Exhaust apparatus for transverse engine

一种排气装置、排气净化装置的技术,应用在排气装置、动力装置、发动机元件等方向,能够解决温度不会及早上升、隧道部截面积增大、增大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

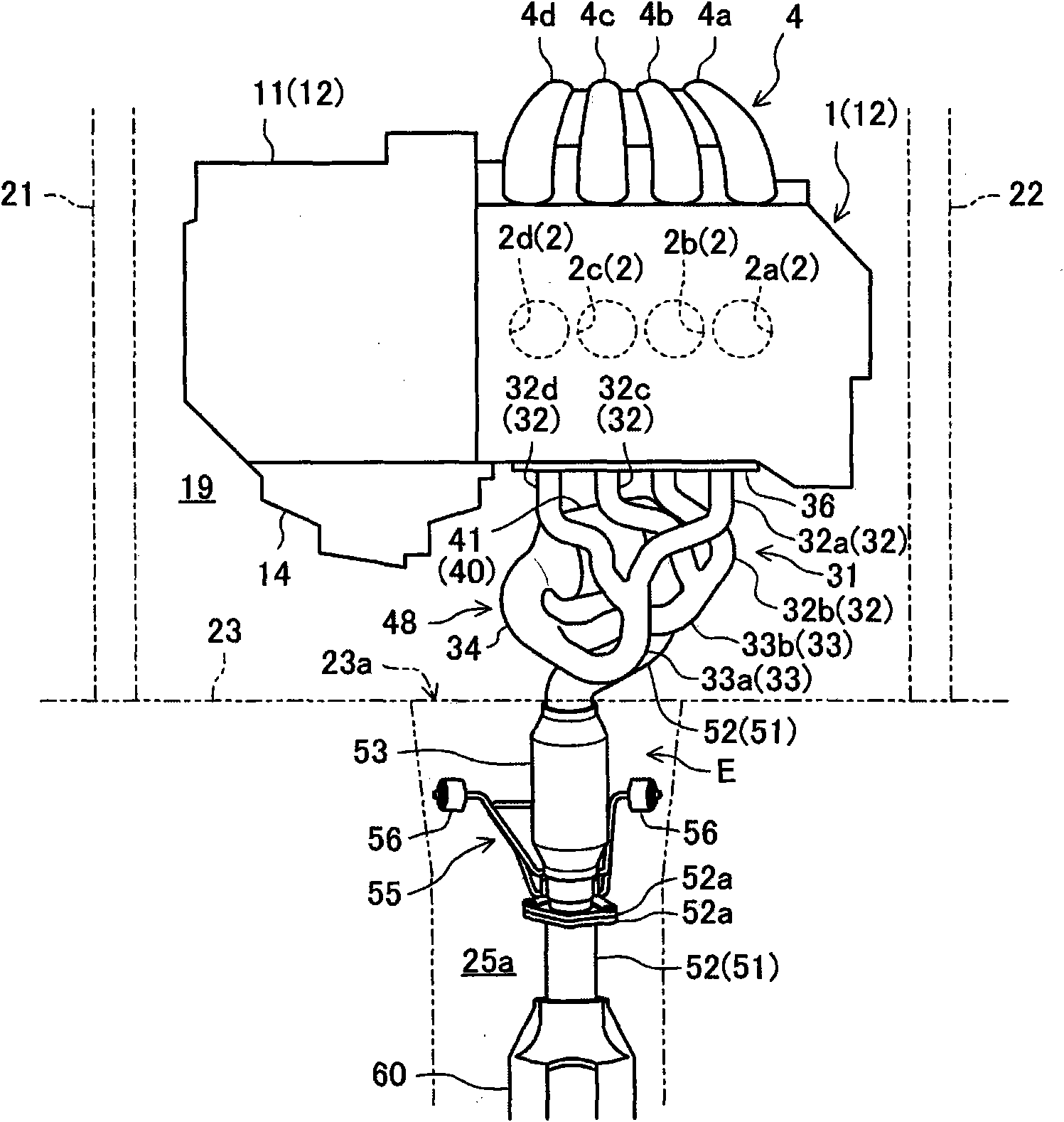

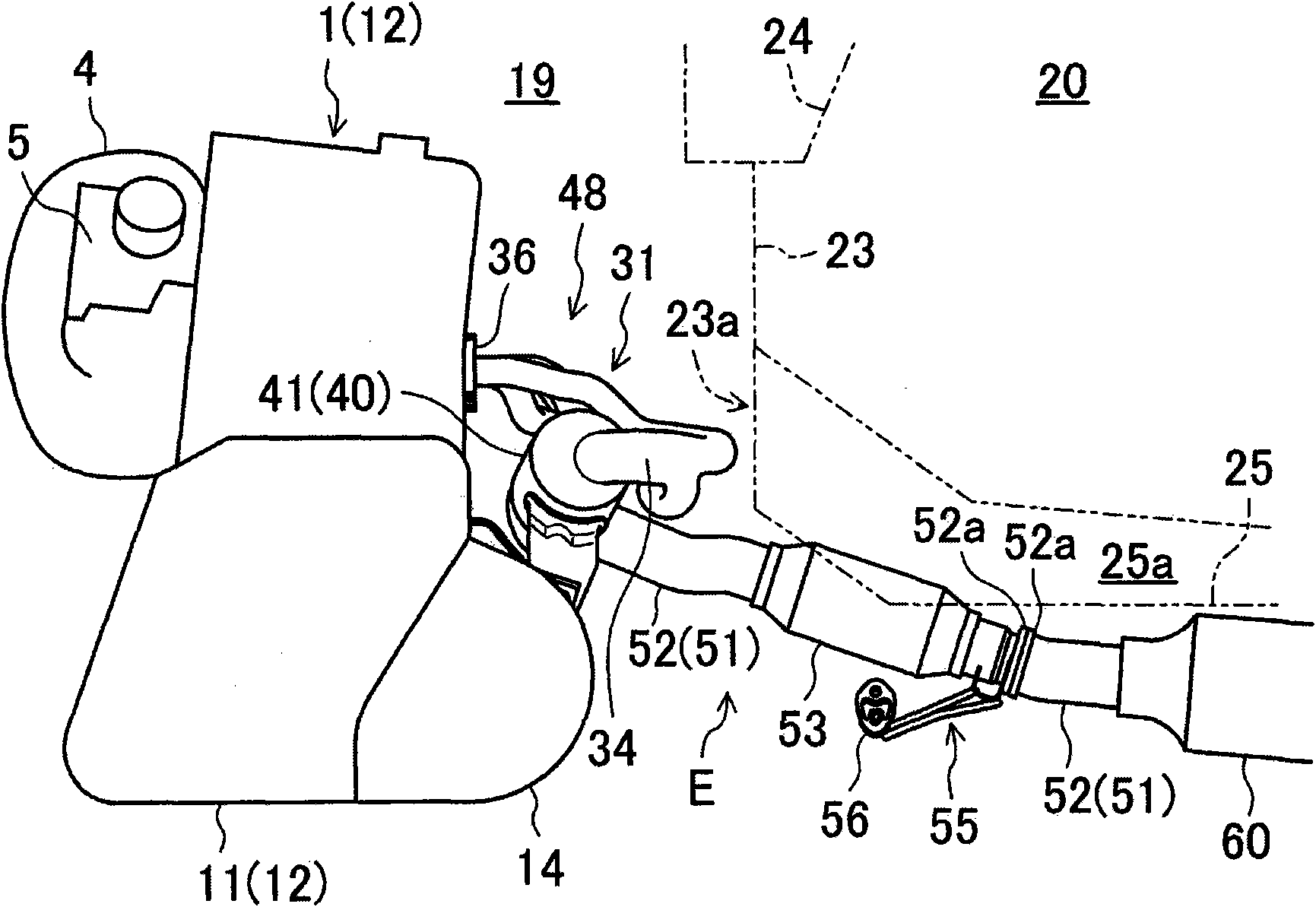

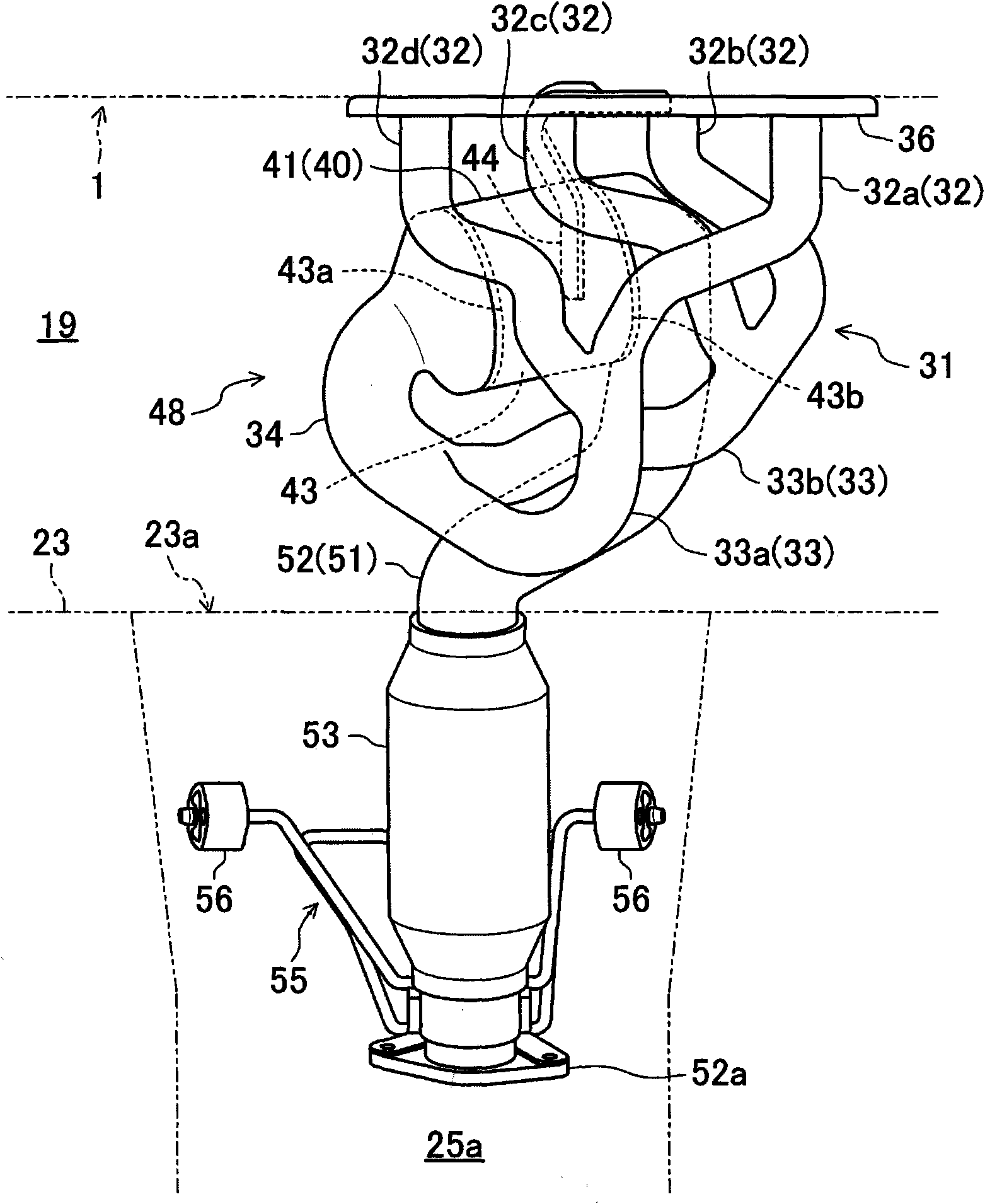

[0022] figure 1 and figure 2 An exhaust device E according to Embodiment 1 of the present invention is shown, and this exhaust device E is an exhaust device of the transverse engine 1 . This engine 1 is an in-line 4-cylinder engine having four cylinders 2 in a row, and it faces the vehicle width direction ( figure 1 The engine room 19 of the front part of the vehicle is arranged laterally in the state of the left-right direction of the vehicle. Below, will correspond to figure 1 to the right of ( figure 2 The right side of the vehicle on the back side of the paper) is called the right side of the vehicle and will correspond to figure 1 to the left of ( figure 2 The left side of the vehicle) is called the left side of the vehicle and will correspond to figure 1 the upper side of ( figure 2 The front side of the vehicle on the left side) is called the vehicle front side and will correspond to figure 1 the lower side of ( figure 2 The rear side of the vehicle is cal...

Embodiment approach 2

[0055] Figure 6 ~ Figure 8 Showing Embodiment 2 of the present invention, the end portions on the exhaust upstream side of the first and second intermediate converging pipe portions 33a and 33b (the converging portion of the first branch pipe portion 32a and the fourth branch pipe portion 32d, and the second branch pipe portion The positional relationship between the pipe portion 32b and the confluence portion of the third branch pipe portion 32c is different from that of Embodiment 1 described above.

[0056] That is, in the present embodiment, the ends on the exhaust gas upstream side of the first and second intermediate converging pipe portions 33a, 33b are arranged at approximately the same position as the third joining portion 37c in the vehicle width direction, and are arranged in the vertical direction. misplaced configurations. Specifically, the method of merging the first branch pipe part 32a and the fourth branch pipe part 32d is the same as that of the first embod...

Embodiment approach 3

[0062] Figure 9 ~ Figure 11 Showing Embodiment 3 of the present invention, the end portions on the exhaust gas upstream side of the first and second intermediate converging pipe portions 33a, 33b (the converging portion of the first branch pipe portion 32a and the fourth branch pipe portion 32d, and the second branch pipe portion The positional relationship between the pipe portion 32b and the confluence portion of the third branch pipe portion 32c is further different.

[0063]That is, in the present embodiment, the exhaust gas upstream end portions of the first and second intermediate converging pipe portions 33a, 33b are arranged at approximately the same position as the third joint portion 37c in the vehicle width direction, as in the second embodiment described above. However, the exhaust gas upstream end portions of the first and second intermediate converging pipe portions 33a, 33b do not overlap each other in plan view, and are displaced from each other in the vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com