Supporting structure of transverse engine

A supporting structure and engine technology, applied in the direction of engine base, supporting machine, mechanical equipment, etc., can solve problems such as durability defects of hydraulic support parts, achieve the effect of improving the degree of freedom of arrangement, increasing the degree of freedom of arrangement, and eliminating longitudinal movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

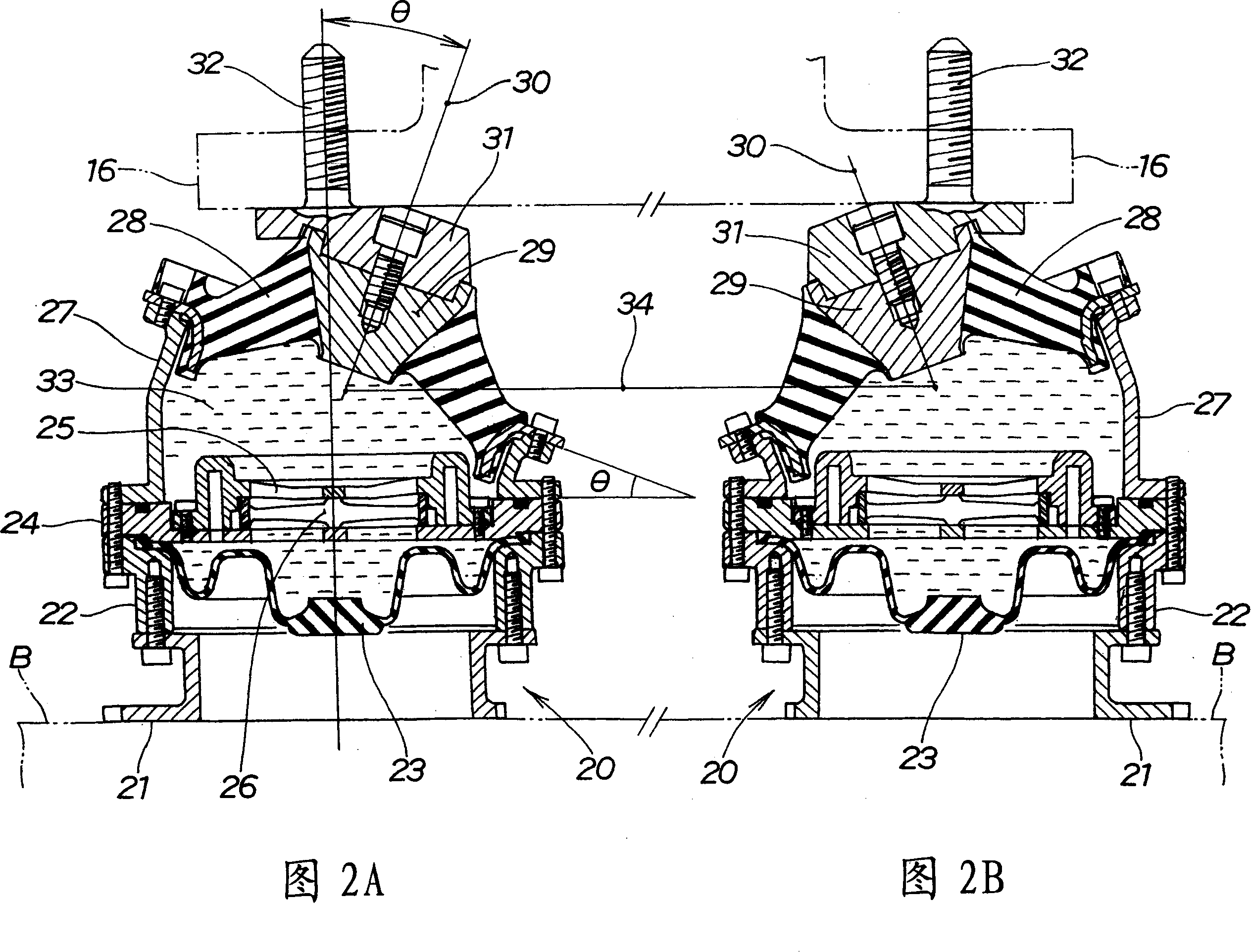

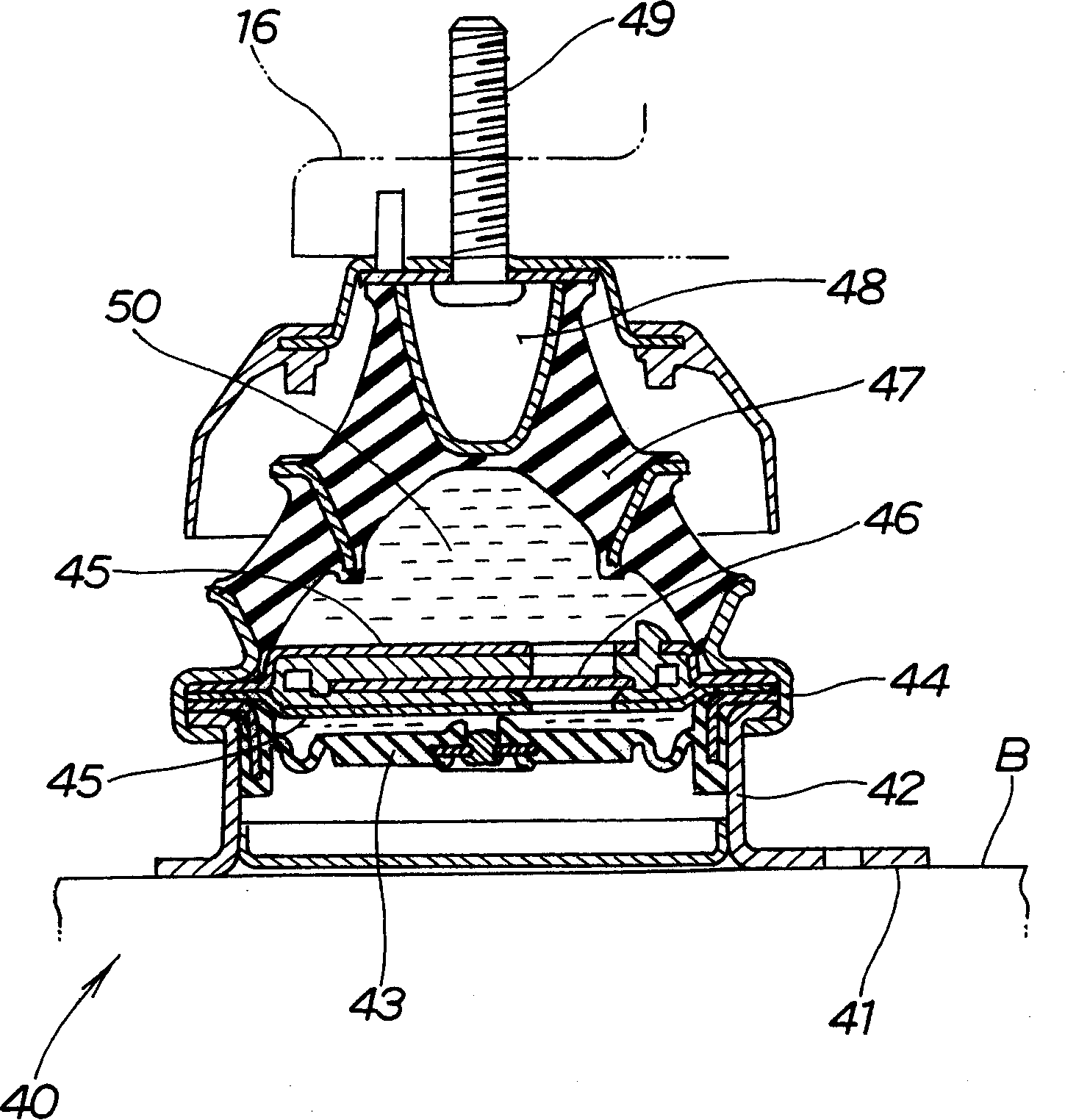

Embodiment Construction

[0060] First of all, since the present invention is under the assumption of a transverse engine, the transverse engine will be described first, followed by the detailed structure of the hydraulic support, and then an exemplary hydraulic support preferably used for the transverse engine. The layout is explained.

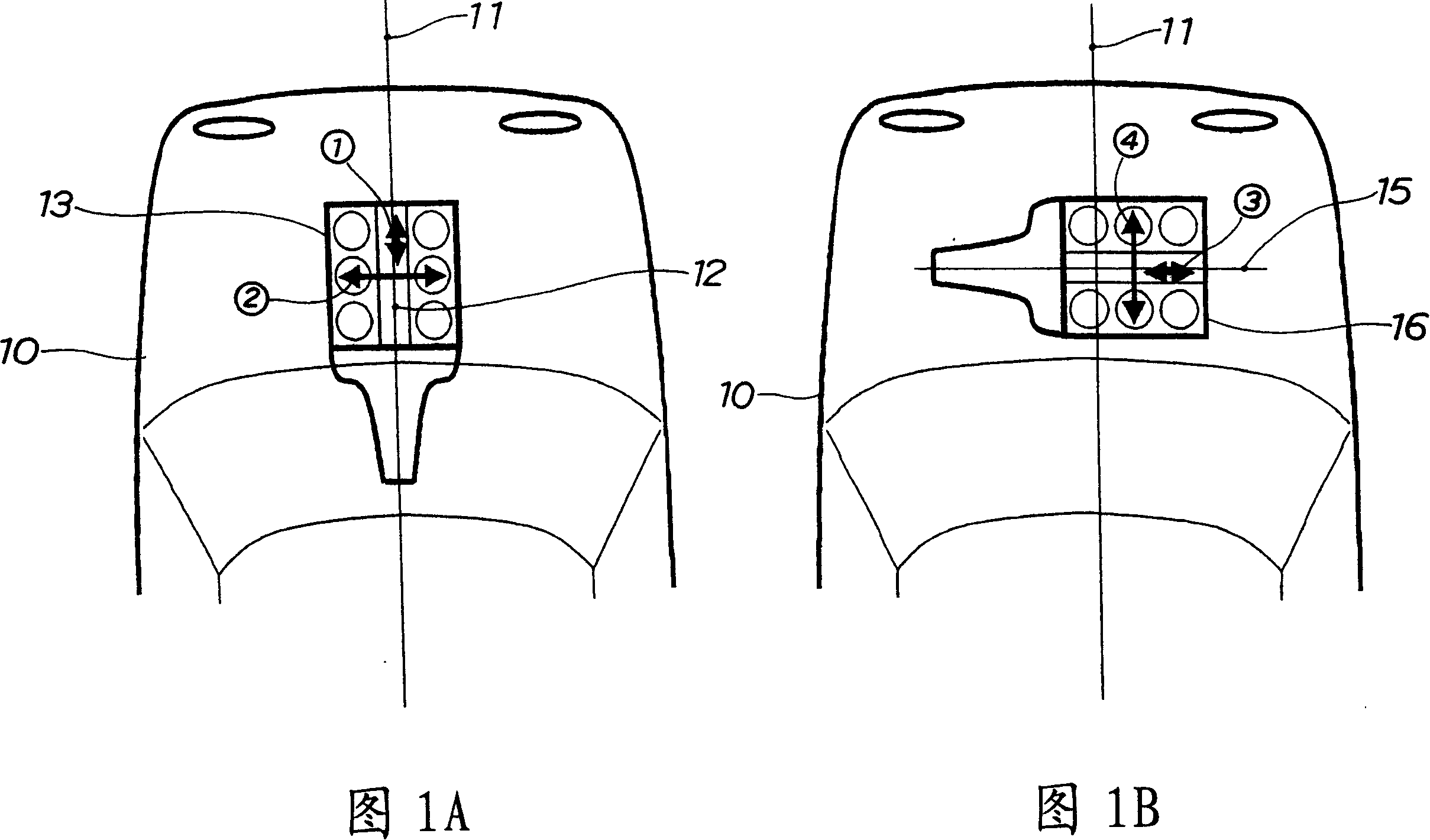

[0061] Reference is now made to FIGS. 1A and 1B , which schematically illustrate a vehicle 10 with a longitudinal engine and a transverse engine, respectively, for comparison.

[0062] An engine arranged with a crankshaft 12 arranged parallel to the longitudinal axis 11 of the vehicle is referred to as a longitudinal engine 13 . Due to the characteristics of the reciprocating engine, the vibration along the crankshaft 12 becomes small as indicated by arrow ①, and the vibration along the direction perpendicular to the crankshaft 12 becomes large as indicated by arrow ②.

[0063] That is, in the longitudinal engine 13, even if the spring constant of the engine mount al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com