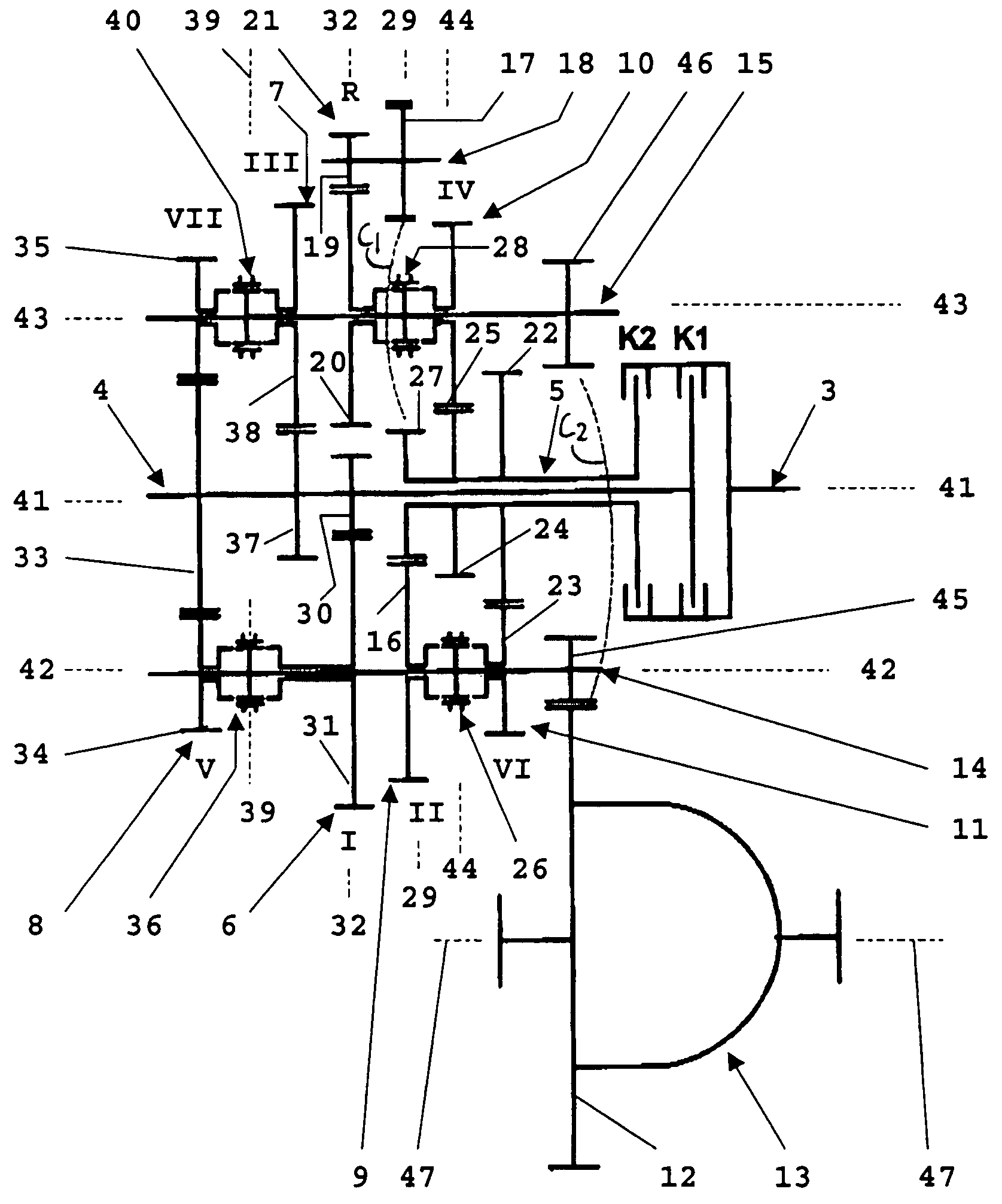

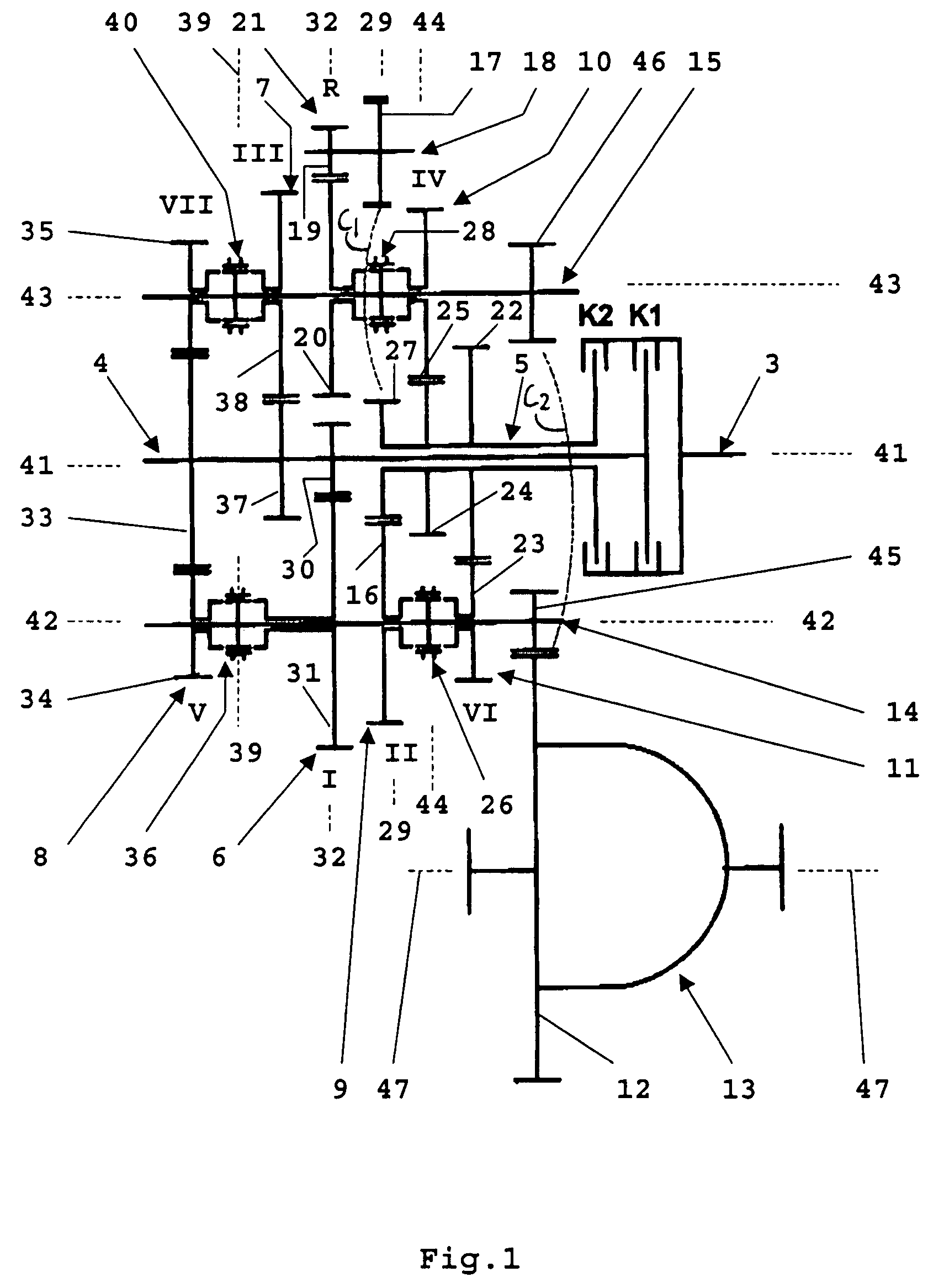

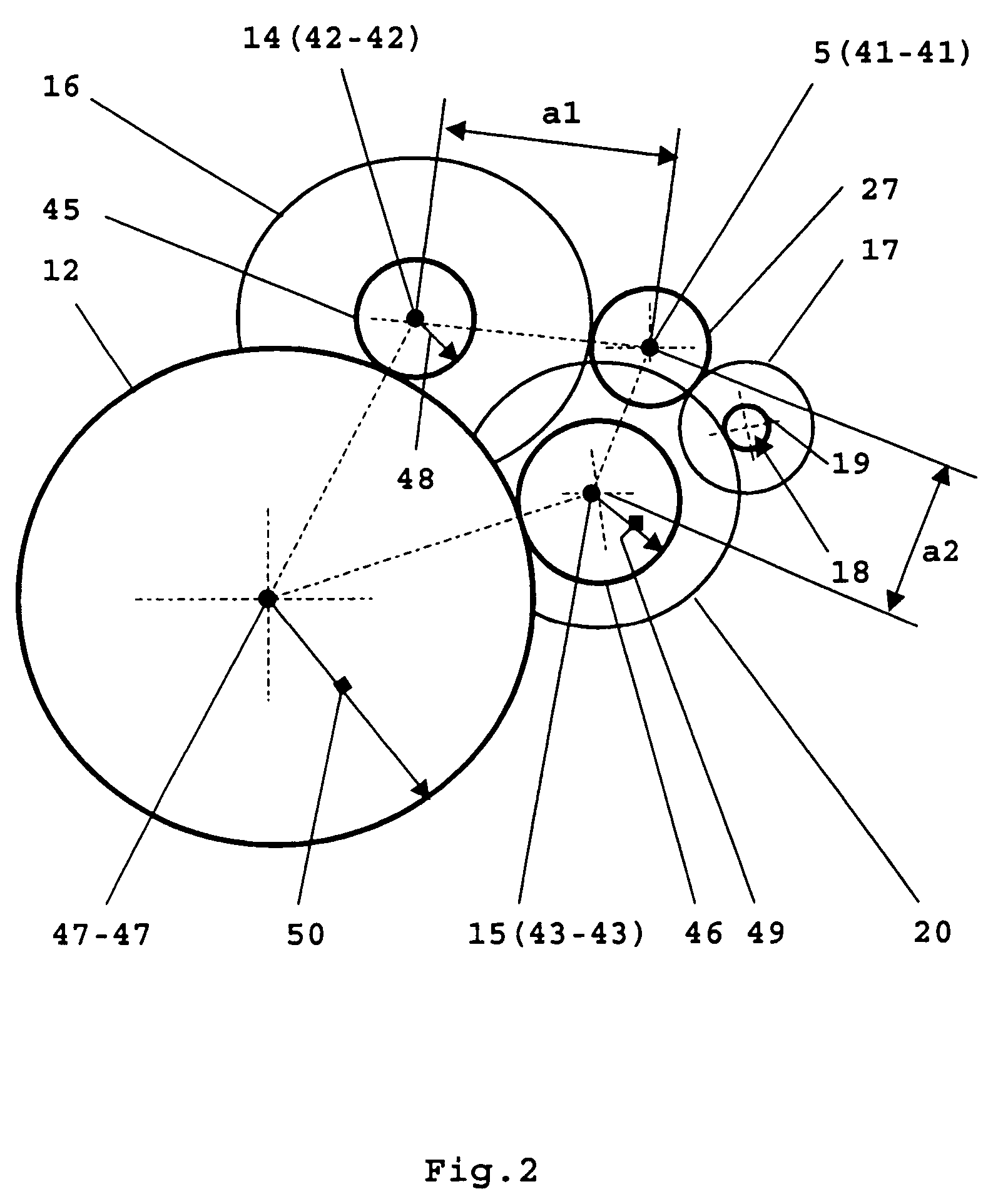

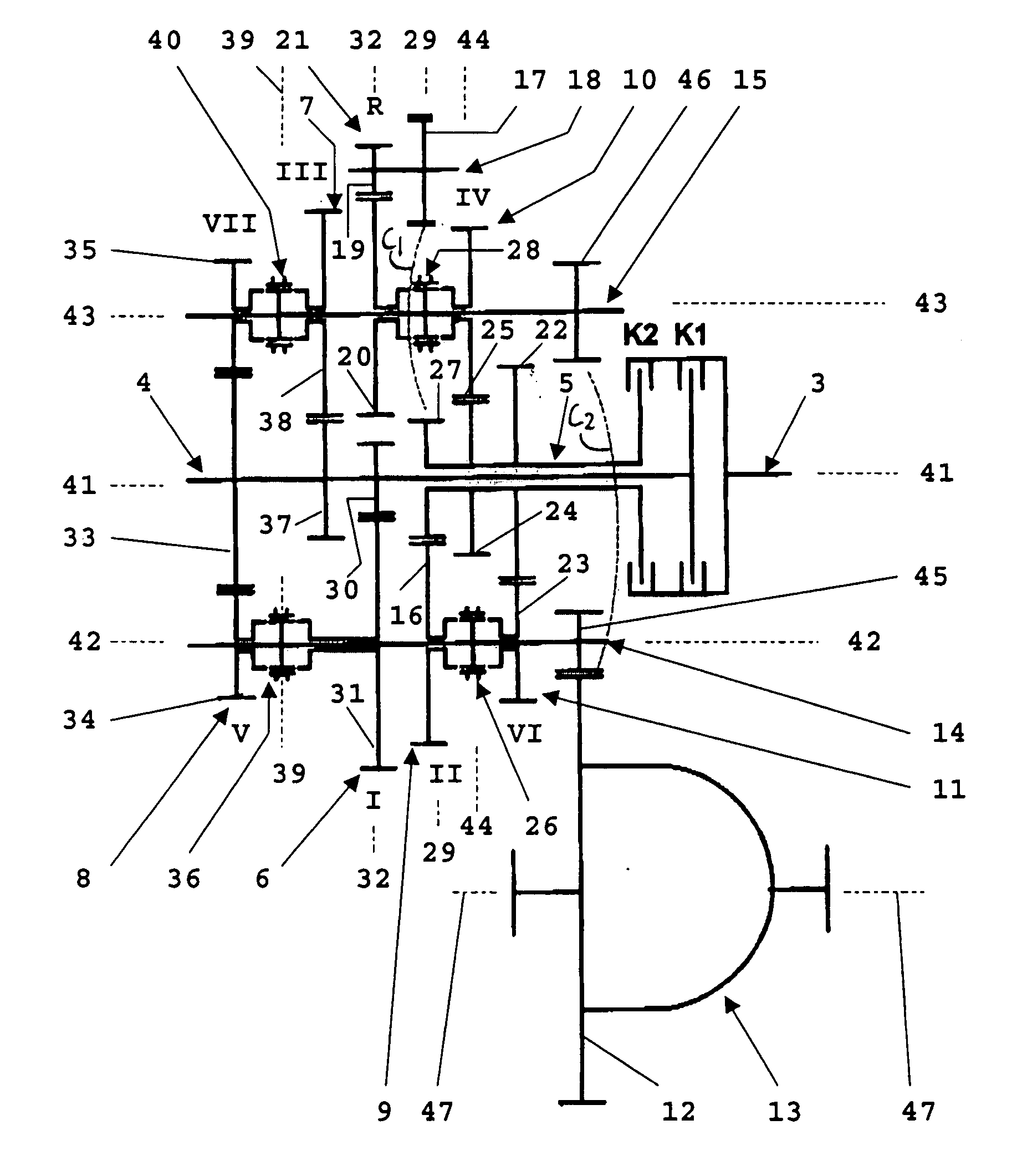

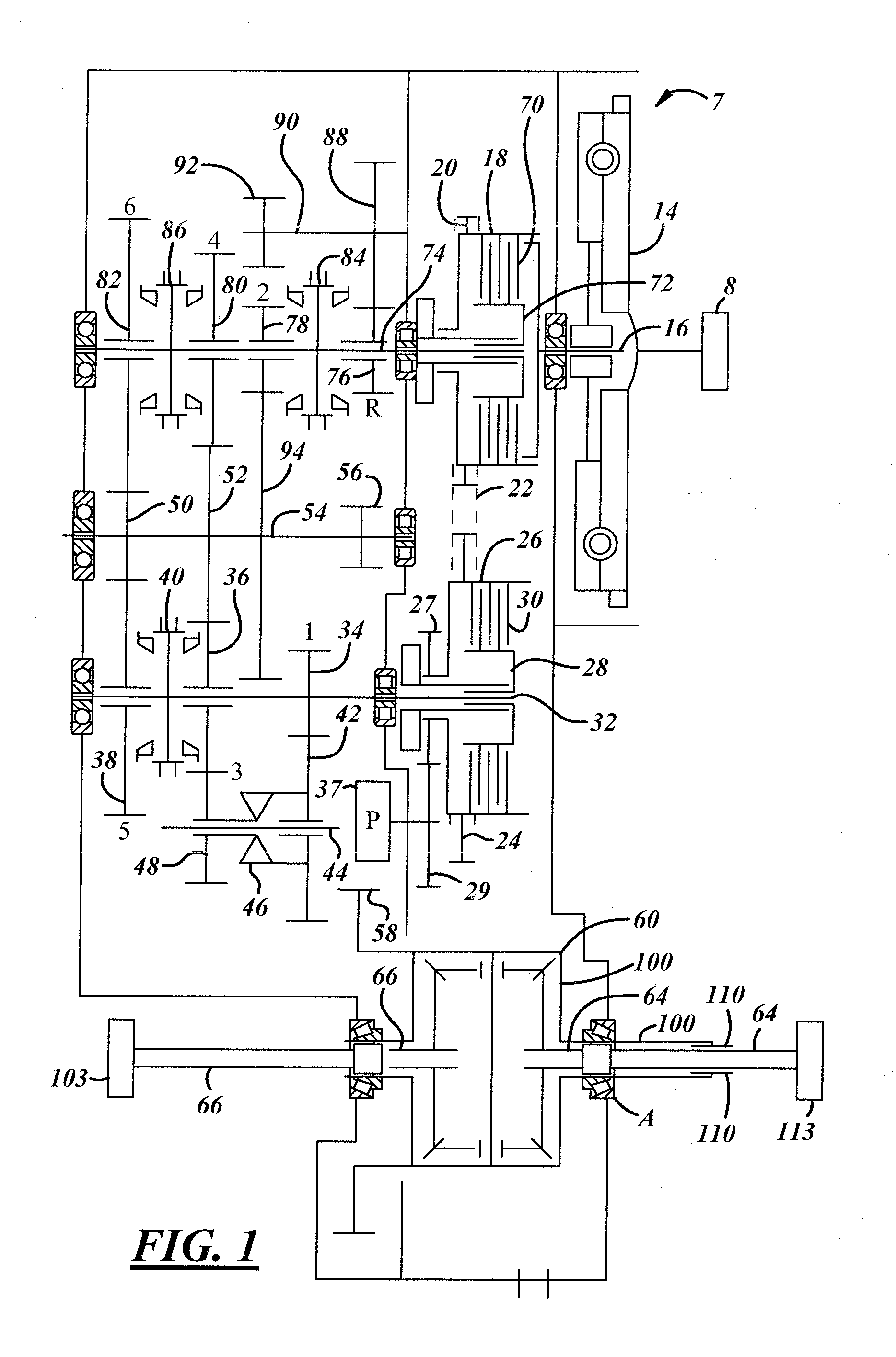

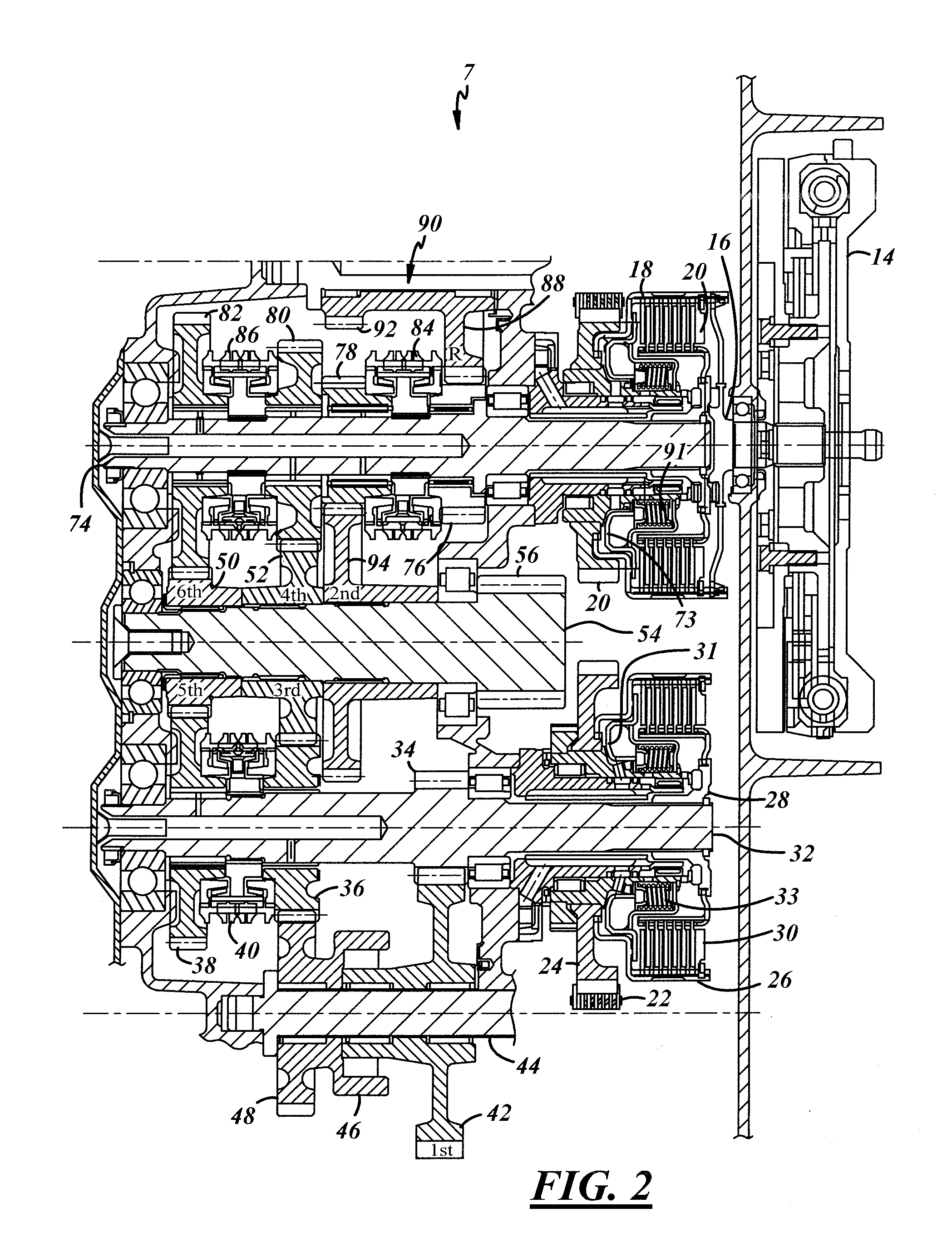

InactiveUS7225696B2Short arrangementCompact designToothed gearingsTransmission elementsJackshaftTransverse engine

Owner:DAIMLER AG

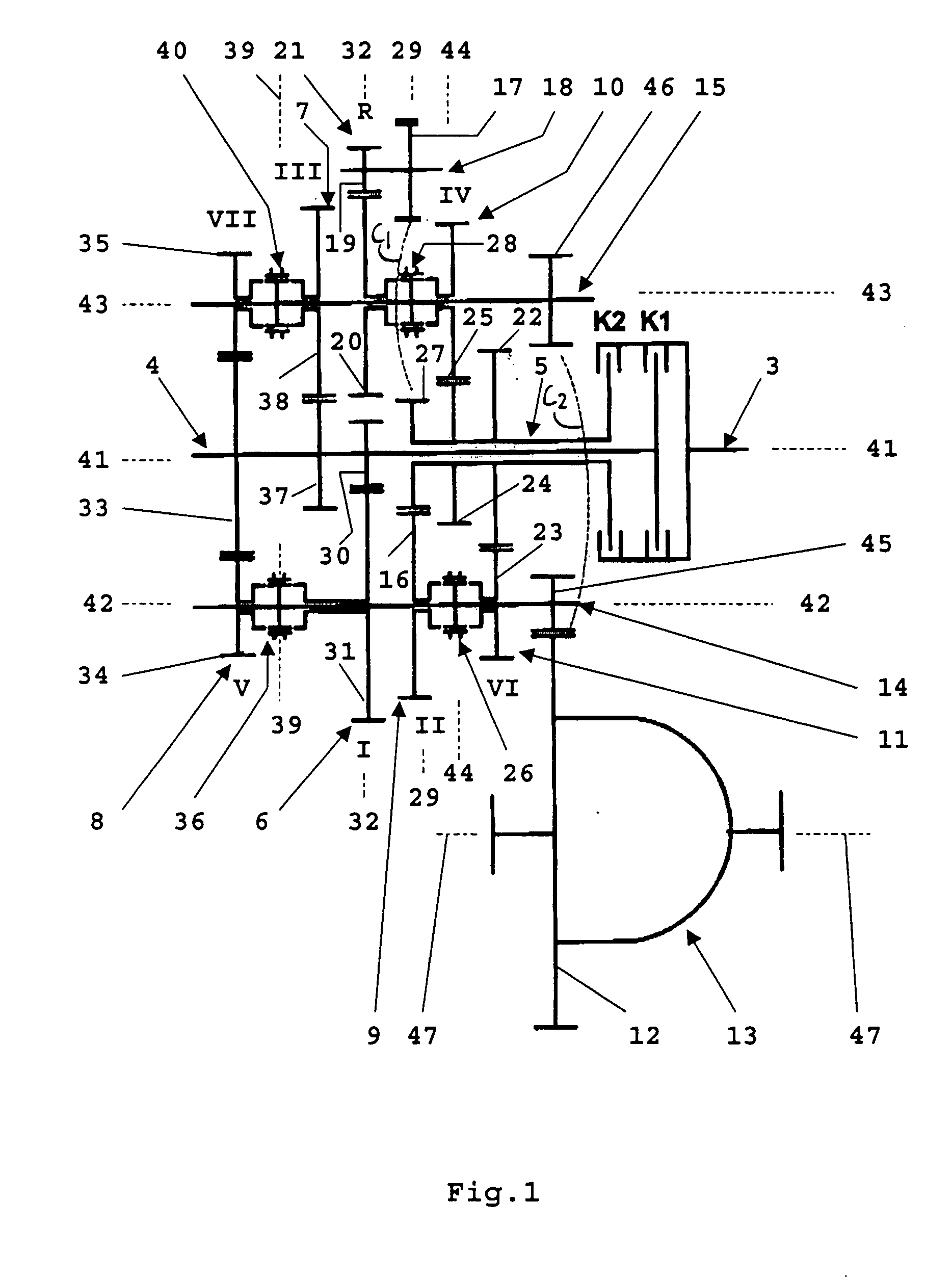

Double clutch transmission

InactiveUS20050193848A1Closely arrangedShort arrangementToothed gearingsTransmission elementsJackshaftTransverse engine

In a double clutch transmission in which an input shaft can be coupled by two load clutches selectively with a central intermediate shaft and a concentric intermediate shaft and each of the intermediate shafts can be operatively connected by gear stages selectively to a first or a second jackshaft arranged in the power output path to a driven vehicle axle, wherein the jackshafts are arranged parallel to the transmission input and intermediate shafts, the intermediate shafts each have at least one gear firmly mounted thereon which forms the input gear for more than one of the gear stages provided for different transmission gear ratios so as to form a compact transmission arrangement, particularly for transverse engine applications.

Owner:DAIMLER AG

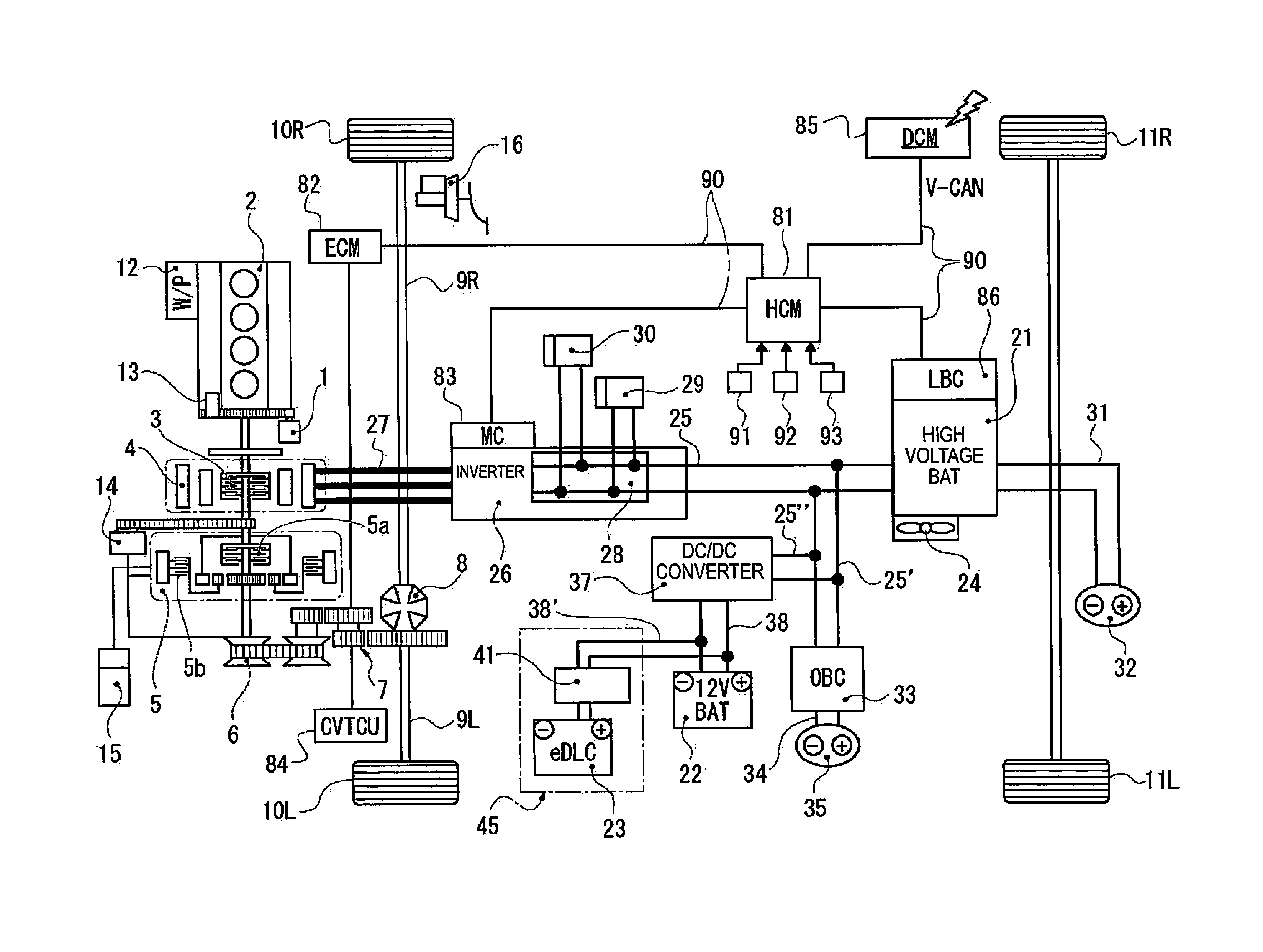

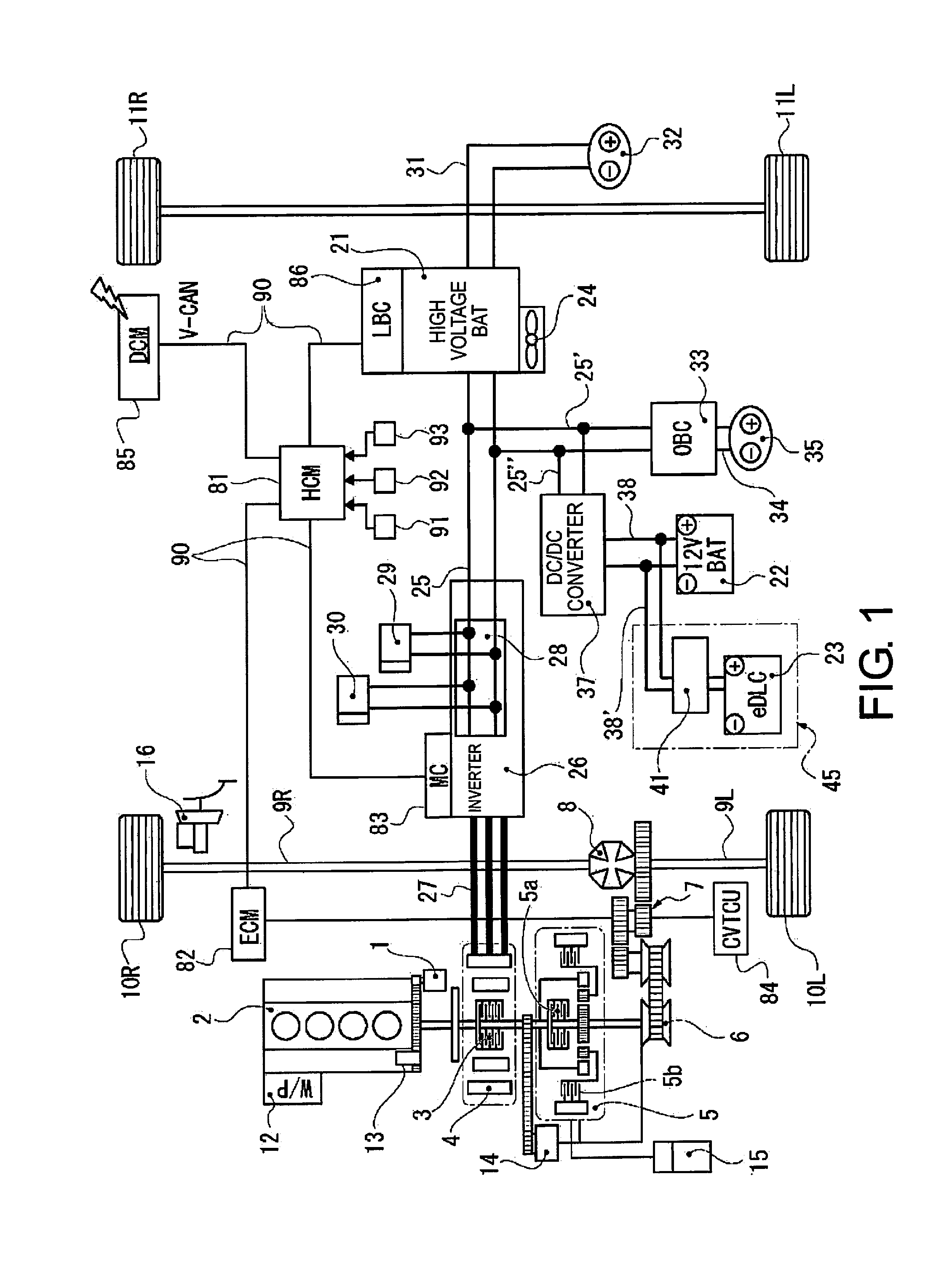

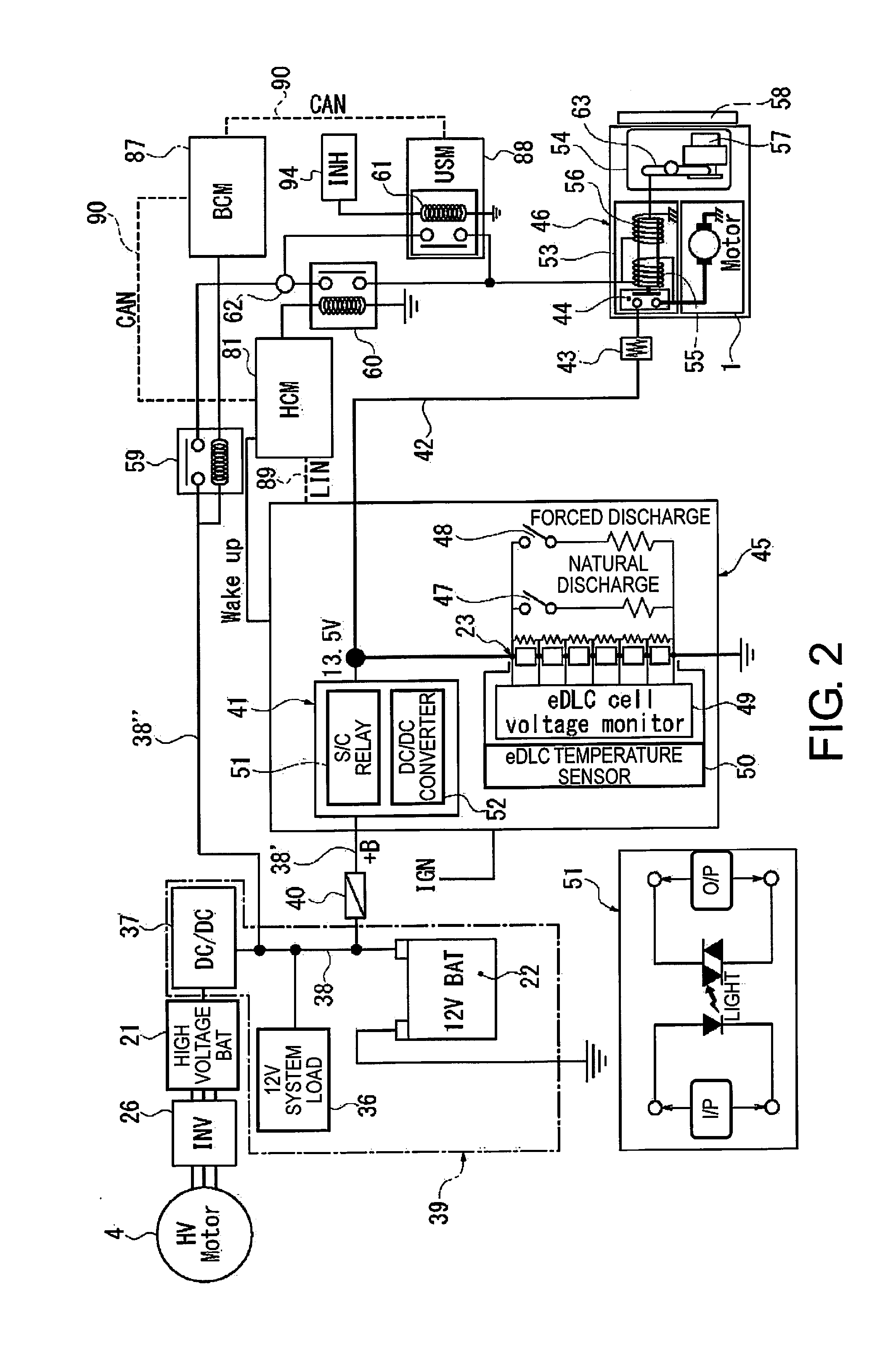

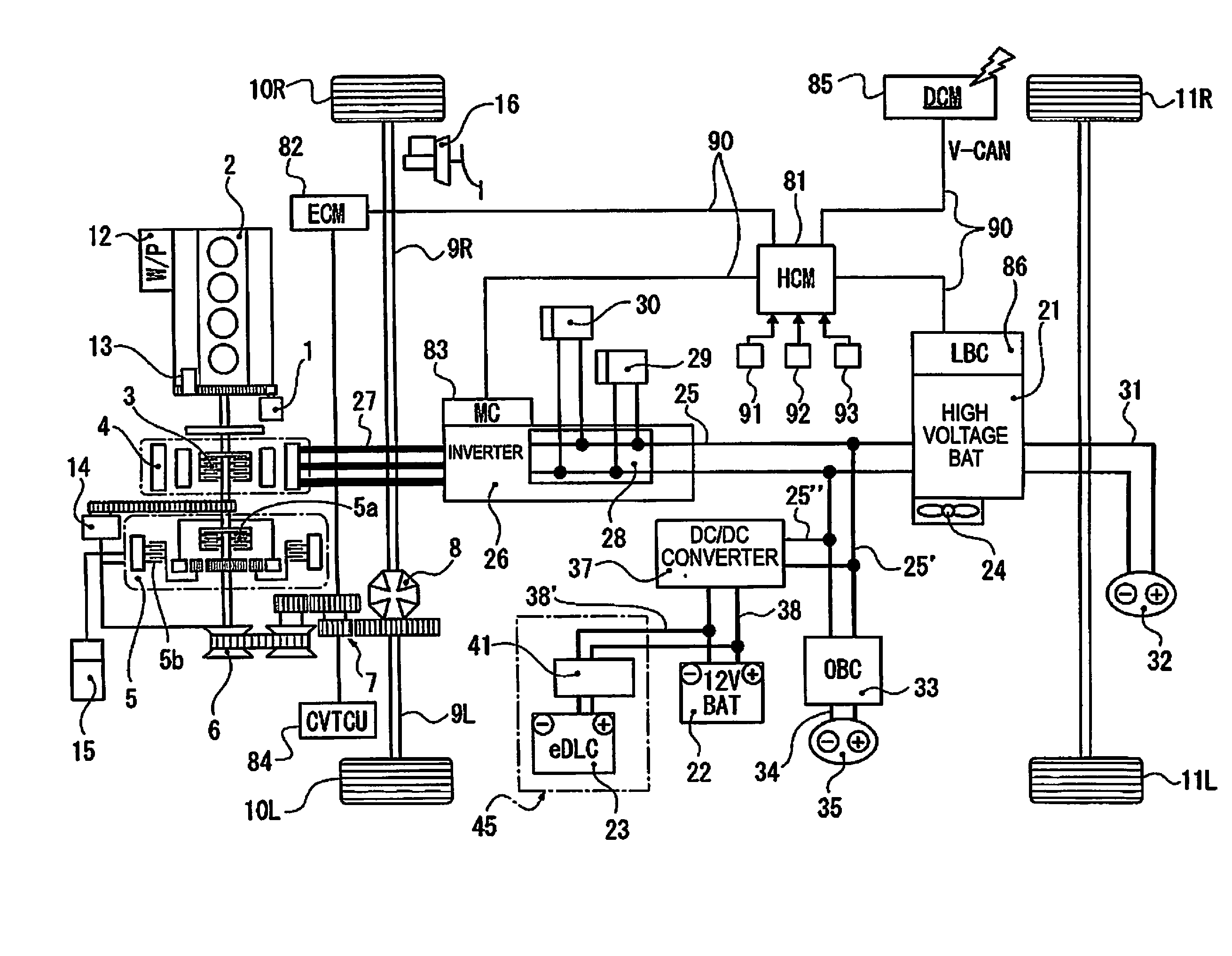

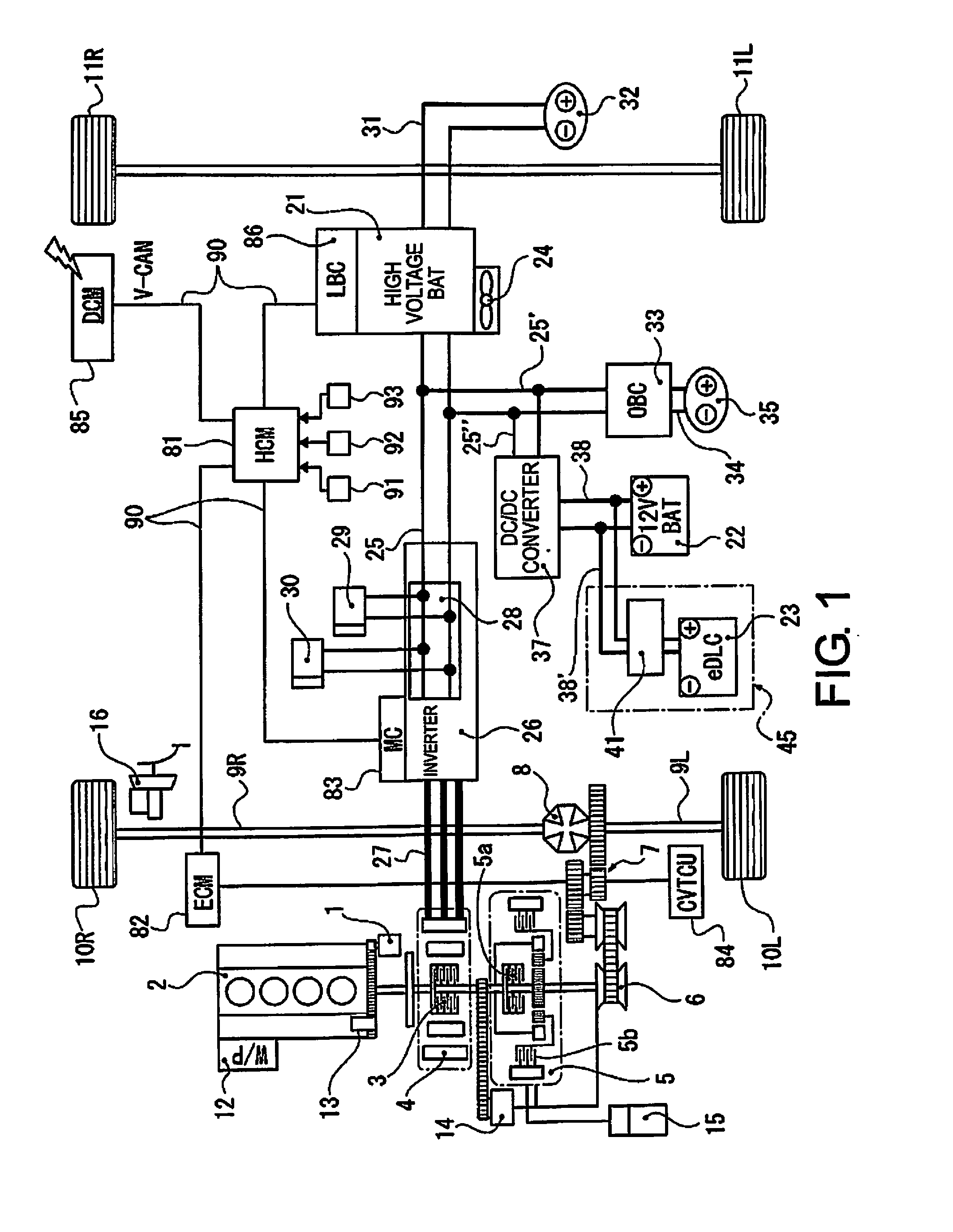

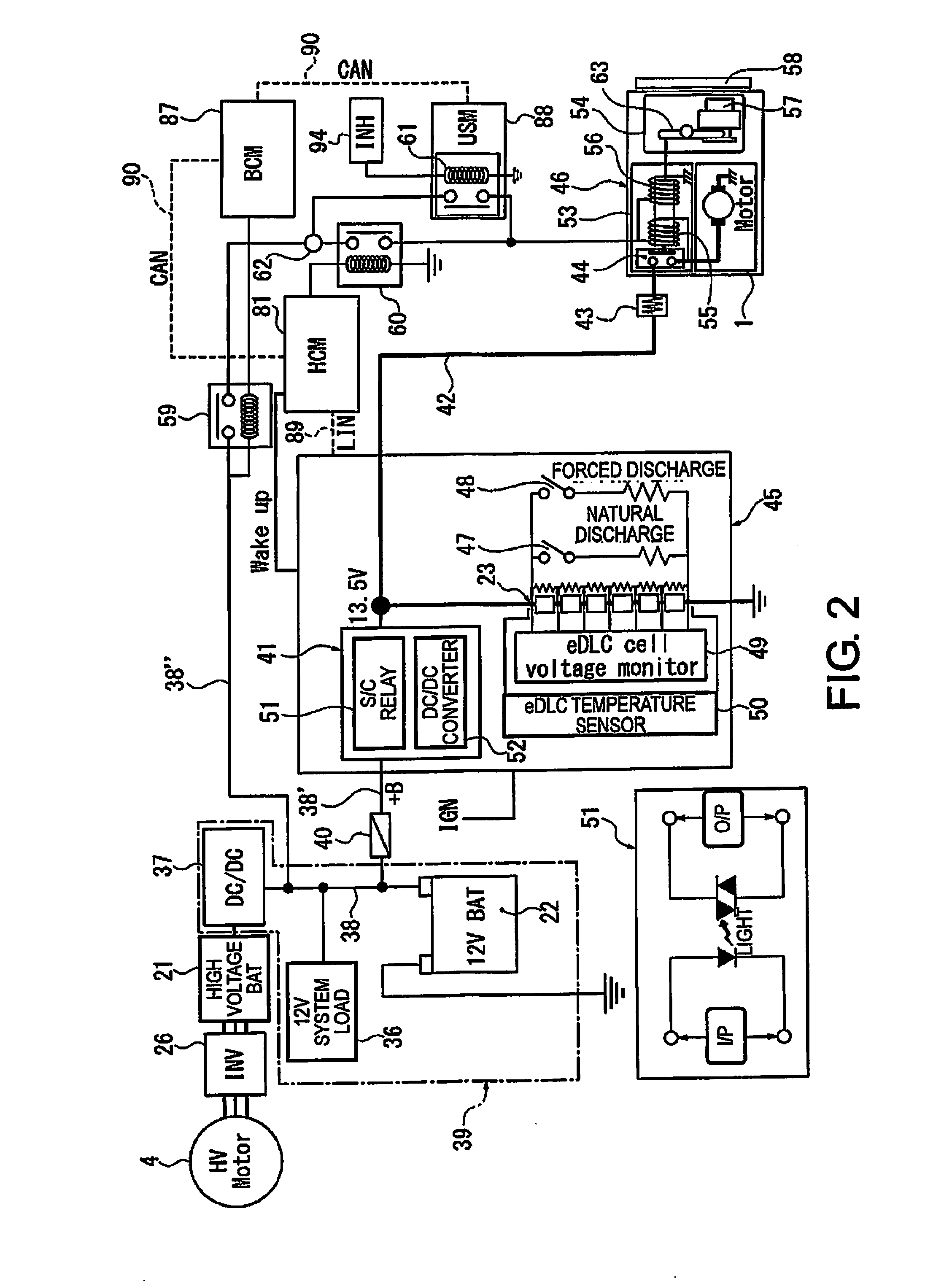

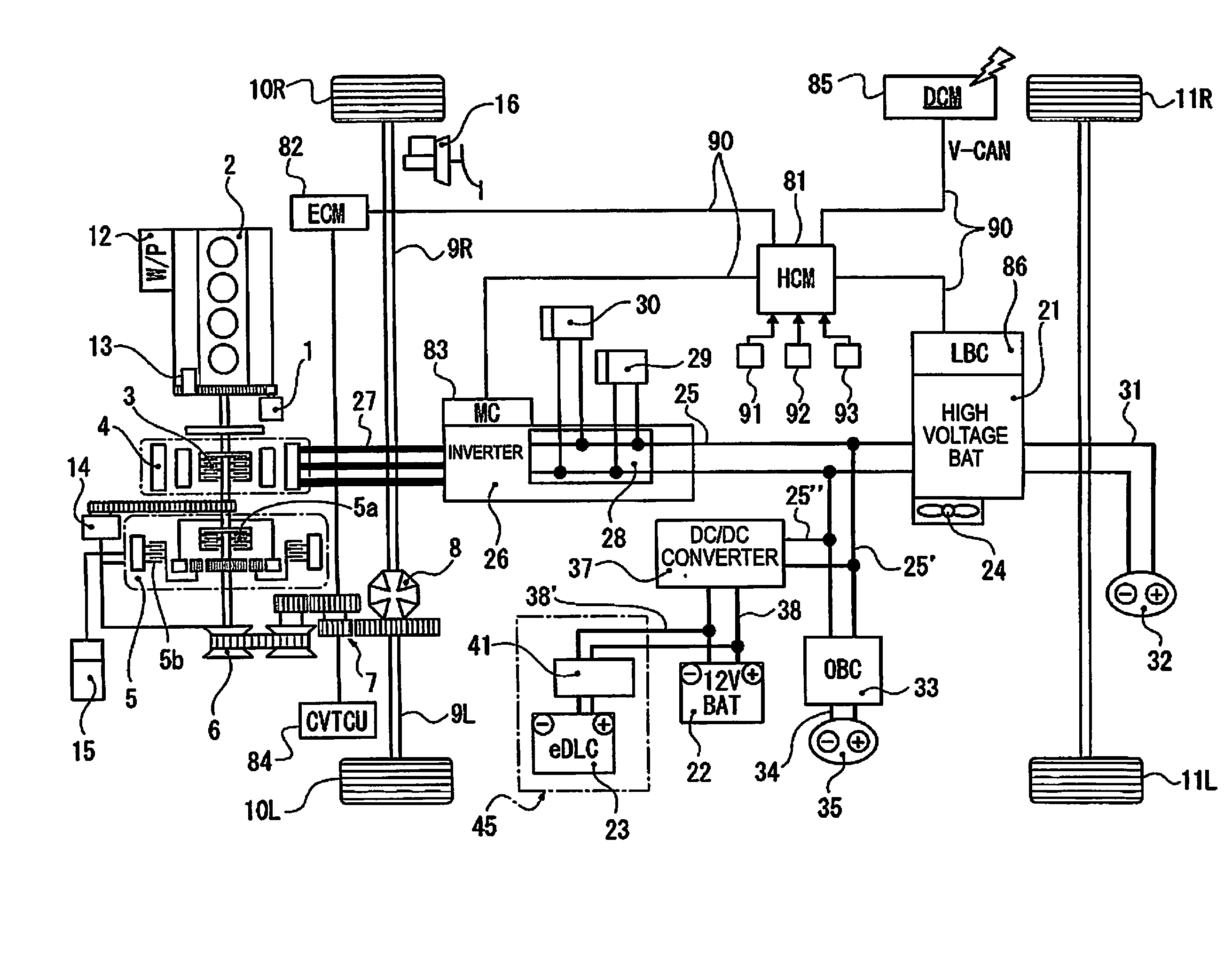

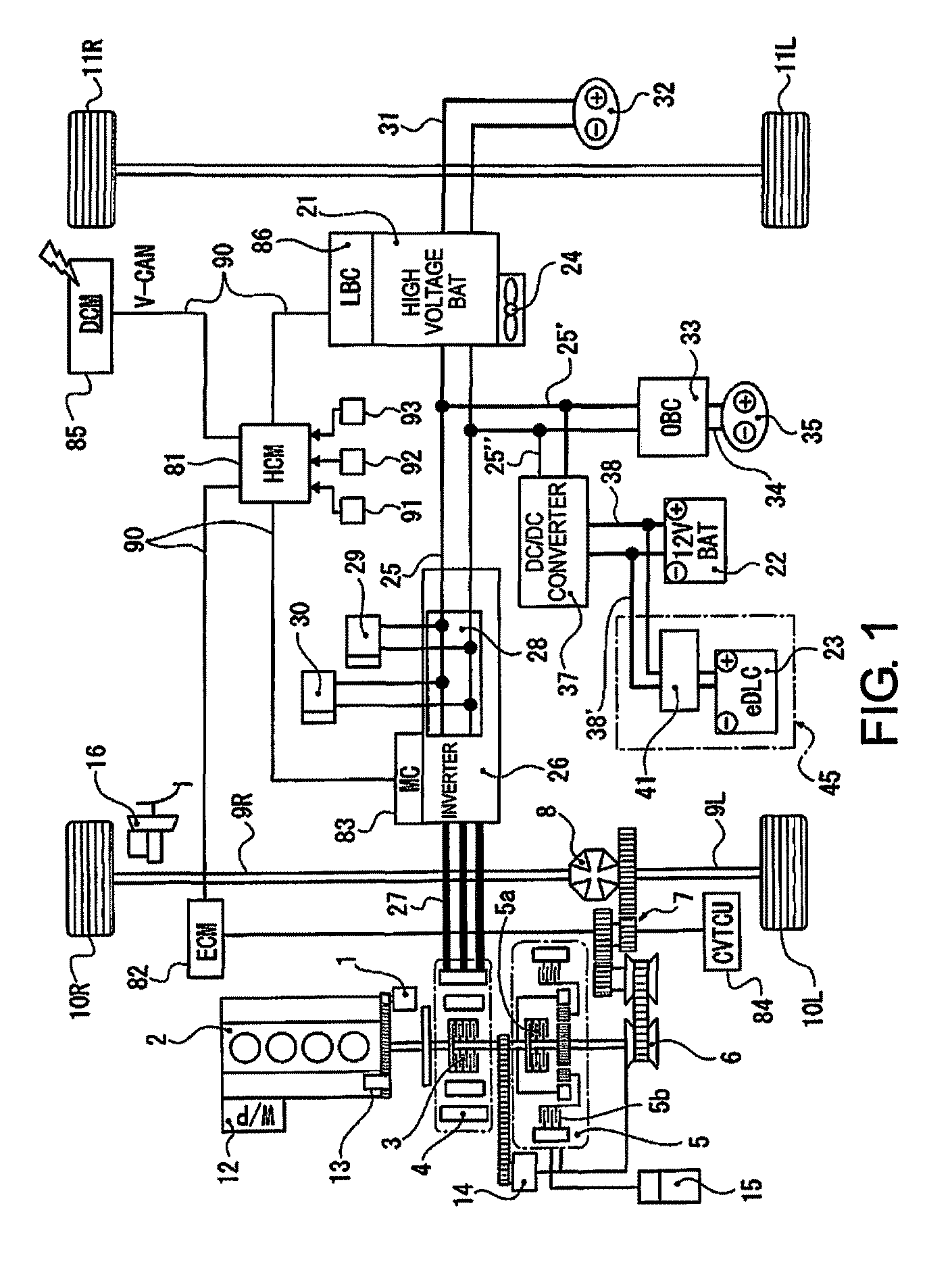

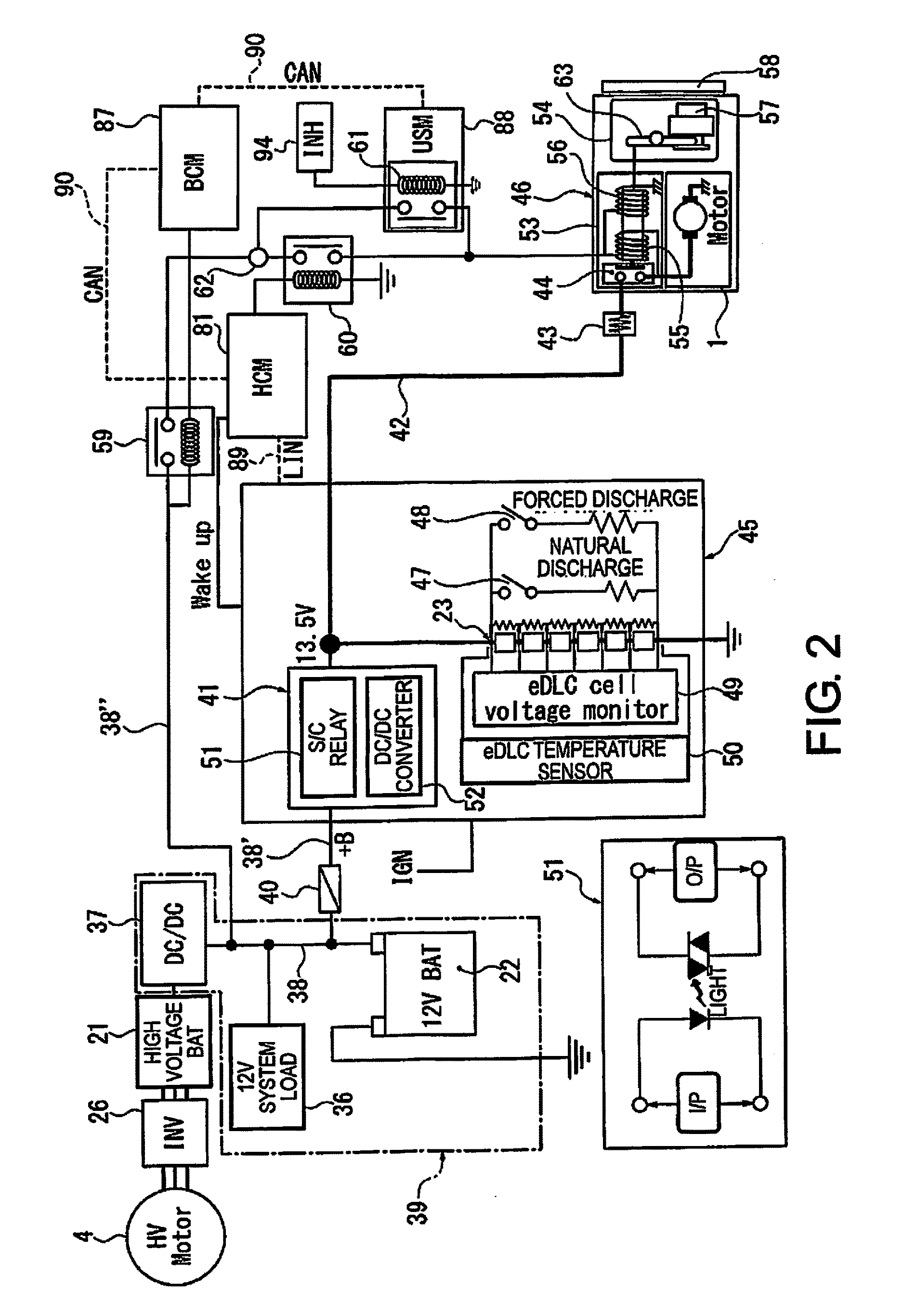

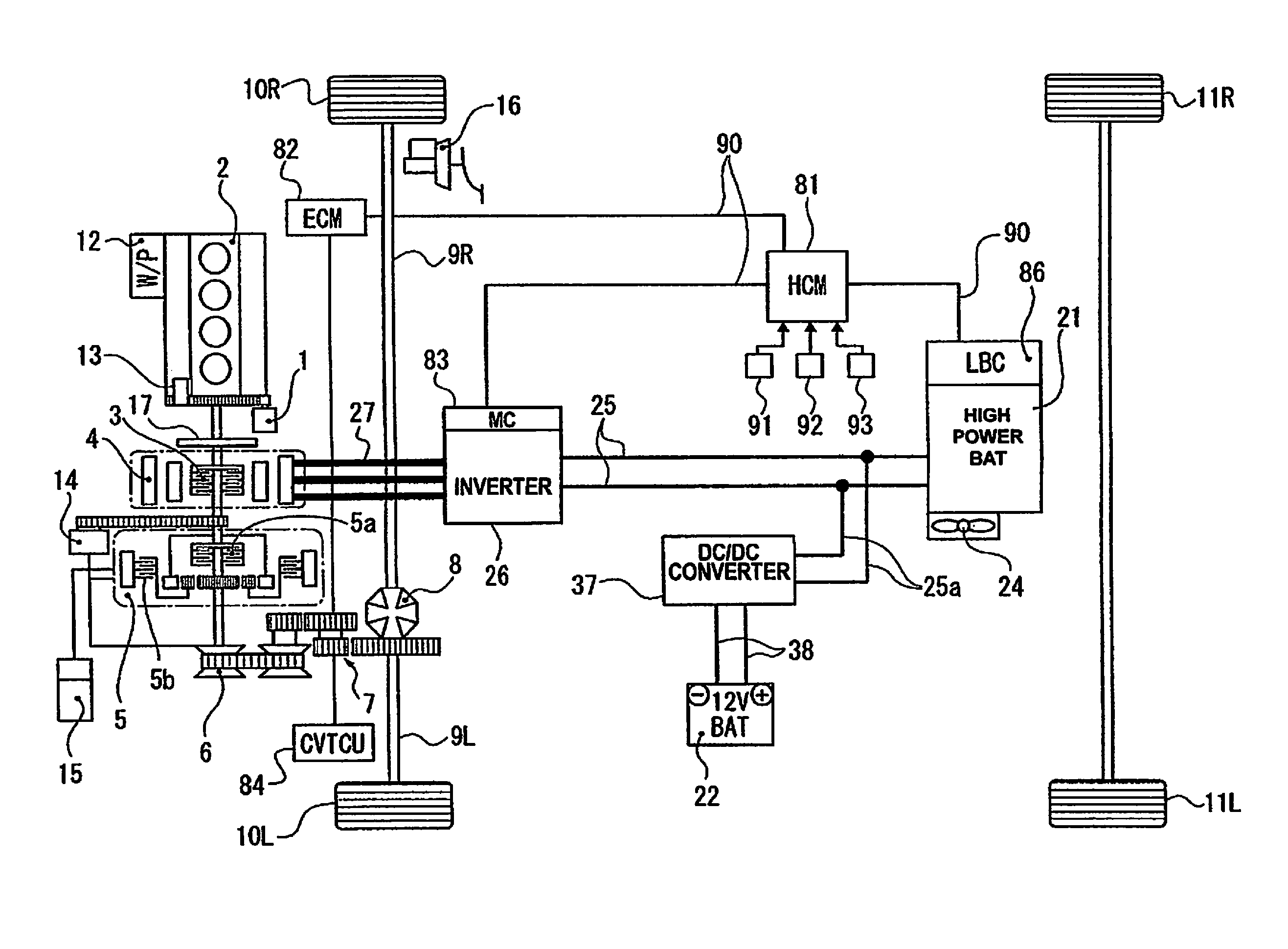

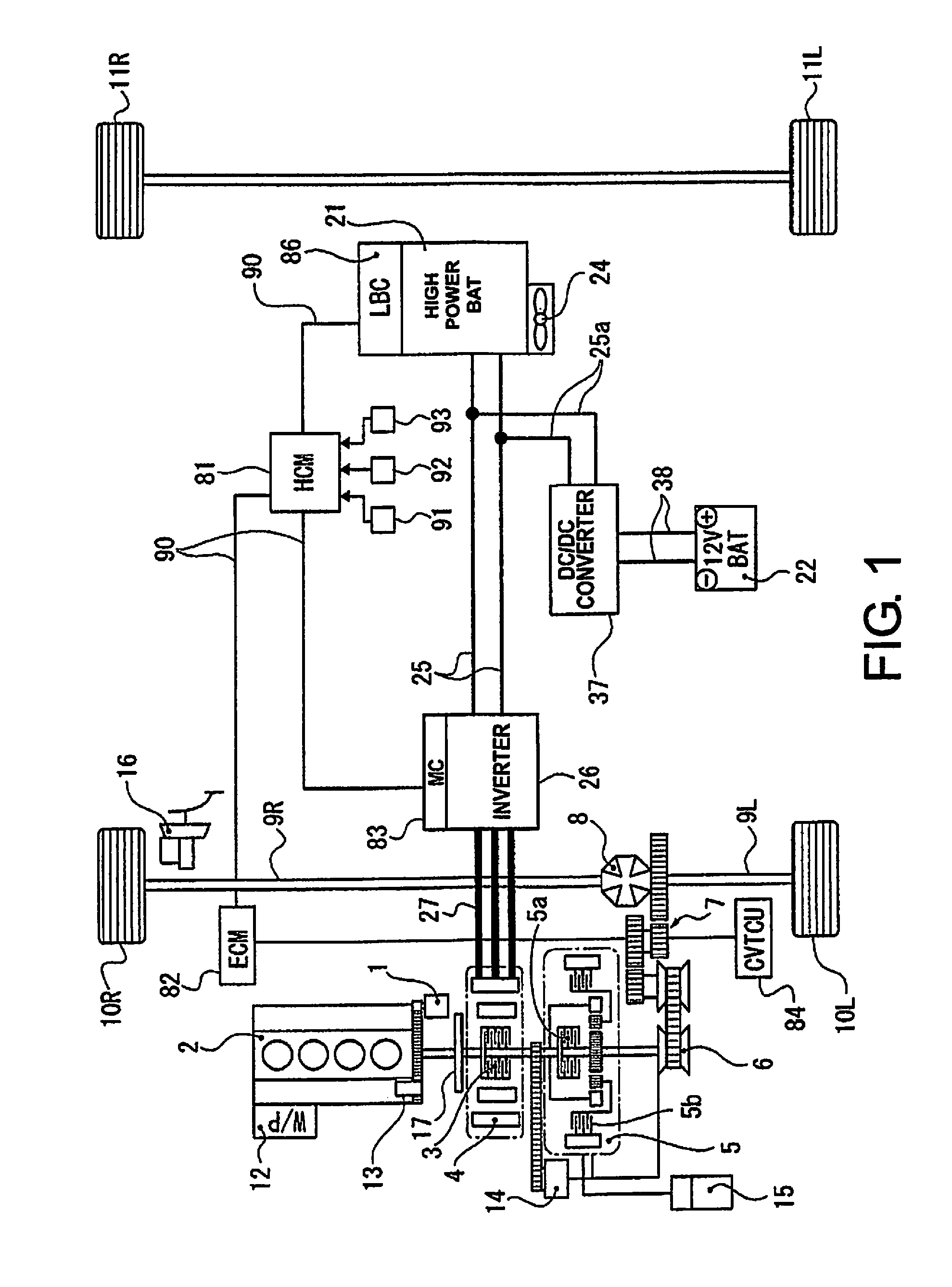

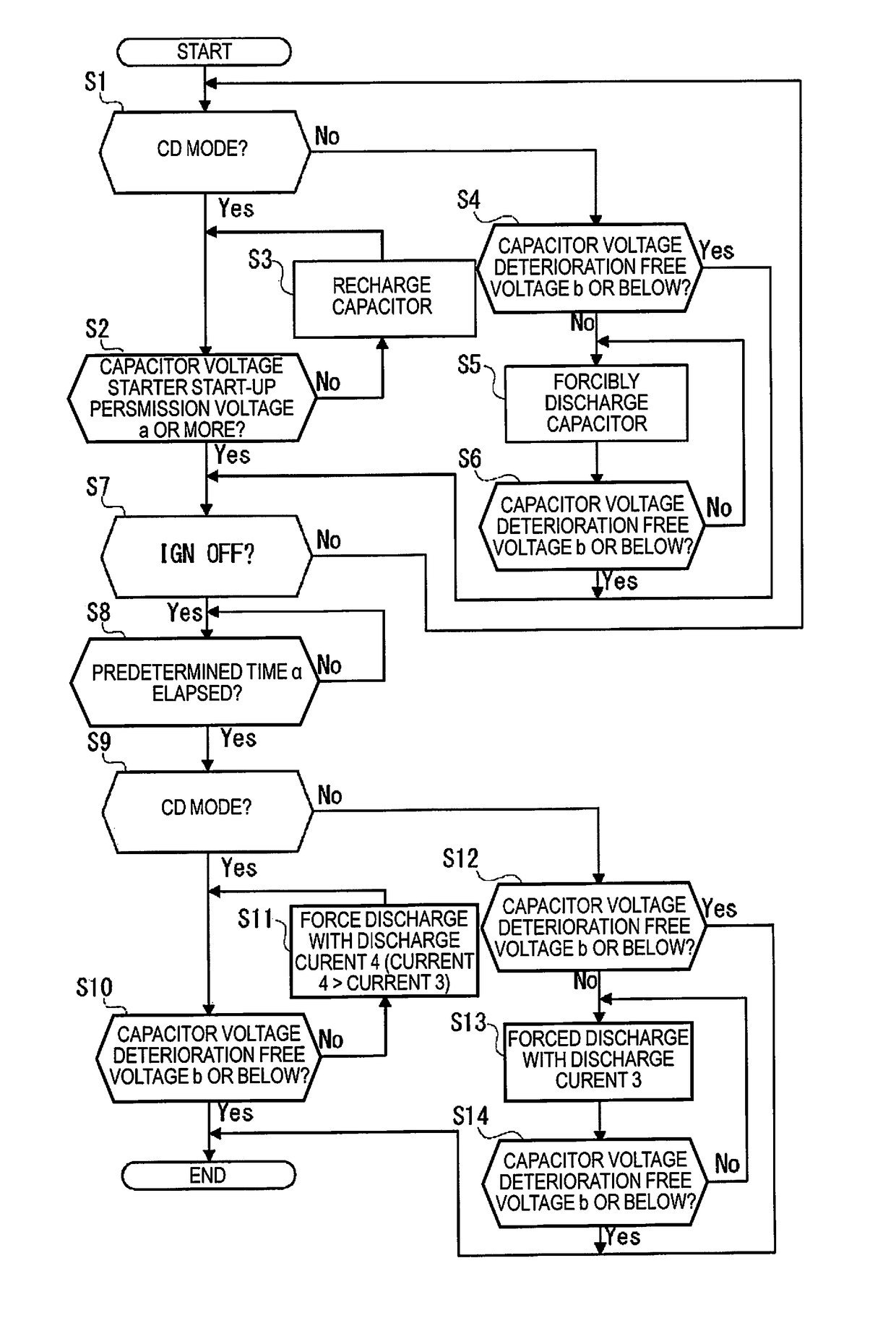

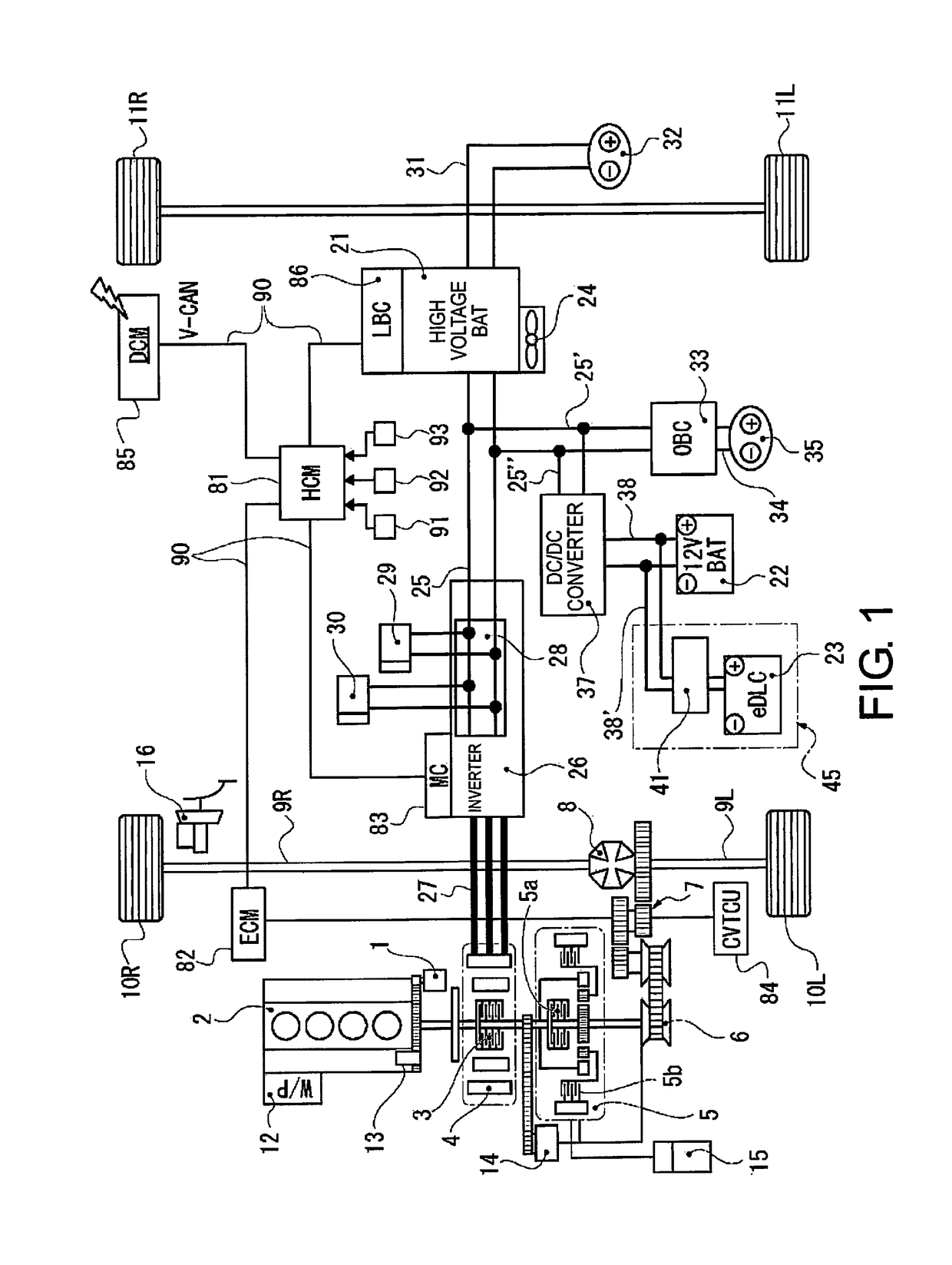

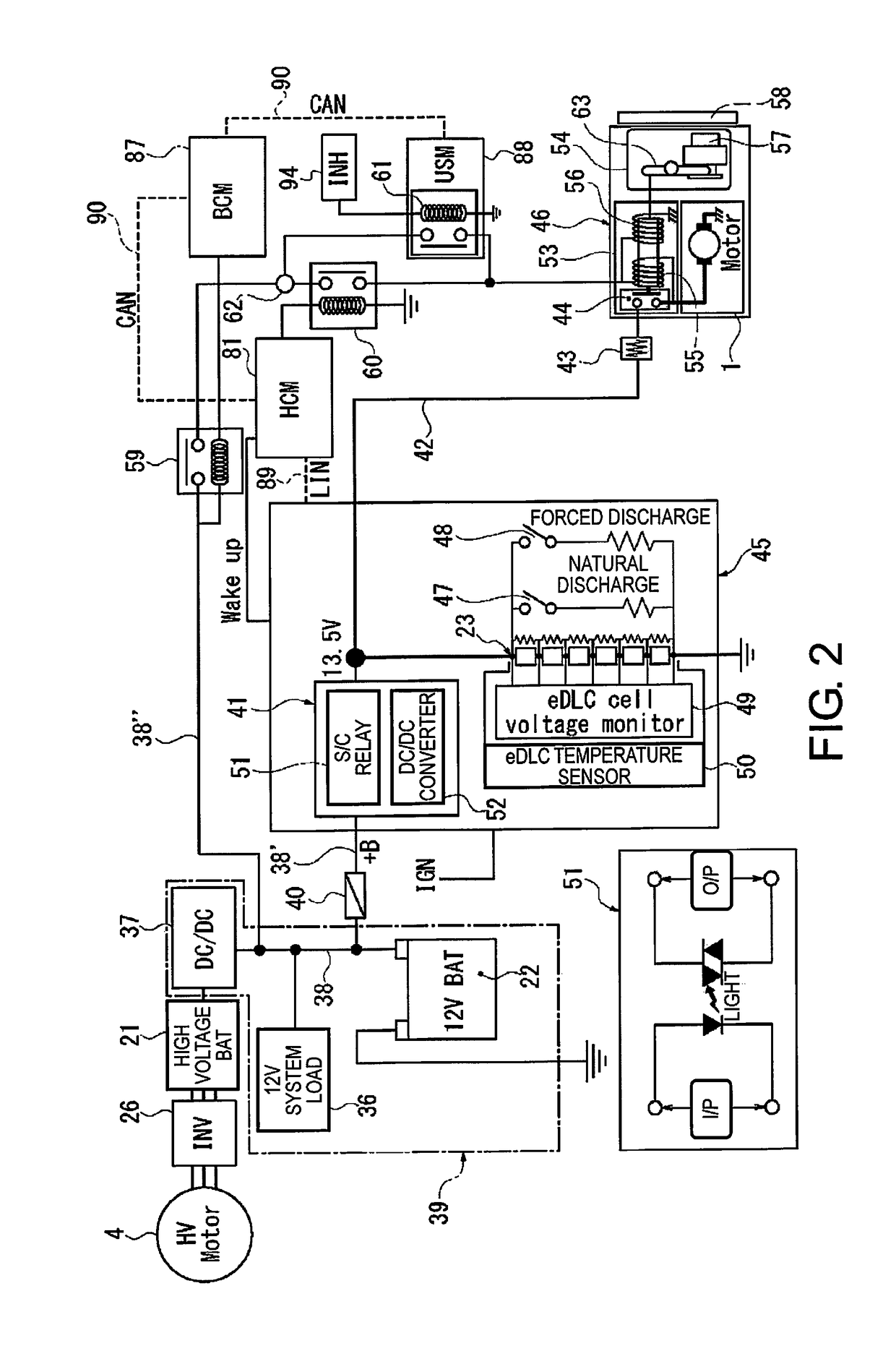

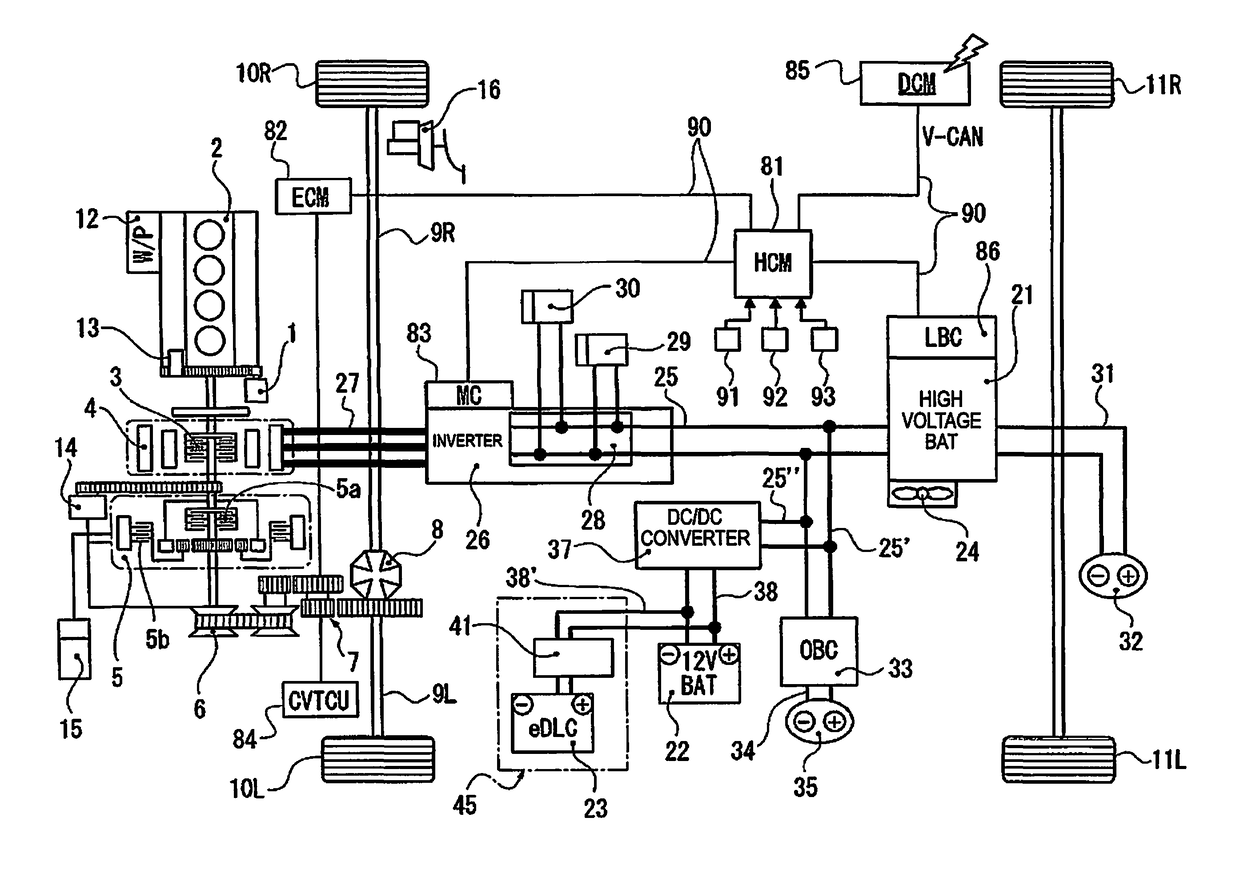

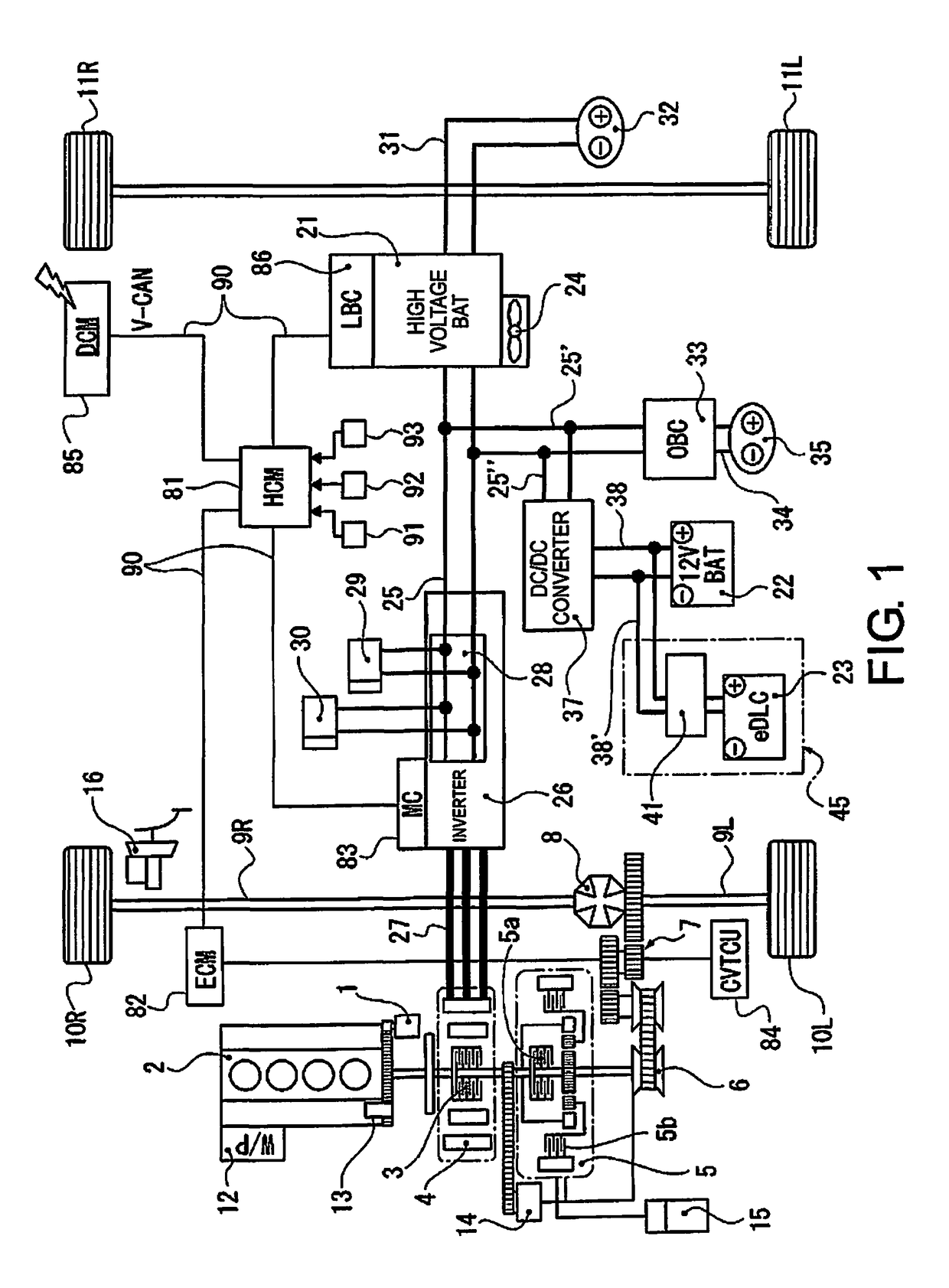

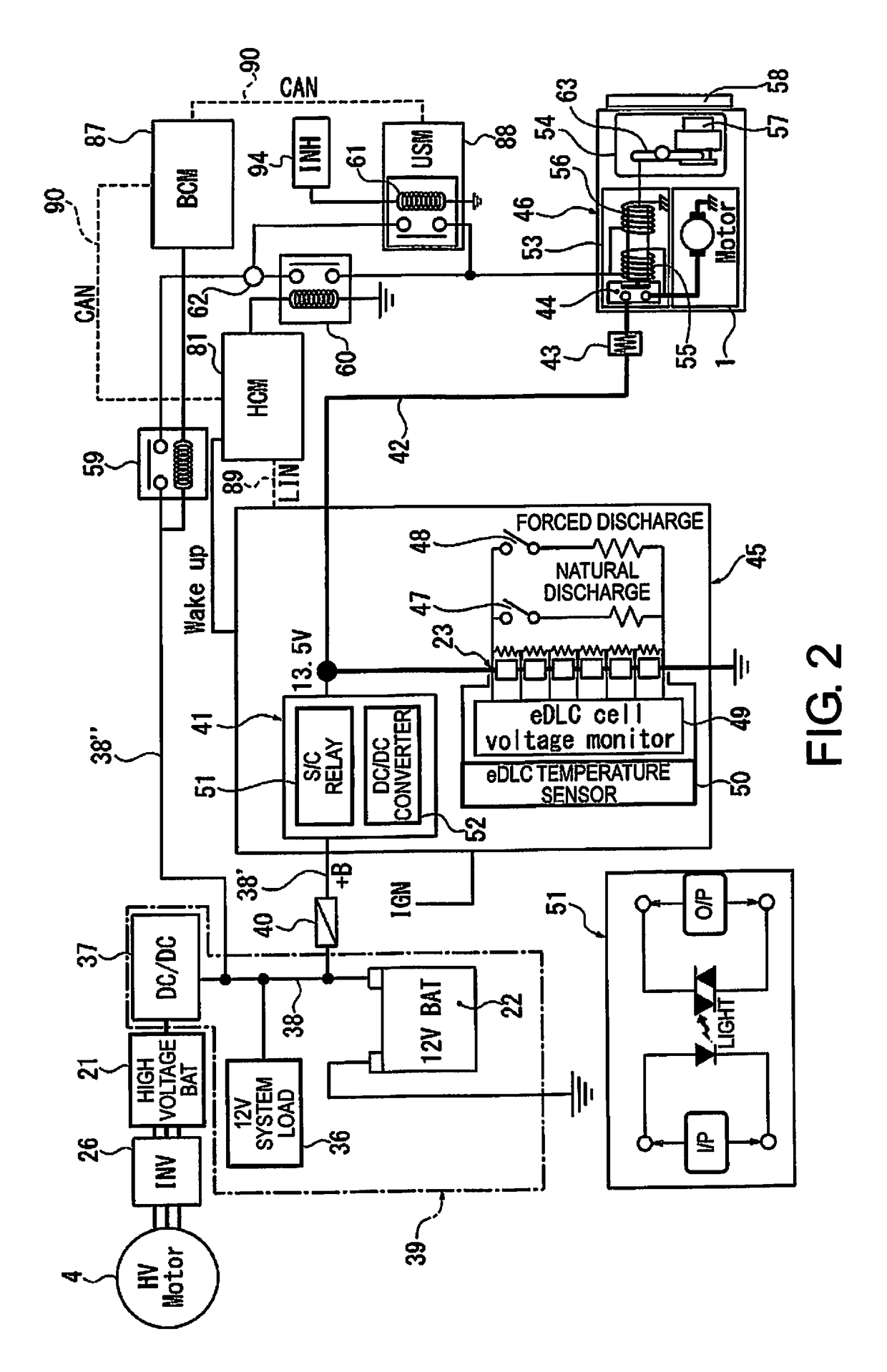

Control system for a plug-in hybrid vehicle

InactiveUS20160082946A1Inhibit deteriorationSuppression of progress of deteriorationHybrid vehiclesDigital data processing detailsCapacitor voltageTransverse engine

A control system for a plug-in hybrid vehicle has a drive system having a starter motor, a transverse engine, and a motor / generator, and also has a power supply system having a high voltage battery; a capacitor; and a hybrid control module that controls charge and discharge of the capacitor. In the control system for an FF plug-in hybrid vehicle in which external charging of the high voltage battery is available, the hybrid control module starts the starter, performs a mode selection control and a charge / discharge control, maintains the capacitor voltage equal to or higher than a voltage that allows the starter to start-up when a CD mode is selected at the time of ignition ON, and maintains a capacitor voltage equal to or less than a voltage at which deterioration does not proceed at the time of ignition ON with the CS being selected.

Owner:NISSAN MOTOR CO LTD

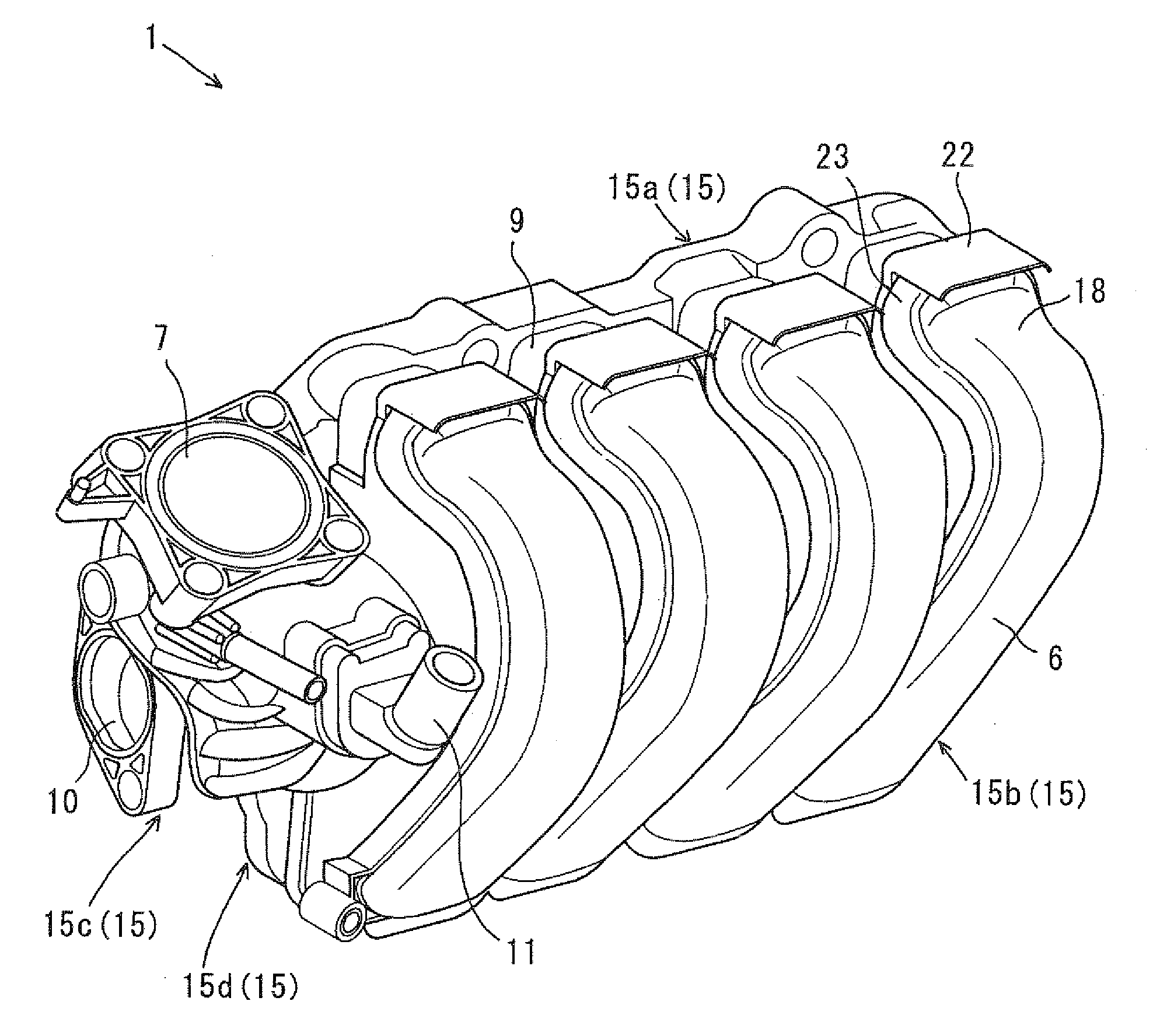

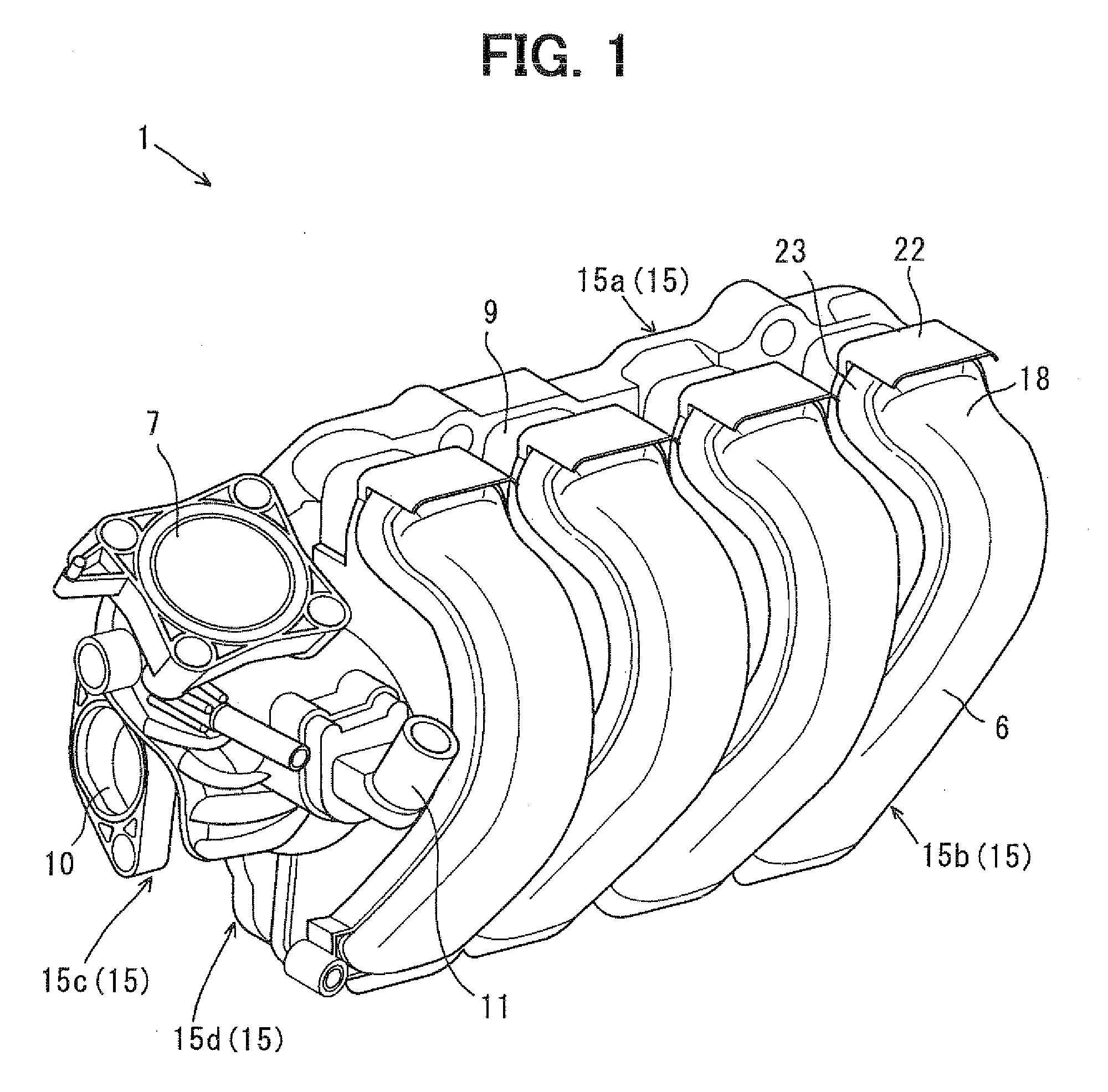

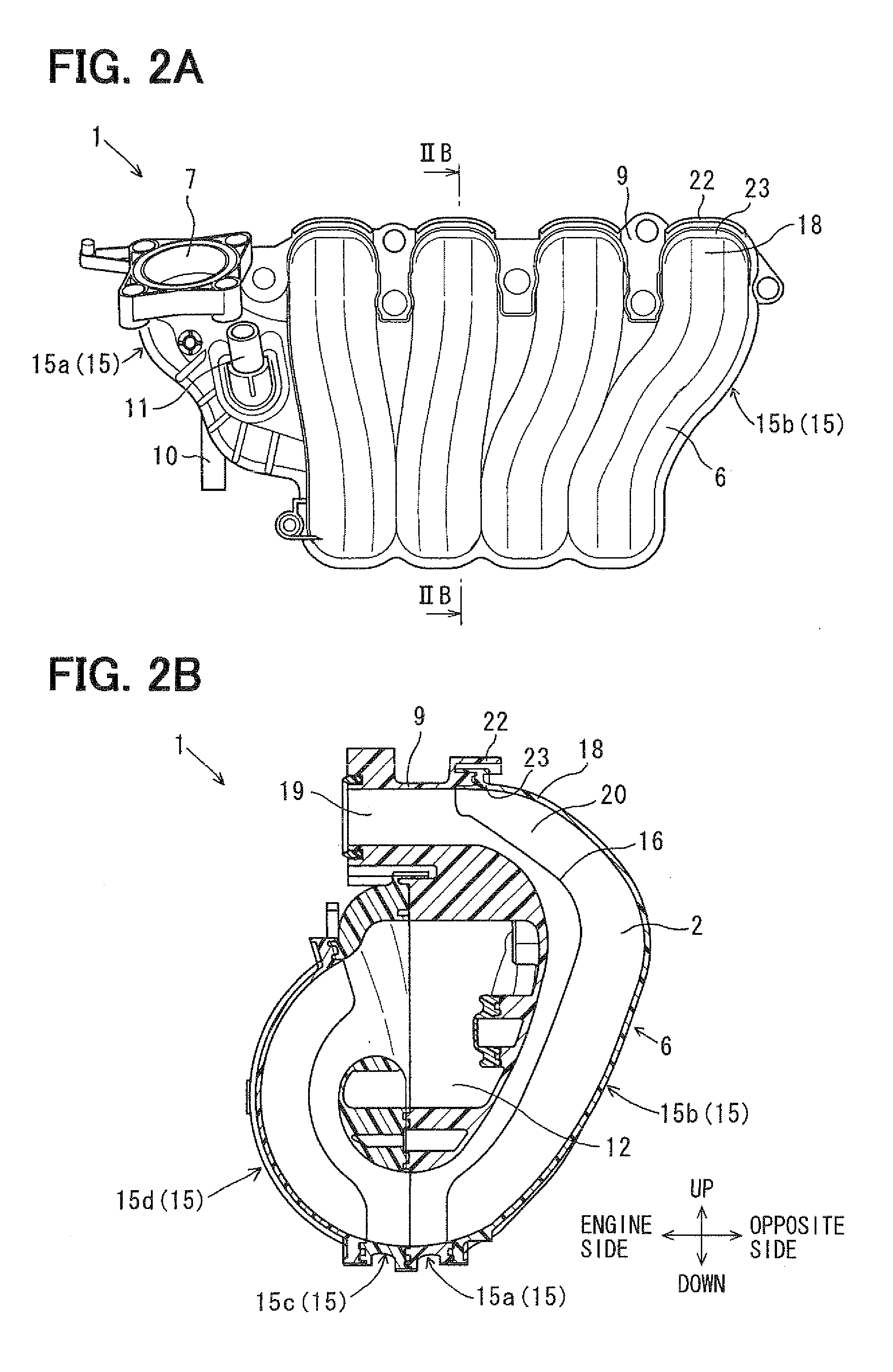

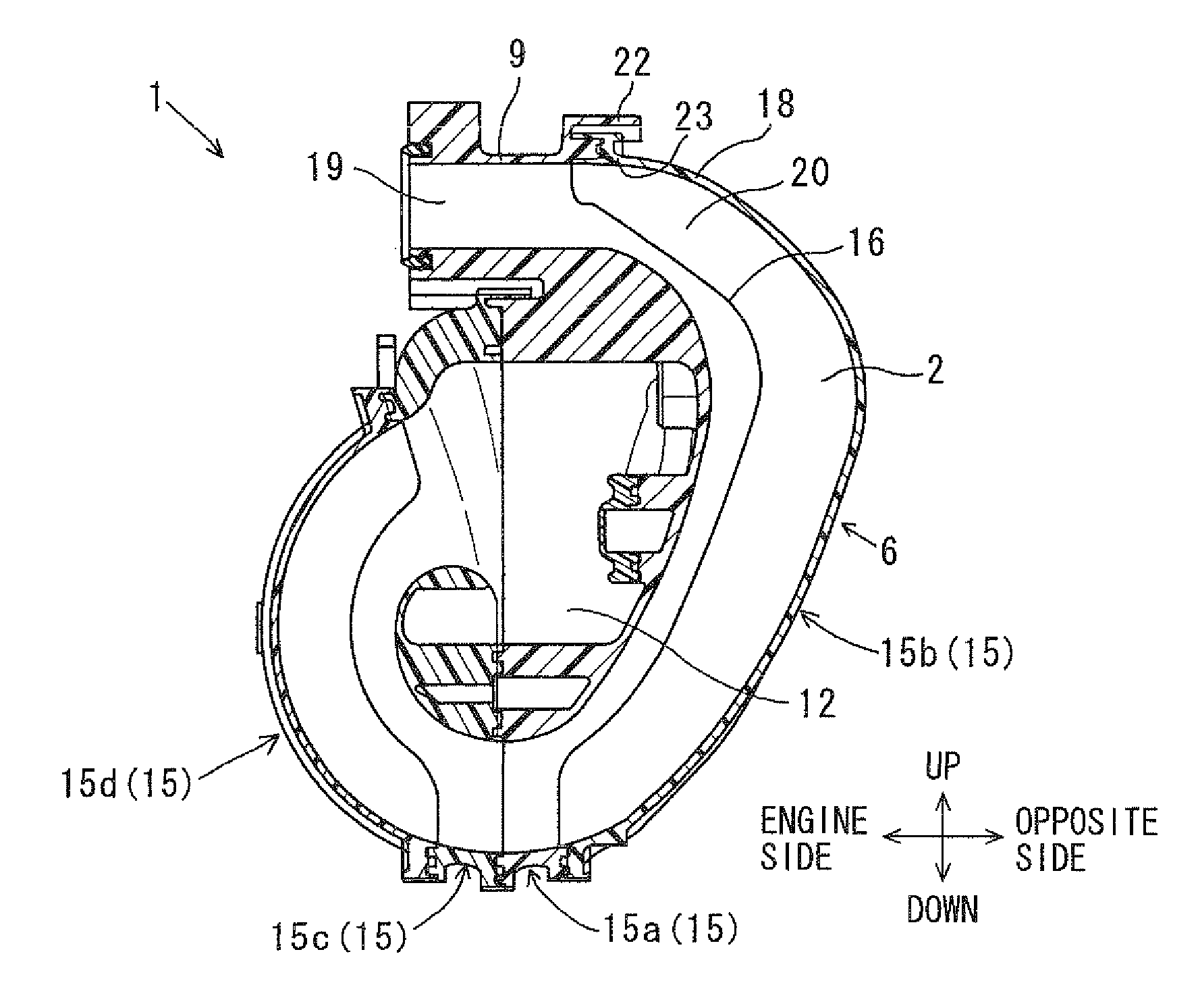

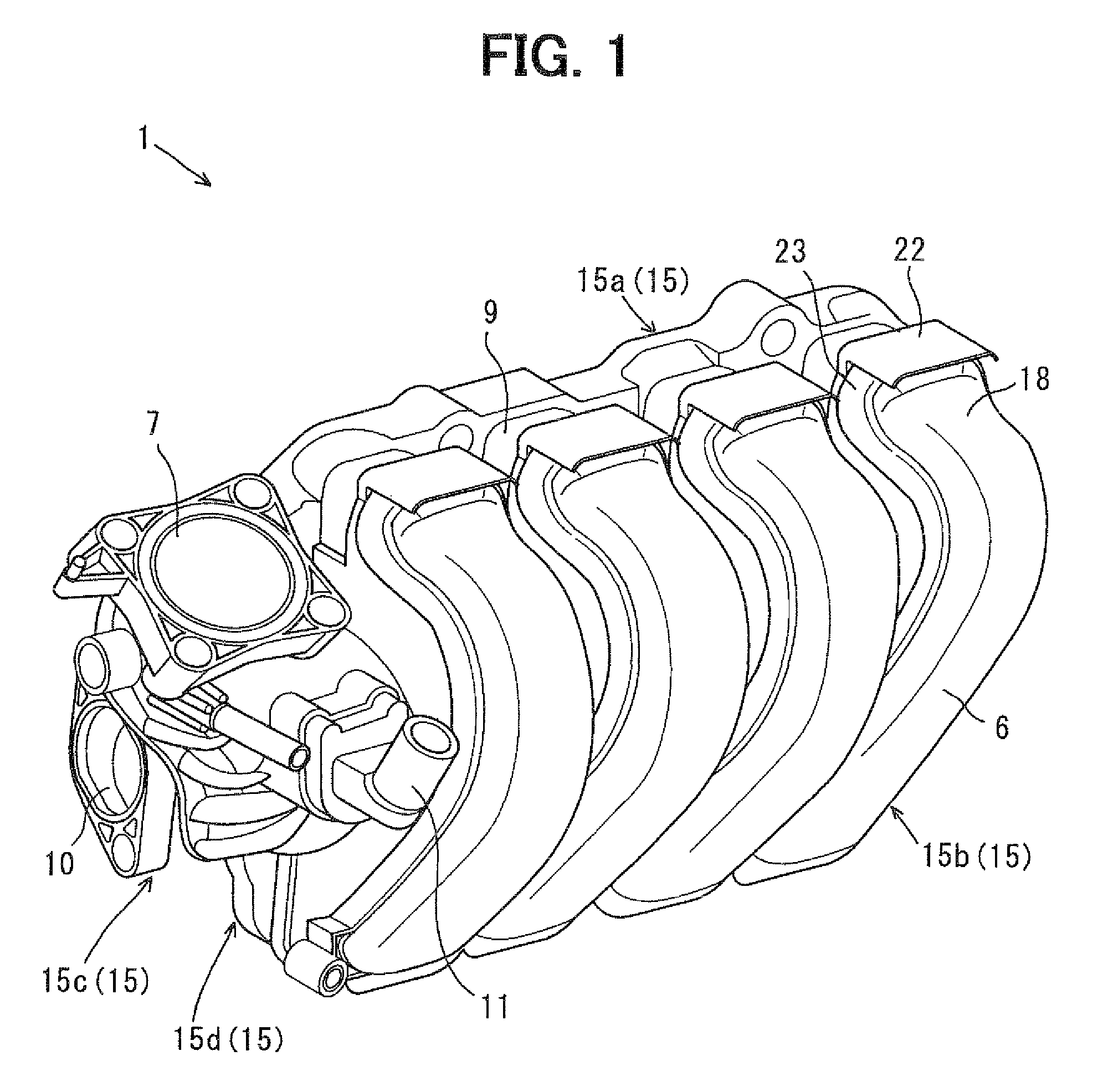

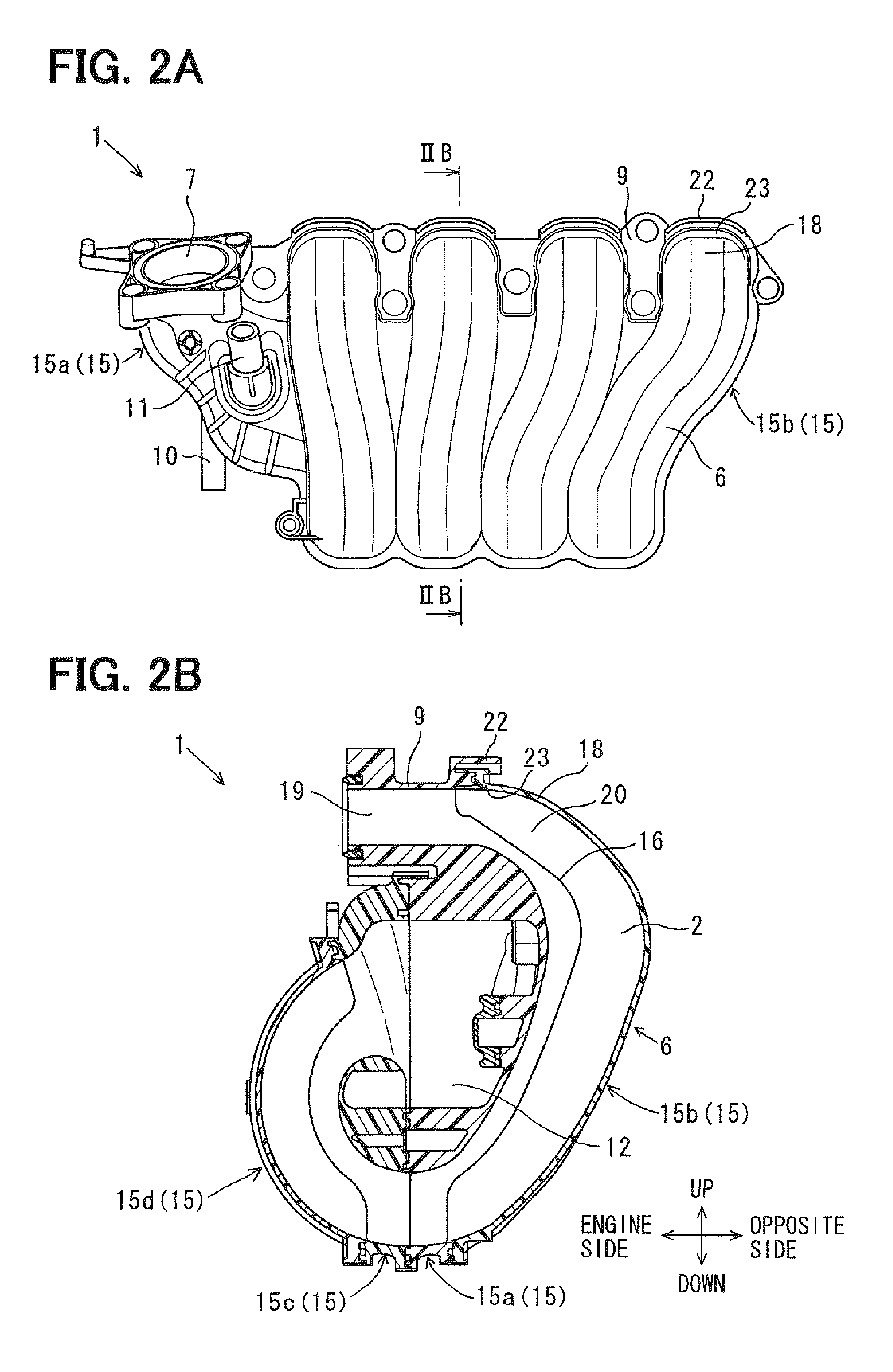

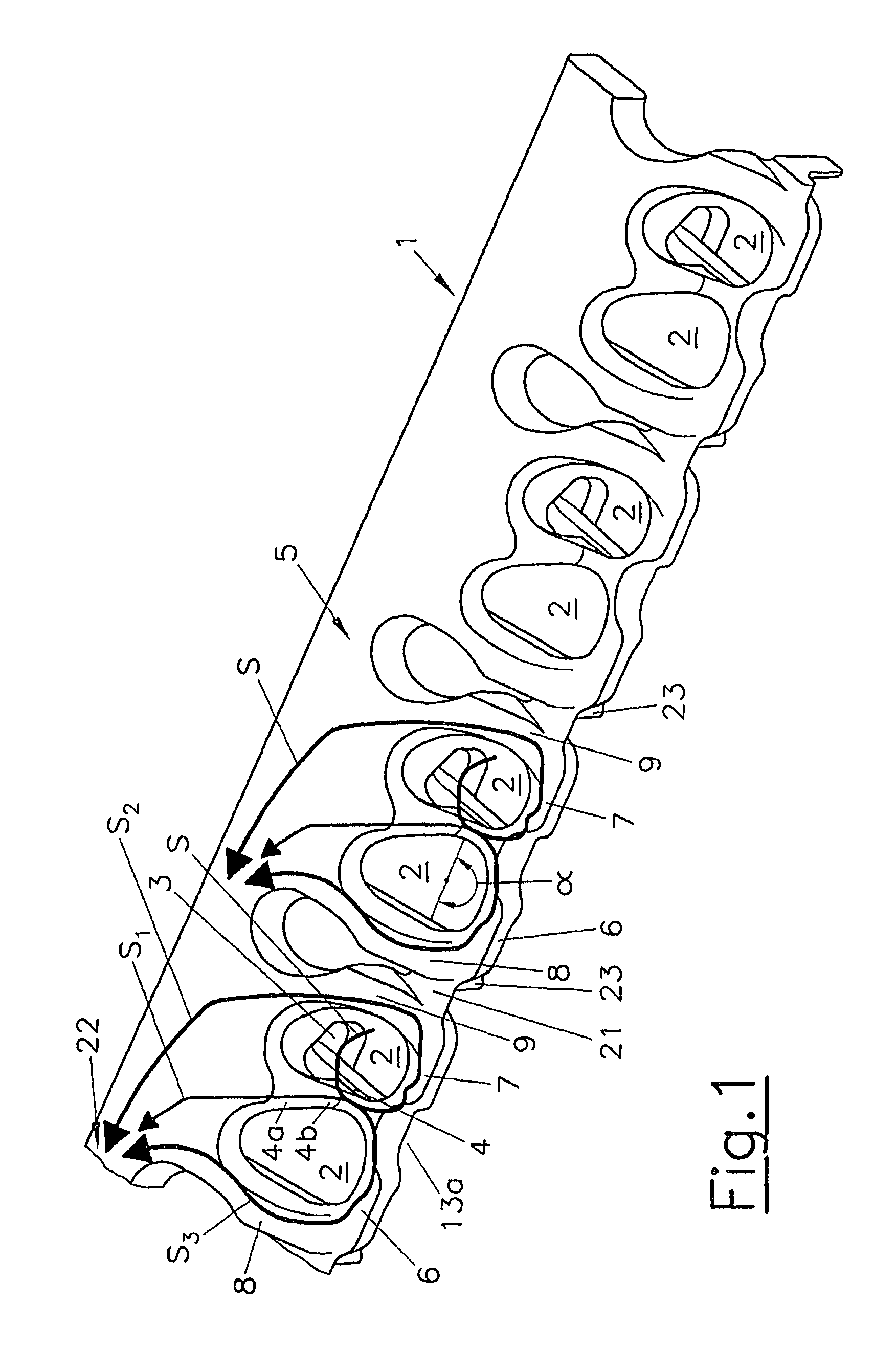

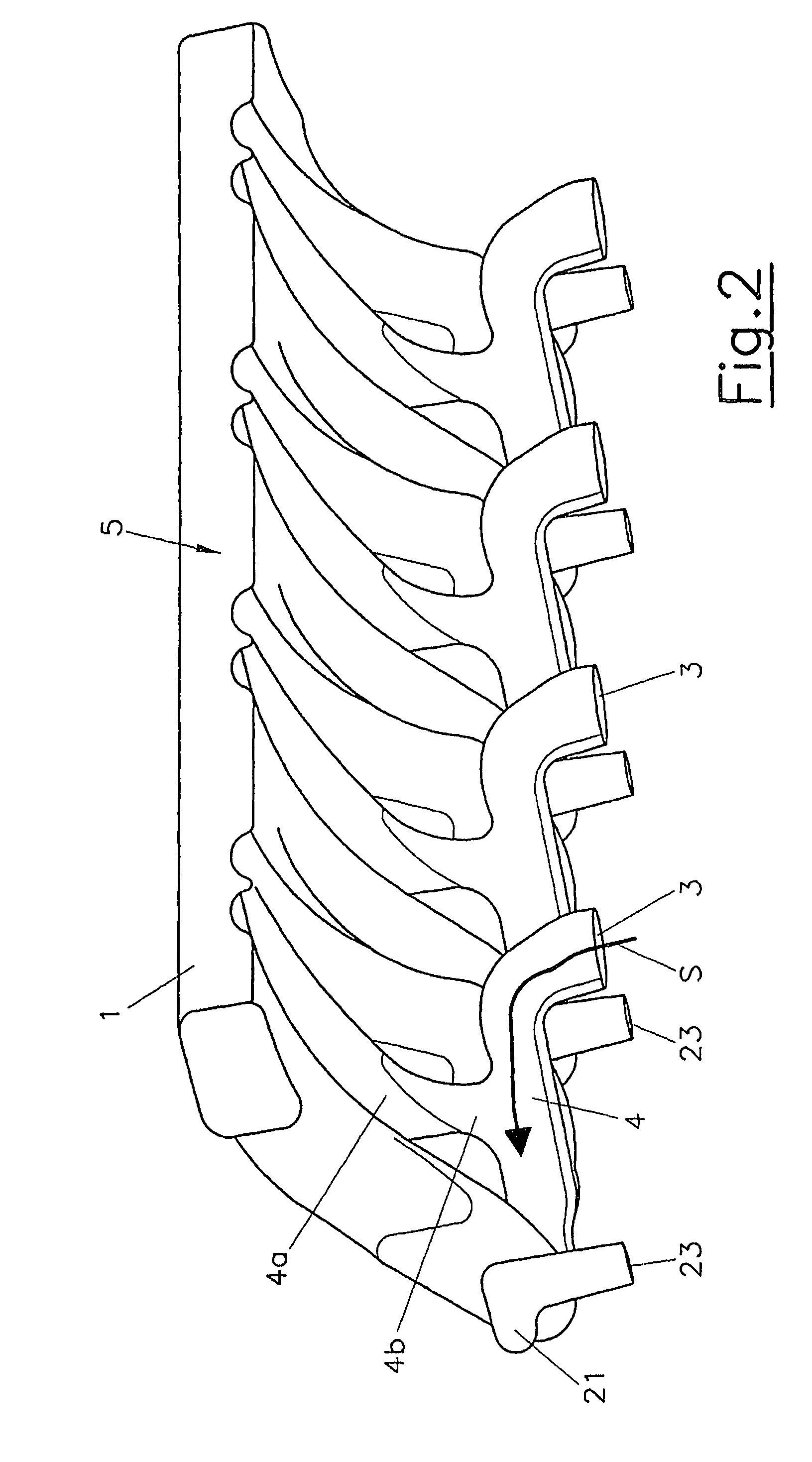

Intake manifold

InactiveUS20090241886A1Reduce the possibilityMachines/enginesAir intakes for fuelTransverse engineEngineering

An intake manifold to be mounted to a traverse engine includes pieces made of resin and welded to each other. The pieces are constructed with a first piece having a connector to be connected to the engine, and a second piece. The second piece has an upper positioning part overlapping with the first piece except for the connector having a linear-shaped outlet passage. The upper positioning part is welded to the first piece so as to define an upstream side passage of the outlet passage. The first piece has a cover, which covers the upper positioning part defining a downstream end of the upstream side passage.

Owner:DENSO CORP

Control system for a plug-in hybrid vehicle

InactiveUS20160107635A1Shorten the timeSuppressing deterioration progressPower operated startersInternal combustion piston enginesCapacitor voltageElectrical battery

A control system for a plug-in hybrid vehicle includes a drive system including a starter motor, a transverse engine, and a motor / generator, and a power supply system including a high voltage battery, a capacitor, and a hybrid control module that controls charging and discharging of the capacitor. In the control system for an FF plug-in hybrid vehicle in which an external charging of the high-power battery is available, the hybrid control module starts the starter, performs mode selection control and charge / discharge control, maintains a capacitor voltage at or below a deterioration free voltage when the CS mode is selected during ignition on, and recharges the capacitor to a starter start-up permission voltage that allows the starter to start when a pre-forecast of the reverse transition from the CS mode to the CD mode is established.

Owner:NISSAN MOTOR CO LTD

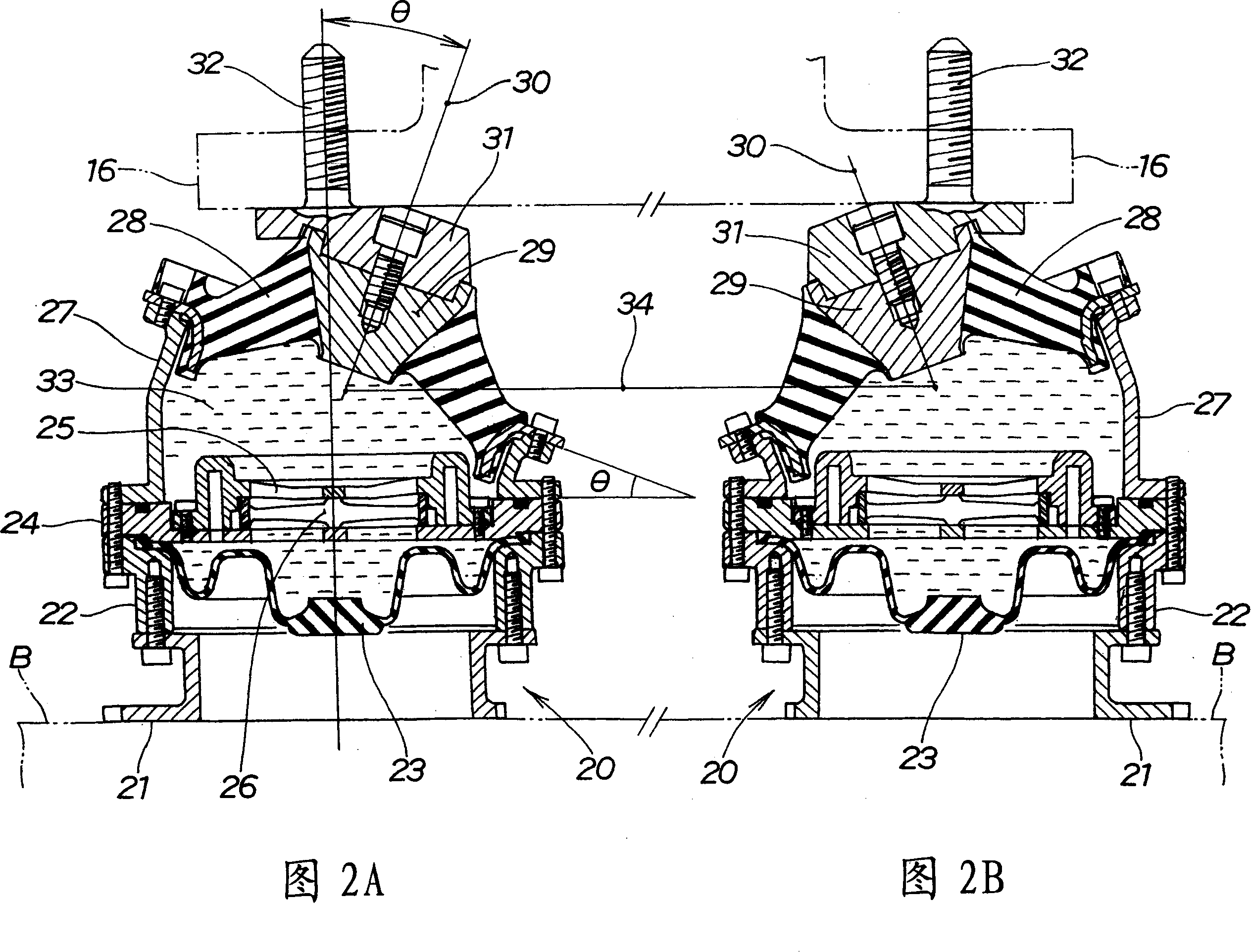

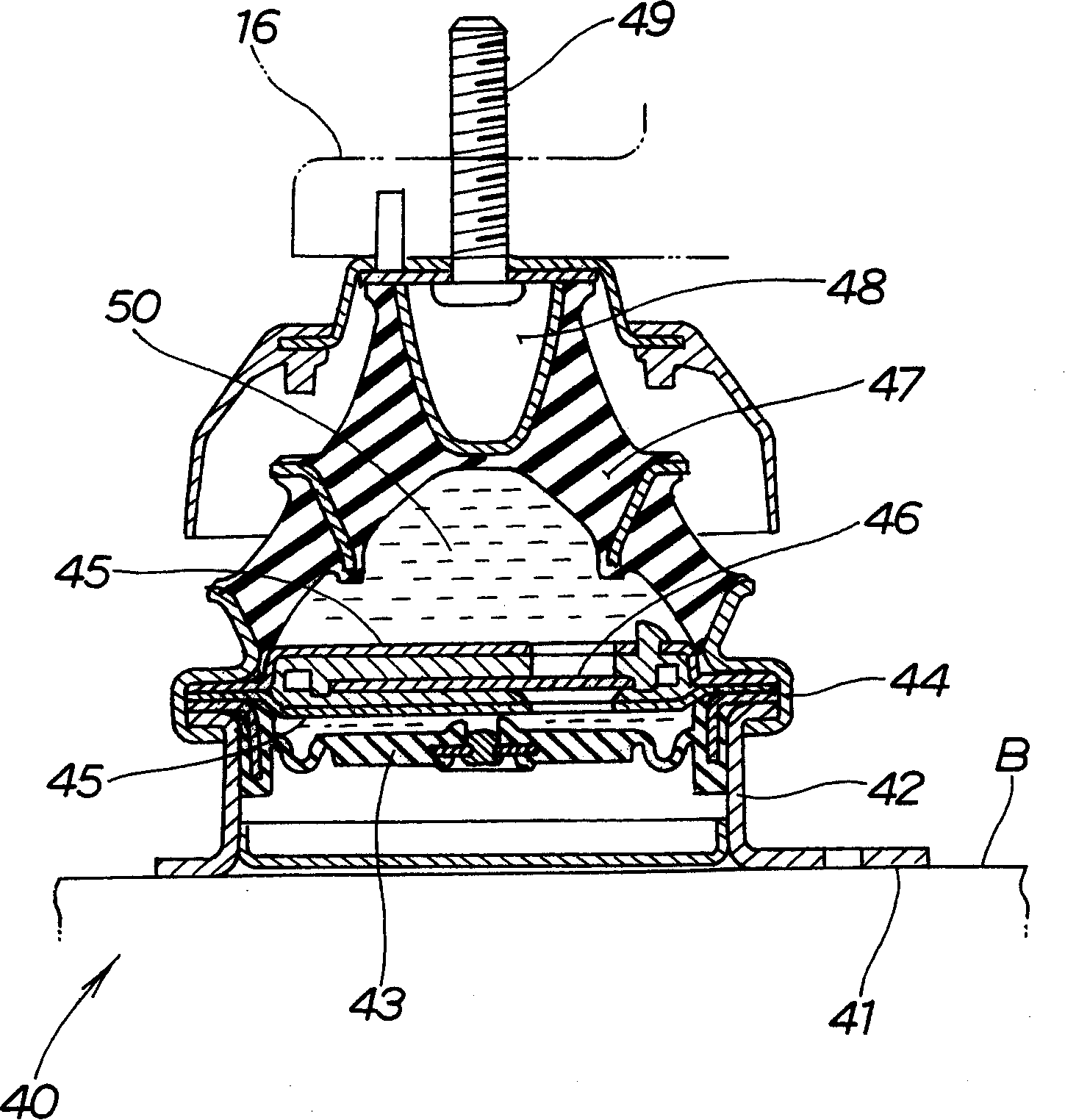

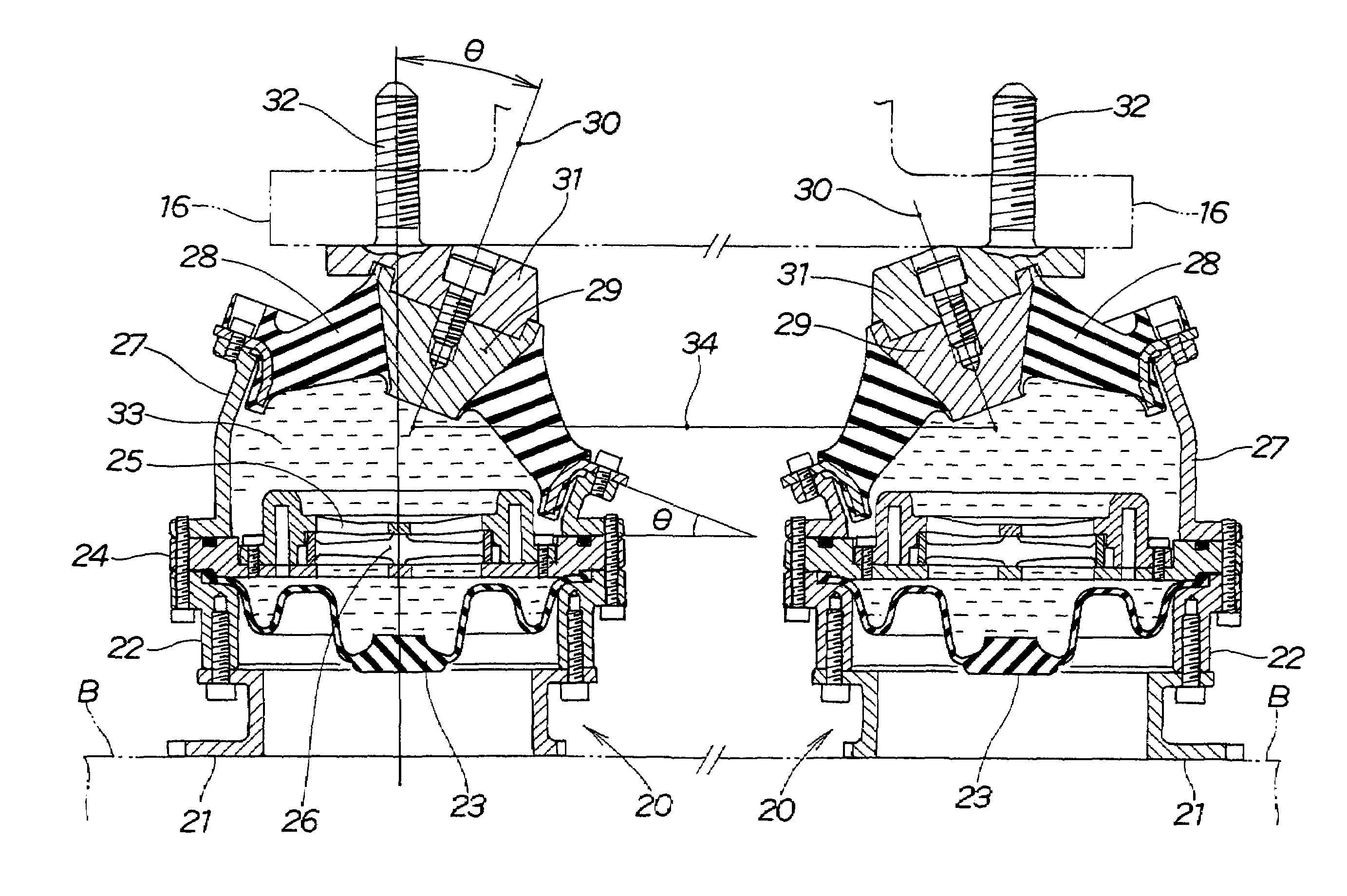

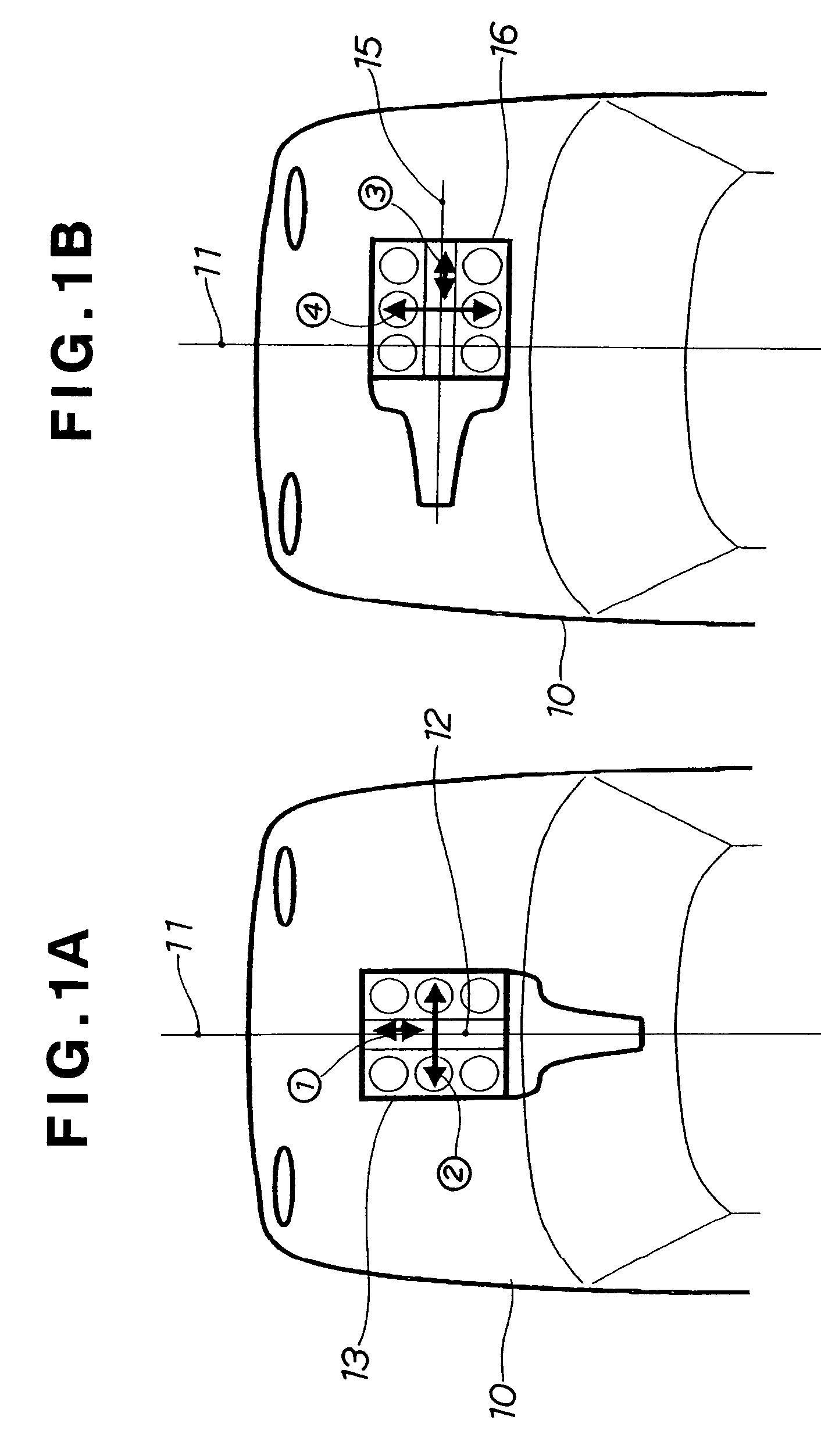

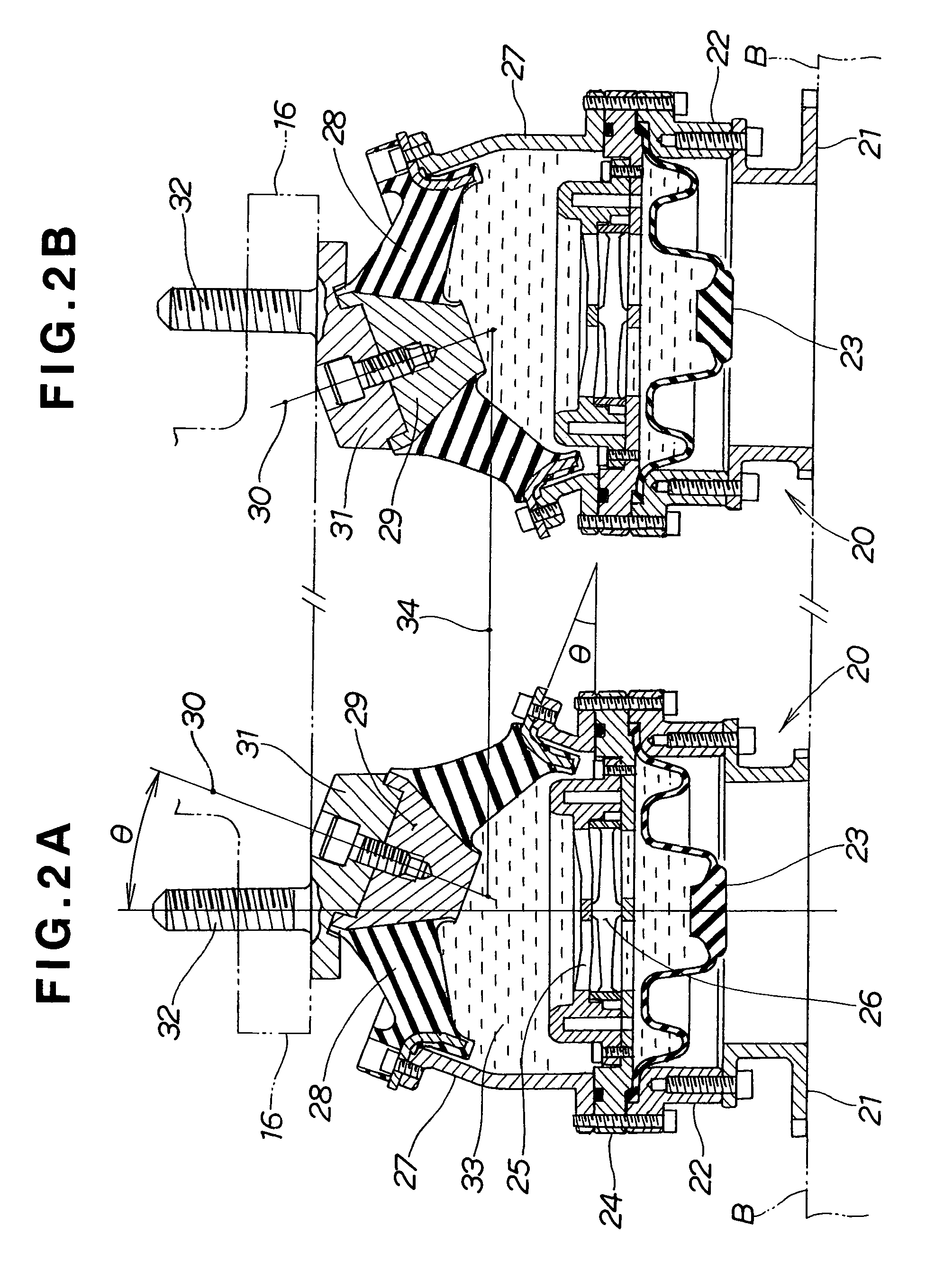

Supporting structure of transverse engine

A structure for supporting, via an engine mount, a transversal engine having a crankshaft (15) laid horizontally at a right angle to a vehicle longitudinal axis (11), on a vehicle body, is disclosed. The engine mount includes at least one inclined hydro mount (20) in which a working fluid (33) is enclosed and a maximum damping generating axis (30) is inclined a predetermined angle with respect to a vertical line. The inclined hydro mount is disposed inwardly of a total width in a power plant (54) which includes the transversal engine and a transmission (53).

Owner:HONDA MOTOR CO LTD +1

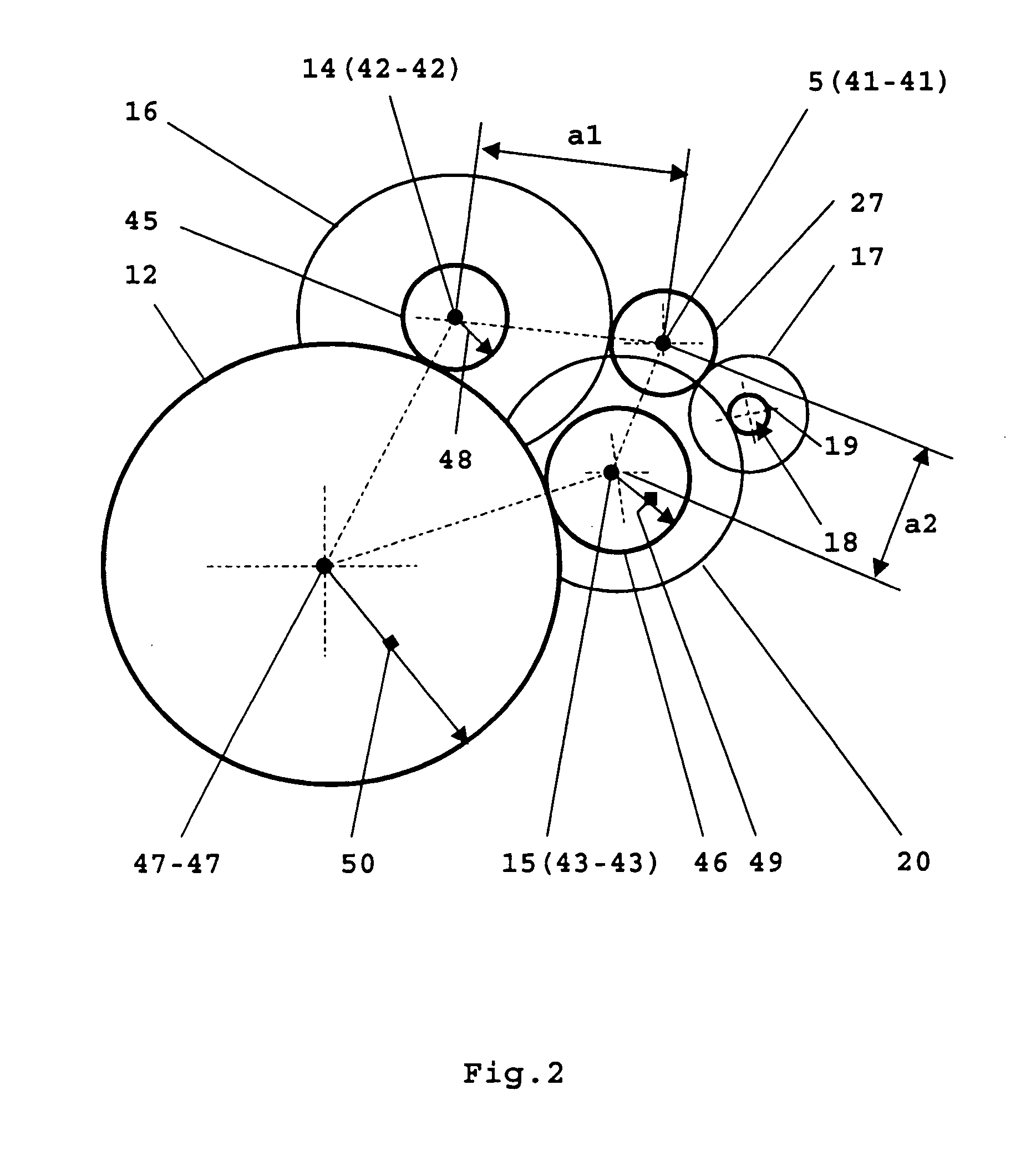

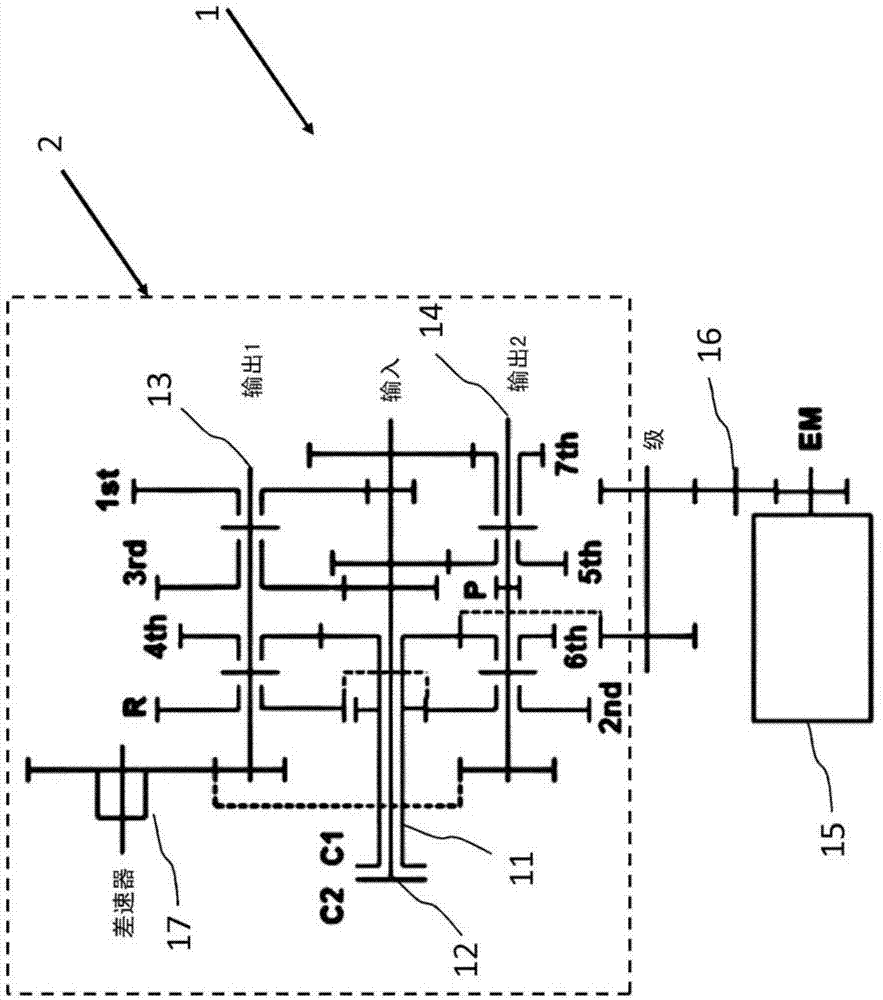

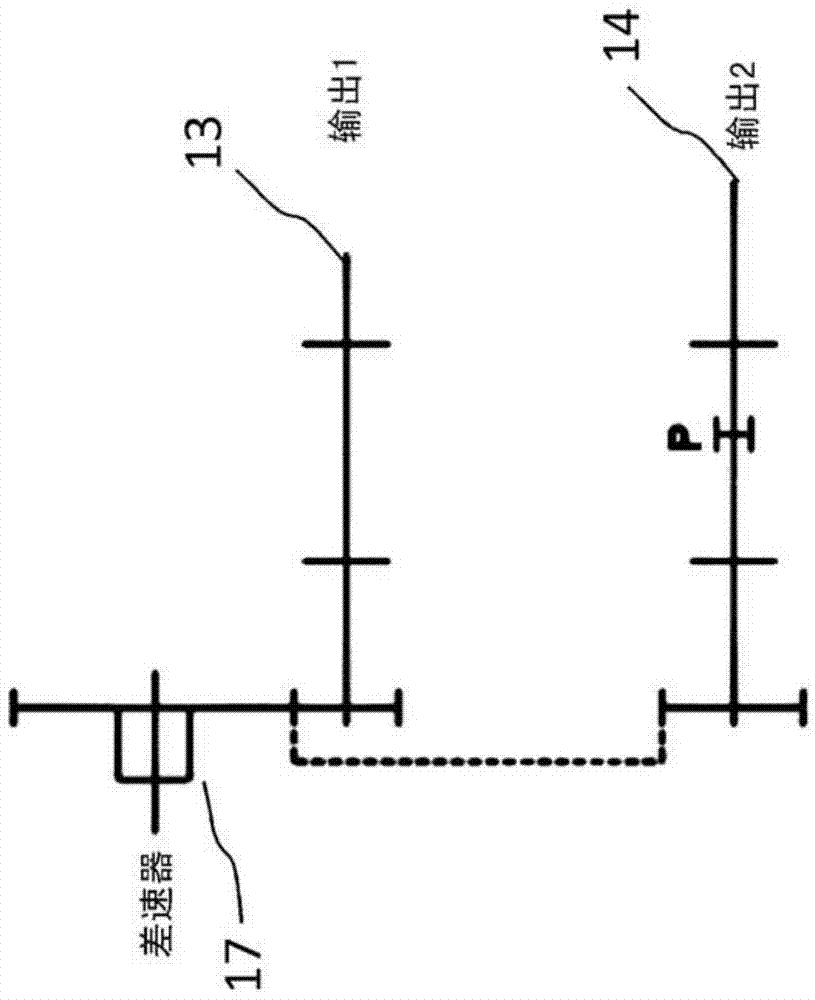

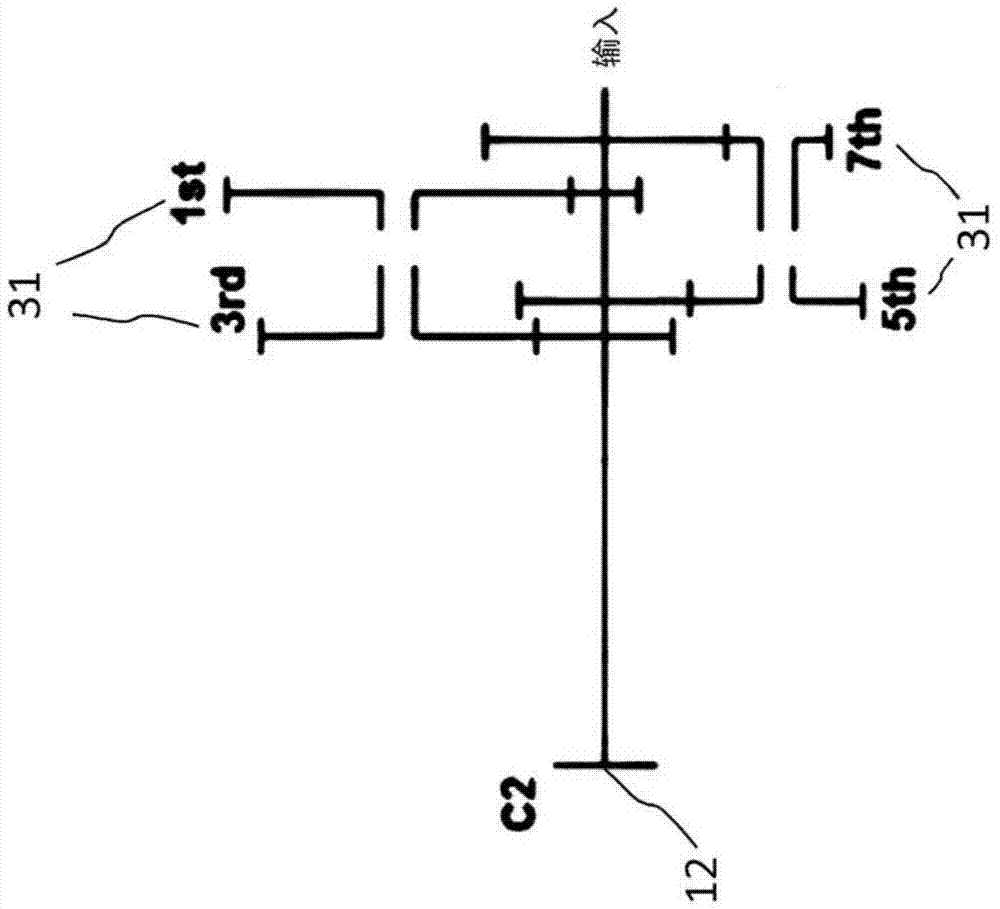

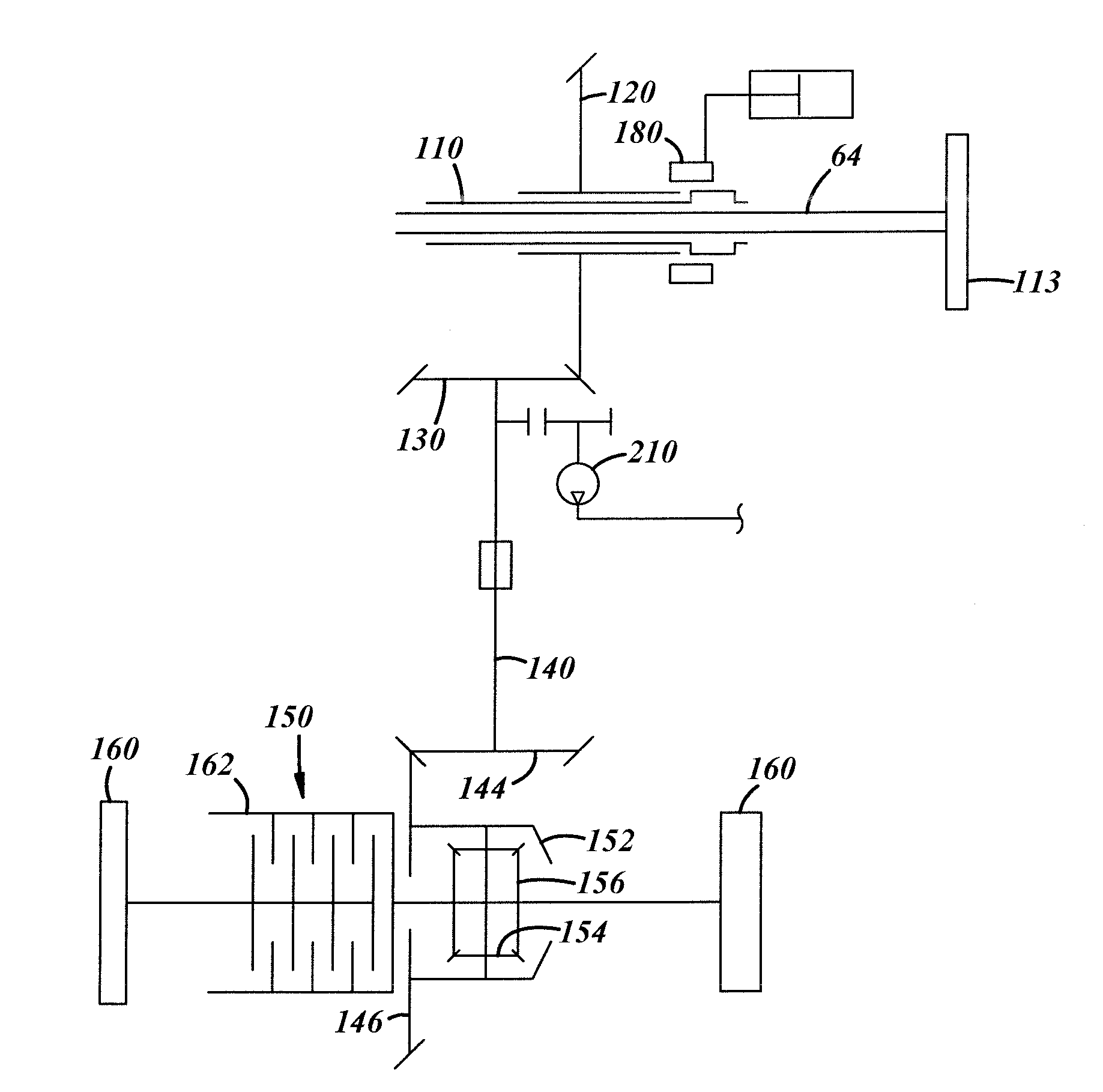

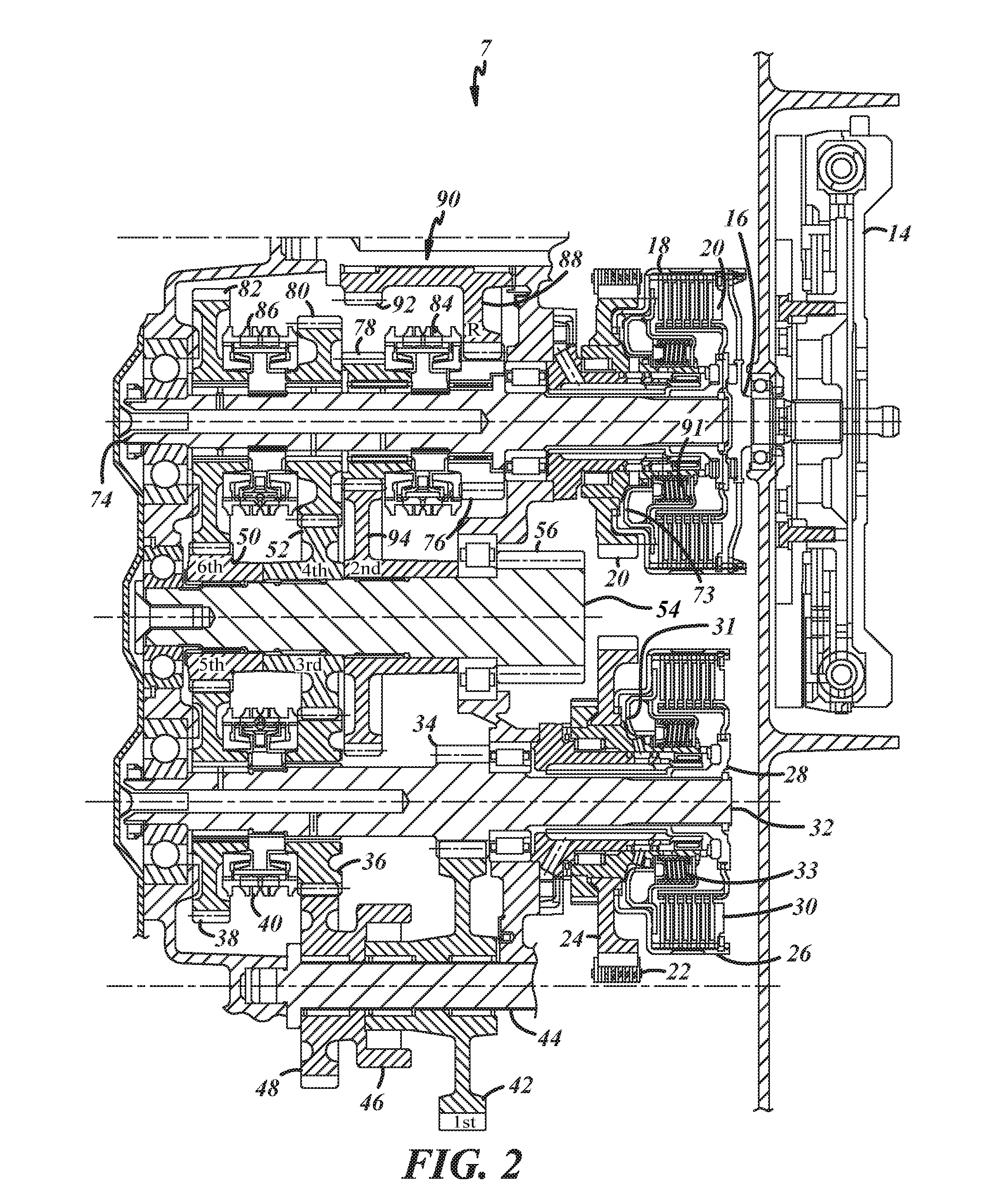

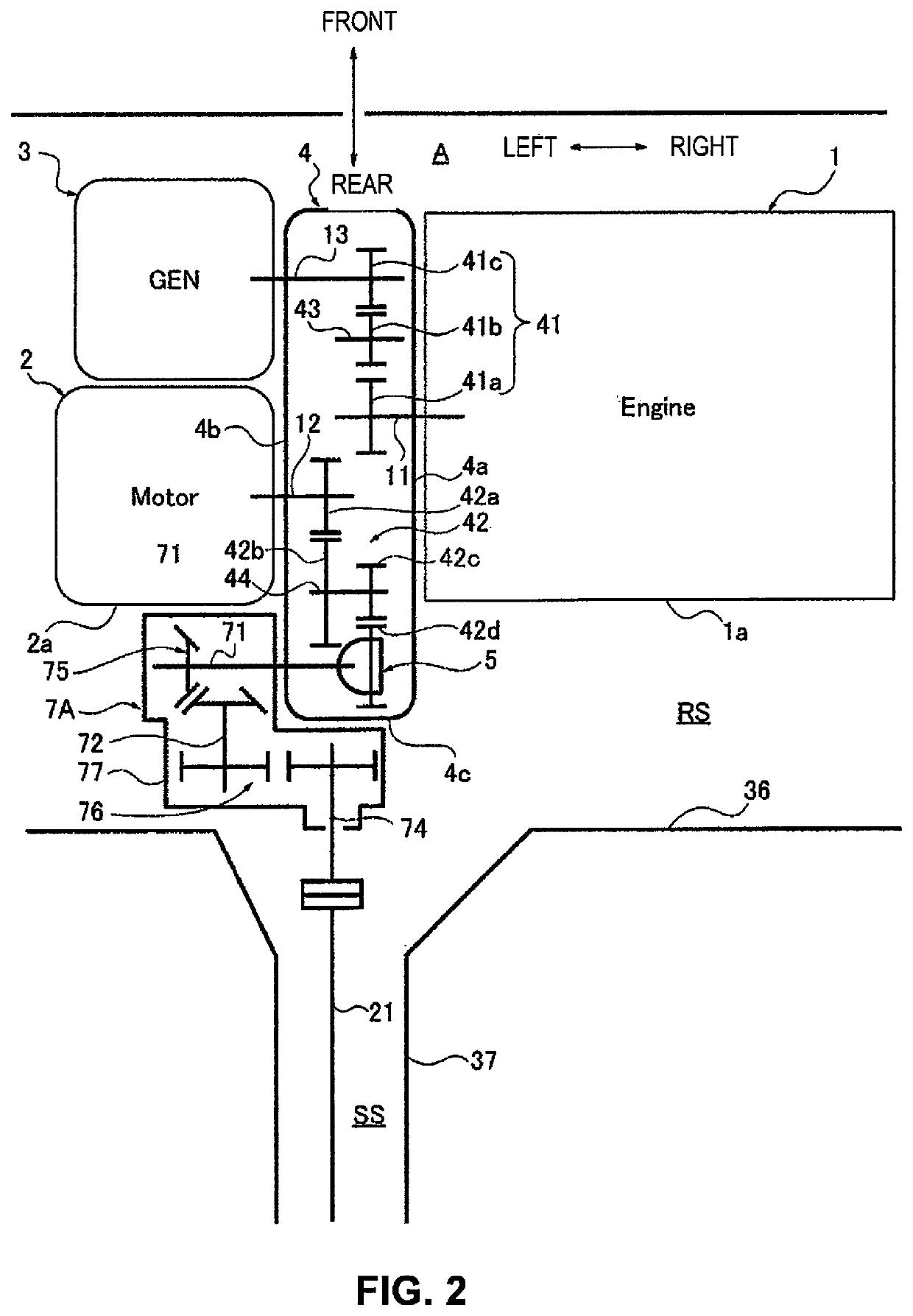

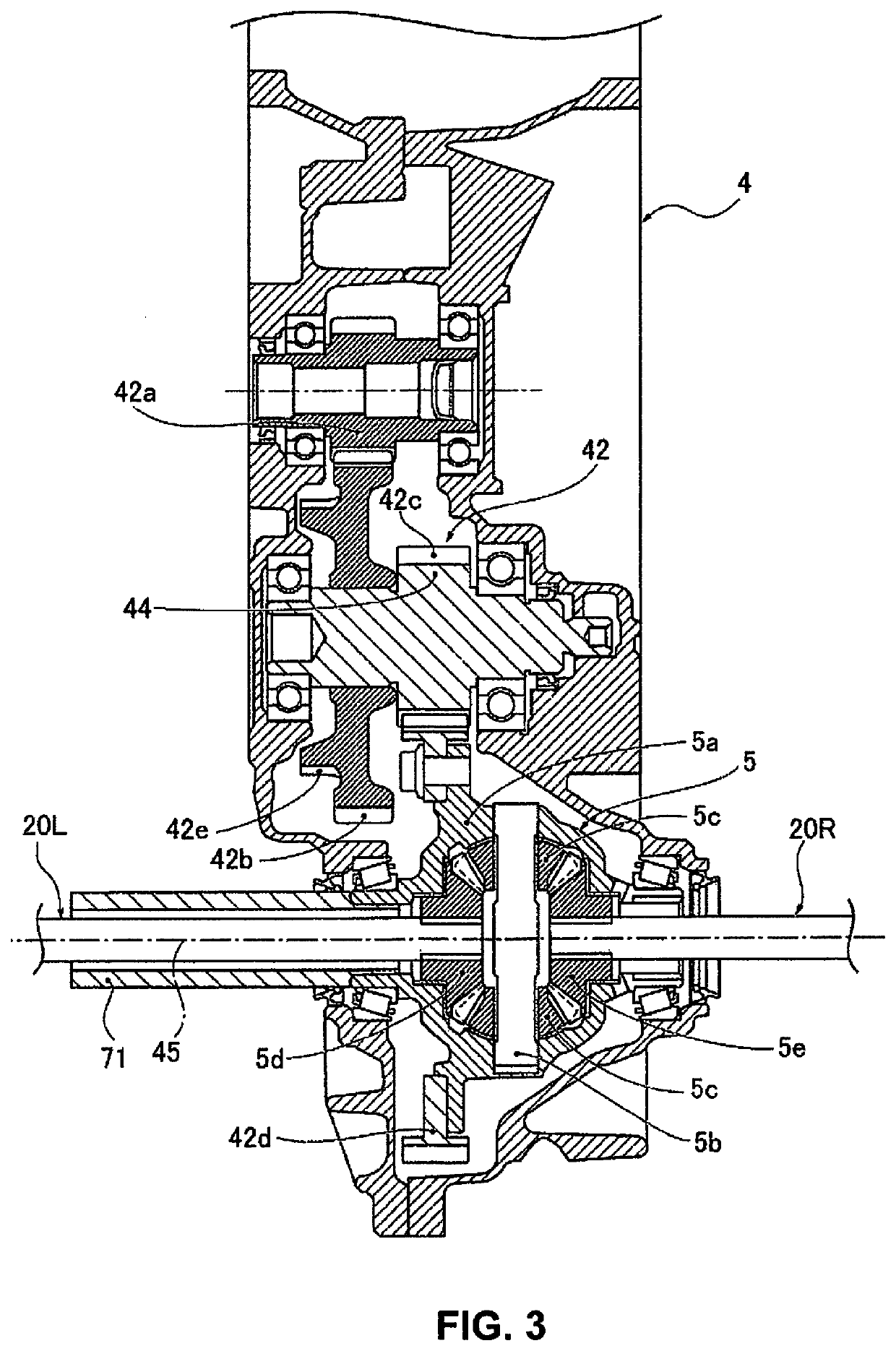

Dual-clutch seven speed transmission arrangement for a hybrid vehicle

Dual-clutch seven speed transmission arrangement and method for use with a transverse engine arrangement in a hybrid vehicle wherein a dual-clutch gearbox comprises an input shaft for odd drive gears (12) and an input shaft for even drive gears (11), respectively arranged in connection to a first (12) and a second (11) clutch. The input shaft for even drive gears (11) is a hollow shaft enclosing said input shaft for odd drive gears (12) and the input shaft for odd drive gears (12) is arranged to host four odd drive gears. The input shaft for even drive gears (11) is arranged to host three even drive gears and a reverse drive gear, and in connection to said input shaft for even drive gears (11) an electric motor (15) is arranged.

Owner:VOLVO CAR CORP

Control system for a plug-in hybrid vehicle

InactiveUS9561792B2Suppression of deterioration progressShorten the timePower operated startersInternal combustion piston enginesElectrical batteryCapacitor voltage

A control system for a plug-in hybrid vehicle includes a drive system including a starter motor, a transverse engine, and a motor / generator, and a power supply system including a high voltage battery, a capacitor, and a hybrid control module that controls charging and discharging of the capacitor. In the control system for an FF plug-in hybrid vehicle in which an external charging of the high-power battery is available, the hybrid control module starts the starter, performs mode selection control and charge / discharge control, maintains a capacitor voltage at or below a deterioration free voltage when the CS mode is selected during ignition on, and recharges the capacitor to a starter start-up permission voltage that allows the starter to start when a pre-forecast of the reverse transition from the CS mode to the CD mode is established.

Owner:NISSAN MOTOR CO LTD

Intake manifold

InactiveUS8037859B2Reduce the possibilityMachines/enginesAir intakes for fuelTransverse engineMechanical engineering

Owner:DENSO CORP

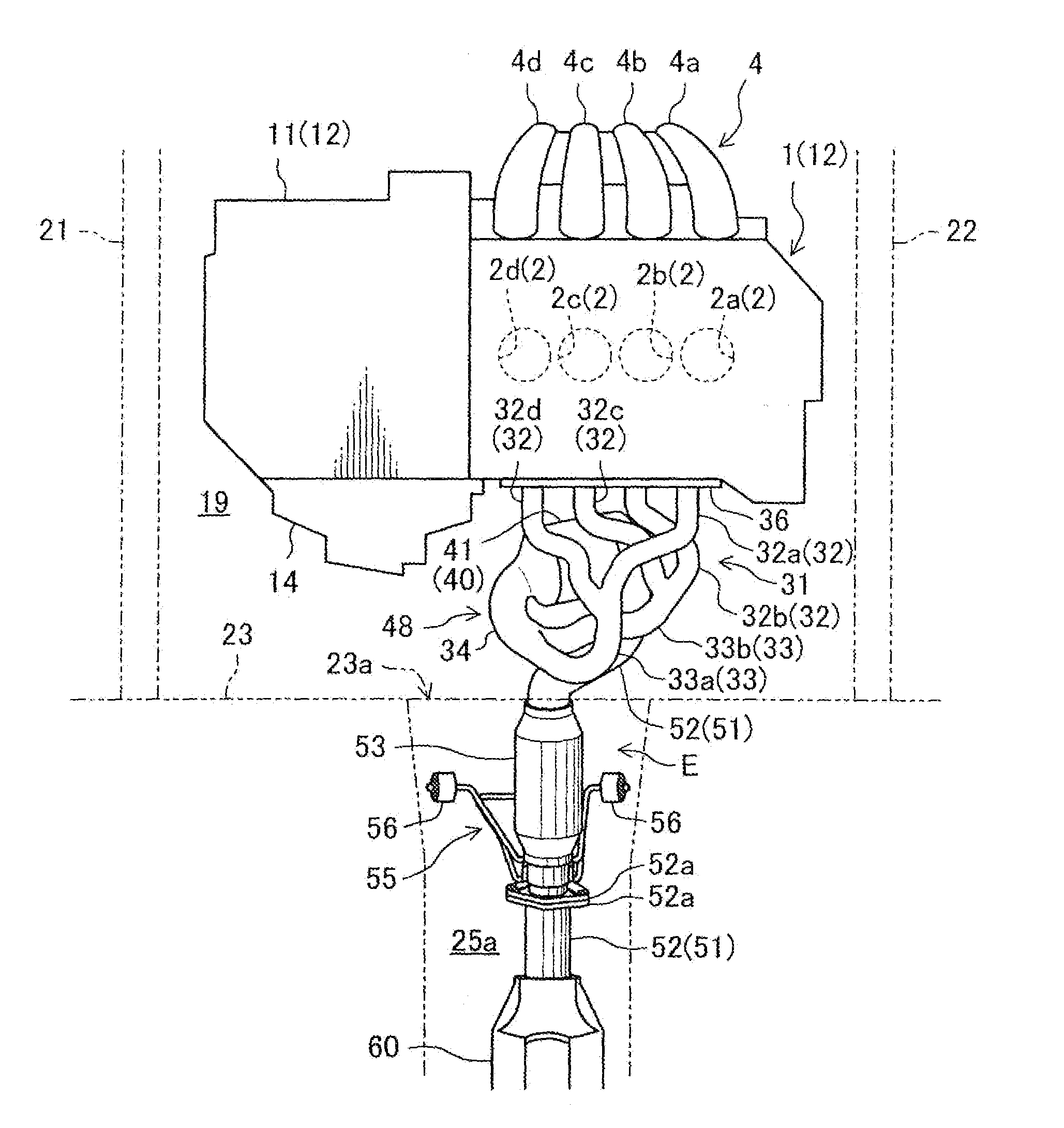

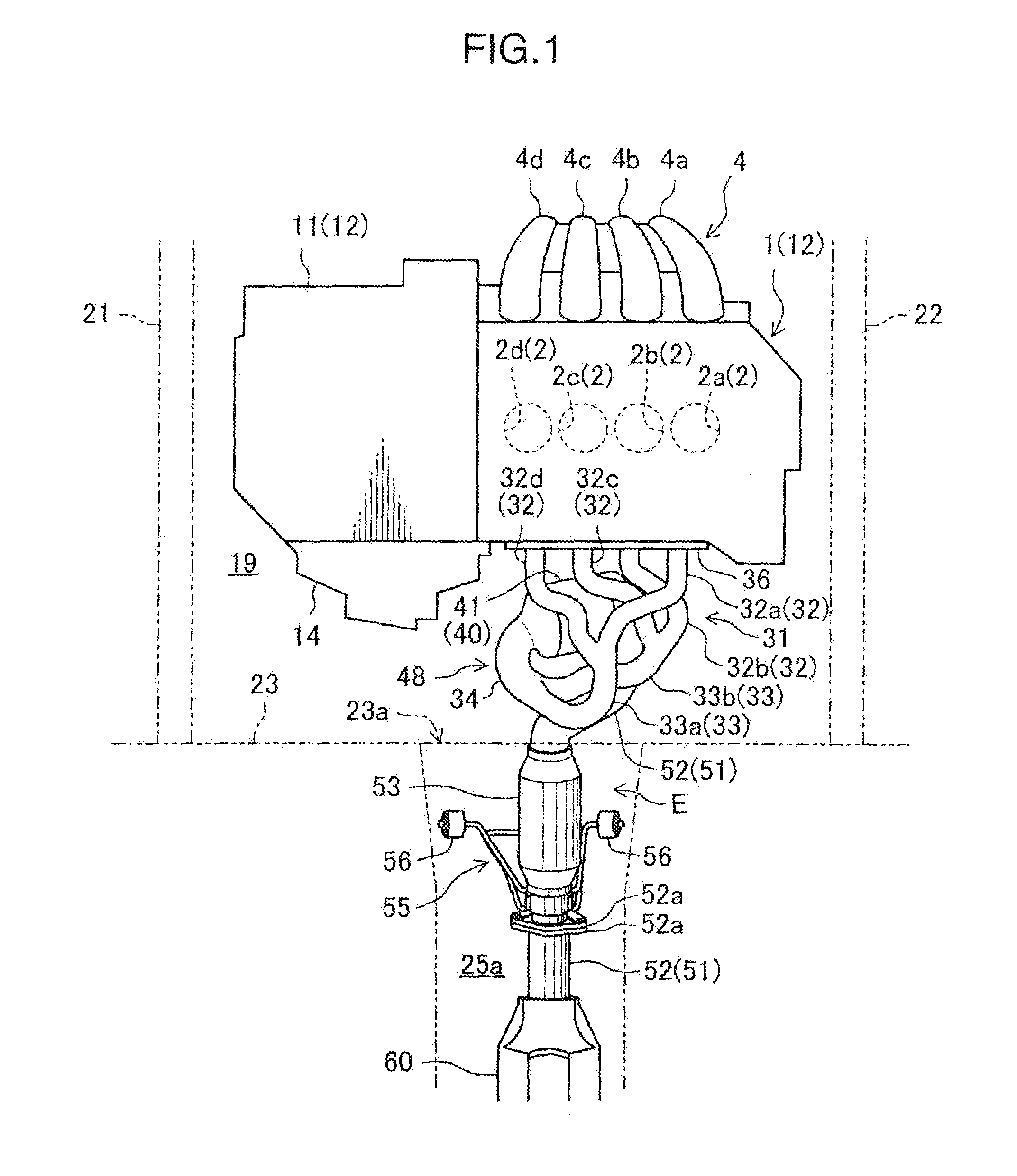

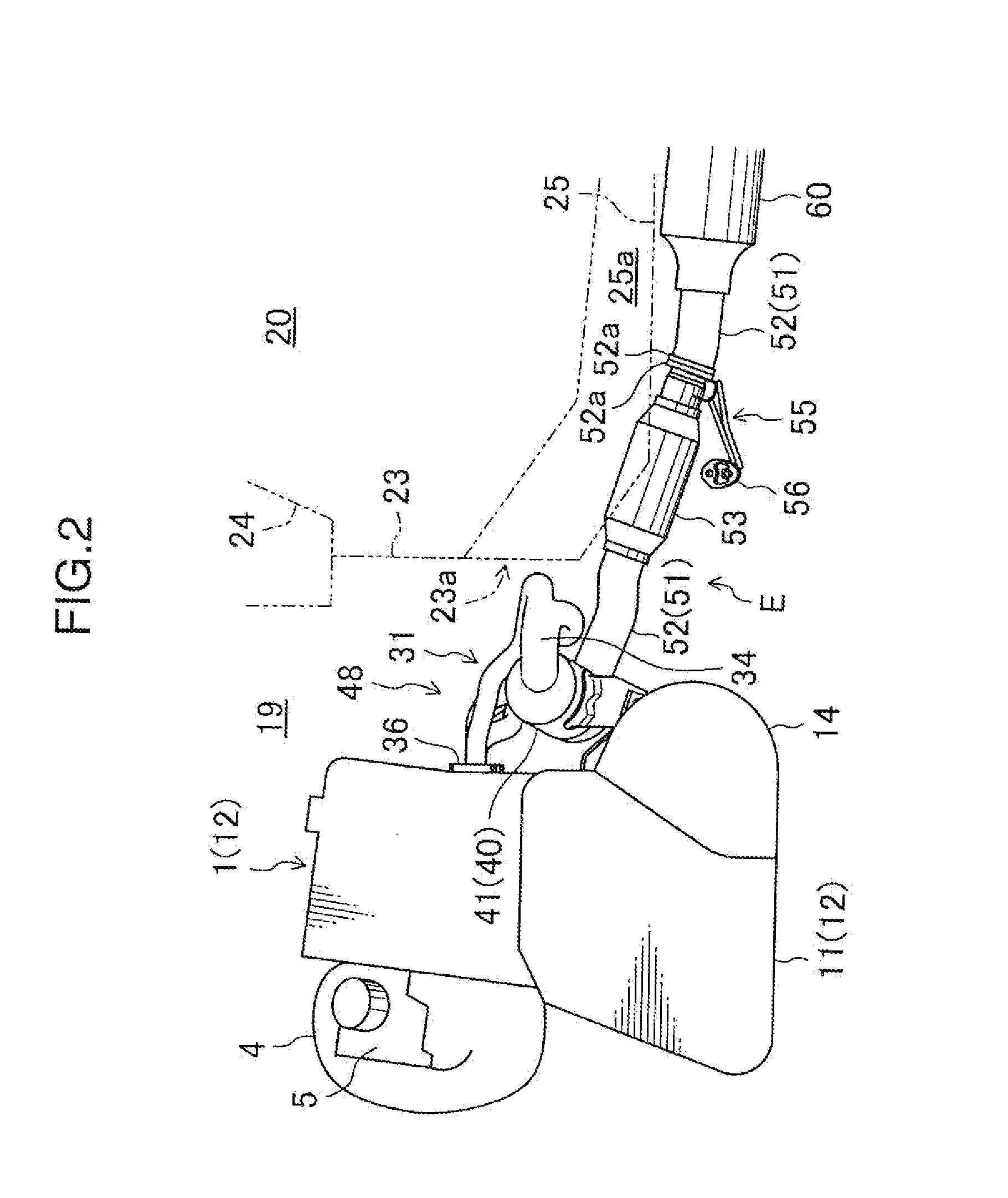

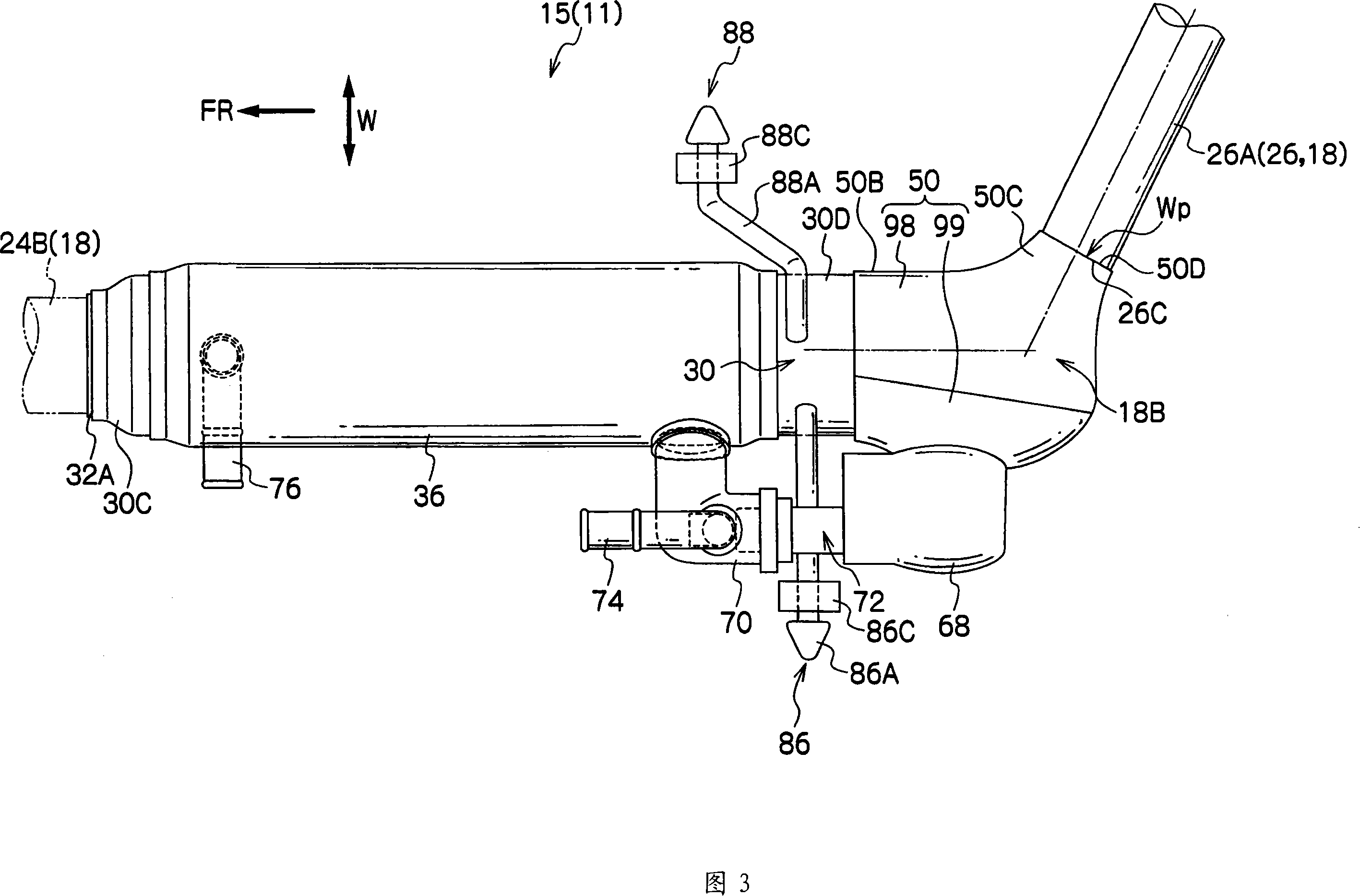

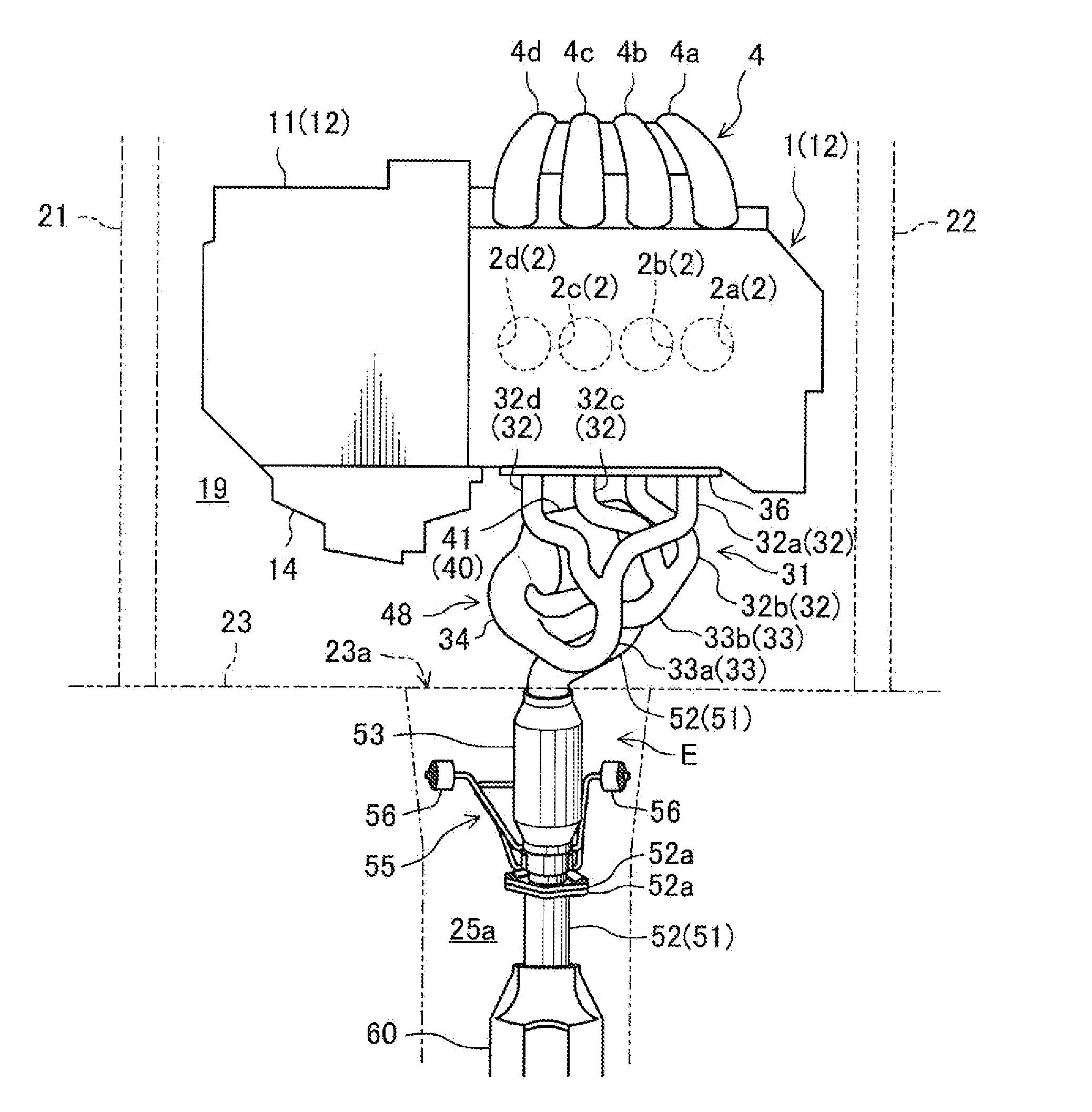

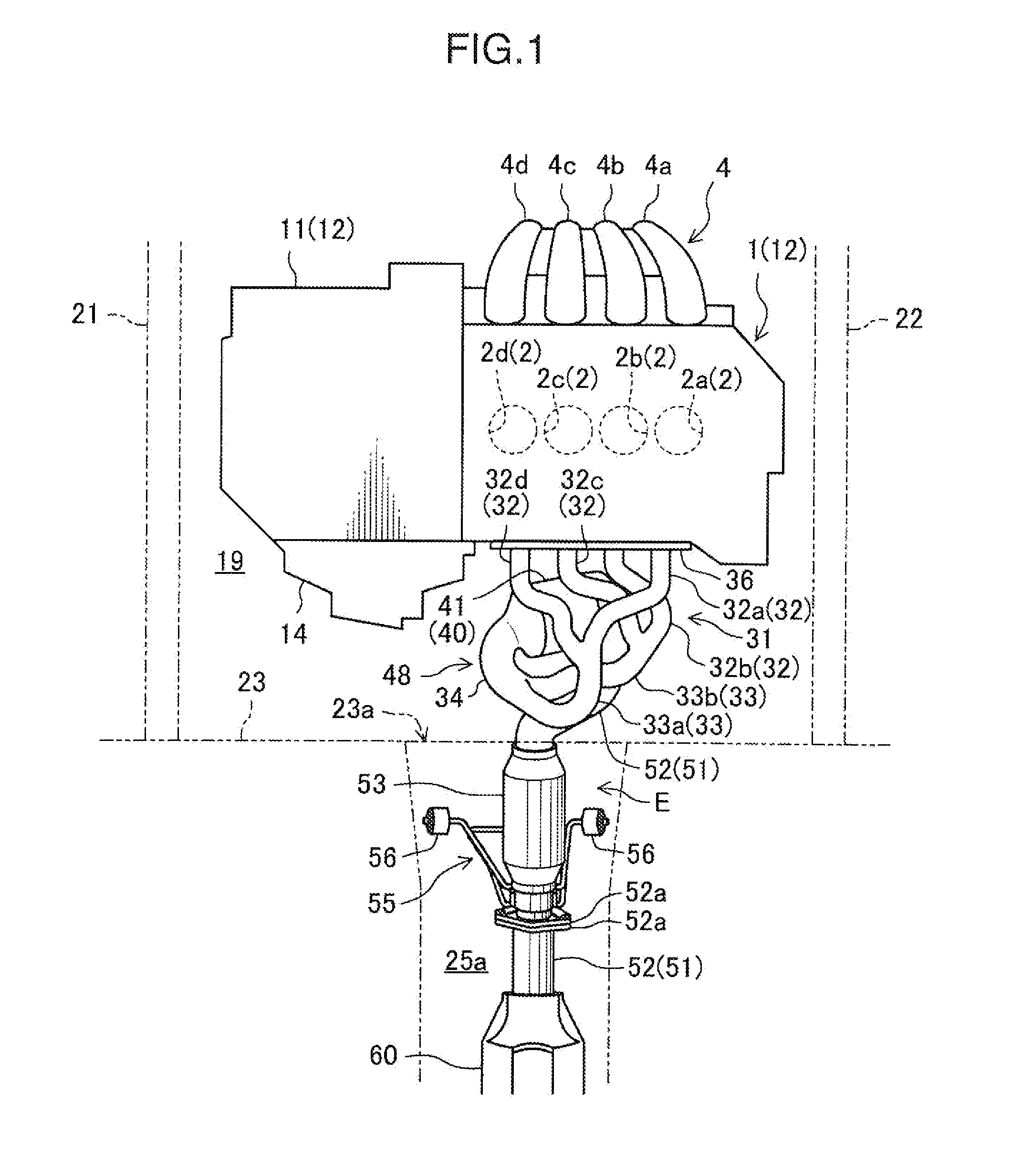

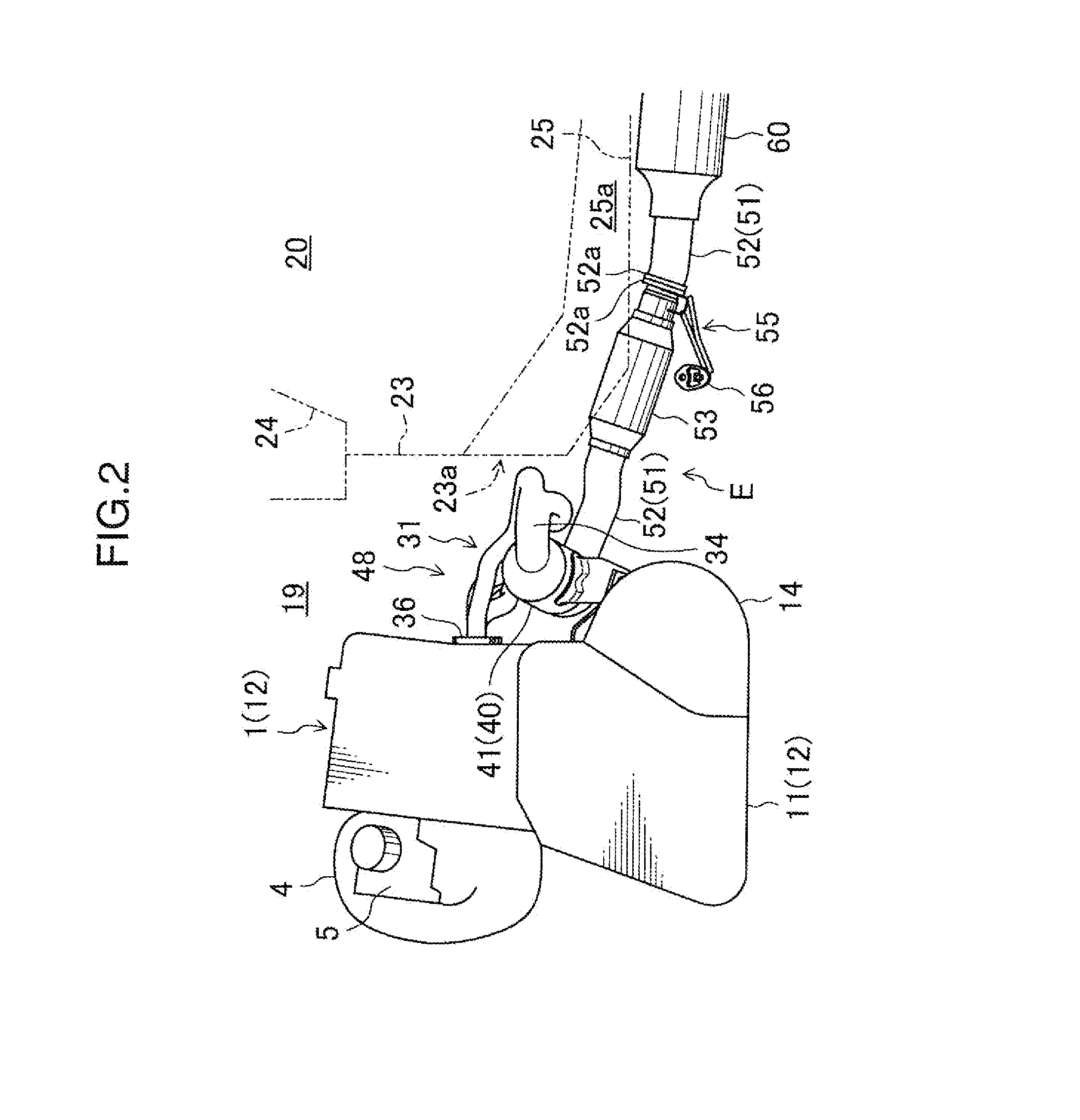

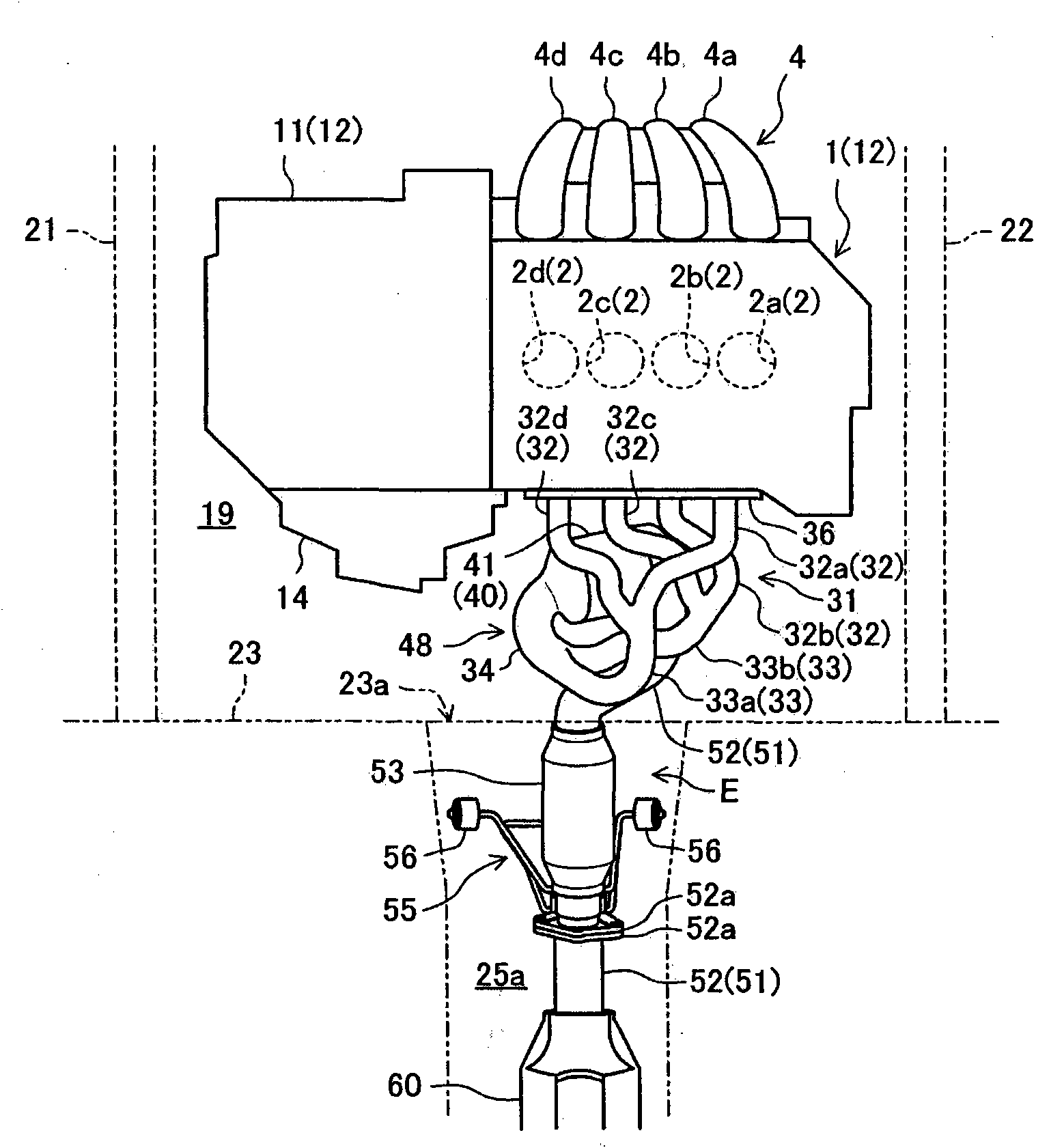

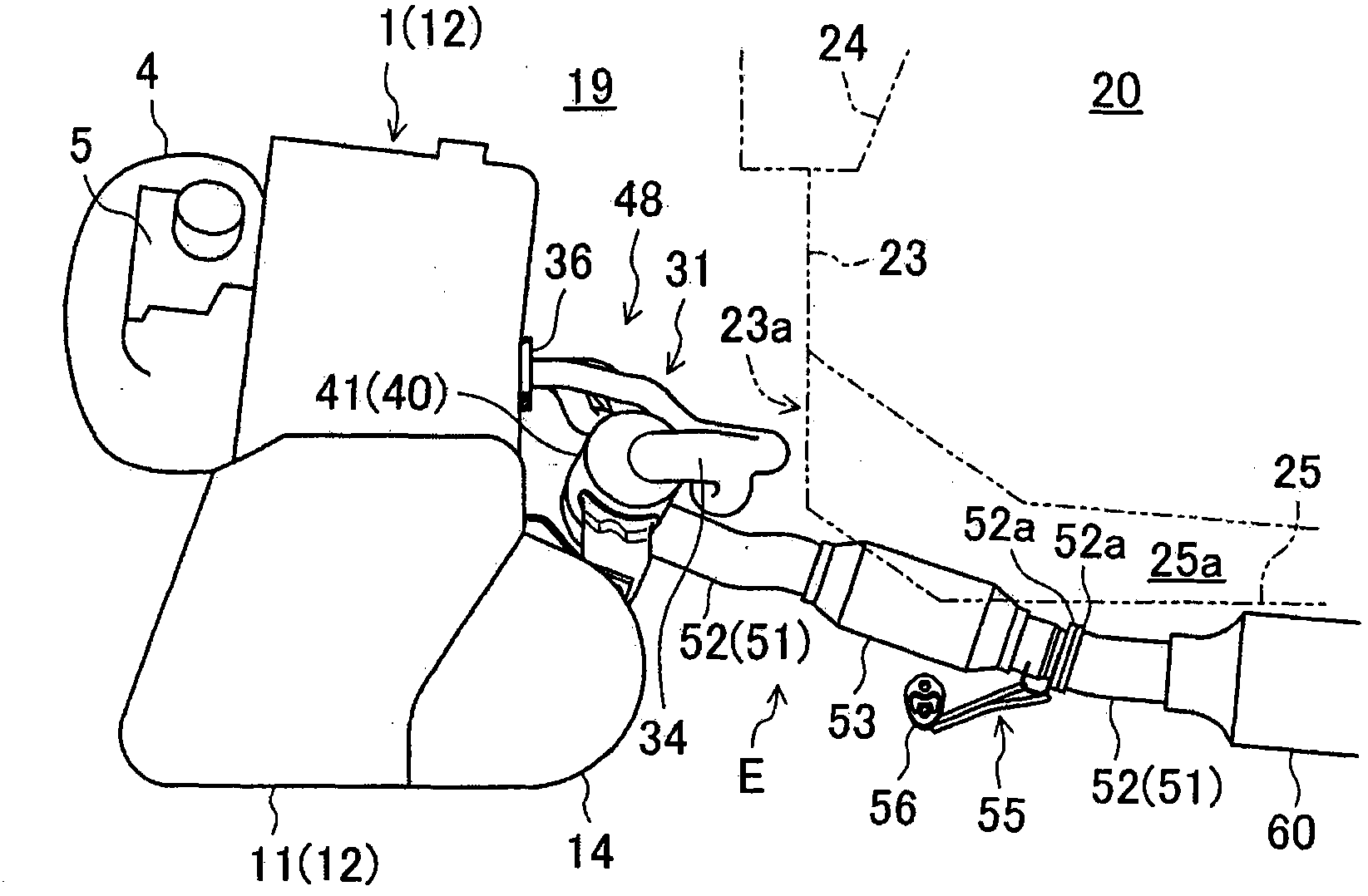

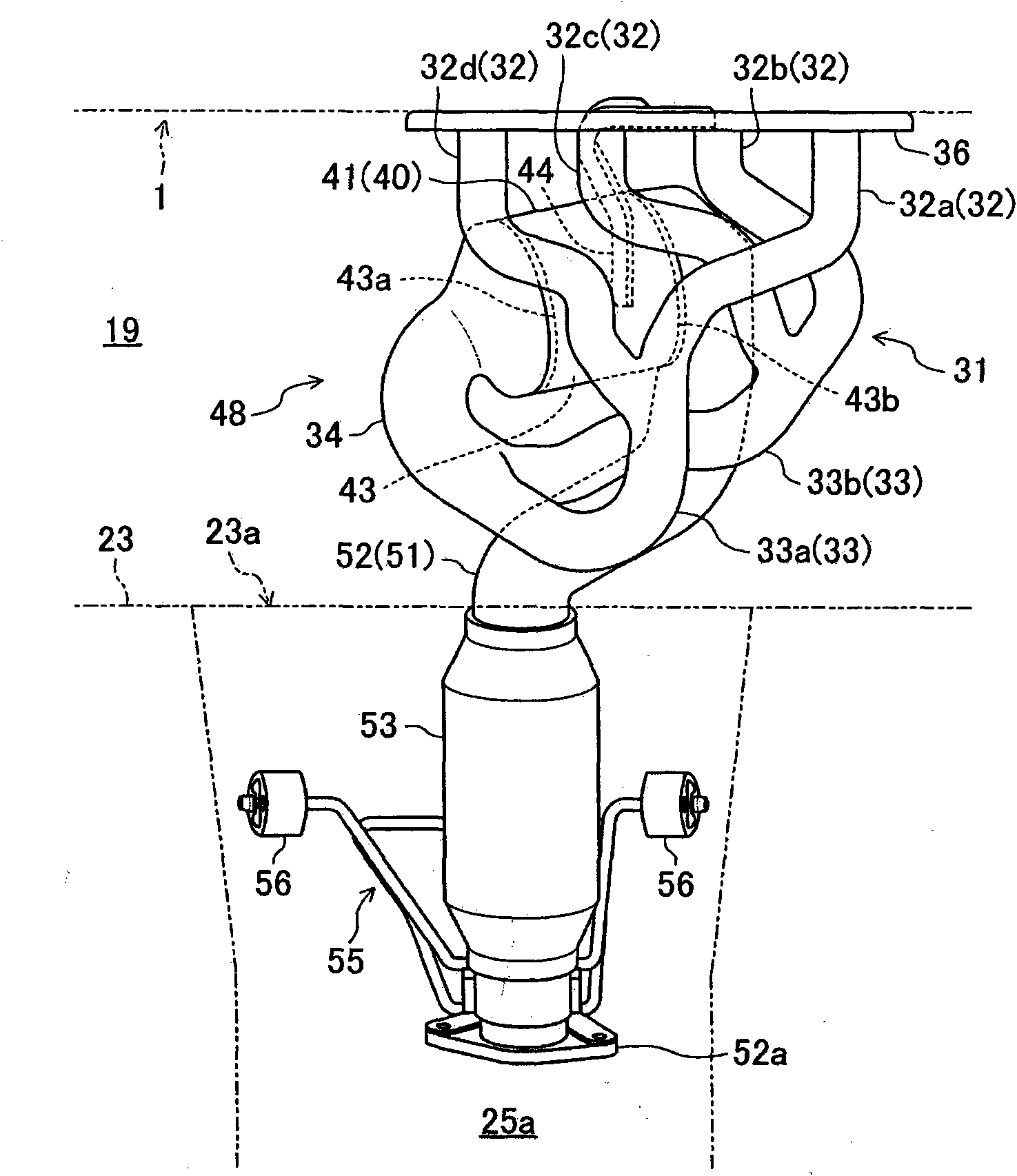

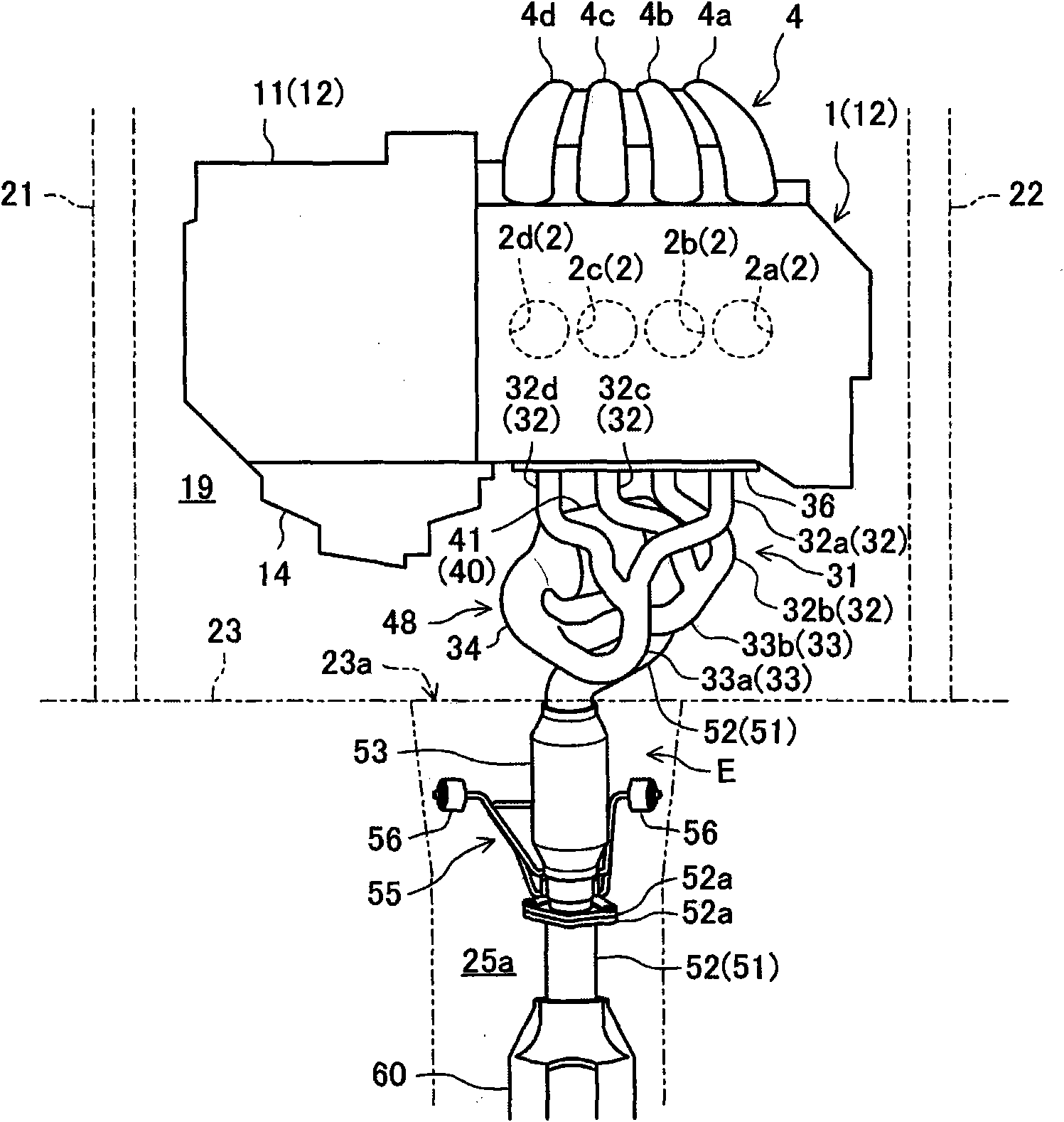

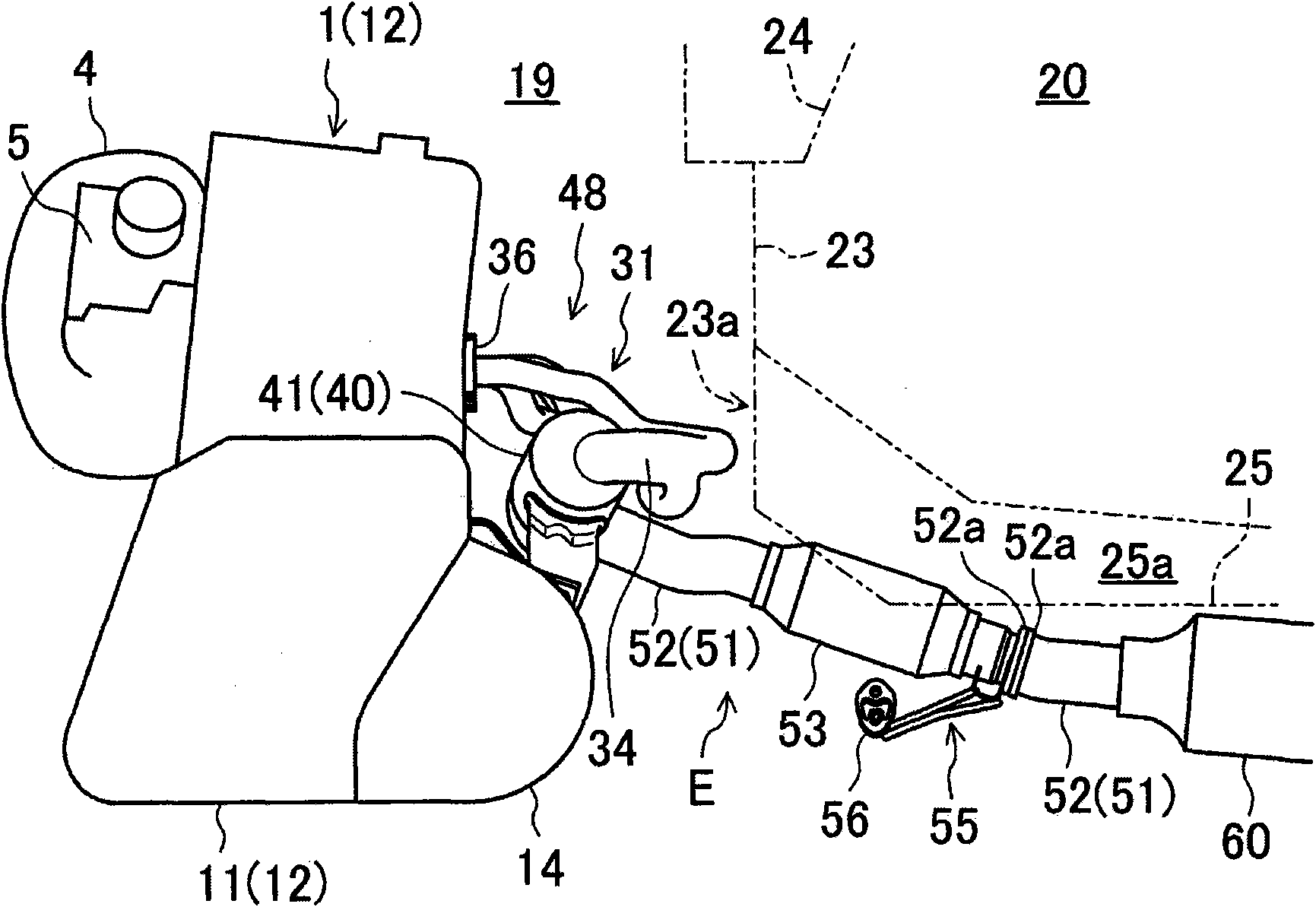

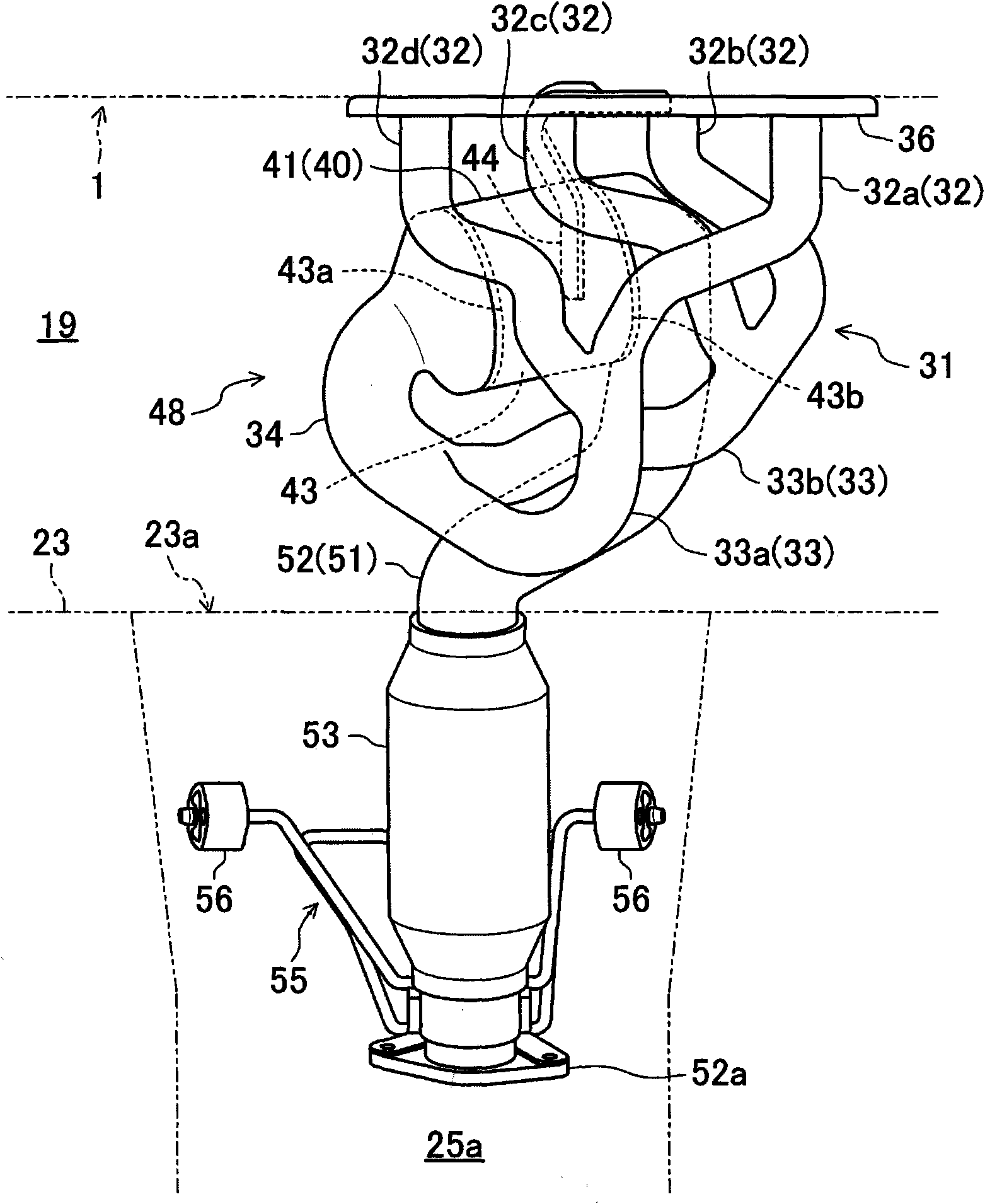

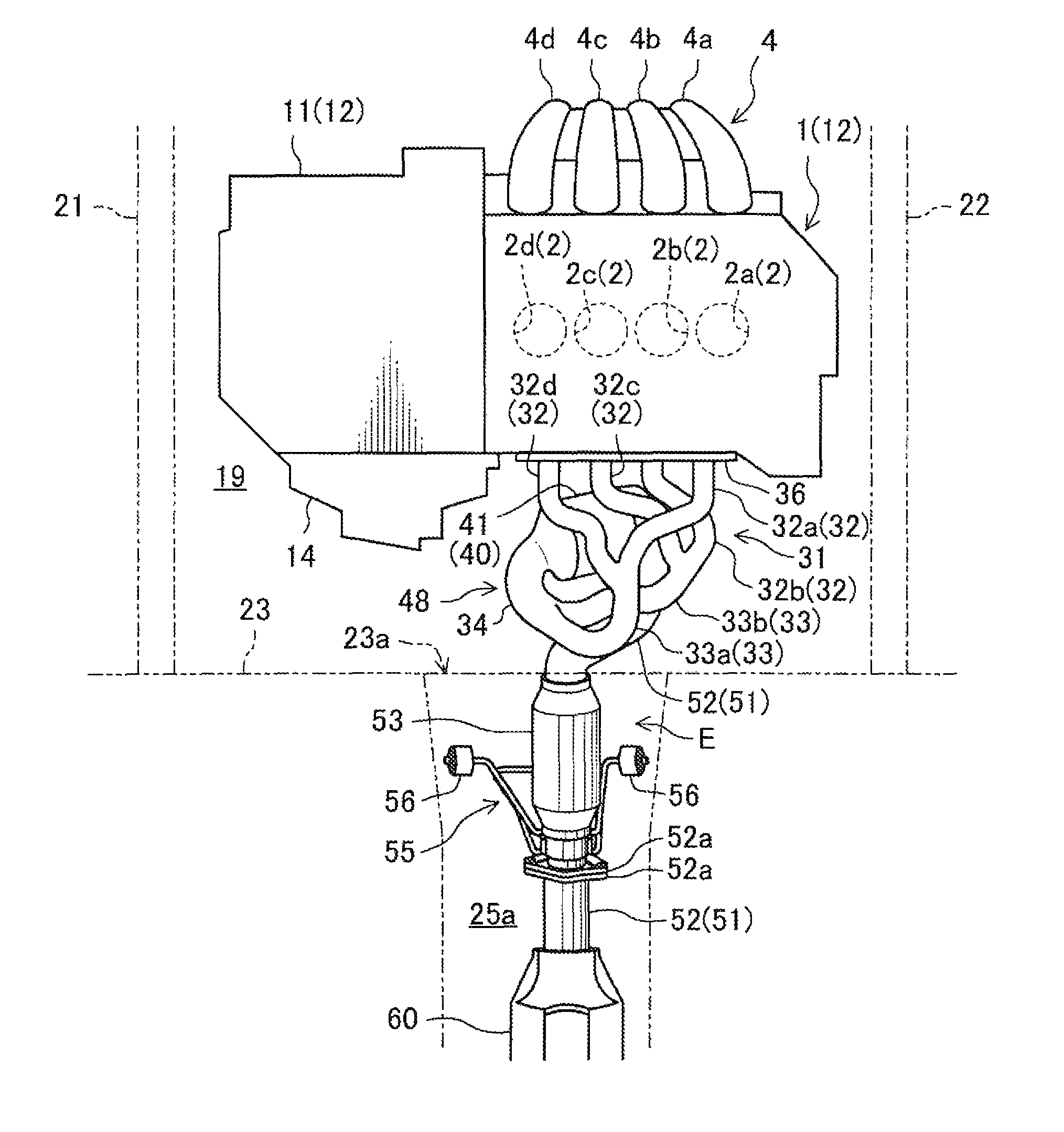

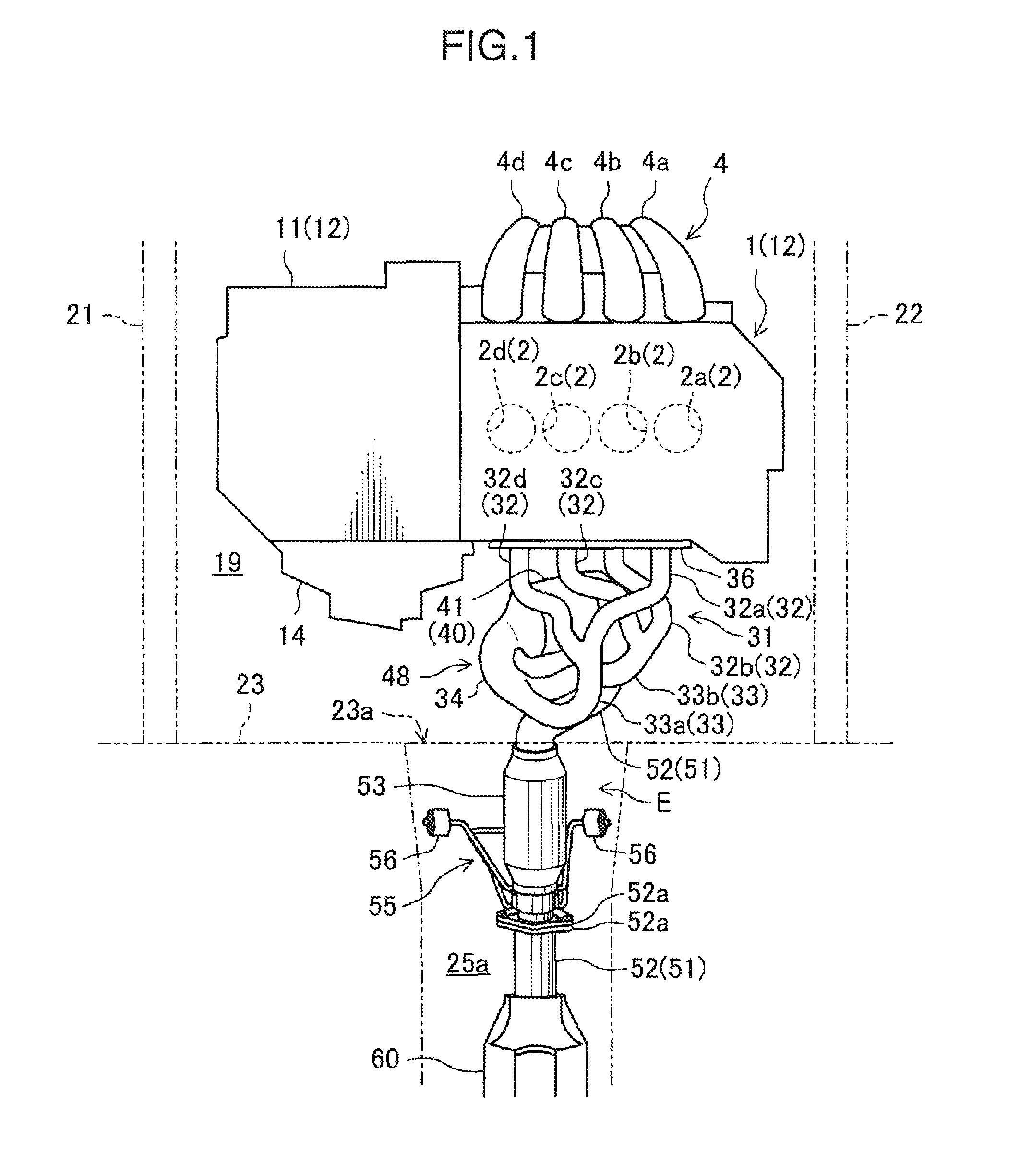

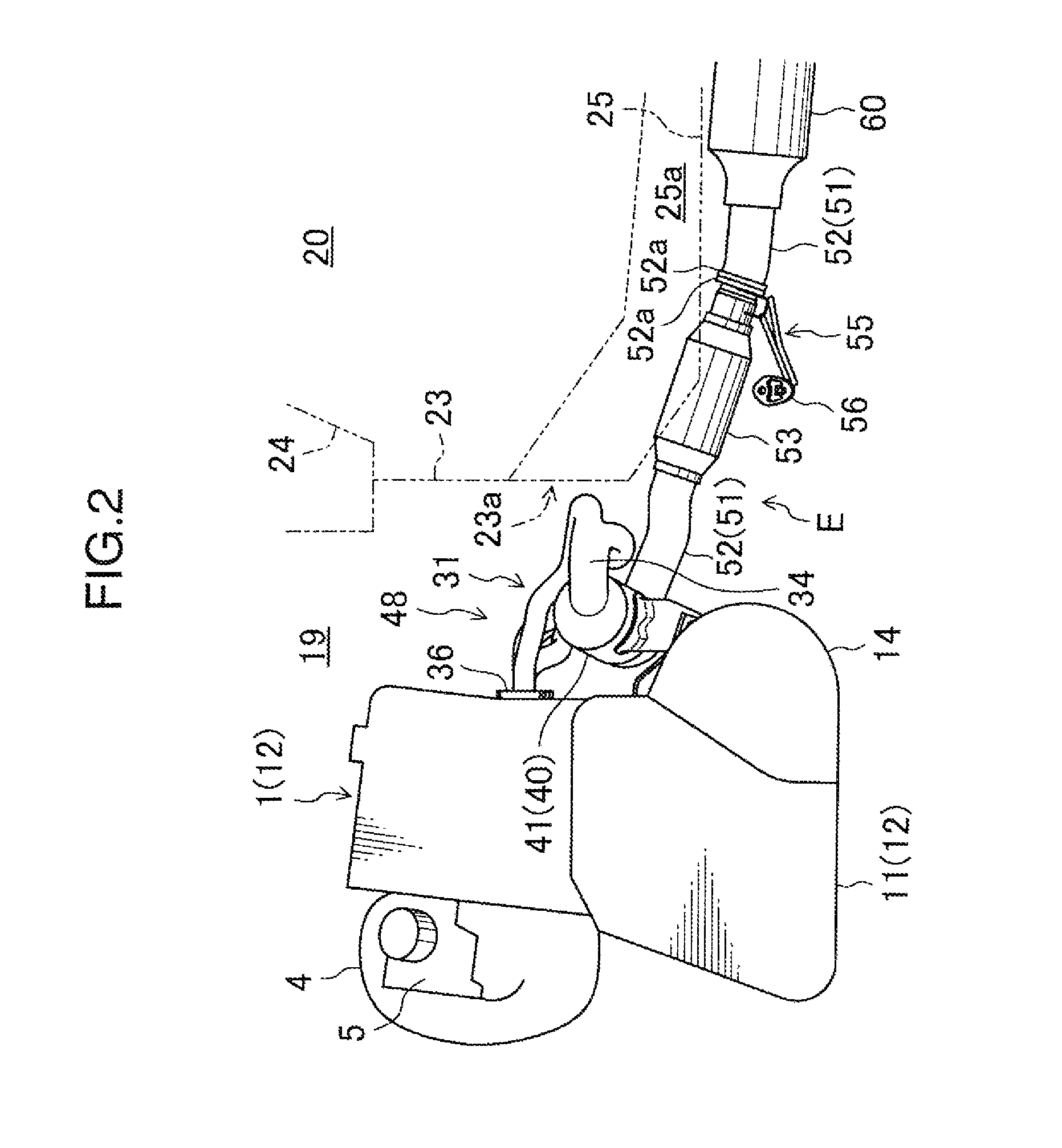

Exhaust apparatus for transverse engine

InactiveUS20110126522A1Increase in temperature of catalystRapid temperature measurementExhaust apparatusSilencing apparatusTransverse engineExhaust pipe

Disclosed is an exhaust apparatus (E) for a transverse engine (1) coupled with a transmission (11) located on one side thereof in a cylinder arrangement direction. The exhaust apparatus (E) has an upstream exhaust assembly (48) which comprises a plurality of branch pipe portions (32), a single exhaust pipe portion (34), and an exhaust gas-purifying unit (40). The exhaust gas-purifying unit (40) is disposed on a vehicle-rear side of the engine (1) to allow a gas passage thereinside to extend approximately in a vehicle-widthwise direction, in top plan view. The upstream exhaust assembly (48) includes, on an exhaust upstream side of the single exhaust pipe portion (34), a section which curves to allow an exhaust downstream region of the section to be oriented toward one side of the vehicle-widthwise direction which is a direction coming close to the transmission (11), in top plan view. The single exhaust pipe portion (34) curves to allow an exhaust downstream region of the single exhaust pipe portion (34) to be oriented toward a vehicle-front side, in top plan view. This makes it possible to compactly lay out the upstream exhaust assembly (48) in an engine compartment (19) without sacrificing a passenger compartment space, and quickly raise a temperature of a catalyst in the exhaust gas-purifying unit (40) during warm-up of the engine (1).

Owner:MAZDA MOTOR CORP

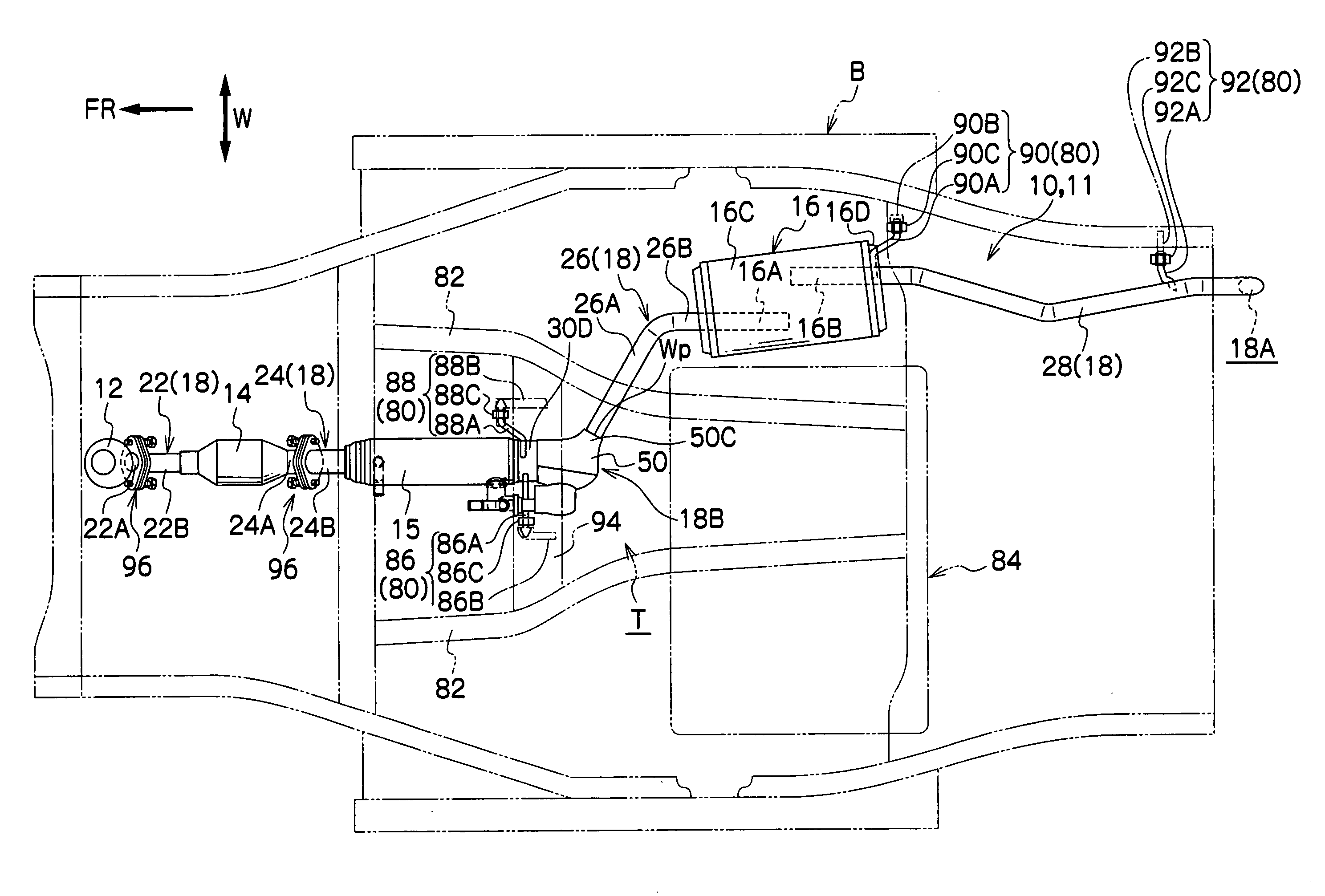

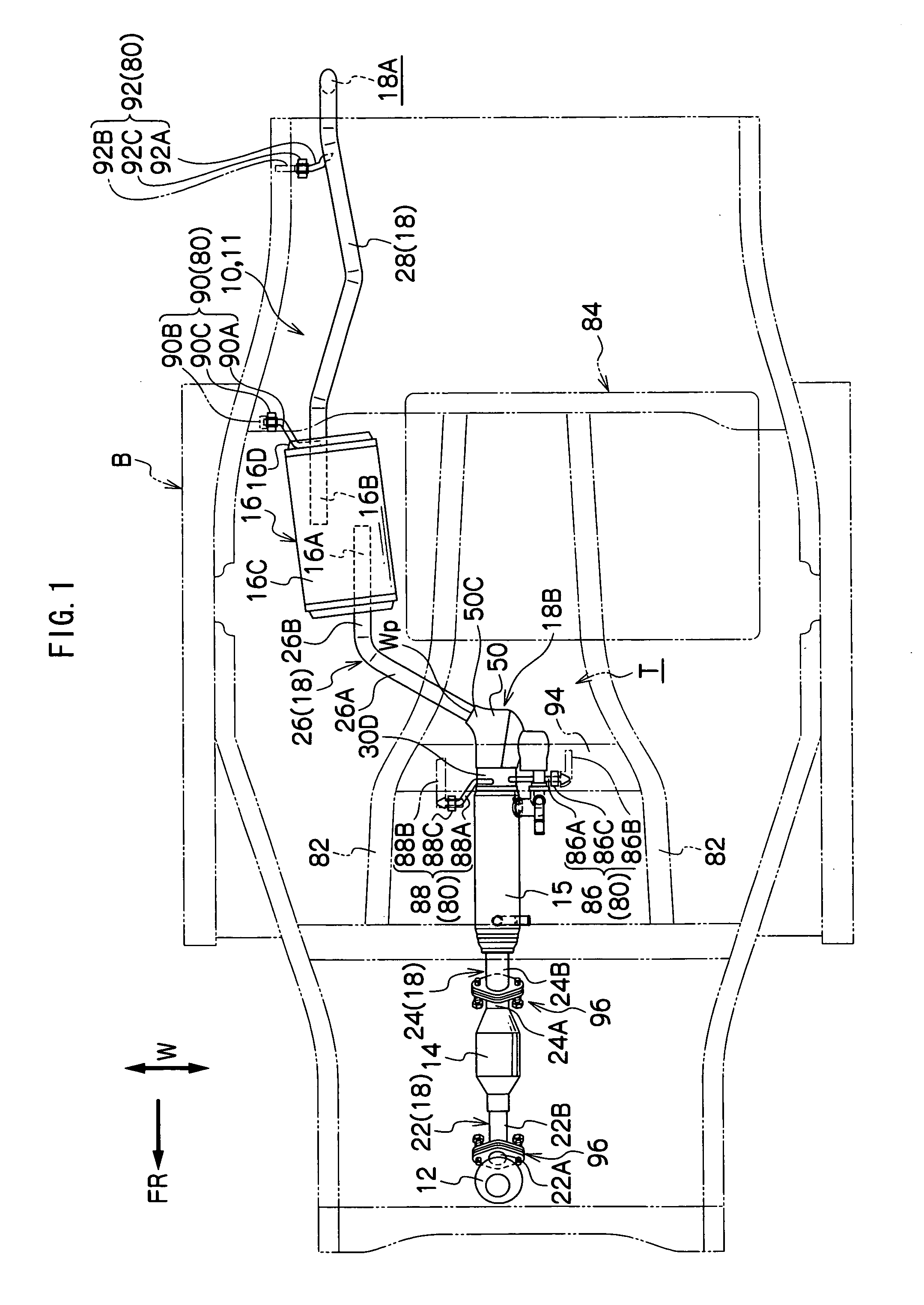

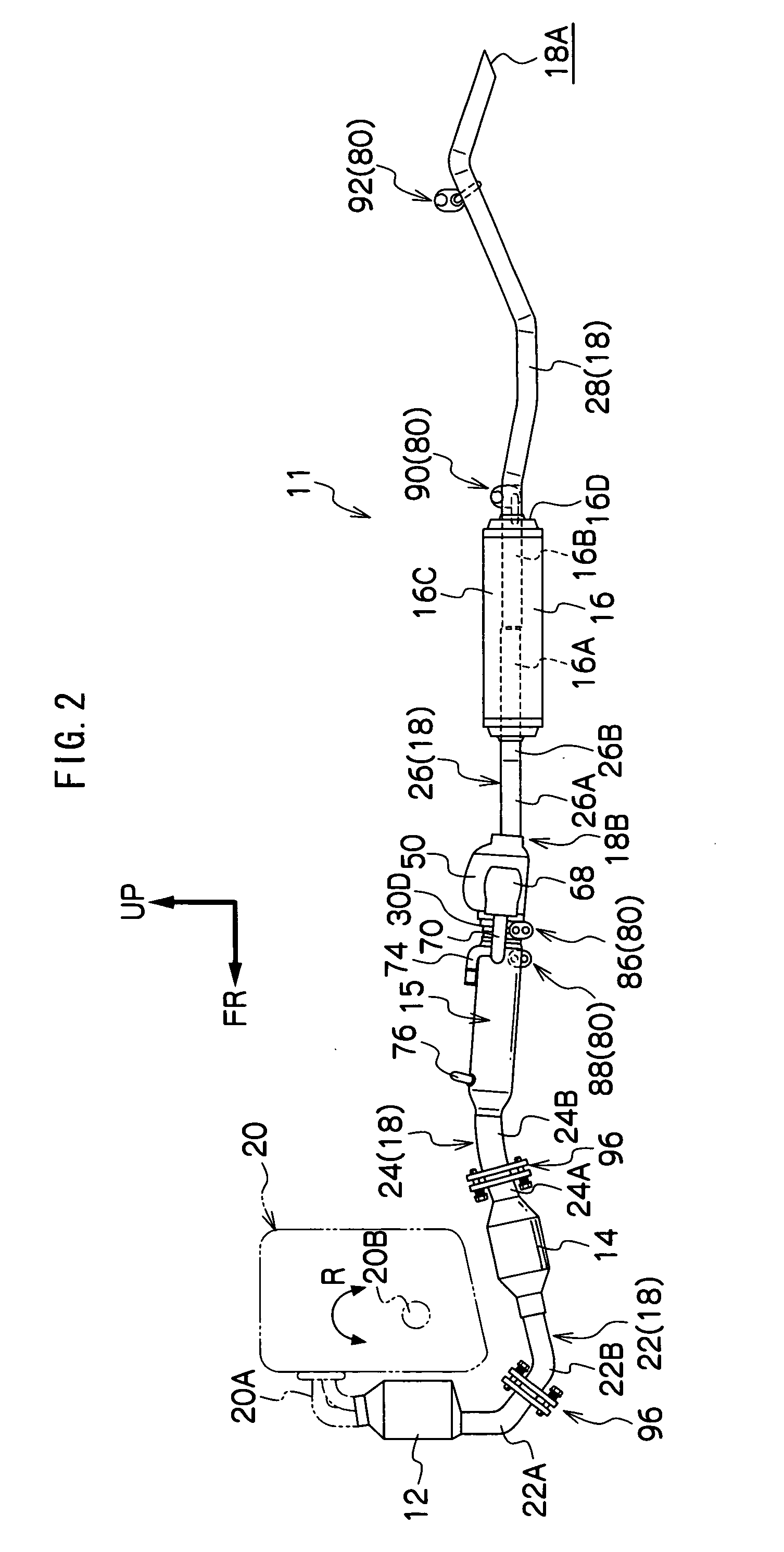

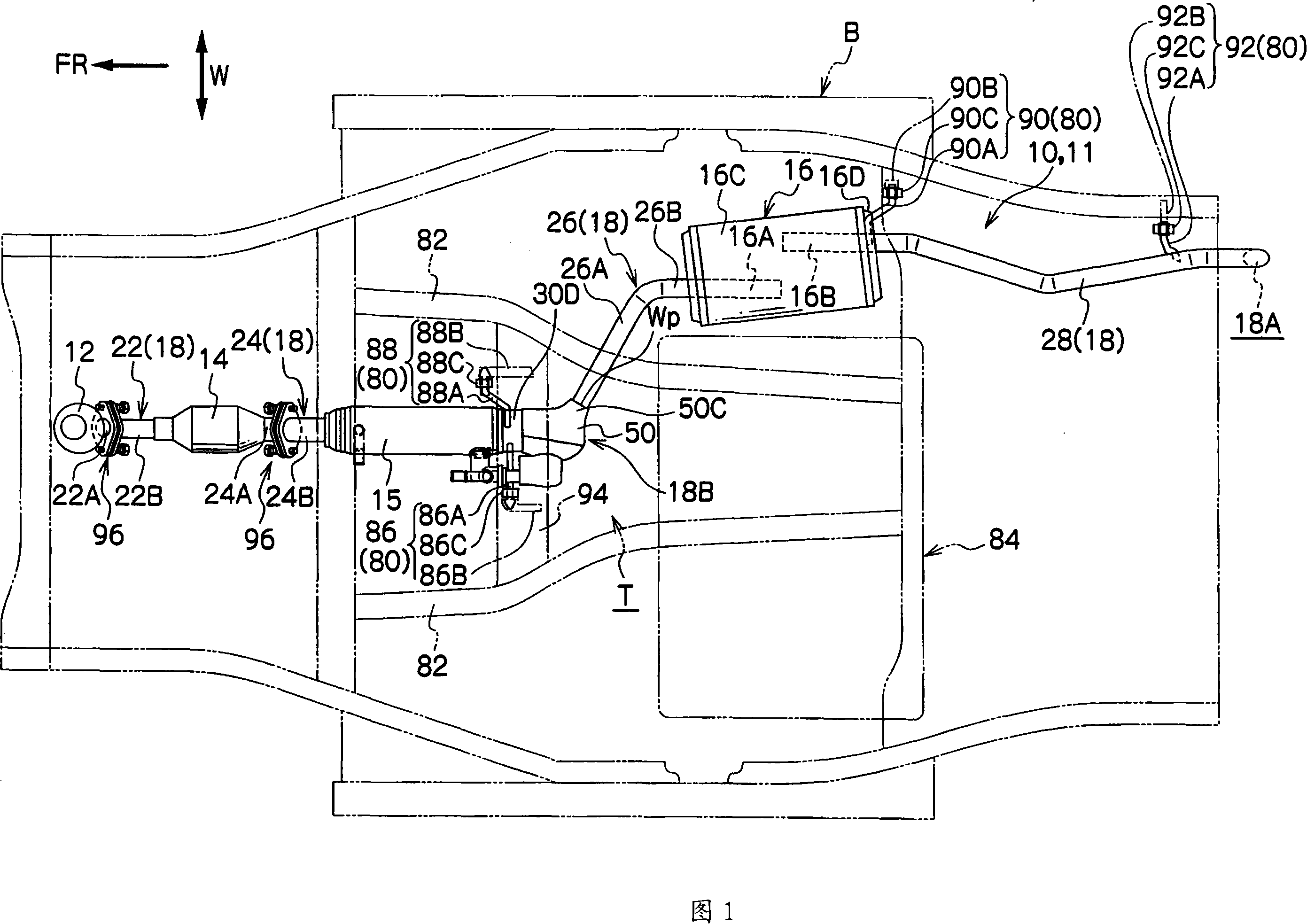

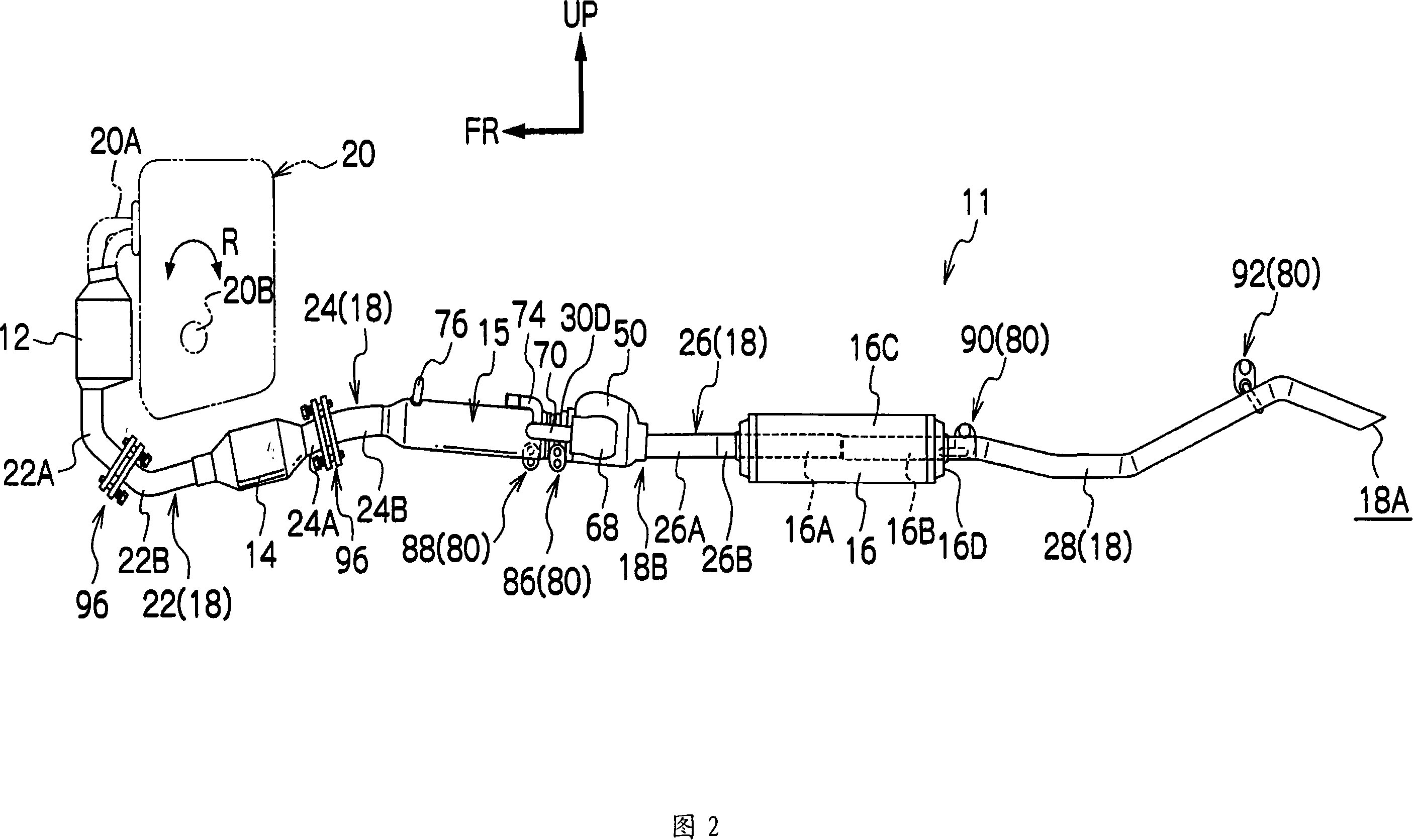

Vehicle exhaust system structure

A vehicle exhaust system structure is obtained which can protect well a bend portion of an exhaust pipe. A vehicle exhaust system structure 10 is intended to discharge exhaust gases of a front-engine front-drive vehicle with a transverse engine from a rear part of a vehicle body and is applied to an exhaust system 11 which is configured such that a first catalytic converter 12, a second catalytic converter 14, an exhaust system heat exchanger 15 and a muffler 16 are disposed sequentially in that order from an upstream side in an exhaust gas flow direction. In the exhaust system 11, a heat exchanger to muffler exhaust pipe 26 which connects the exhaust system heat exchanger 15 to the muffler 16 has an inclined portion 26A, and a portion of the exhaust system 11 which lies further rearwards than the exhaust system heat exchanger 15 is suspended from the vehicle body by a suspension unit 80. Provided on a catalytic converter to heat exchanger exhaust pipe 24 which connects the second catalytic converter 14 to the exhaust system heat exchanger 15 is a ball joint 96 which permits a relative displacement between the second catalytic converter 14 and the exhaust system heat exchanger 15.

Owner:TOYOTA JIDOSHA KK

Support structure for transversal engine

InactiveUS7117969B2Increased durabilityMake up a shortfall in the damping performanceUnderstructuresPlural diverse prime-mover propulsion mountingWorking fluidTransverse engine

A structure for supporting, via an engine mount, a transversal engine having a crankshaft laid horizontally at a right angle to a vehicle longitudinal axis, on a vehicle body, is disclosed. The engine mount includes at least one inclined hydro mount in which a working fluid is enclosed and a maximum damping generating axis is inclined a predetermined angle with respect to a vertical line. The inclined hydro mount is disposed inwardly of a total width in a power plant which includes the transversal engine and a transmission.

Owner:HONDA MOTOR CO LTD

Vehicle exhaust system structure

A vehicle exhaust system structure is obtained which can protect well a bend portion of an exhaust pipe. A vehicle exhaust system structure is intended to discharge exhaust gases of a front-engine front-drive vehicle with a transverse engine from a rear part of a vehicle body and is applied to an exhaust system which is configured such that a first catalytic converter, a second catalytic converter, an exhaust system heat exchanger and a muffler are disposed sequentially in that order from an upstream side in an exhaust gas flow direction. In the exhaust system, a heat exchanger to muffler exhaust pipe which connects the exhaust system heat exchanger to the muffler has an inclined portion, and a portion of the exhaust system which lies further rearwards than the exhaust system heat exchanger is suspended from the vehicle body by a suspension unit. Provided on a catalytic converter to heat exchanger exhaust pipe which connects the second catalytic converter to the exhaust system heat exchanger is a ball joint which permits a relative displacement between the second catalytic converter and the exhaust system heat exchanger.

Owner:TOYOTA JIDOSHA KK

Front wheel drive based power transfer unit (PTU) with hydraulically actuated disconnect

An arrangement of a vehicle is provided having normal transverse engine / transmission normal two-wheel drive operation which can be selectively placed into four-wheel drive operation wherein a pump which powers the coupling or uncoupling can be positioned downstream of a power takeoff unit without utilization of an electrically powered pump or transmission powered pump.

Owner:BORGWARNER INC

Exhaust apparatus for transverse engine

ActiveUS20110126521A1Increase in temperature of catalystRapid temperature measurementExhaust apparatusSilencing apparatusTransverse engineExhaust gas

An exhaust upstream section (48) of an exhaust apparatus (E) comprises a plurality of branch pipe portions (32), a plurality of intermediate collector pipe portions (33), a final collector pipe portion (34), and an exhaust gas-purifying unit (40). The exhaust gas-purifying unit (40) is disposed on a vehicle-rear side of an engine (1) to allow a gas passage thereinside to extend approximately in a vehicle-widthwise direction, in top plan view. Each of the plurality of intermediate collector pipe portions (33) curves to allow an exhaust downstream region of the intermediate collector pipe portion (33) to be oriented toward one side or the other side of the vehicle-widthwise direction, in top plan view, and the final collector pipe portion (34) curves to allow an exhaust downstream region of the final collector pipe portion (34) to be oriented toward a vehicle-front side, in top plan view. This makes it possible to compactly lay out the exhaust upstream section (48) in an engine compartment (19) without sacrificing a passenger compartment space, and quickly raise a temperature of a catalyst in an exhaust gas-purifying unit (40) during warm-up of the engine (1).

Owner:MAZDA MOTOR CORP

Exhaust apparatus for transverse engine

InactiveCN102085805ACompact configurationWithout sacrificing spaceExhaust apparatusSilencing apparatusTransverse engineExhaust pipe

An upstream exhaust assembly (48) of an exhaust apparatus (E) of the present invention comprises: a plurality of branch pipe portions (32), a single exhaust pipe portion (34), and an exhaust gas-purifying unit (40). The exhaust gas-purifying unit (40) is disposed on a vehicle-rear side of the engine (1) to allow a gas passage thereinside to extend approximately in a vehicle-widthwise direction, in top plan view. The upstream exhaust assembly (48) includes, on an exhaust upstream side of the single exhaust pipe portion (34), a section which curves to allow an exhaust downstream region of the section to be oriented toward one side of the vehicle-widthwise direction which is a direction coming close to the transmission (11), in top plan view. The single exhaust pipe portion (34) curves to allow an exhaust downstream region of the single exhaust pipe portion (34) to be oriented toward a vehicle-front side, in top plan view. This makes it possible to compactly lay out the upstream exhaust assembly (48) in an engine compartment (19) without sacrificing a passenger compartment space, and quickly raise a temperature of a catalyst in the exhaust gas-purifying unit (40) during warm-up of the engine (1).

Owner:MAZDA MOTOR CORP

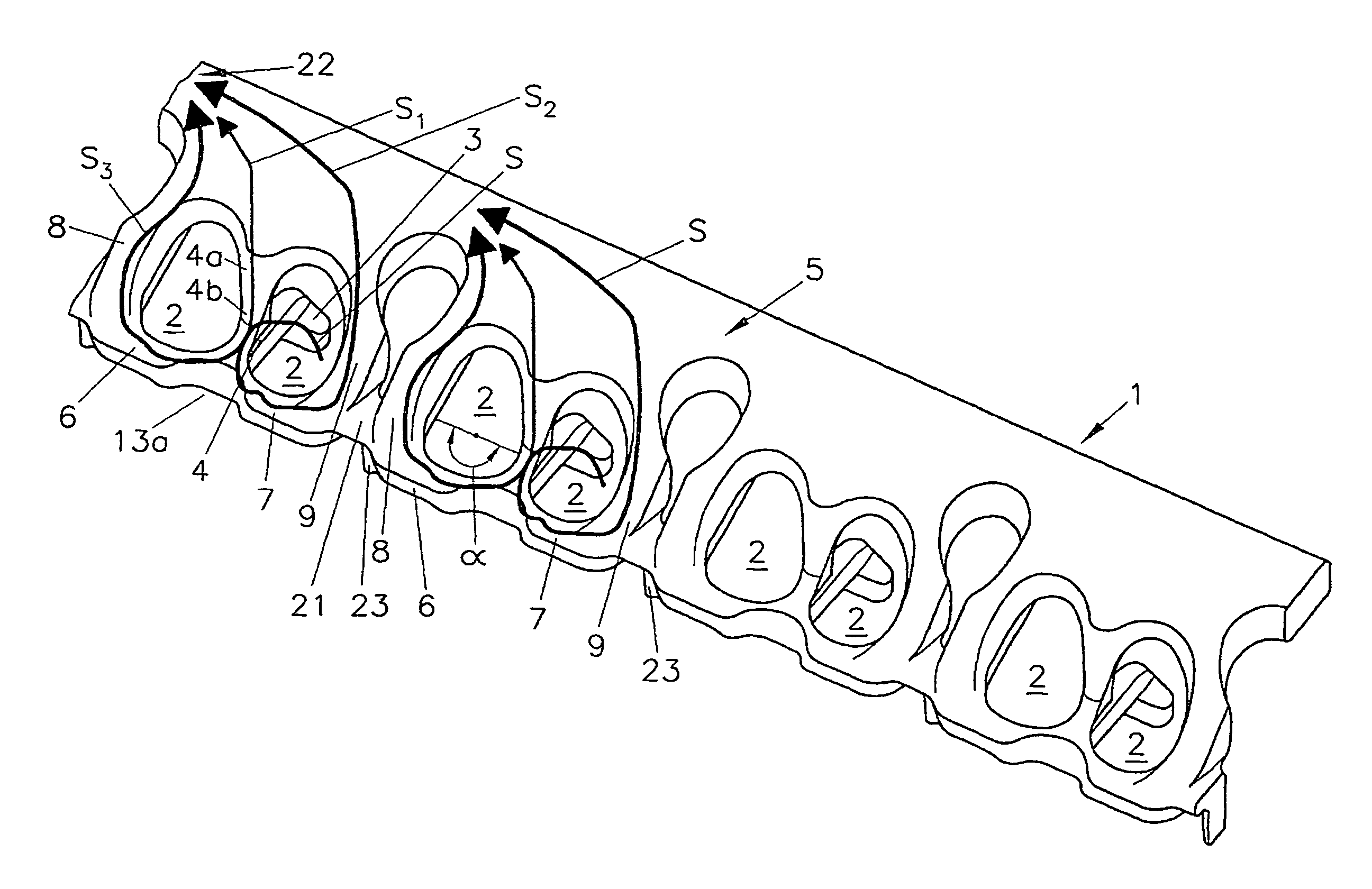

Cylinder head of an internal combustion engine

ActiveUS8662028B2Improve cooling effectHigh strengthLiquid coolingCylinder headsCylinder headExternal combustion engine

A cylinder head of an internal combustion engine with several cylinders includes an inlet side and an outlet side with at least two outlet channels per cylinder, wherein a first coolant jacket is arranged in the cylinder head, the first coolant jacket including a first coolant collection channel which extends along the cylinder head on the outlet side over the outlet channels. The first coolant collection channel is connected to cooling chambers at least partially surrounding the outlet channels, the cooling chambers being in a fluidic connection with at least one transfer opening in a cylinder head gasket plane, wherein one first transfer opening per cylinder is arranged in a first transverse engine plane containing a cylinder axis, and wherein a first transverse cooling passage extends from each first transfer opening in the first transverse engine plane between two respective outlet channels, the first transverse cooling passage splitting into two cooling sub-passages in the area of the cylinder axis. Each cooling sub-passage respectively surrounds an outlet channel in the area of a respective outlet opening over an angle (α) of approximately 180° and each cooling sub-passage is connected to the coolant collection channel by means of a second transverse cooling passage, wherein each second transverse cooling passage is arranged in the area of a second transverse engine plane extending through at least one cylinder head bolt bore.

Owner:AVL LIST GMBH

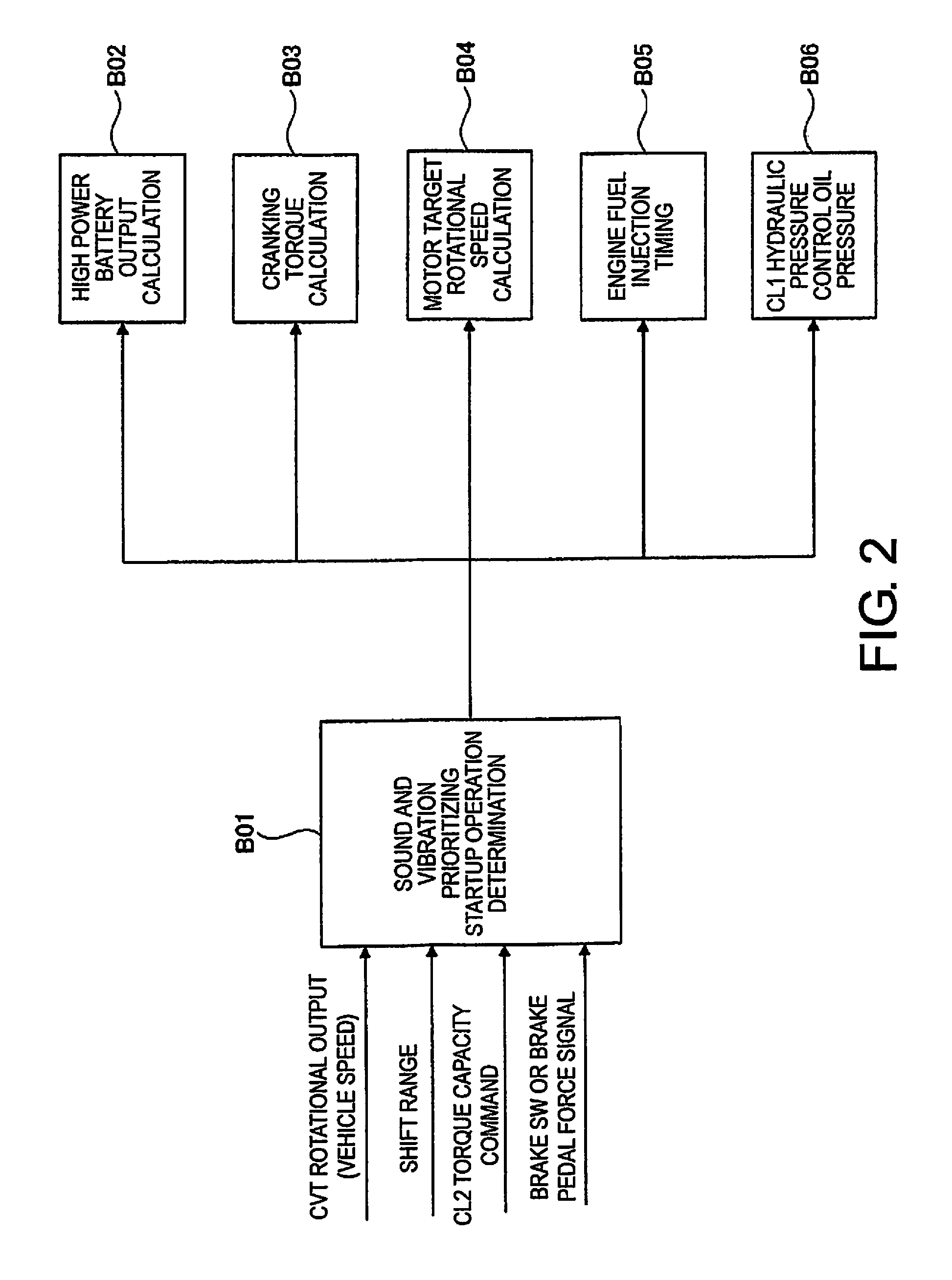

Hybrid vehicle control device

ActiveUS9586469B2Quiet engine startSuppress generationElectrical controlGas pressure propulsion mountingTransverse engineEngineering

A hybrid vehicle control device is provided for controlling a drive system in a hybrid vehicle. The hybrid vehicle control device is provided with a hybrid control module that begins engagement of a clutch, and cranks a transverse engine using a motor / generator as a drive source, when a request is made to start an engine in an EV mode. The hybrid control module has a “normal start mode” and a “sound and vibration prioritizing startup mode” as engine startup modes. The “normal start mode” prioritizes drive force response performance. The “sound and vibration prioritizing startup mode” prioritizes sound and vibration reduction performance. If a drive range is selected and the vehicle is stopped when an engine startup request is made, then the “sound and vibration prioritizing startup mode” is selected, and the transverse engine is started.

Owner:NISSAN MOTOR CO LTD

Exhaust pipe flexible joint structure

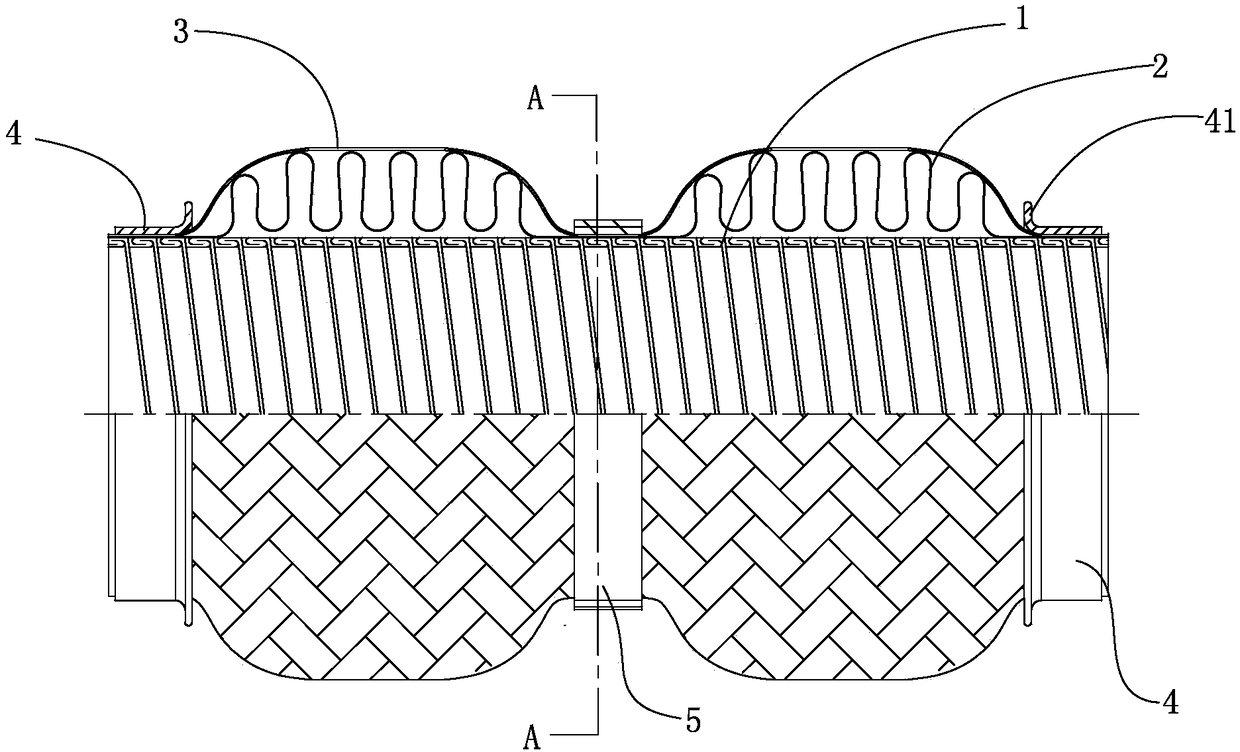

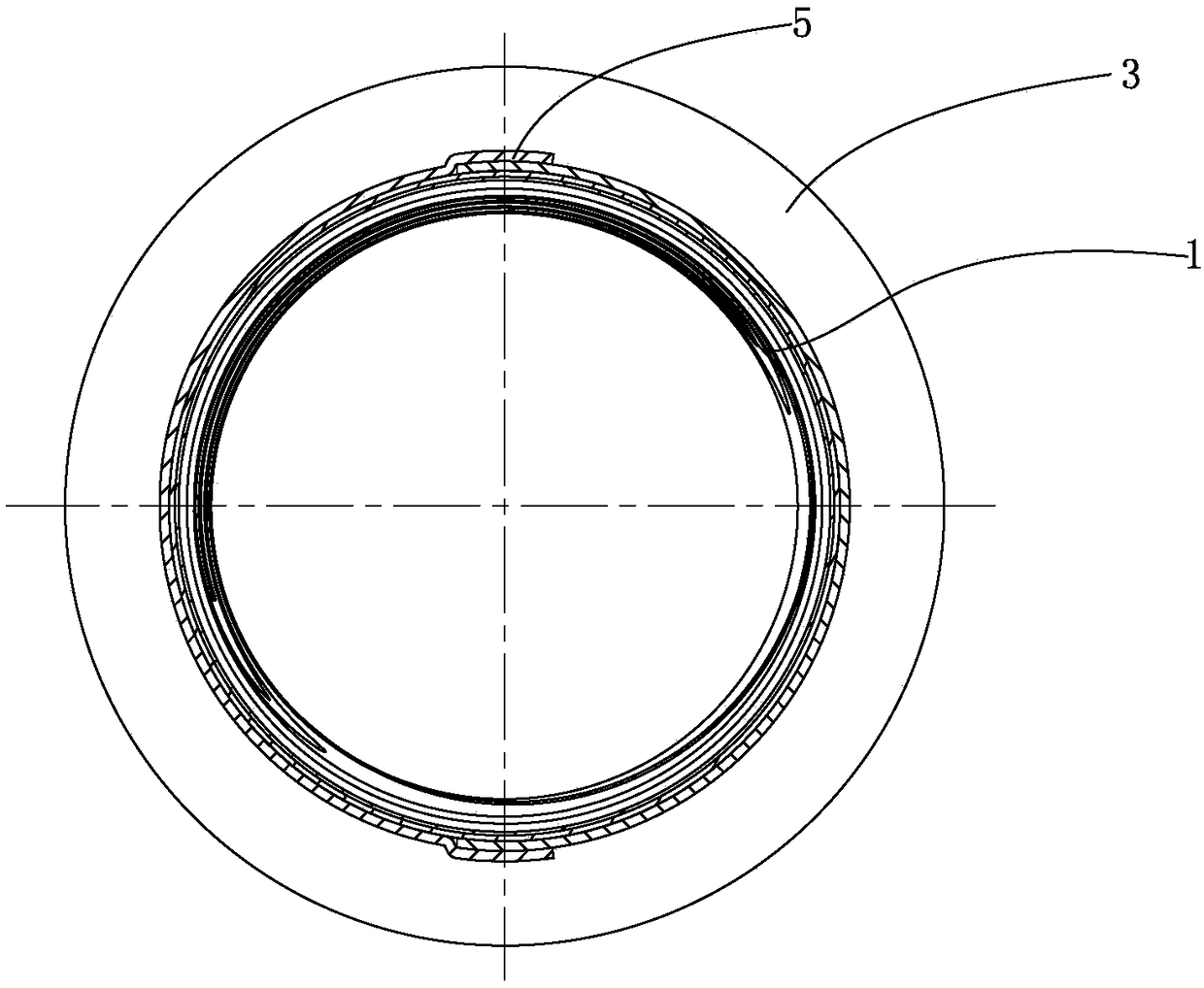

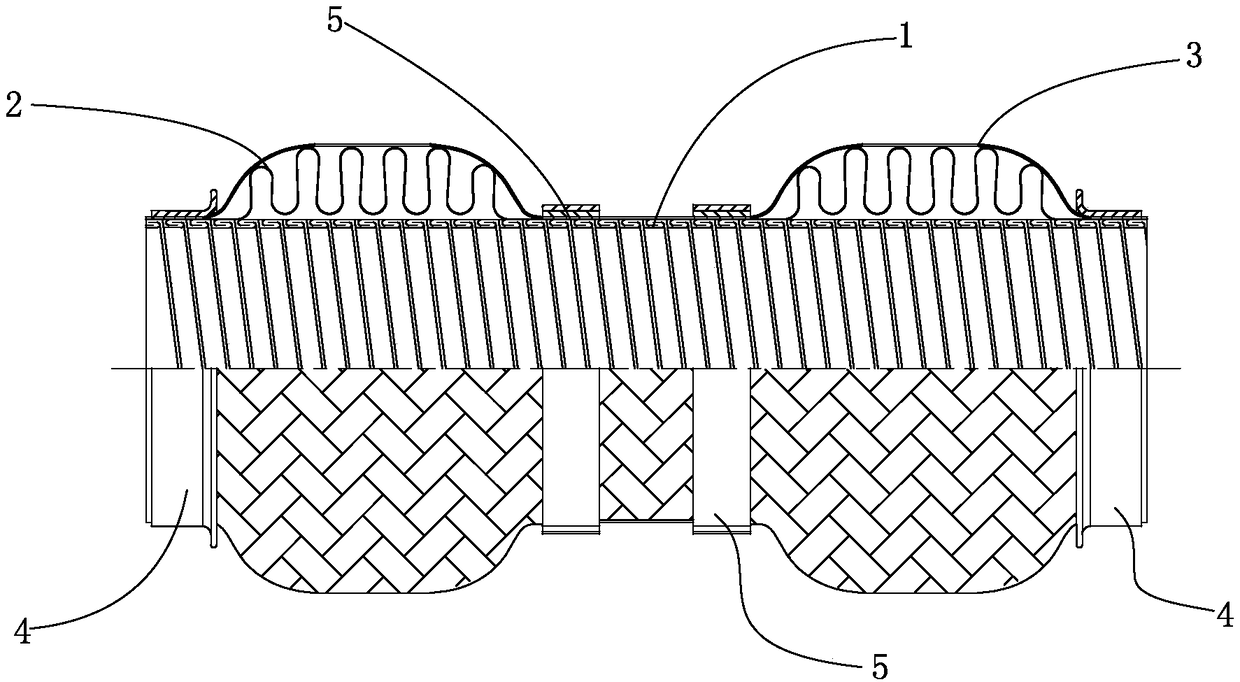

PendingCN108757136AFit closelyReduce stressSilencing apparatusAdjustable jointsLongitudinal engineTransverse engine

The invention relates to an exhaust pipe flexible joint structure. The exhaust pipe flexible joint structure is mainly used in a vehicle exhaust pipe structure, and comprises a corrugated pipe and braided meshes, wherein the corrugated pipe and the braided meshes are coaxially arranged in sequence from inside to outside in a sleeving mode; and the exhaust pipe flexible joint structure is characterized by comprising at least two sections of the braided meshes, moreover, the two ends of each section of the braided mesh are fixedly connected with the corrugated pipe on the inner side through fixing pieces, and the length of each section of braided mesh is smaller than or equal to 200 mm. According to the exhaust pipe flexible joint structure, a better damping effect is achieved, the NVH effect of the whole vehicle is improved; moreover, in a transverse-engine front-drive automobile, when relatively large swing occurs in the front row of an exhaust system, the shearing deformation of the corrugated pipe inside can be converted into bending deformation through the tightly-attached braided meshes, in an longitudinal-engine rear-drive automobile, when the front row of the exhaust system rotates, the braided meshes can well share a part of the torque, then the stress of the corrugated pipe inside is greatly reduced, and the service life of the corrugated pipe inside is prolonged.

Owner:NINGBO KINROM IND

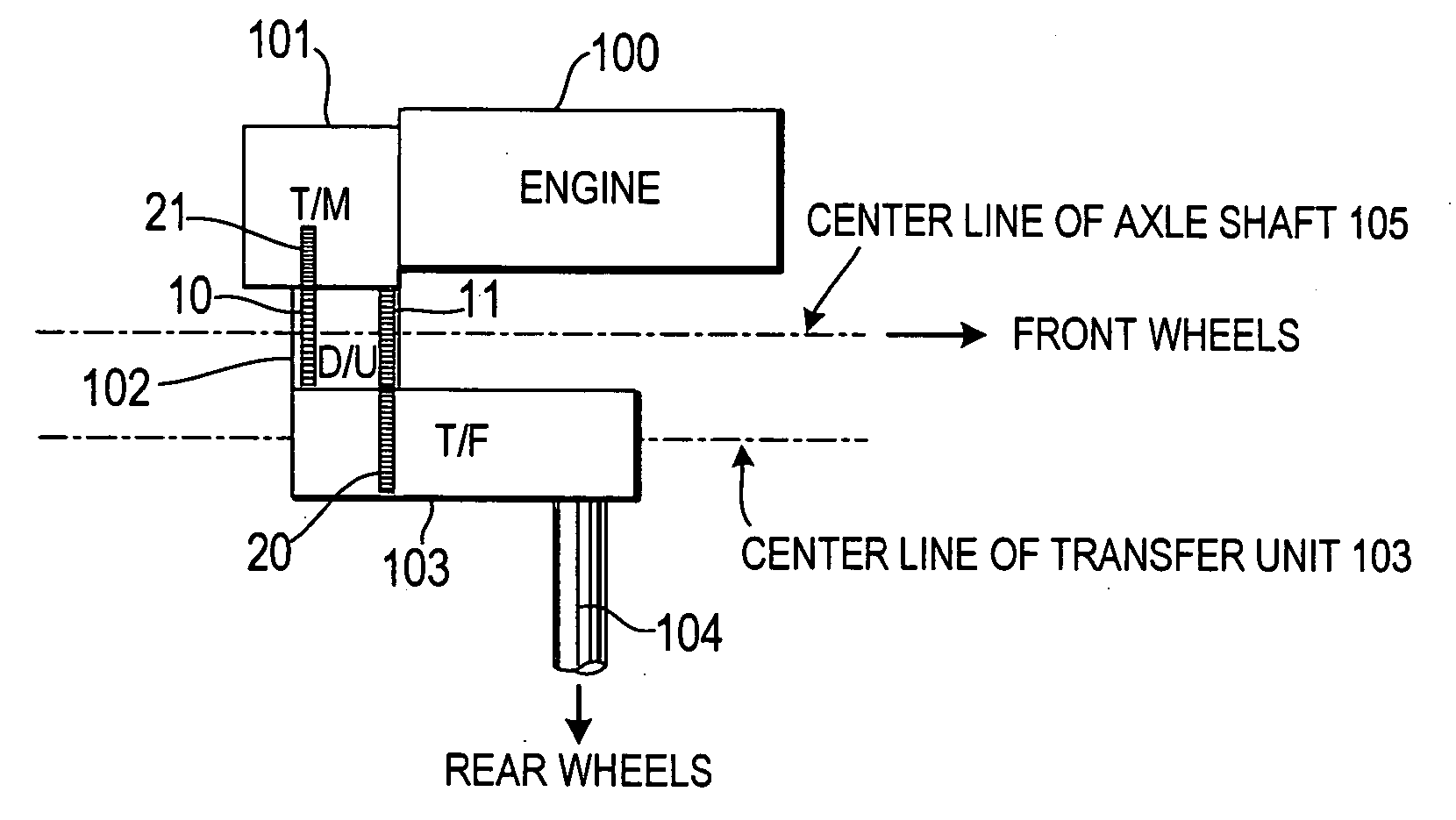

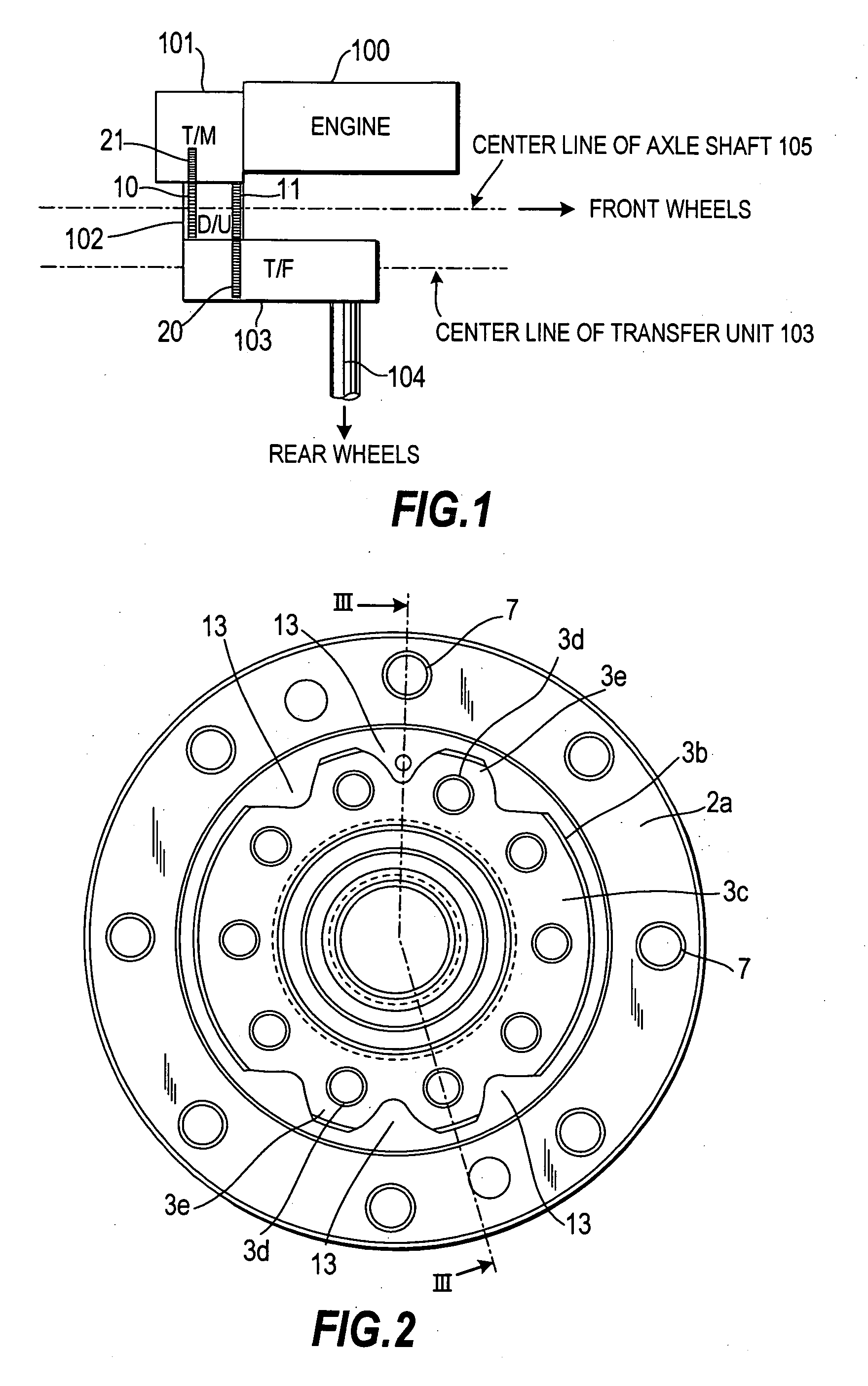

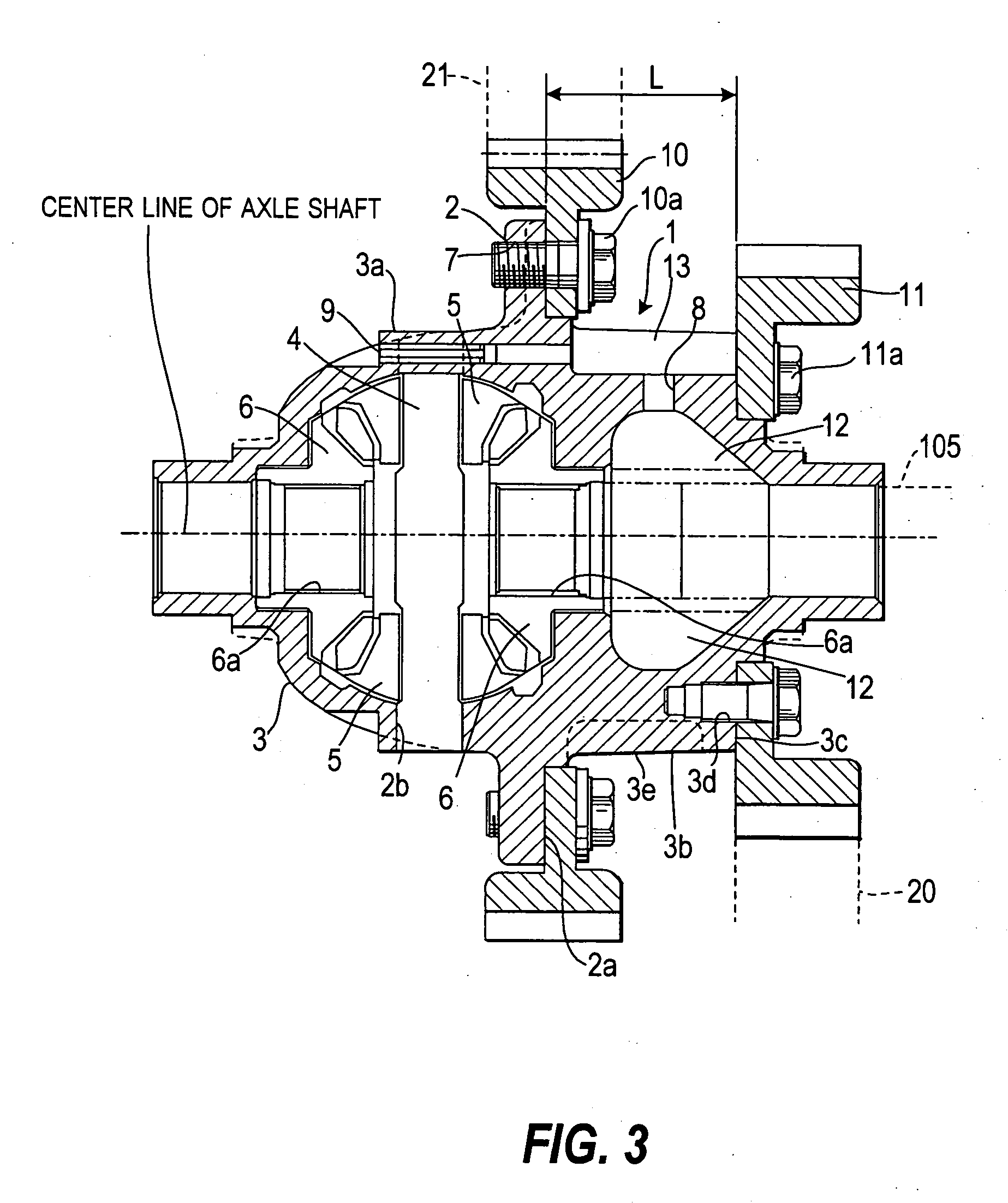

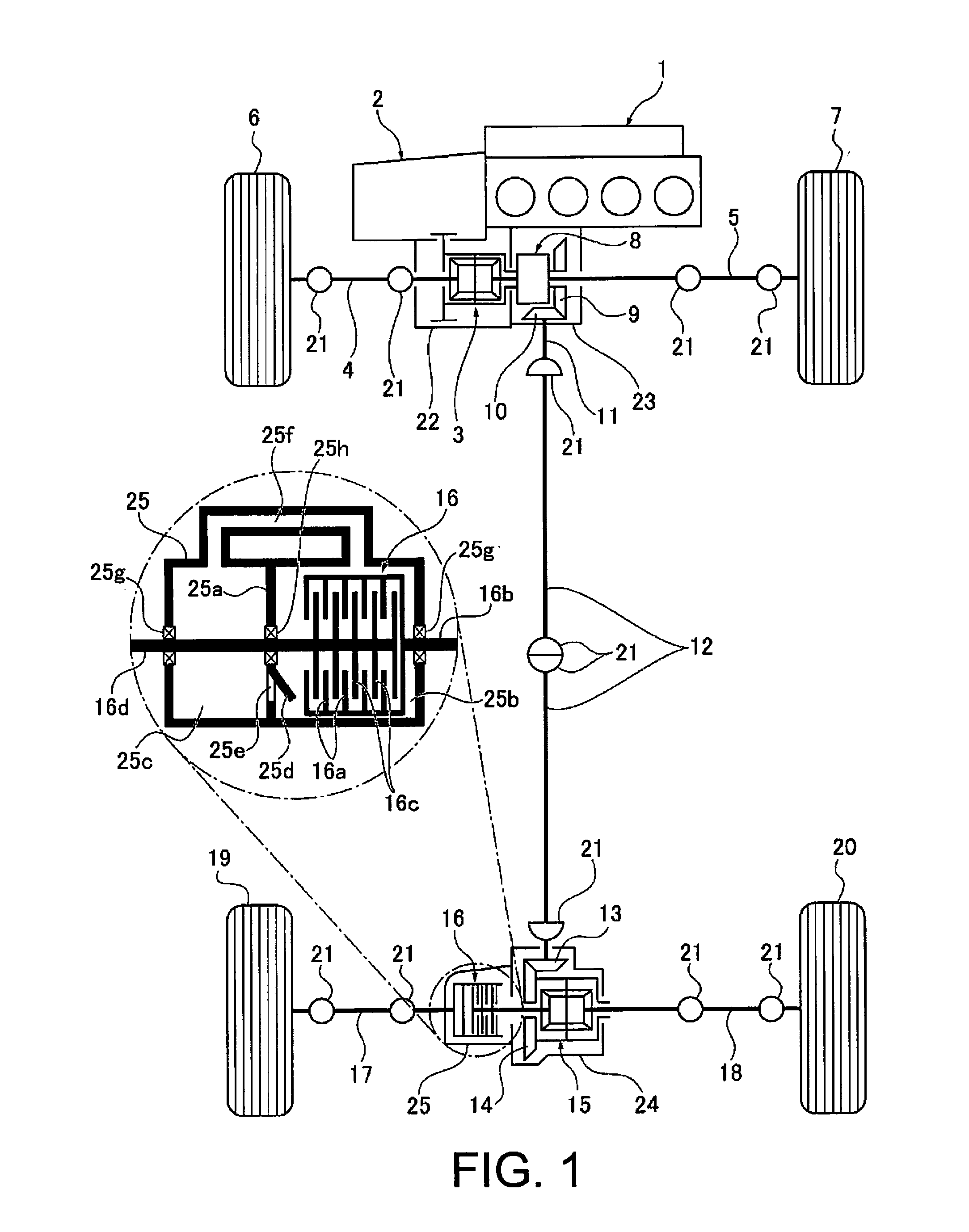

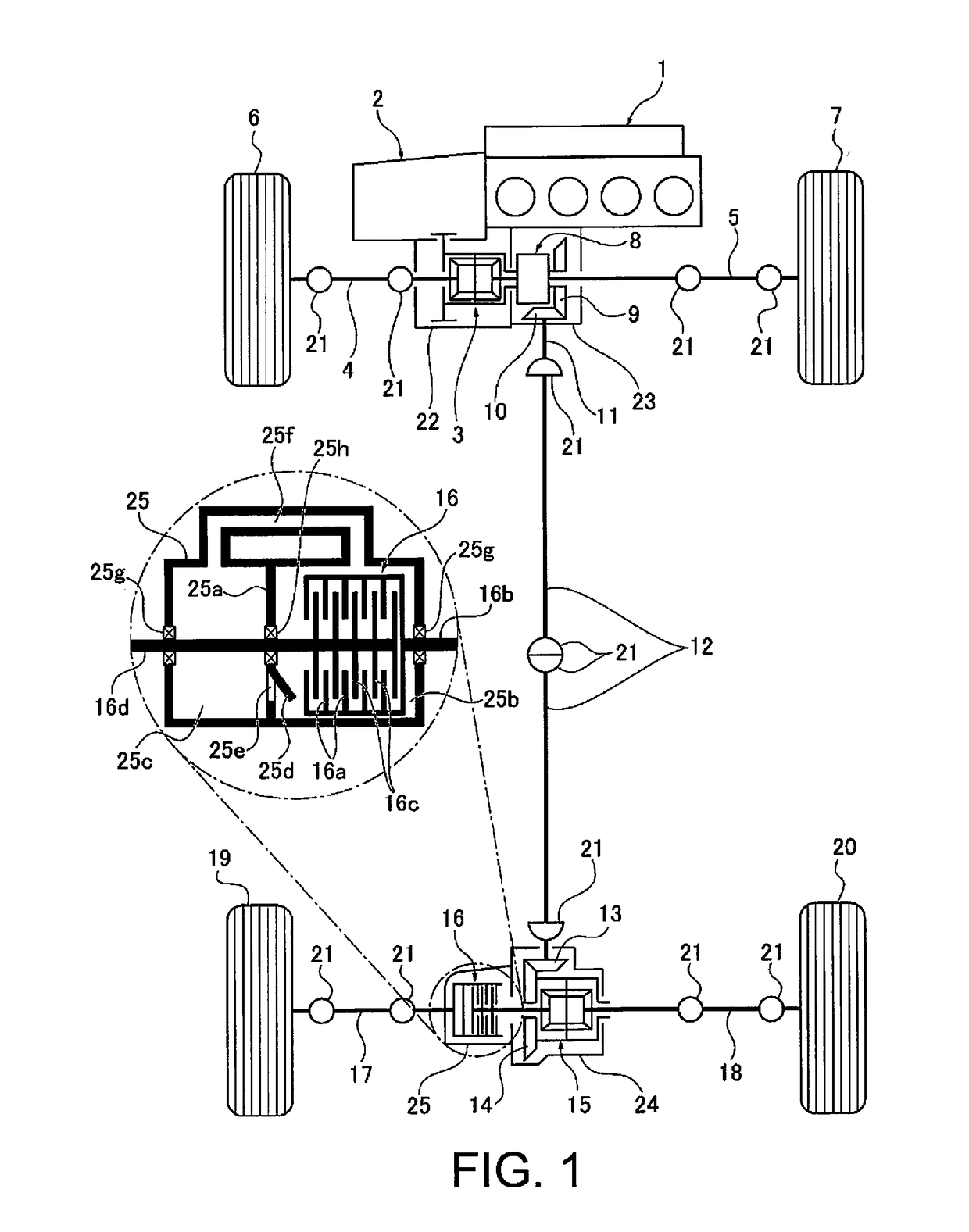

Drive mechanism for a four wheel drive transverse engine-mounted vehicle

InactiveUS20050221942A1Reduce weightSecure spaceGearboxesGear lubrication/coolingTransverse engineDrive shaft

A differential unit (102) is provided with a ring gear (10) that meshes with an output gear (21) of a transmission (101), an axle shaft (105) that is connected to front wheels, and a drive gear (11) that is fixed by screws to a plurality of boss portions (3e) and spaced apart from the ring gear (10). A transfer unit (103) disposed rearward of the differential unit (102) is provided with a driven gear (20) that meshes with the drive gear (11). Drive force is transmitted from the driven gear (20) to a propeller shaft (104), and the propeller shaft (104) transmits the drive force to rear wheels. First material-removed portions (12) made of concave portions are formed in an inner circumference of a portion of a case (1) to which the axle shaft (105) is mounted. Second material-removed portions (13) made of concave portions that extend in an axial direction of the axle shaft (105) are formed between the plurality of boss portions (3e).

Owner:JATCO LTD

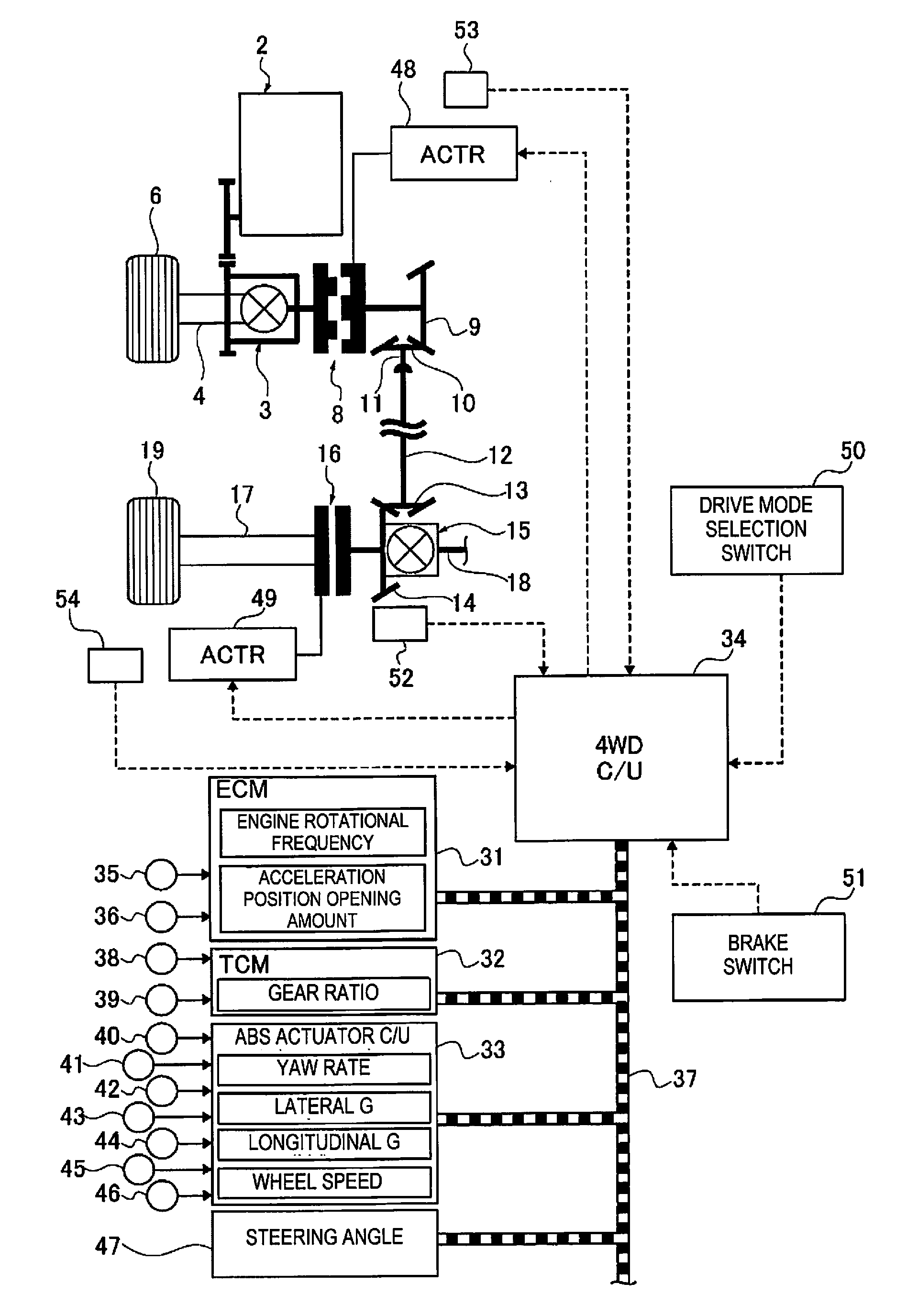

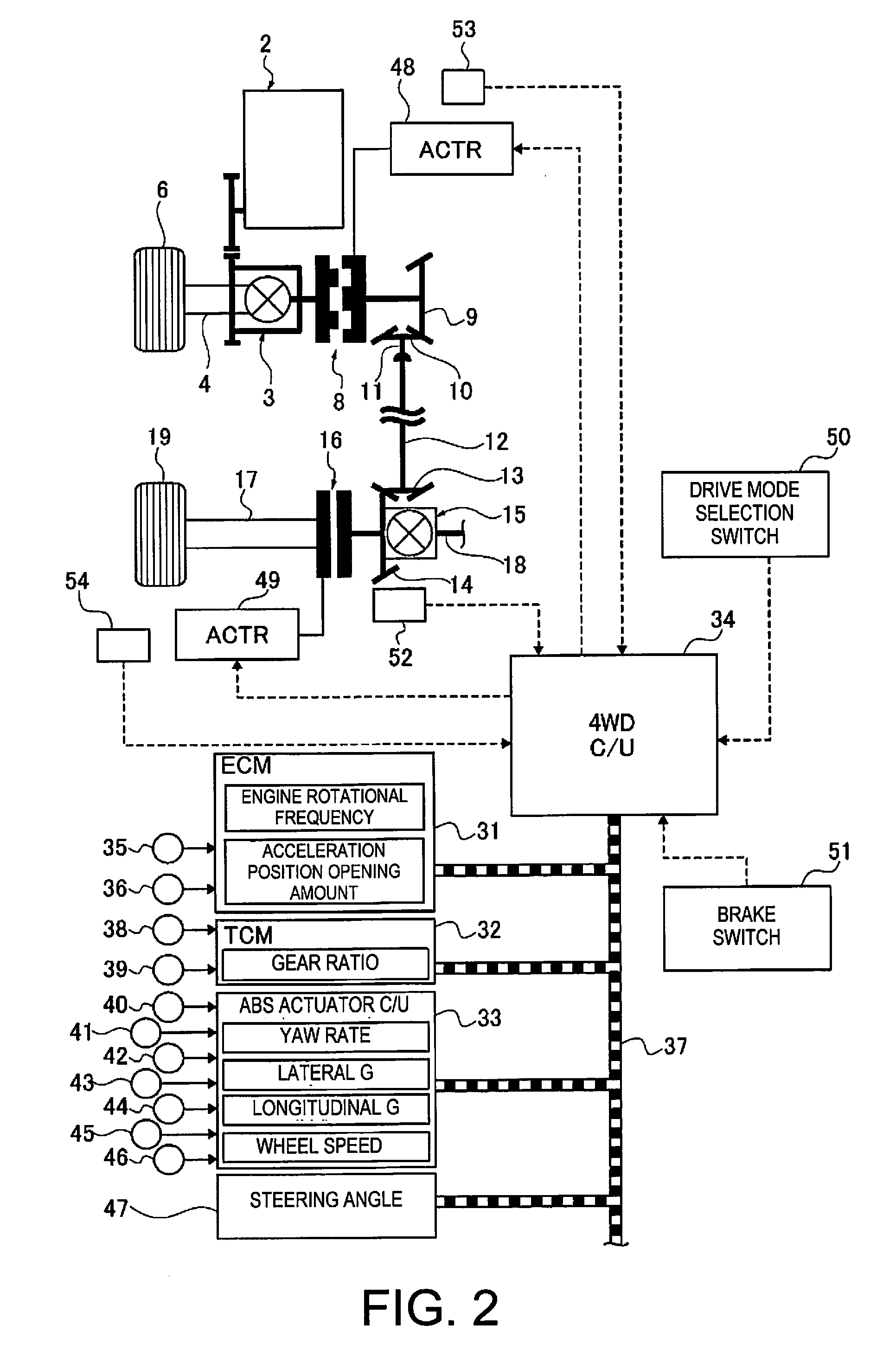

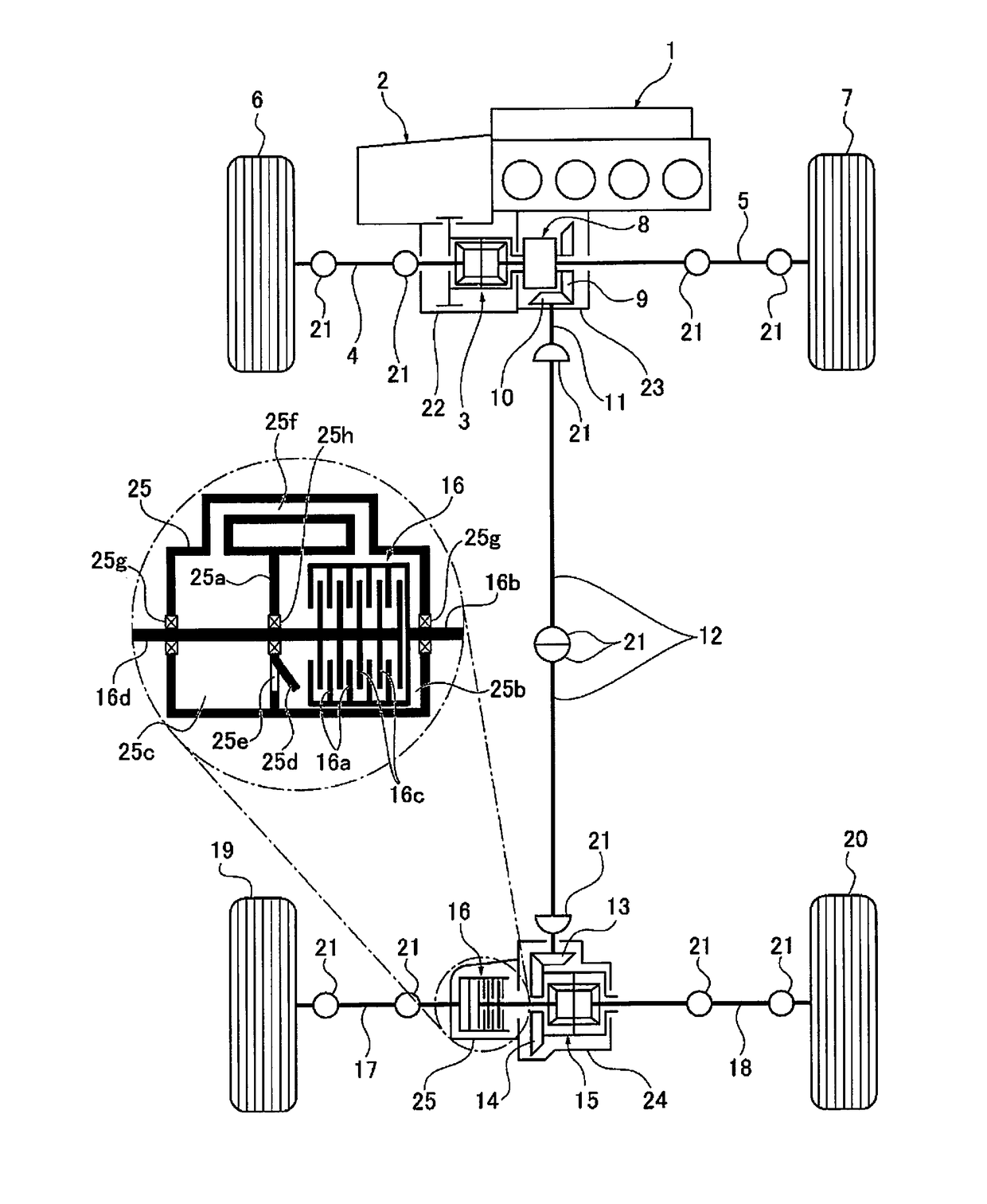

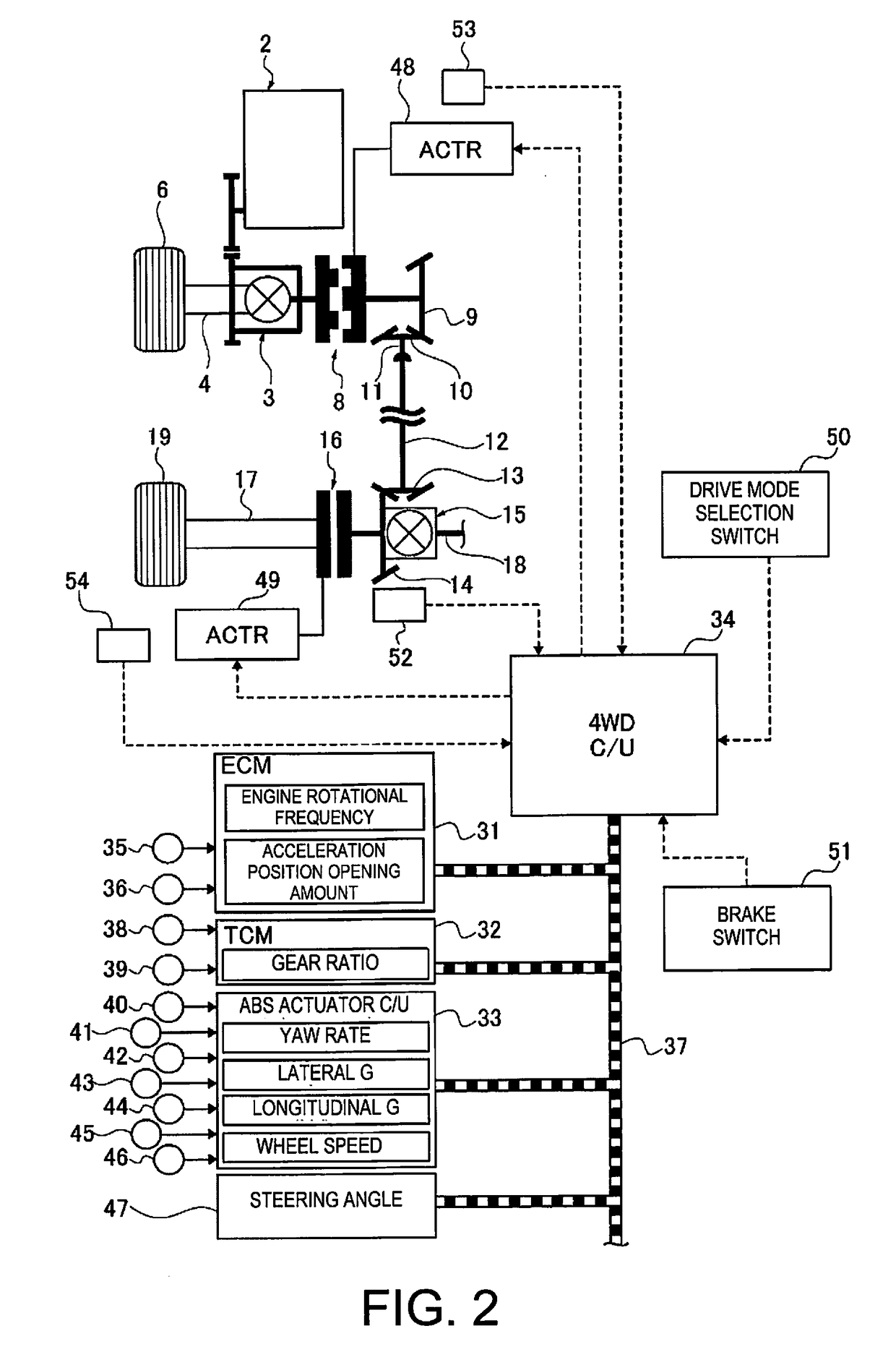

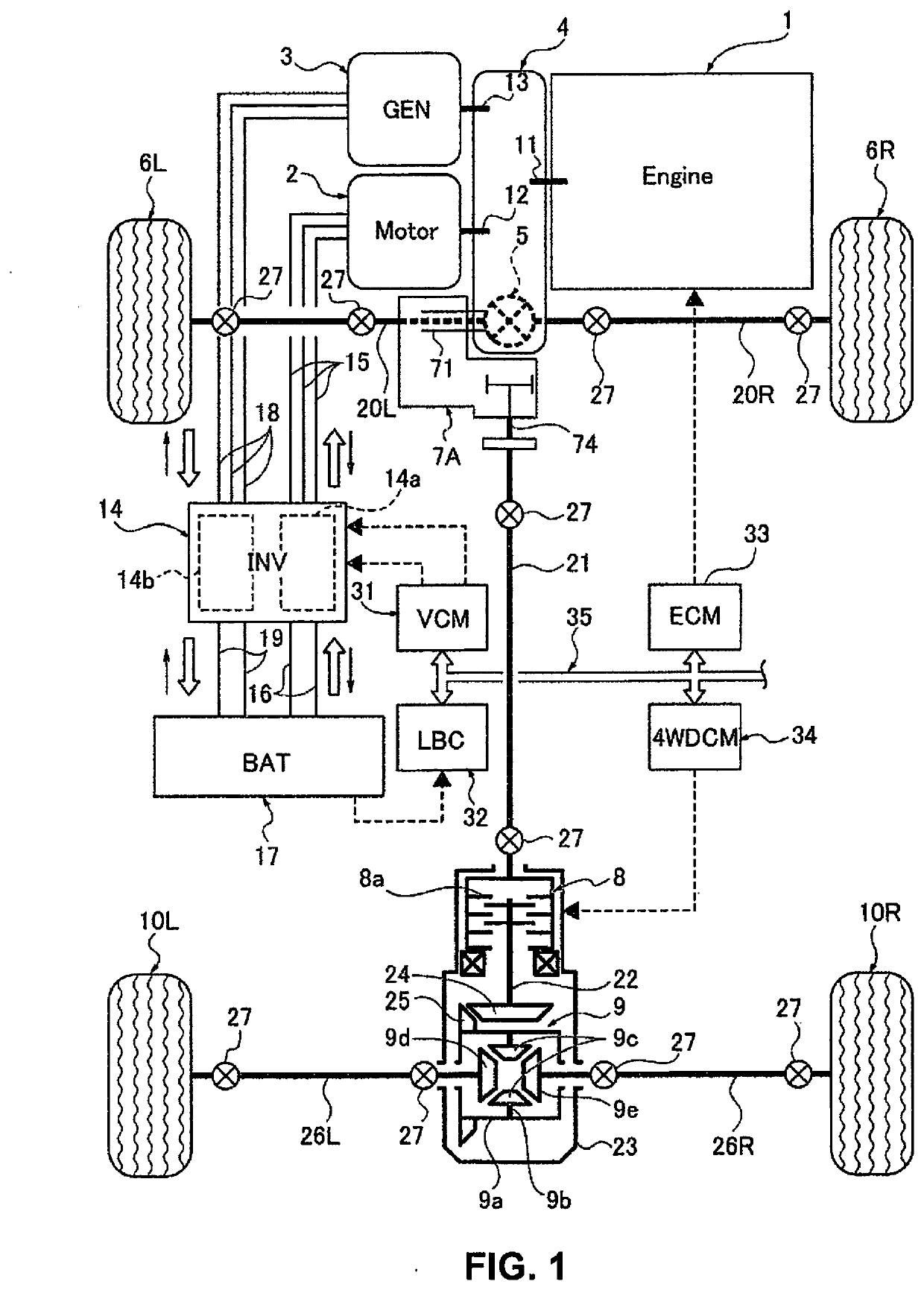

Clutch control device for four-wheel-drive vehicle

ActiveUS20170028843A1Eliminate waiting timeImprove performanceFluid actuated clutchesVehicle sub-unit featuresClutch controlTransverse engine

A vehicle clutch control device is provided for switching from a two-wheel drive traveling to a four-wheel drive traveling. The vehicle clutch control device includes a dog clutch that separates a rear wheel drive from a front wheel drive by releasing the dog clutch, an electronically controlled coupling that distributes a driving force of a transverse engine to left and right rear wheels in accordance with a clutch connection capacity, and a four-wheel drive control unit. The four-wheel drive control unit switches the drive mode to one of a disconnect two-wheel drive mode in which the dog clutch and the electronically controlled coupling are released, a connect four-wheel drive mode in which the dog clutch and the electronically controlled coupling are engaged, and a stand-by two-wheel drive mode in which the dog clutch is engaged while the electronically controlled coupling is released.

Owner:NISSAN MOTOR CO LTD

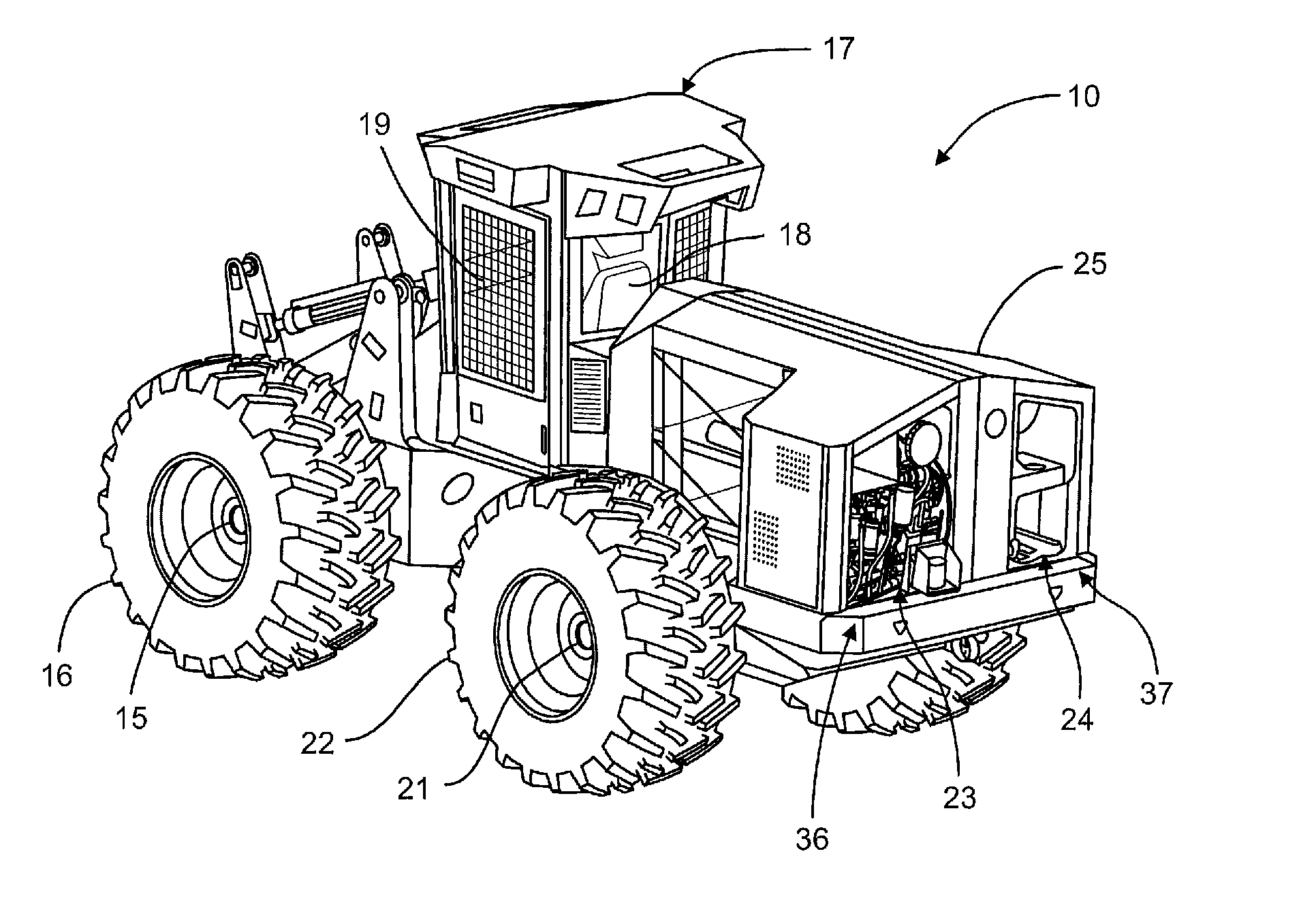

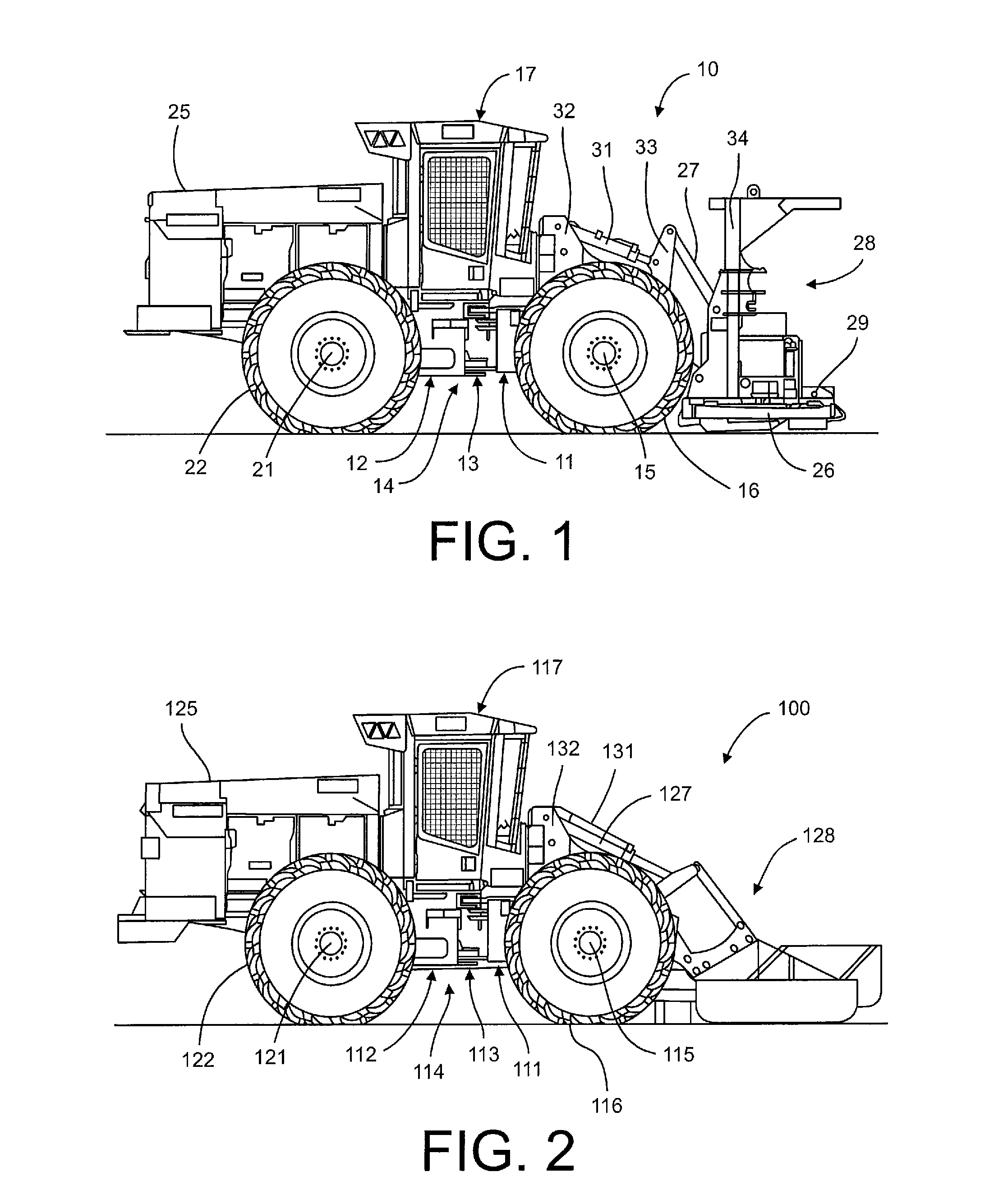

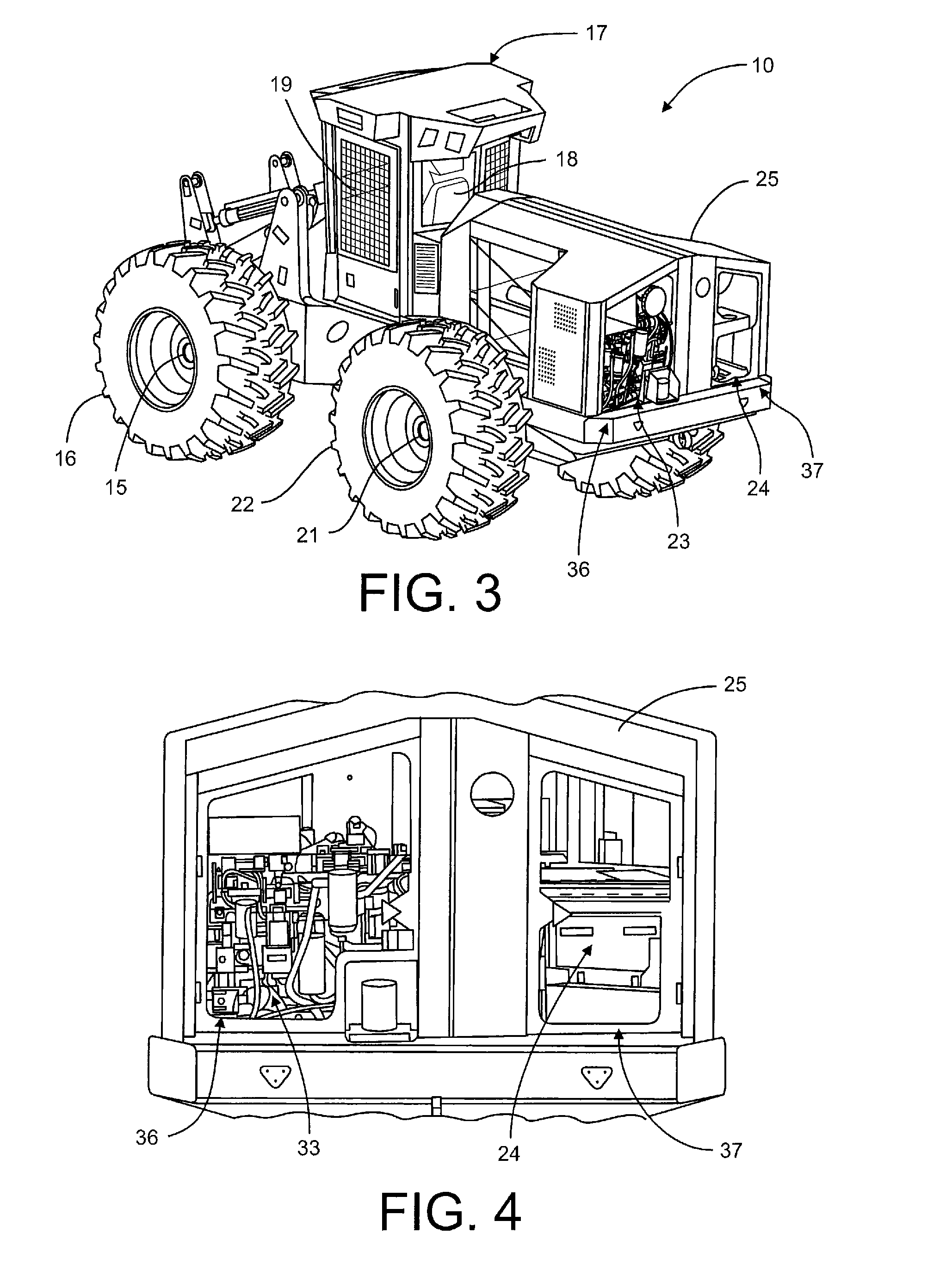

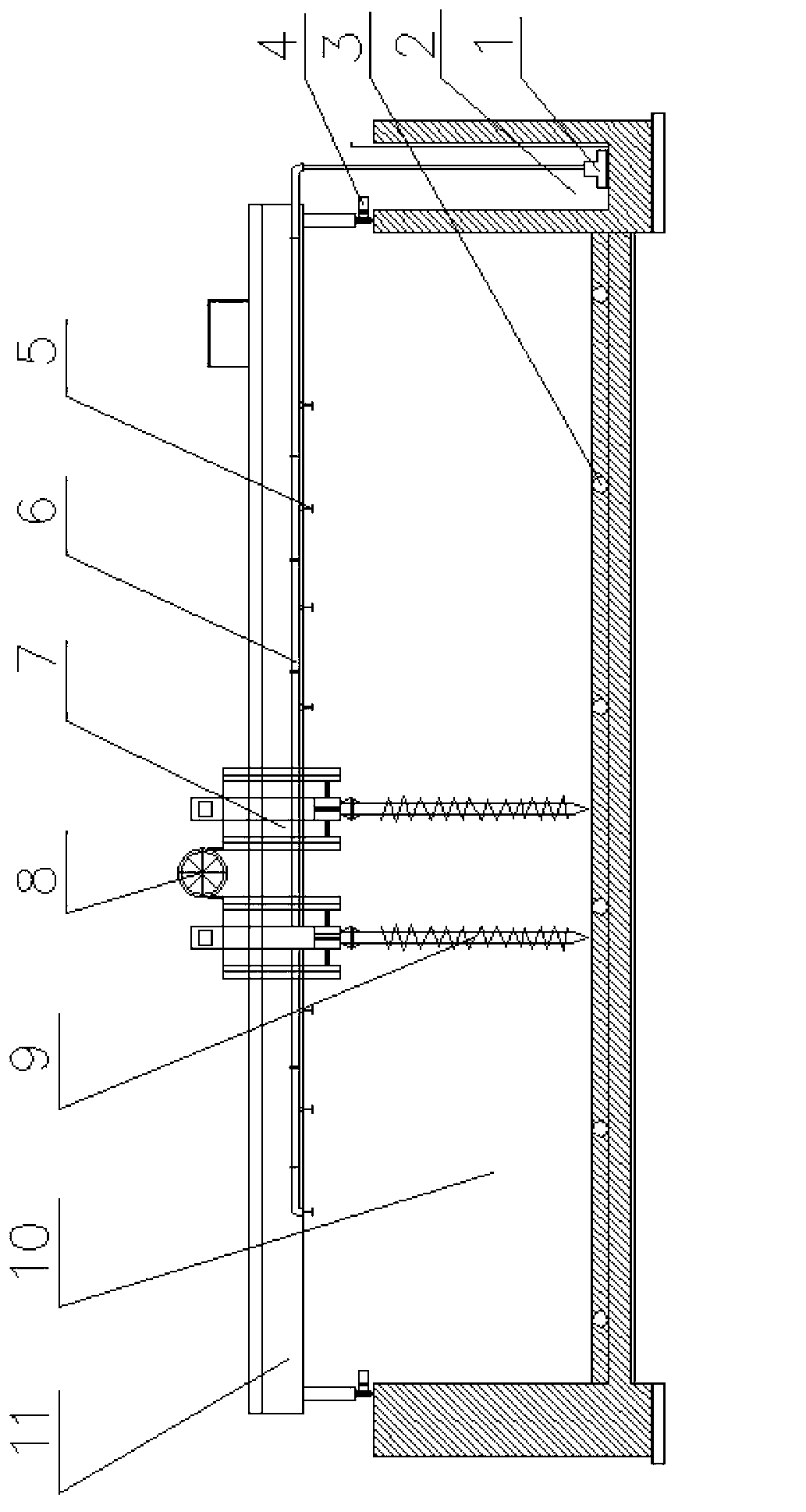

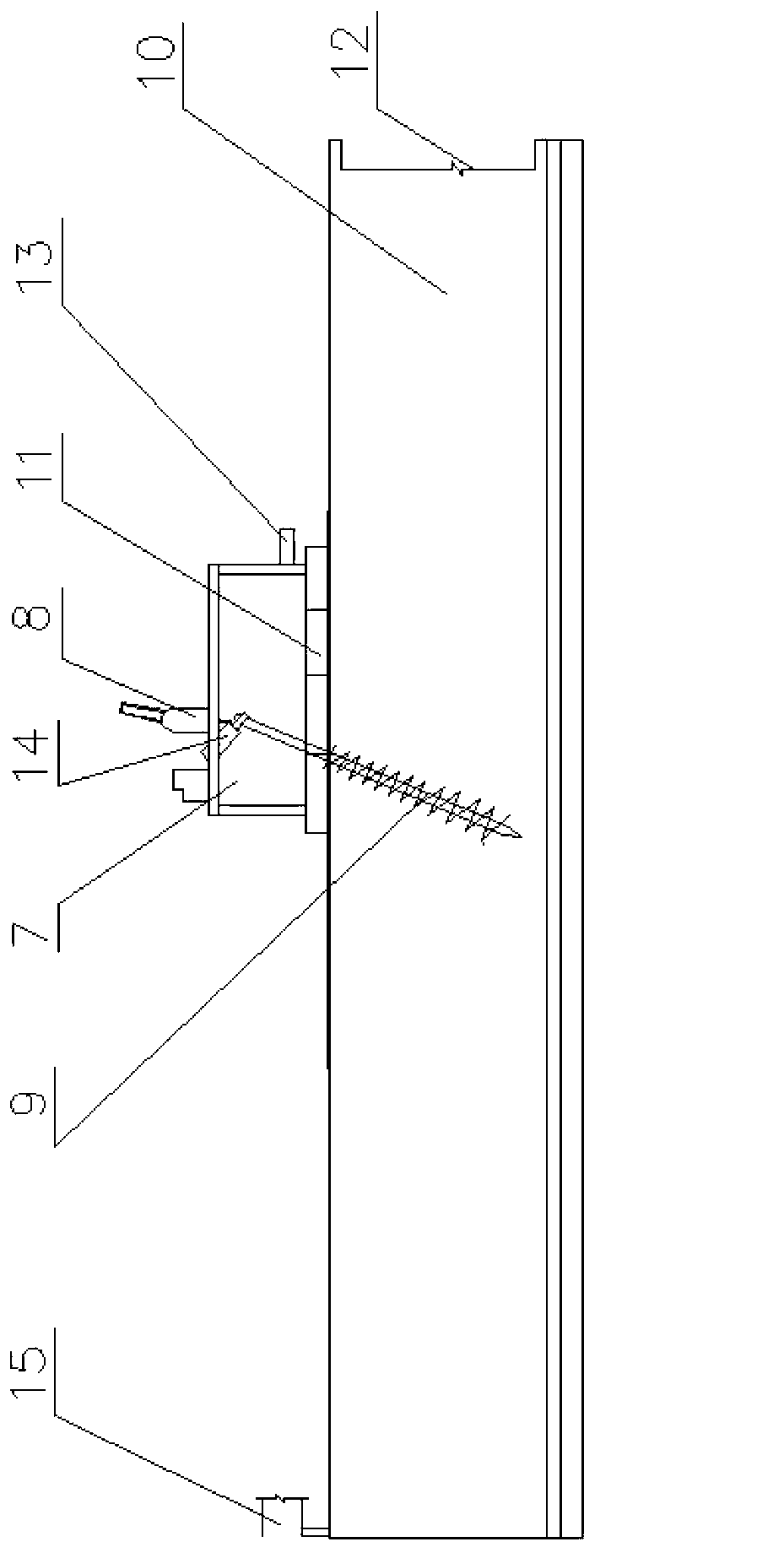

Forestry Machines with Transverse Engine and Hydraulic System Installation

A wheeled forestry tractors design, such as that for a wheel feller-buncher or a site prep tractor, is disclosed. The disclosed design includes a front axle connected to a rear axle by an articulated chassis. A cab is supported between and above the front and rear axles by the chassis. An engine and a hydraulic system are mounted opposite the rear axle from the cab and in a side-by-side relationship with the engine being aligned transversely with respect to the chassis and parallel to the rear axle. The engine is mounted transversely or parallel with respect to the rear axle and slightly behind the rear axle to improve the weight distribution between the front and rear axles or between the front and rear frames. By mounting the engine transversely and on one side of the rear of the tractor and the hydraulic system on the other side of the tractor in combination with placing the fuel tank in alignment with the engine and the oil tank in alignment with the hydraulic system, improved left to right weight distribution is also achieved.

Owner:CATERPILLAR INC

Exhaust apparatus for transverse engine

InactiveCN102085804AWithout sacrificing spaceThe temperature risesExhaust apparatusSilencing apparatusTransverse engineAutomotive engineering

The present invention provides an exhaust apparatus for a transverse engine. An exhaust upstream section (48) of the exhaust apparatus (E) comprises a plurality of branch pipe portions (32), a plurality of intermediate collector pipe portions (33), a final collector pipe portion (34), and an exhaust gas-purifying unit (40). The exhaust gas-purifying unit (40) is disposed on a vehicle-rear side of an engine (1) to allow a gas passage thereinside to extend approximately in a vehicle-widthwise direction, in top plan view. Each of the plurality of intermediate collector pipe portions (33) curves to allow an exhaust downstream region of the intermediate collector pipe portion (33) to be oriented toward one side or the other side of the vehicle-widthwise direction, in top plan view, and the final collector pipe portion (34) curves to allow an exhaust downstream region of the final collector pipe portion (34) to be oriented toward a vehicle-front side, in top plan view. This makes it possible to compactly lay out the exhaust upstream section (48) in an engine compartment (19) without sacrificing a passenger compartment space, and quickly raise a temperature of a catalyst in an exhaust gas-purifying unit (40) during warm-up of the engine (1).

Owner:MAZDA MOTOR CORP

Control system for a plug-in hybrid vehicle

InactiveUS9744960B2Suppression of progress of deteriorationInhibit deteriorationCharging stationsPropulsion using engine-driven generatorsCapacitor voltageTransverse engine

A control system for a plug-in hybrid vehicle has a drive system having a starter motor, a transverse engine, and a motor / generator, and also has a power supply system having a high voltage battery; a capacitor; and a hybrid control module that controls charge and discharge of the capacitor. In the control system for an FF plug-in hybrid vehicle in which external charging of the high voltage battery is available, the hybrid control module starts the starter, performs a mode selection control and a charge / discharge control, maintains the capacitor voltage equal to or higher than a voltage that allows the starter to start-up when a CD mode is selected at the time of ignition ON, and maintains a capacitor voltage equal to or less than a voltage at which deterioration does not proceed at the time of ignition ON with the CS being selected.

Owner:NISSAN MOTOR CO LTD

Control system for a plug-in hybrid vehicle

ActiveUS9663098B2Shorten the timeTime requiredVehicle sub-unit featuresElectric motor startersElectrical batteryCapacitor voltage

A control system for a plug-in hybrid vehicle includes a drive system including a starter motor, a transverse engine, and a motor / generator, and a power supply system including a high voltage battery, a capacitor, and a hybrid control module that controls charging and discharging of the capacitor. A cell voltage monitor for detecting the voltage of the capacitor is provided, the control system being capable of normal external charging and quick external charging of the high voltage battery. The hybrid control module starts the starter, performs charge and discharge control, and maintains a capacitor voltage at and above a starter start-up enabling voltage at which it is possible to start the starter during ignition off and external charging is set to the quick external charging.

Owner:NISSAN MOTOR CO LTD

Clutch control device for four-wheel-drive vehicle

ActiveUS10000118B2Improve performanceEliminate waiting timeFluid actuated clutchesVehicle sub-unit featuresClutch controlTransverse engine

A vehicle clutch control device is provided for switching from a two-wheel drive traveling to a four-wheel drive traveling. The vehicle clutch control device includes a dog clutch that separates a rear wheel drive from a front wheel drive by releasing the dog clutch, an electronically controlled coupling that distributes a driving force of a transverse engine to left and right rear wheels in accordance with a clutch connection capacity, and a four-wheel drive control unit. The four-wheel drive control unit switches the drive mode to one of a disconnect two-wheel drive mode in which the dog clutch and the electronically controlled coupling are released, a connect four-wheel drive mode in which the dog clutch and the electronically controlled coupling are engaged, and a stand-by two-wheel drive mode in which the dog clutch is engaged while the electronically controlled coupling is released.

Owner:NISSAN MOTOR CO LTD

Manure treatment system

InactiveCN103073167ASimple structureEasy and flexible operationClimate change adaptationExcrement fertilisersHuman wasteLiquid manure

The invention discloses a manure treatment system, which is characterized in that a beam is arranged above a corridor-like manure treatment pond, wherein a stirring device is mounted on the beam; the stirring device is provided with an underneath type spiral stirring rod; a radial oil cylinder is mounted on the upper end of the spiral stirring rod; a blower and a transverse engine are mounted on the stirring device; a manure pipe is arranged on one side of the beam; multiple manure nozzles are arranged on the manure pipe; a longitudinal sliding mechanism is mounted between both sides of the beam and the side wall of the manure treatment pond; a liquid manure groove is arranged in one side of the manure treatment pond; a manure pump is mounted in the manure groove; the manure pump is communicated with the manure pipe on the beam; and a blast pipe is mounted at the bottom of the manure treatment pond. The manure treatment system solves the problems of incompleteness in fermentation and environmental pollution when the manure is treated by performing aerobic fermentation with anaerobic biogas or filled strains, and is widely used for treating animal wastes of a farm and treating human wastes and organic substances in the urban garbage dump.

Owner:青岛派如环境科技有限公司

Power transfer unit (PTU) assembly with hydraulically actuated disconnect rear output shaft

An arrangement of a vehicle is provided having normal transverse engine / transmission normal two-wheel drive operation which can be selectively placed into four-wheel drive operation wherein a pump which powers the coupling or uncoupling is independent of the transmission lubrication pump and is powered by the transmission.

Owner:BORGWARNER INC

Power transmission device for four wheel drive vehicle

ActiveUS20200298700A1Inability to preventToothed gearingsGas pressure propulsion mountingRotational axisTransfer case

In a power transmission device of a four-wheel drive electrically driven vehicle, the power source includes a transverse engine supported on one side surface of a gear case, and a motor supported on the other side surface. A transfer case is supported on the same side surface of the gear case as the motor. The transfer case has a transfer input shaft arranged in the vehicle width direction, a transfer output shaft arranged in the longitudinal direction of the vehicle, a bevel gear pair and a transfer gear pair. The bevel gear pair and the transfer gear pair transmit power by changing a rotational axis direction to an essentially orthogonal direction between the transfer input shaft and the transfer output shaft. An output shaft gear provided on the transfer output shaft of the transfer case is disposed in a position overlapping the gear case in a vehicle width direction.

Owner:NISSAN MOTOR CO LTD

Exhaust apparatus for transverse engine

ActiveUS8549837B2Increase temperatureRapid temperature measurementExhaust apparatusSilencing apparatusIn vehicleTransverse engine

An exhaust upstream section (48) of an exhaust apparatus (E) comprises a plurality of branch pipe portions (32), a plurality of intermediate collector pipe portions (33), a final collector pipe portion (34), and an exhaust gas-purifying unit (40). The exhaust gas-purifying unit (40) is disposed on a vehicle-rear side of an engine (1) to allow a gas passage thereinside to extend approximately in vehicle-widthwise direction, in top plan view. Each of the plurality of intermediate collector pipe portions (33) curves to allow an exhaust downstream region of the intermediate collector pipe portion (33) to be oriented toward one side or the other side of the vehicle-widthwise direction, in top plan view, and the final collector pipe portion (34) curves to allow an exhaust downstream region of the final collector pipe portion (34) to be oriented toward a vehicle-front side, in top plan view.

Owner:MAZDA MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com